Abstract

Starch was isolated from the seeds of ripe and unripe fruits of achachairu (Garcinia humilis) using three extraction methods: neutral, using distilled water at pH 7.0, acid, using ascorbic acid solution at pH 4.0, and alkaline, using sodium hydroxide solution at pH 10.0. After extraction, the starches were characterized in terms of proximate composition and antioxidant, morphological, structural, thermal and spectrometric properties. In general, the highest starch yield was observed for neutral extraction, although the morphological structure and proximate composition revealed higher purity for the starch obtained by acid extraction. Starches obtained from mature matrices can be characterized as products with a high-amylose content, as they resulted in amylose contents greater than 50%. However, alkaline extraction, in addition to promoting greater agglomeration and damaged starch, is also related to the reduction in amylose–lipid complexes. The viscosity parameters of the starches confirmed their apparent levels of amylose, mainly those extracted from mature seeds. Starches also showed antioxidant activity, especially those obtained by neutral extraction, since the highest total phenolic content was determined in this sample, while the other extractions (acid and alkaline) showed results according to method affinity for antioxidant activity. The results suggest that the attributes of the starches found in achachairu seeds make them viable for use in several applications, mainly in the development of biodegradable films, especially for starches obtained in neutral extraction, whose rheological characteristics proved to be favorable for this application.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Starch is both the most important supply of carbohydrates in plants and the main source of calories in the human diet; it is also a non-toxic and renewable resource [1].

The structural properties of starch play a significant role in food processing, as well as in the development of new products [2]. In general, the food sector is responsible for the largest proportion of starch consumption, although starch is also used for the processing of various materials in the paper, chemical, pharmaceutical and textile industries [1, 3].

In the production sector, the pursuit of innovative technologies has led to the search for new ingredients having distinct characteristics and structures; such ingredients include non-conventional starches, which are isolated from sources having distinctive properties that set them apart from heavily used conventional starches, with regard to applicability and nutritional content [4, 5]. There is therefore a growing interest in the extraction of starch from new cultivars, as well as in the reuse of underutilized vegetable matrices [6, 7].

In view of the above, the starch extracted from achachairu seeds is a promising alternative that may be incorporated into the industrial sector, since the composition of these seeds (which make up approximately 15% of the fruit) is rich in carbohydrates. Various extraction techniques for obtaining non-conventional starch have been attracting attention, since altering variables such as the pH of the solution may result in starches having different characteristics, thus facilitating the possibility of specialized applications for individual starches according to the specific advantages they provide [8,9,10]. Such applications of non-conventional starches include the development of biodegradable films, the substitution of fat in cold meats, breaded foods and hamburgers, the elaboration of gluten-free doughs and the encapsulation of various compounds [11, 12].

The achachairu is a fruit belonging to the Garcinia genus, from the Clusiaceae family and humilis species. Though the plant is originally from Bolivia, it also grows in diverse regions of Brazil. The Garcinia humilis species has the ability to perform various functions in the human organism, including healing, digestive and laxative activities; it also is effective against rheumatism, gastric ulcers and inflammation [13]. Moreover, both its leaves and fruits contain biflavonoid and benzene compounds, which are related to immunotoxic, anti-inflammatory and anticancer activities [14]. There are currently no studies in the literature involving the extraction of starch from the achachairu seed, although a few studies exist showing that it does possess potential antioxidant properties that are similar to those present in the fruit itself [15, 16].

Although the functional characteristics of the fruit have been scientifically verified, the available data is still very sparse, especially with regard to the seed, which is usually treated as a waste product. Therefore, the goal of this study was to use different extraction techniques to isolate and characterize the starch present in achachairu seeds from fruits obtained at different maturation stages, in order to identify their properties and thus serve as a guide for future applications.

Material and methods

Material

The achachairu seeds were obtained from fruits collected in the rural region of the city of Corupa (S26°25′01,9″; W49°18′07,5″), in the state of Santa Catarina, Brazil, during the months of December and April, which correspond to the unripe (UN) and ripe (RI) maturation stages, respectively (Fig. 1). The achachairu fruits were cleansed using an aqueous 1% sodium hypochlorite solution and the seeds were removed from the pulp, after which they were first frozen (193.15 K) and then freeze-dried (Benchtop Pro 8L XL-70, Virtis Sp Scientifica) under the following operating conditions: vacuum pressure 31 mT, temperature, 198.85 K. After drying, the seeds were ground into flower using a knife mill (MA630/1, Marconi Ltda., Brazil), resulting in a fine (45 mesh) sample. The flours thus obtained were vacuum-packed in low-density polyethylene bags (PEBD) and kept under refrigeration (277.15 K) until the starch was extracted.

Methods

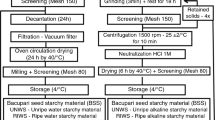

Starch extraction and yield

The seed flours from both ripe (RI) and unripe (UN) achachairu were submitted to three different extraction methods, producing neutral (NS), acid (ACS) and alkaline starches (ALS) (Fig. 2). For the neutral extraction, the method followed was a modified form of that described by Hornung et al. [17], according to which the seed flours were suspended in distilled water (1:2 m/v), pH 7.0 and subsequently stored under refrigeration (278.15 K—24 h). For the acid extraction, the flours were treated with a 1% (m/v) ascorbic acid (C6H8O) solution, pH 4.0, and subsequently stored in a refrigerated environment (278.15 K—24 h), according to the method described by Maniglia and Tapia-Blácido [8]. The flours used in the alkaline extraction were placed in a 0.25% NaOH solution, pH 10, in a proportion of 1:2 (m/v), and then stored (278.15 K—24 h), according to the method described by these same authors, Maniglia and Tapia-Blácido [8].

For all extractions, the prepared solutions were homogenized after storage using an industrial blender (3 min), after which they were sieved (80 mesh). The resulting pastes were decanted (277.15 K—24 h), the supernatants discarded, and the re-suspension process was repeated using distilled water until a pH value of 7.0 had been achieved. The samples were then centrifuged (1500 rpm—10 min), and the final precipitates were filtered under vacuum, after which they were dried in an oven with air circulation and renewal (313.15 K—24 h). The dry starches were then sieved to standard size (60 mesh), vacuum-packed in low-density polyethylene bags, and stored under refrigeration and in the absence of light.

The yield of each starch was determined according to the method described by Wang and Chong [18], using the relationship of the initial mass of the flour and the mass of the extracted starch, as shown in Eq. 1.

Centesimal composition and amylose content

The centesimal characterization of the starches consisted of analyzing their moisture, ash, total protein and total dietary fiber contents, according to the protocols of the AOAC [19]: 934.01, 942.05, 990.03 and 985.29. The lipid content was determined according to the method described by Bligh and Dyer [20], and total carbohydrates were calculated by subtraction (100% − (%moisture + %ash + %protein + % fiber + %lipid)).

Apparent amylose content was determined using the colorimetric method described by Martinez and Cuevas [21], which is based on the transmission of light via the color complex formed by the amylose upon reaction with iodine.

Total phenolic compounds and antioxidant activity

Antioxidant activity was determined by evaluating the methanolic extract of the starches according to the method described by Pantèlic et al. [22]. The prepared samples were submitted to total phenolic compound and antioxidant assays (DPPH, FRAP and ABTS). In order to determine total phenolic compounds, the Folin–Ciocalteu spectrophotometric method was used, based on the procedure described by Singleton et al. [23]. The DPPH method (1,1-dienil-2-picrilhidrazila), which quantified the DPPH radical scavenging capacity via absorbance (515 nm), was conducted as described by Brand-Williams et al. [24]. The method proposed by Benzie and Strain [25] was used to determine antioxidant capacity based on the reduction in the ferric ion (FRAP). The method described by Re et al. [26] was used to determine the antioxidant activity of the starches using ABTS (2,2-azino-bis-3-ethylbenzothiazoline-6-sulfonic acid).

Morphological properties

Scanning Electron Microscopy (SEM)

The starch granules (NES, ACS and ALS) were observed by means of scanning electron microscopy (SEM) using a Tescan Vega 3 microscope (Kohoutovice, Czech Republic). The samples were first prepared by being fixed using adhesive copper supports and metalized by coating with gold under vacuum using a Sputter Coater SCD 050 (Balzers). The micrographs were taken at magnifications of 4500 at an acceleration of 15 kV and under low vacuum. Particle size was determined using the ImageJ free software (version 1.49 v).

X-ray diffractometry (XRD)

The diffractometry (XRD) patterns of the starches were obtained using an X-ray diffractometer (Bruker—D8 Advance model), which used a radiation of Cu Kα (λ = 1542 Å) configured at 40 kV and 20 mA. Scattered radiation was measured at the angular interval between 5º and 80º (2θ), with a flow rate of 2 ° min−1, at a step of 0.041º. The graphical representation was generated using the Origin 8.6 software (Origin Lab, Massachusetts, EUA). To determine the relationship between the incident X-ray wavelength, the angle of incidence and the spacing between the planes of the crystalline lattice of starches, the Bragg's Law was applied, described according to Eq. 2.

Thermal properties

The thermogravimetric curves (TG/DTG) were obtained using the PerkinElmer TGA 4000 system (PerkinElmer Inc., Waltham, Massachusetts, EUA) by means of the method described by Hornung et al. [1]. Approximately, 6 mg of each sample was used, which was analyzed while being heated from 303.15 to 1023.15 K at a rate of 283.15 K min−1.

The differential scanning calorimetry graphs (DSC) were obtained using a DSC 8000 device (PerkinElmer Inc., Waltham, Massachusetts, EUA). The samples, which had been previously hydrated in a proportion of 4:1 (water/starch, m/m), were heated at a rate of 283.15 K min−1, beginning at 303.15 K and continuing until a final temperature of 373.15 K. The analysis was conducted in a nitrogen atmosphere (20 mL min−1).

The results obtained from the TG/DTG and DSC curves were read using Pyris™ software (PerkinElmer Inc., Waltham, Massachusetts, EUA).

Paste viscosity

The behavior of the starch pastes (NS, ACS and ALS) was determined using 2.25 g samples in 25 mL of distilled water placed in a Rapid Visco Analyzer (Perten, RVA 4500, Huddinge, Sweden), according to the description of the RVA 20.05 method, suggested by the manufacturer Perten Instruments. The profile used was that described by Ravi et al. [27], as appears in the International Association for Cereal Science and Technology [28]. The analysis evaluated the properties of peak viscosity, final viscosity, tendency to retrograde, time necessary in order to achieve peak viscosity and average temperature of the starch pastes.

Fourier transform infrared (FTIR)

The method used to conduct the Fourier transform infrared (FTIR) spectroscopy analysis was that described by Maniglia and Tapia-Blácido [8], using a Vertex 70 infrared spectrophotometer (Bruker, USA), which operated within the spectral range of 400–4000 cm−1, with a resolution of 4 cm−1 and 1024 scans.

Statistical analysis

The experimental data were submitted to an analysis of variance (ANOVA) and a Tukey test in order to compare the significance among the results at a 95% confidence level (p < 0.05). The program STATISTICA 10.1 Software (Stat Soft, Inc., Tulsa, OK, USA) was used for this analysis.

Results and discussion

Starch extraction and yield

The technique that resulted in the greatest observed starch yield (for both maturation stages of the seed) was the neutral extraction method (38.40 g × 100 g−1—UN and 62.43 g × 100 g−1—RI) (Table 1). A large yield was likewise observed for starch from ripe seeds using the alkaline extraction method (43.84 g × 100 g−1), the results being similar to those observed by Villarreal et al. [10], who obtained starch from amaranth flower using both alkaline extraction and alkaline extraction combined with proteolytic digestion (45.29 and 46.18 g. 100 g−1, respectively). The lowest yield was observed for starch obtained using acid extraction, whose average value (22.23 g × 100 g−1) exhibited no difference between the two maturation stages.

It is assumed that the greater yield is due to the presence of other constituents that might have been loaded during extraction and counted as part of the final starch content. This hypothesis may be verified by means of the centesimal composition analysis, which is discussed below. The presence of non-starch constituents in the starches is related to the methods used during the extraction process, in addition to variables such as additional purification stages, maturation stage and matrix preparation conditions [29].

The purity of the starch may be compromised due to the tendency of the carbohydrate molecules to interact with the constituents derived from the vegetable matrices. These compounds include lipids, proteins and fibers, which frequently adhere to surfaces or become trapped between the starch grains [30].

Centesimal composition and amylose content analysis

The centesimal composition characterization (Table 1) revealed that the moisture contents of the starches range from 5.75 to 7.90 g × 100 g−1. These values are within the limit imposed by Resolution 263/05 of the Brazilian government, described by ANVISA, which states that the maximum humidity allowed for starches obtained from grains is 15.0 g × 100 g−1 (p/p) [31].

Of the three extraction techniques, it was observed that the neutral technique preserved the greatest protein (7.87 g × 100 g−1) and lipid (13.73 g × 100 g−1) contents in starches produced from unripe seeds. According to Damodaran et al. [32], most proteins from vegetable sources are soluble in an alkaline pH; however, extraction using ascorbic acid proved to be more efficient in removing both protein (5.10 g × 100 g−1—UN and 3.27 g × 100 g−1—RI) and lipid contents (10.05 g × 100 g−1—UN and11.65 g × 100 g−1—RI) from the starches, resulting in a greater carbohydrate yield (76.36 g × 100 g−1—UN and 77.80 g × 100 g−1—RI). This suggests that starches obtained using this extraction method are purer than those obtained using the other two methods. The association between metabolites and the biosynthesis of the compounds in the seed formation process is dependent upon other factors, such as climate, soil and other cultivation conditions. Therefore, proteomic and metabolomic analyses must be conducted in order to achieve a comprehensive understanding of the seed constituents [33].

Regarding the amylose content, the acid and alkaline extractions did not exhibit any significant differences when results for the same maturation stage were compared, although they did exhibit a greater amylose content, possibly due to the effects of modifying the pH of the solution, since under such conditions, the lipids are solubilized, thus reducing the presence of amylose–lipid complexes and therefore allowing the leaching of the amylose molecule [8].

According to Lineback [34], although differences in apparent amylose content are observed among starches with different vegetable origins, it generally makes up between 20 and 30% of starches obtained from grains and approximately 17% of starches obtained from manioc. The same author also states that starches composed only of amylopectin are known as waxy starches; these may be found in some starchy varieties of maize, barley and wheat. Starches with amylose contents greater than 50%, known as high-amylose starches, have different applications, due to their viscosity properties being the opposite of those of waxy starches.

The apparent starch contents observed were greater than 30% for all starches, the smallest values being observed for starches obtained using the neutral extraction method (30.23 g × 100 g−1 for the UN-NS and 52.21 g × 100 g−1 for the RI-NS).

In general, the values observed for all extraction methods pointed toward greater apparent amylose values for RI starches (between 52.21 and 57.71 g × 100 g−1), thus indicating that these samples may be classified as high-amylose starches (Table 1). According to Wu et al. [35], several physiological changes that may influence the apparent amylose content occur during the seed maturation stage, during which the amylose proportion tends to increase over time.

Starches characterized as high-amylose starches may be easily used in the development of films and exhibit the fluidity necessary for the formation of gels, due to the interaction of the amylose with the water molecules. These starches may be applied in products for which crunchiness is a desirable characteristic and as protection against excessive oil absorbance during their preparation; they are therefore recommended for use in nuggets and other breaded products. Starches having high-amylose contents also exhibit favorable characteristics for the chewy candy industry, since they comprise up to 50% of candy formulations [36, 37].

Total phenolic compounds and antioxidant activity

In general, the greatest values for total phenolic content (TPC) and antioxidant activity as determined by DPPH and FRAP were observed for the NS. However, for the ABTS analysis, both ACS and ALS exhibited values superior to those of NS. It was also observed that the starches isolated from the unripe matrix exhibited greater TPC values than those isolated from the ripe matrix, showing differences of approximately 32.01, 59.61 and 0.29% for the neutral, acid and alkaline extractions, respectively. However, the greatest reductions were observed for the FRAP method, which exhibited reductions of 89.86 and 62.18% from the unripe stage to the ripe stage for acid and alkaline extractions, respectively (Table 2).

Although the total phenolic content was obtained in the neutral extraction, in the antioxidant activity, it was verified that the extraction technique can vary according to the affinity of the method used, since the ABTS differed from the DPPH and FRAP when comparing the starches of the different extractions (neutral, acidic and alkaline). However, the factor with the greatest impact on the results of these analyses was the ripening stage of the samples.

In vegetables, phenolic compounds are considered secondary metabolites that occur naturally and are used as a defense mechanism in the plants. They also participate in their development during maturation and in the reproduction of the vegetable material [31]. Therefore, unripe fruits tend to contain a greater proportion of secondary metabolites than ripe fruits, since these compounds are necessary for their development. The results obtained in this study agree with those of other studies that report that the concentration of phenolic compounds gradually diminishes as the fruit ripens [38, 39].

The presence of antioxidant compounds in achachairu starches may represent an opportunity for these products to be developed and applied in innovative ways. One example is the use of starches as an alternative renewable source for producing biodegradable and functional films. This application has already been explored using an amylaceous matrix with added antioxidant agents in order to obtain an active film [40]. Studies exist involving combinations such as beet waste products in gelatin capsules [41], olive bagasse in chitosan [42], mango peel flour [43] and a variety of other fruit and vegetable waste products [44, 45]. According to Adilah et al. [46], the incorporation of bioactive compounds in the development of films promotes a synergistic effect that enhances the antioxidant capacity of the packaging.

In view of the environmental appeal, low cost, flexibility and transparency attributed to starch-based films [47], the authors suggest that the use of starches obtained from the achachairu seed, especially those obtained using the neutral extraction method, which exhibited a greater antioxidant potential, be pursued as a promising possibility for application in the packaging industry.

Morphological properties

Scanning electron microscopy (SEM)

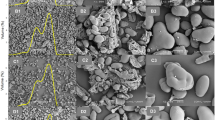

The morphology and dimensions of starch granules vary according to their botanical source, the extraction method used, and the conditions of the extraction matrix. Starch granules normally exhibit an oval shape with rounded ends and a diameter that may vary between 1 and 110 µm [48], with a record of ∼1 µm for the smallest granule found in nature, referring to quinoa starch [49]. The studied starches presented predominantly oval structures (Fig. 3), with dimensions occurring in a narrow range of variation, from 21.38 to 31.16 µm (Table 3); their diameters can be considered medium, because among the commercially available starches, rice starch has diameters between 3 and 5 µm, while potato starch has diameters ranging between 10 and 5 µm. An example of a starch that exhibits intermediate dimensions is maize starch, whose diameters range from 5 to 26 µm, the average diameter being approximately 15 µm [50].

Although the appearance of the NS granules was similar to that normally exhibited by starch granules, their structures also exhibited other linked constituents, perhaps compounds that were loaded during the extraction process. The ACS micrographs were more defined, although they still show some structures attached to the granules. However, higher purity can be suggested in these samples, corroborating the results of the proximate composition for both extractions, whose protein and lipid contents were observed to be higher for the NS and lower for the ACS [51] also observed that starches extracted using an aqueous medium exhibit trace of other constituents, especially proteins. However, Silveira and Tápia-Blácido [52] state that none of the methods cited are capable of producing starches that are entirely pure, since none of the proposed solutions remove all the protein, lipid, fiber, phenolic compound and carotenoid content present in the structures.

For starches extracted using the alkaline medium, grouped structures were observed, which contained granules that were damaged and interconnected, thus revealing that the reagent used had acted upon the starch molecules. According to Suortti et al. [53], starch granules become vulnerable to the alkaline medium, resulting in the breakage of weaker bonds and the ionization of glucose groups having the hydroxyl radical; this causes the residual content of the starch structures to agglomerate.

Visually, by means of scanning electron microscopy, it was possible to perceive that the acid extraction allows obtaining starch granules of greater purity; without the presence of other constituents as occurs in the neutral extraction. The alkaline extraction, on the other hand, facilitates the agglomeration of the granules, also promoting a greater concentration of damaged starches in the final amount.

X-ray diffractometry (XRD)

The X-ray diffraction patterns recorded from the Bragg’s angle were similar to those found in the study by Rodriguez-Garcia et al. [54], whose interplanar spaces are found at 7878, 5867, 5136, 3859 and 3339 Å for amaranth starch. Such data associate the structure of starches with the A-amylose type, since the diffraction patterns are divided into A-amylose and B-amylose, although both are indistinctly associated [55, 56]. The A-type corresponds to an orthorhombic structure, while B-type corresponds to a hexagonal structure [54]. According to the authors, the crystalline structure of starch presents the beginning of the hexagonal phase marked by initial peaks at 5.639º, while the orthorhombic phase starts at higher values, above 9.074º. Therefore, this finding affirms that the starch profiles of achachairu seeds are defined by A-type, since in all samples, the interplanar spaces corresponded to the orthorhombic phase in the crystalline structure (Table 4).

The graphical reading from the diffractometer indicated a slightly higher definition in the NS peaks (Fig. 4). However, the resulting graphic profile of the samples, regardless of the extraction method, can be correlated with the diffractogram produced by commercial potato starch [57].

In general, the crystalline portions of the granules are formed from part of the linear structure present in the amylopectin molecule, which forms double helicoidal structures, whereas the amorphous portion is formed by chains of amylose and part of the branches of the amylopectin molecules [58]. In this regard, it was seen that the area corresponding to crystallinity was more evident in the RI samples, which exhibited higher peaks.

It has been observed that during the maturation process of an amylaceous matrix, the crystalline portion becomes amorphous due to the partial degradation of the starch, a transformation that results in a greater proportion of amylose [59]. These observations corroborate the results found in the current study, which found that apparent amylose contents were higher for the ripe stages; however, they also disagree with the relationship between crystallinity and the proportion of amylose and amylopectin. In this regard, it is possible that the crystalline portion formed as a result of the conformation of the double helix and the large number of long chains in the amylose molecule portions, as observed by [60], who reported these characteristics in starches having a high-amylose content and a crystallinity pattern showing peaks similar to those observed in the present study.

The extraction techniques did not interfere with the characterization of the structures verified by X-ray diffraction, being similar in the three patterns analyzed (neutral, acidic and alkaline starches).

Thermal properties

Thermogravimetric (TG) and derived thermogravimetric (DTG) analysis

It was observed that the thermogravimetric curves exhibited a difference in the dimensions of the peaks of the samples (Fig. 5), thus indicating a change in mass loss (Δm) among the various maturation stages and starch steeping methods.

The decomposition data of the samples supported the observations from the graphical visualization, exhibiting lower Δm values for the NS during the first event (Table 5). In contrast, although in the more elongated peaks of the third event observed for the ACS the structures exhibited a sharper definition, their narrowness resulted in reduced mass loss for both maturation stages.

According to Soliman et al. [61], the first event is associated with the dehydration of the samples, whose assessment parameter may be fixed at the temperature 423.15 K. Minor mass losses during this event occurred for the NS (7.44%—UN and 8.66%—RI), an observation that is consistent with the lower humidity content observed for this sample (Table 1) as compared to that of the remaining UN samples. The thermal behavior is dependent on the primary and secondary matter present in the crystalline structure of the starch, whose complexity hinders the release of water molecules, thus requiring higher peak temperatures [62]. In this case, since RI-NS exhibited a greater apparent amylose content (52.21 g × 100 g−1) and a peak temperature higher than 342.36 K, in contrast with UN–NS (30.23 g × 100 g−1 apparent amylose and a peak temperature of 325.55 K), these factors may have been responsible for the higher temperature observed for the RI during the first event.

For UN starches, those extracted using the acid and alkaline steeping exhibited smaller thermal stability ranges (ACS: 392.6–454.24 K and ALS: 386.54–450.5 K) as compared to the neutral method (375.28–456.4 K), whereas for the RI starches, the acid and alkaline extractions exhibited improved ranges (398.74–468.85 K and 386.9–462.55 K, respectively).

The second event is considered to begin at 573.15 K, at which point the depolymerization of the starch, which undergoes irreversible alterations, is observed [63].

Upon analyzing each maturation stage during the second thermal event, it was observed that the greatest values for the depolymerization of the macromolecules were exhibited by the ACS (66.52–70.08 Δm/% for UN and RI, respectively), whereas the lowest mass loss values were exhibited by the NS (63.53–58.35 Δm/% for UN and RI, respectively). This result may be correlated with the carbohydrate contents (Table 1) observed in the samples, for which the ACS exhibited higher values that those of the NS.

The presence of residual proteins was observed in all samples analyzed; these proteins may interfere with the thermal behavior, since among the decomposition products present during this event are glycosidic derivatives, complex gasses and compounds resulting from the Maillard reaction, which occurs at high temperatures through amino acids and reducing sugars [64].

The third thermal event is attributed to carbonization. This is the stage during which the decomposition of acids, saturated fats and the remaining compounds resulting from the polymerization of the previous event reaches its conclusion [65]. It was observed for all samples that degradation occurred between 773.15 and 873.15 K. The correlation of the ash content was consistent with the residual mass loss of each sample, since the remaining material corresponds to the inorganic residue content present in each starch.

A greater residue, temperature variation amplitude and peak temperature (797.78 K) were observed for the UN-NS for the carbonization (third) event. This observation presupposes that there was no total degradation of the sample, although it exhibited the greatest amplitude. According to Lawal [66], the disintegration of granules that require high temperatures may be a result of the breakage of certain complex bonds, especially in the amylopectin molecule, whose structural characteristics make complete carbonization difficult. This corroborates the thermal data observed for this event, since the UN-NS was the starch with the lowest amylose content, thus suggesting that it has a greater amylopectin content.

Differential scanning calorimetry (DSC)

The flow of heat associated with the gelatinization process occurred around 343.15 K, during which clear peaks formed for RI-ACS and for RI-ALS, and in general exhibited greater stability for RI-NS; in the curves that represent the UN starches, a slight peak was visible only for UN-NS (Fig. 6).

The stability seen in the curves may be a result of the relationship between the amylose and the lipid content. During the gelatinization process, the amylose complexes formed from the lipid load remain constant throughout the temperature variation, in some cases making possible an increase in peak temperature [67]. However, the elevated gelatinization temperatures in starches rich in amylose may also be a result of the joint crystallization that occurs between the amylose and amylopectin [68].

An analysis of the change in temperature (ΔT) in Table 6 revealed that the greatest observed values were consistent with the graphs that showed the greatest stability, as was discussed above, for the samples UN-ACS, UN-ALS and RI-NS, attributed to the following variations: 280.28, 280.42 and 280.47 K.

However, the small temperature range in the gelatinization process suggests starch chains with a low degree of polydispersity [69]. This characteristic reflects in a smaller distribution of starch molecular mass [70], favoring the crystallization of amylose [71]. This structure can justify the observation made in the XRD analysis by relating the maturation stage with the crystalline portion of the starches.

The RI starches exhibited the greatest values for change in enthalpy (ΔH) and peak temperature (Tp), except for ALS, whose ΔH was relatively low for both maturation stages (Table 6). Change in enthalpy is associated with the amount of energy required during the gelatinization process [72]; therefore, it is possible that the alkaline steeping caused a reduction in the structural complexity of the starch, thus resulting in a lower energy demand during its gelatinization process. However, starch containing a high-amylose content requires a higher temperature and more energy in order to modify its conformation, since the organization of the double helices may be influenced by the amylose molecule by means of its interference in the density and packing of the amylopectin chains [73]. This agrees with results observed for RI-NS and RI-ACS starches, whose enthalpy values and amylose contents were higher than those of the UN starches.

The peak temperature values were similar for all samples, regardless of the type of extraction performed, being confined to the range between 342.84 and 344.16 K. Values similar to these have been observed for maize starches (both untreated and with acid modification), which exhibited peak temperatures of 345.59 and 342.75 K, respectively [74].

Paste viscosity

By means of the viscosity parameters (Table 7), it was seen that the RI starches exhibited the highest peak values over the shortest period of time, especially RI-ACS. The RI starches also exhibited higher final viscosity values as compared to the UN starches. This finding was confirmed by the graph generated in the analysis (Fig. 7), whose curves showed the formation of peaks for starches from ripe matrices in contrast to the resistance in the formation of viscosity peaks of starches from unripe seeds. The resulting data found that the stage of maturation influenced the viscosity of the starch paste. According to the study on starch properties of potato cultivars, the peak viscosity is significantly higher in late harvest starches compared to early harvest [75]. Madsen and Christensen [76] and Lui et al. [77] also indicated increases in the peak viscosity of the starch paste during the ripening period, corroborating to the present study.

The peak viscosity can also be related to the rheological regime in terms of dilution, transition and saturation of the pastes [78,79,80]. In this sense, Fig. 7 shows the changes in the viscosity peak as a function of the maturation stage of the starchy matrices, indicating the linear behavior in the unripe starches. According to Quemada [79] and Quemada [80], viscosity changes may result from aggregates or accumulations caused by interparticle forces. In addition, Quemada [79] affirms that the apparent viscosity of the paste increases as a function of the higher volumetric concentration of the starch particles.

The final viscosity values are proportionally related to the levels of amylose present in the starch; even a modest content is sufficient to affect the peak viscosity of the paste [81]. The results obtained agree with the apparent amylose data, which exhibited lower values for UN starches as compared to RI starches. Amylose content and final viscosity are parameters associated with the tendency of the starch to retrograde [82].

The gradual increase in viscosity until the final state is achieved occurs by means of the reorganization of the molecules that make up the starch, especially amylose. This molecular reorganization occurs during the cooling process and is described as retrogradation; it results in the formation of a gel that is opaquer and has irreversible characteristics [83].

The values identified for the retrogradation tendency revealed that, in general, the UN starches exhibit low retrogradation, especially UN-NS, with a value of only 90 cP, in contrast to RI, whose greatest value, 611 cP, was observed for RI-ACS. This reinforces the assertion regarding amylose content, which was observed in greater proportions in the RI starches. In contrast, the NS exhibited a lower tendency to retrograde when compared to the ACS; this may have occurred as a result of the composition of the individual starches, since the neutral extraction exhibited greater quantities of other loaded constituents, whereas the acid extraction resulted in purer starches. According to Perera and Hoover [84], retrogradation properties are influenced by previous starch steeping involving elements such as change of pH, degreasing and hydroxypropylation, all of which affect the structural arrangement of the amylaceous chains, thus modifying the stability of the granules. However, although the pH is an influential parameter on the paste properties, in the present study, the degree of maturation had a greater impact on the results than the extraction method used to obtain the starches.

Due to the syneresis that results from the retrogradation process, one of the parameters used to estimate the durability of the amylaceous gel for storage or application is its tendency to retrograde. This property demonstrates that these starches may be used as thickeners in the aging of breads or other products with high amylaceous contents that are meant for refrigeration [85].

Starches with high-amylose contents tend to retrograde more readily. These starches are therefore best applied in products in which oil absorption must be prevented, as well as in chewable bases. Moreover, due to their high gelling capacity, these starches are promising alternatives for the development of films [36, 37].

Finally, the average temperature of the paste was similar for all starches evaluated, occurring within the range of 341.15–342.15 K; this is consistent with the gelling temperature observed in the differential scanning calorimetry.

Fourier transform infrared (FTIR)

The spectrums of the infrared regions were seen to be similar, exhibiting vibrations at coinciding peaks for all maturation stages and starch extraction methods (Fig. 8).

The initial interval corresponded to the region between 3300 and 2900 cm−1, a range that is attributed to axial deformation of OH and CH bonds [86] and also indicative of the formation of hydrogen bonds as a result of the d-glycose molecule [87]. The most prominent peak in this region occurred at approximately 2930 cm−1, and may possibly be related to the stretching of CH bonded to the hydrogen atoms, as reported by Tapia-Blacido et al. [88], who identified this phenomenon at an absorption of 2921 cm−1.

The formation of small peaks was observed between 1750 and 1130 cm−1, with a more prominent peak at 1700 cm−1. This region is identified by the absorption of esterified and non-esterified carboxylic groups, carbonyl esters and bands associated with amide I and amide II groups related to the presence of proteins in the samples [89]. This range is also attributed to the vibrations of the bonded water molecule in the amorphous region of the starch granules, identified at the wavelengths 1646 and 1300 cm−1 [90, 91].

The band that ranges from 1060 to 600 cm−1 exhibited the final starch peaks. This range includes vibrations related to the structures of carbohydrates [92], especially near the peak at 900 cm−1, which is associated with the stretching of the COH bond in the starch chain [93]. The stretching of primary and secondary alcohols and ethers (COC) present in the polymeric structures of the starches occurs within the manifestations observed in the 1157–1014 cm−1 range [57].

Although they were obtained by different extraction techniques, the characterization of the achachairu seed starches was similar to the spectrum described for potato starch [94], which exhibited six principal peaks that illustrated the axial deformations of OH and OH, vibrations related to the water molecule and conformations that make up an amylaceous structure.

Conclusions

This work studied the viability of three techniques used to isolate starch from flours made from achachairu seeds that were harvested at different maturation stages. In general, it was possible to identify the attributes of the starch granules by means of their morphological, thermal and antioxidant characteristics, as well as paste viscosity. The starch yield was seen to be greatest when the neutral extraction was used, and lower when acid extraction was used, the purity being inversely proportional. Regarding alkaline extraction, it was observed that this pH condition promotes the agglomeration of granules, as well as a higher content of damaged starch. These observations were also verified both by both centesimal composition and morphology.

For RI starches, the amylaceous composition was seen to have a high-amylose content and may be classified as a high-amylose product. However, it was possible to verify that the conditions of acid or alkaline pH; far from neutrality, they reduce the concentration of amylose–lipid complexes and may interfere with all amylose molecules in starch. The identified amylose contents corroborated the thermal and viscosity analysis, in which a high retrogradation tendency was observed. This property allows for its application in the development of films and agents used in food products for which oil absorption must be limited during processing; therefore, starch obtained by neutral extraction is particularly recommended for this function. The antioxidant characteristics identified in starches, mainly those obtained using the neutral extraction method, also suggest them as promising materials for the development of films.

Finally, it was possible to verify that the extraction techniques did not have a great impact on the results of X-ray diffractometry, differential scanning calorimetry and Fourier transform infrared.

References

Hornung PS, Oliveira CS de, Lazzarotto M, Lazzarotto SR da S, Schnitzler E. Investigation of the photo-oxidation of cassava starch granules: Thermal, rheological and structural behaviour. J Thermal Anal Calorimetry. 2016. https://doi.org/10.1007/s10973-015-4706-x

Sangseethong K, Termvejsayanon N, Sriroth K. Characterization of physicochemical properties of hypochlorite and peroxide oxidized cassava starches. Carbohyd Polym. 2010. https://doi.org/10.1016/j.carbpol.2010.05.003.

de Oliveira CS, Andrade MMP, Colman TAD, da Costa FJOG, Schnitzler E. Thermal, structural and rheological behaviour of native and modified waxy corn starch with hydrochloric acid at different temperatures. J Thermal Anal Calorimetric. 2014. https://doi.org/10.1007/s10973-013-3307-9.

Barbosa MC. Efeito da adição de proteína nas propriedades físicas e reológicas dos géis obtidos a partir de amido de semente de jaca (Artocarpus Integrifólia). Dissertação (Mestrado em Engenharia de Alimentos) – Itapetininga: Universidade Estadual do Sudoesta da Bahia – UESB; 2013. pp. 91.

Kim YS, Wiesenborn DP, Orr PH, Grant LA. Screening potato starch for novel properties using differential scanning calorimetry. J Food Sci. 1995. https://doi.org/10.1111/j.1365-2621.1995.tb06292.x.

Pinto VZ, Vanier NL, Deon VG, Moomand K, El Halal SLM, Zavareze EDR, Lim LT, Dias ARG. Effects of single and dual physical modifications on pinhão starch. Food Chem. 2015. https://doi.org/10.1016/j.foodchem.2015.04.037.

Wang X, Chen L, Li X, Xie F, Liu H, Yu L. Thermal and rheological properties of breadfruit starch. J Food Sci. 2011. https://doi.org/10.1111/j.1750-3841.2010.01888.x.

Maniglia BC, Tapia-Blácido DR. Isolation and characterization of starch from babassu mesocarp. Food Hydrocolloids. 2016. https://doi.org/10.1016/j.foodhyd.2015.11.001.

Alcázar-alay SC, Angela M, Meireles A. Physicochemical properties, modifications and applications of starches from different botanical sources. Food Sci Technol. 2015. https://doi.org/10.1590/1678-457X.6749.

Villarreal ME, Ribotta PD, Iturriaga LB. Comparing methods for extracting amaranthus starch and the properties of the isolated starches. LWT Food Sci Technol. 2013. https://doi.org/10.1016/j.lwt.2012.11.009.

Nogueira GF, Fakhouri FM, Oliveira RA de. Extraction and characterization of arrowroot (Maranta arundinaceae L.) starch and its application in edible films. Carbohydrate Polymers. 2018. https://doi.org/10.1016/j.carbpol.2018.01.024

Silva HR da, Assis D da C de, Prada AL, Silva JOC, Sousa MB, Ferreira AM, Amado JRR, Carvalho H de O, Santos AVT de LT, Carvalho JCT. Obtaining and characterization of anthocyanins from Euterpe oleracea (açaí) dry extract for nutraceutical and food preparations. Revista Brasileira de Farmacognosia. 2019. https://doi.org/10.1016/j.bjp.2019.03.004

Molin MMD, Silva S, Alves DR, Quintão NLM, Monache FD, Filho VC, Niero R. Phytochemical analysis and antinociceptive properties of the seeds of garcinia achachairu. Arch Pharmacal Res. 2012. https://doi.org/10.1007/s12272-012-0405-3.

Cury GC, Gisbert MCA, Porcel WJR. Um estudo da fruta comestível de Garcinia gardeneriano. Revista Boliviana de Química, La Paz- Bolívia. 2016. https://doi.org/10.32404/rean.v4i5.2189

Bagattoli PCD. Phytochemical profile and evaluation of antioxidant and cytotoxicity activity of fruits from the flora of the state of Santa Catarina (SC), Brazil. Dissertação (Mestrado em Produtos Naturais e Substâncias Bioativas) – Itajaí: Universidade do Vale do Itajaí; 2013. pp. 123.

Virgolin LB, Seixas FRF, Janzantti NS. Composition, content of bioactive compounds, and antioxidant activity of fruit pulps from the Brazilian Amazon biome. Pesqui Agropecu Bras. 2017. https://doi.org/10.1590/S0100-204X2017001000013.

Hornung PS, Ávila S, Lazzarotto M, Lazzarotto SR da S, Siqueira GL de A, Schnitzler E, Ribani RH. Enhancement of the functional properties of Dioscoreaceas native starches: Mixture as a green modification process. Thermochimica Acta. 2017. https://doi.org/10.1016/j.tca.2017.01.006

Wang YJ, Chong SW. Effect of pericarp removal of wet-milled corn starch. Cereal Chem. 2006. https://doi.org/10.1094/CC-83-0025.

AOAC, American association of official analytical chemists. Official methods of analysis ofthe American association ofofficial analytical chemists. USA: Gaithersburg; 2000.

Bligh EG, Dyer WJ. A rapid method of total lipid extraction and purification. Can J Biochem Physiol. 1959. https://doi.org/10.1139/o59-099.

Martínez C, Cuevas F. Evaluación de la calidad culinaria y molinera del arroz. Centro Internacional de Agricultura Tropical (CIAT). 1989. https://doi.org/10.1017/CBO9781107415324.004.

Pantelić MM, Dabić Zagorac D, Davidović SM, Todić SR, Bešlić ZS, Gašić UM, Tešić ŽL, Natić MM. Identification and quantification of phenolic compounds in berry skin, pulp, and seeds in 13 grapevine varieties grown in Serbia. Food Chem. 2016. https://doi.org/10.1016/j.foodchem.2016.05.051.

Singleton VL, Orthofer R, Lamuela-Raventós RM. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1974; 1998. https://doi.org/10.1016/S0076-6879(99)99017-1

Brand-Williams W, Cuvelier ME, Berset C. Use of a free radical method to evaluate antioxidant activity. LWT Food Sci Technol. 1995. https://doi.org/10.1016/S0023-6438(95)80008-5.

Benzie I, Strain J. The ferric reducing ability of plasma (FRAP) as a measure of “Antioxidant power”: the FRAP assay analytical biochemistry. Anal Biochem. 1996. https://doi.org/10.1006/abio.1996.0292.

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radical Biol Med. 1999. https://doi.org/10.1016/S0891-5849(98)00315-3.

Ravi R, Manohar RS, Rao PH. Use of Rapid Visco Analyser (RVA) for measuring the pasting characteristics of wheat flour as influenced by additives. J Sci Food Agric. 1999. https://doi.org/10.1002/(SICI)1097-0010(199909)79:12%3c1571::AID-JSFA400%3e3.0.CO;2-2.

International Association for Cereal Science and Techonology - ICC, Schwechat, Austria. 1995. Retrivied from: https://www.infona.pl/resource/bwmeta1.element.baztech-article-BPOA-0013-0017. Accessed 6 Jan 2021.

Abdel-Aal ESM, Hernandez M, Rabalski I, Hucl P. Composition of hairless canary seed oil and starch-associated lipids and the relationship between starch pasting and thermal properties and its lipids. LWT. 2020. https://doi.org/10.1016/j.lwt.2020.109257.

Tester RF, Yousuf R, Kettlitz B, Röper H. Use of commercial protease preparations to reduce protein and lipid content of maize starch. Food Chem. 2007. https://doi.org/10.1016/j.foodchem.2007.04.041.

Brasil. Agência Nacional de Vigilância Sanitária – RDC 263 de 22 de setembro de 2005. Regulamento Técnico Para Produtos de Cereais, Amidos, Farinhas e Farelos

Damodaran S, Parkin KL, Fennema OR. Química de Alimentos de Fennema, 4th ed. Porto Alegre: Artmed; 2010.

Singha KT, Sreeharsha RV, Mariboina S, Reddy AR. Dynamics of metabolites and key regulatory proteins in the developing seeds of Pongamia pinnata, a potential biofuel tree species. Ind Crops Prod. 2019. https://doi.org/10.1016/j.indcrop.2019.111621.

Lineback DR. The starch granule: organization and properties. Bakers Digest; 1984. pp. 16–21.

Wu J, Wang X, Ma S. Study on Changes in the characteristics of key carbohydrates in wheat during the after-ripening period. Grain Oil Sci Technol. 2018. https://doi.org/10.3724/sp.j.1447.gost.2018.18012.

Collona P, Leloup V, Buléon A. Limiting factors of starch hydrolysis. Euro J Clin Nutrition. 1992. https://europepmc.org/article/med/1330526

Parker R, Ring SG. Aspects of the physical chemistry of starch. Adv Carbohydr Chem. 2001. https://doi.org/10.1016/S0096-5332(08)60122-8.

Maieves HA, López-Froilán R, Morales P, Pérez-Rodríguez ML, Ribani RH, Cámara M, Sánchez-Mata MC. Antioxidant phytochemicals of Hovenia dulcis Thunb. peduncles in different maturity stages. J. Funct. Foods. 2015. https://doi.org/10.1016/j.jff.2015.01.044

Sampaio CRP, Hamerski F, Ribani RH. Antioxidant phytochemicals of Byrsonima ligustrifolia throughout fruit developmental stages. J Funct Foods. 2015. https://doi.org/10.1016/j.jff.2015.08.004.

Mali S, Grossmann MVE, Yamashita F. Filmes de amido: produção, propriedades e potencial de utilização. Semina: Ciências Agrárias. 2010. https://doi.org/10.5433/1679-0359.2010v31n1p137

Iahnke AOES, Costa TMH, Rios A de O, Flôres SH. Antioxidant films based on gelatin capsules and minimally processed beet root (Beta vulgaris L. var. Conditiva) residues. J Appl Polymer Sci. 2016. https://doi.org/10.1002/app.43094

Crizel T de M, Rios A de O, Alves V, Bandarra N, Moldão-Martins M, Flôres SH. Active food packaging prepared with chitosan and olive pomace. Food Hydrocolloids. 2018. https://doi.org/10.1016/j.foodhyd.2017.08.007

Torres-León C, Vicente AA, Flores-López ML, Rojas R, Serna-Cock L, Alvarez-Pérez OB, Aguilar CN. Edible films and coatings based on mango (var. Ataulfo) by-products to improve gas transfer rate of peach. LWT. 2018. https://doi.org/10.1016/j.lwt.2018.07.057

Ferreira MSL, Fai AEC, Andrade CT, Picciani PH, Azero EG, Gonçalves ÉCBA. Edible films and coatings based on biodegradable residues applied to acerolas (Malpighia punicifolia L.). J Sci Food Agric. 2016. https://doi.org/10.1002/jsfa.7265

Andrade RMS, Ferreira MSL, Gonçalves ÉCBA. Development and characterization of edible films based on fruit and vegetable residues. J Food Sci. 2016. https://doi.org/10.1111/1750-3841.13192.

Adilah AN, Jamilah B, Noranizan MA, Hanani ZAN. Utilization of mango peel extracts on the biodegradable films for active packaging. Food Packag Shelf Life. 2018. https://doi.org/10.1016/j.fpsl.2018.01.006.

Zainuddin SYZ, Ahmad I, Kargarzadeh H. Cassava starch biocomposites reinforced with cellulose nanocrystals from kenaf fibers. Compos Interfaces. 2013. https://doi.org/10.1080/15685543.2013.766122.

Hoover R. Composition, molecular structure, and physicochemical properties of tuber and root starches: A review. Carbohyd Polym. 2001. https://doi.org/10.1016/S0144-8617(00)00260-5.

Li G, Zhu F. Amylopectin molecular structure in relation to physicochemical properties of quinoa starch. Carbohyd Polym. 2017. https://doi.org/10.1016/j.carbpol.2017.02.014.

Singh N, Singh J, Kaur L, Sodhi NS, Gill BS. Morphological, thermal and rheological properties of starches from different botanical sources. Food Chem. 2003. https://doi.org/10.1016/S0308-8146(02)00416-8.

Palacios-Fonseca AJ, Castro-Rosas J, Gómez-Aldapa CA, Tovar-Benítez T, Millán-Malo BM, Del Real A, Rodríguez-García ME. Effect of the alkaline and acid treatments on the physicochemical properties of corn starch. CYTA J Food. 2013. https://doi.org/10.1080/19476337.2012.761651.

Silveira TMG, Tápia-Blácido DR. Is isolating starch from the residue of annatto pigment extraction feasible? Food Hydrocolloids. 2018. https://doi.org/10.1016/j.foodhyd.2017.09.027.

Suortti T, Gorenstein MV, Roger P. Determination of the molecular mass of amylose. J Chromatogr A. 1998. https://doi.org/10.1016/S0021-9673(98)00831-0.

Rodriguez-Garcia ME, Hernandez-Landaverde MA, Delgado JM, Ramirez-Gutierrez CF, Ramirez-Cardona M, Millan-Malo BM, Londono-Restrepo SM. Crystalline Structures of the main components of Starch. Curr Opin Food Sci. 2020. https://doi.org/10.1016/j.cofs.2020.10.002.

Hsien-Chih HW, Sarko A. The crystal structure of A-starch: is it double helical? Carbohydr Res. 1977. https://doi.org/10.1016/S0008-6215(00)80566-2.

Hsien-Chih HW, Sarko A. The double-helical molecular structure of crystalline a-amylose. Carbohydr Res. 1978. https://doi.org/10.1016/S0008-6215(00)84464-X.

Lima BNB, Cabral TB, Neto RPC, Tavares MIB, Pierucci APT. Characterization of commercial edible starch flours. Polimeros. 2012. https://doi.org/10.1590/S0104-14282012005000062.

Souza RCR, Andrade CT. Investigação dos processos de gelatinização e extrusão de amido de milho. Polímeros. 2000. https://doi.org/10.1590/s0104-14282000000100006.

Xu R. Investigation on after-ripening mechanism of wheat. Zhengzhou: Henan University of Technology. 2013. https://doi.org/10.3724/SP.J.1447.GOST.2018.18012

Weber FH, Collares-Queiroz FP, Chang, YK. Caracterização físico-química, reológica, morfológica e térmica dos amidos de milho normal, ceroso e com alto teor de amilose. Ciência e Tecnologia de Alimentos [online]. 2009. https://doi.org/10.1590/S0101-20612009000400008

Soliman AAA, El-Shinnawy NA, Mobarak F. Thermal behaviour of starch and oxidized starch. Thermochim Acta. 1997. https://doi.org/10.1016/s0040-6031(97)00040-3.

Rodrigues SC, da Silva AS, de Carvalho LH, Alves TS, Barbosa R. Morphological, structural, thermal properties of a native starch obtained from babassu mesocarp for food packaging application. J Market Res. 2020. https://doi.org/10.1016/j.jmrt.2020.11.030.

Aggarwal P, Dollimore D. A thermal analysis investigation of partially hydrolyzed starch. Thermochim Acta. 1998. https://doi.org/10.1016/s0040-6031(98)00355-4.

Adebowale KO, Afolabi TA, Olu-Owolabi BI. Functional, physicochemical and retrogradation properties of sword bean (Canavalia gladiata) acetylated and oxidized starches. Carbohyd Polym. 2006. https://doi.org/10.1016/j.carbpol.2005.12.032.

Micić DM, Ostojić SB, Simonović MB, Pezo LL, Simonović BR. Thermal behavior of raspberry and blackberry seed flours and oils. Thermochim Acta. 2015. https://doi.org/10.1016/j.tca.2015.08.017.

Lawal OS. Studies on the hydrothermal modifications of new cocoyam (Xanthosoma sagittifolium) starch. Int J Biol Macromol. 2005. https://doi.org/10.1016/j.ijbiomac.2005.12.016.

Morrison WR. Starch lipids and how they relate to starch granule structure and functionality. Cereal Food World. 1995; pp. 437–446.

Vandeputte GE, Vermeylen R, Geeroms J, Delcour JA. Rice starches. I. Structural aspects provide insight into crystallinity characteristics and gelatinisation behaviour of granular starch. J Cereal Sci. 2003. https://doi.org/10.1016/S0733-5210(02)00140-6

Cai J, Man J, Huang J, Liu Q, Wei W, Wei C. Relationship between structure and functional properties of normal rice starches with different amylose contents. Carbohyd Polym. 2015. https://doi.org/10.1016/j.carbpol.2015.02.067.

Zou J, Xu MJ, Wen LR, Yang B. Structure and physicochemical properties of native starch and resistant starch in Chinese yam (Dioscorea opposita Thunb.). Carbohydrate Polymers. 2020. https://doi.org/10.1016/j.carbpol.2020.116188

Hu X, Huang Z, Zeng Z, Deng C, Luo S, Liu C. Improving resistance of crystallized starch by narrowing molecular weight distribution. Food Hydrocolloids. 2020. https://doi.org/10.1016/j.foodhyd.2020.105641.

Eliasson AC. Carbohydrates in food. New York: Marcel Dekker; 1996. p. 664.

Cooke D, Gidley MJ. Loss of crystalline and molecular order during starch gelatinisation: origin of the enthalpic transition. Carbohyd Res. 1992. https://doi.org/10.1016/0008-6215(92)85063-6.

Beninca C, Demiate IM, Lacerda LG, Filho MASC, onashiro M, Schnitzler E. Thermal behavior of corn starch granules modified by acid treatment at 30 and 50 °C. Eclética Química. 2008. https://doi.org/10.1590/S0100-46702008000300002

Noda T, Tsuda S, Mori M, Takigawa S, Matsuura-Endo C, Saito K, Mangalika WHA, Hanaoka A, Suzuki Y, Yamauchi H. The effect of harvest dates on the starch properties of various potato cultivars. Food Chem. 2004. https://doi.org/10.1016/j.foodchem.2003.09.035.

Madsen MH, Christensen DH. Changes in viscosity properties of potato starch during growth. Starch/Stärke. 1996. https://doi.org/10.1002/star.19960480702.

Lui Q, Weber E, Currie V, Yada R. Physicochemical properties of starches during potato growth. Carbohyd Polym. 2003. https://doi.org/10.1016/S0144-8617(02)00138-8.

Acosta-Osorio AA, Herrera-Ruiz G, Pineda-Gómez P, Cornejo-Villegas MA, Martínez-Bustos F, Gaytán M, Rodríguez-García ME. Analysis of the apparent viscosity of starch in aqueous suspension within agitation and temperature by using rapid visco analyzer system. Mech Eng Res. 2011. https://doi.org/10.5539/mer.v1n1p110

Quemada D. Rheology of concentrated disperse systems: II. A model for non-newtonian shear viscosity in steady flows. Rheological Acta. 1978. https://doi.org/10.1007/BF01522036

Quemada D. Rheology of concentrated disperse systems: III. General features of the proposed non-newtonian model. Comparision with experimental data. Rheological Acta. 1978. https://doi.org/10.1007/BF01522037

Zeng M, Morris CF, Batey IL, Wrigley CW. Sources of variation for starch gelatinization, pasting, and gelation properties in wheat. Cereal Chem. 1997. https://doi.org/10.1094/CCHEM.1997.74.1.63.

OroI T, Limberger VM, M.Z. Miranda MZ de, Richards NSPS, Gutkoski LC, Francisco A de. Pasting properties of whole and refined wheat flour blends used for bread production. Ciência Rural. 2013. https://doi.org/10.1590/S0103-84782013005000026

Ragaee S, Abdel-Aal ESM. Pasting properties of starch and protein in selected cereals and quality of their food products. Food Chem. 2006. https://doi.org/10.1016/j.foodchem.2004.12.012.

Perera C, Hoover R. Influence of hydroxypropylation on retrogradation properties of native, defatted and heat-moisture treated potato starches. Food Chem. 1999. https://doi.org/10.1016/S0308-8146(98)00130-7.

Marcon MJA, Avancini SRP, Amante ER. Propriedades químicas e tecnológicas do amido de mandioca e do polvilho azedo. Florianópolis: Editora da UFSC; 2007.

Silverstein R, Webster F. Identificaçao Espectrofotométrica de Compostos Organicos, Livros Tecnicos e Científicos Editora: AS, 6a Edição; 2006. pp. 67–135.

Wang N, Zhang X, Han N, Bai S. Effect of citric acid and processing on the performance of thermoplastic starch/montmorillonite nanocomposites. Carbohyd Polym. 2009. https://doi.org/10.1016/j.carbpol.2008.09.021.

Tapia-Blácido DR, Sobral PJA, Menegalli FC. Potential of Amaranthus cruentus BRS Alegria in the production of flour, starch and protein concentrate: Chemical, thermal and rheological characterization. J Sci Food Agric. 2010. https://doi.org/10.1002/jsfa.3946.

Leão DP, Franca AS, Oliveira LS, Bastos R, Coimbra MA. Physicochemical characterization, antioxidant capacity, total phenolic and proanthocyanidin content of flours prepared from pequi (Caryocar brasilense Camb.) fruit by-products. Food Chem. 2017. https://doi.org/10.1016/j.foodchem.2017.01.027

Zhang SD, Zhang YR, Zhu J, Wang XL, Yang KK, Wang YZ. Modified corn starches with improved comprehensive properties for preparing thermoplastics. Starch/Staerke. 2007. https://doi.org/10.1002/star.200600598.

Kizil R, Irudayaraj J, Seetharaman K. Characterization of irradiated starches by using FT-Raman and FTIR spectroscopy. J Agric Food Chem. 2002. https://doi.org/10.1021/jf011652p.

Pelissari FM, Andrade-Mahecha MM, Sobral PJDA, Menegalli FC. Isolation and characterization of the flour and starch of plantain bananas (Musa paradisiaca). Starch/Staerke. 2012. https://doi.org/10.1002/star.201100133.

Vicentini NM, Dupuy N, Leitzelman M, Cereda MP, Sobral PJDA. Prediction of cassava starch edible film properties by chemometric analysis of infrared spectra. Spectrosc Lett. 2005. https://doi.org/10.1080/00387010500316080.

Mendes FM. Produção e Caracterização de Bioplásticos a partir de Amido de Batata, Poster session presentation at the meeting of 10°. Congresso Brasileiro de Polímeros: Maringá; 2009.

Acknowledgements

The authors would like to thank the Post-Graduation Program in Food Engineering (Federal University of Paraná, Curitiba, Brazil) for the support provided and achachairu producer Edgar Gessner, who provided the fruits used in this study.

Funding

The research was financially supported by CAPES (Coordination for the Improvement of Higher Education Personnel) granted to M. Ikeda (Grant number 88882.381643/2019–01); and the National Council for Scientific and Technological Development to R. H. Ribani (Grant number 432361/2018–9).

Author information

Authors and Affiliations

Contributions

MI involved in conceptualization, methodology, validation, formal analysis, investigation, data curation, writing—original draft, writing—review and editing and project administration. BPC involved in conceptualization, software, formal analysis, investigation and writing—review and editing. AMM involved in methodology, validation, formal analysis, investigation, and writing—review and editing. IAEP involved in formal analysis, investigation and writing—review and editing. RHR involved in conceptualization, validation, resources, data curation, writing—review and editing, visualization and supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ikeda, M., Costa, B.P., de Melo, A.M. et al. Impact of the ripening process and extraction method on the properties of starch from achachairu seeds. J Therm Anal Calorim 148, 4151–4169 (2023). https://doi.org/10.1007/s10973-023-12034-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12034-2