Abstract

Passive thermal augmentation is preferred in the design of compact and energy efficient domestic solar water heating systems (DSWH). Current study investigates the impact of modified DSWH with Kenics insert brazed with rod and spacer sequentially on the heat augmentation, and flow pressure, and frictional attributes. The thermal performance and flow friction characteristics have also been analyzed for different rod and spacer lengths such as 0.125, 0.25, and 0.5 m for twist designed with a stable twist ratio of 3. Experimental results reveal the drop in Nusselt number when the rod and the spacer span increase; and the flow pressure drop (ΔP) decreases significantly while extending the same in comparison with full kenics twist. Further, the increment in pressure drop and heat removal was observed significantly in twist and rod inserts of minimum twist ratio and rod length compared to twist and spacer combination. Interrelationships developed for Nusselt number (Nu) and Friction factor (ft) show close agreement between estimated and experimental values.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Thermosyphon solar water heating systems are popular since their introduction as they present one of the most attractive and cost-effective technologies for harnessing and utilizing solar energy. Also, the simplicity and reliability of these systems have led to their its utilization all over the world. The single-glazed, flat plate type is commonly employed for providing hot water for different applications.

Endless efforts have been made by the researchers to improve the performance of DSWH systems, and to minimize the size and cost. From the literature, it is known that the performance of the collector could be increased by improving the outside convective heat transfer coefficient (ho), the conduction heat between the absorber plate and the riser tube, and the internal convective heat transfer coefficient (hi). In general, hi between the riser tube and the water has low value in a commercial system due to laminar fluid flow. Insertion of swirl flow generators, categorized under passive method of heat augmentation, is a well proven technique and is utilized in many commercial heat transfer systems like heat exchangers, air heaters, and condensers.

Innovative passive heat transfer augmentations in pipe exchangers, comprehensively reviewed and presented by Liu and Skar [1], concluded that the twisted tape insert performs efficiently in laminar flow reign and its the effectiveness by the use of other passive techniques like ribs, conical nozzle, conical ring, etc., is significantly higher. The impact on the pipe friction, the fluid Nusselt number, and the thermo-fluidic attributes of a round section with dissimilar twist designs investigated by Rahimi et al. [2] proved that the performance of tube with jagged insert is comparatively better than the other ones. Wongcharee and Smith Eiamsa-ard [3] investigated a circular tube with twist inserts on stand-in axes and with wings to observe the effects on heat removal, friction, and thermal attributes. Findings show both heat augmentation and flow friction induced by all inserts have been consistent, surpassing plain tubes. They further established that Nusselt number, flow resistance, and thermal attainment improve upon incrementing the wing-chord ratio.

The use of center-cleared twist insert and short-width twist insert in a round section in a laminar flow regime has been analyzed by Guo et al. [4] established that the thermal performance of the tube with a center-cleared twist could be improved by a maximum of 20% in comparison with the tube with normal twist insert. It is also proved from the results that the use of a center-cleared twist insert is an encouraging means for laminar flow convective heat augmentation. Sivashanmugam and Suresh [5] explored the performance attributes of the annular section with helix screw twist insert of multiple TR and twist sets of varying order of TR and concluded coefficient of heat transfer improves with an increase in TR. Consequences of using helical twists inserted in a tube for heat enhancement have been experimented with by Eiamsa-ard and Pongjet Promvonge [6] endorsed the use of helical twist inserts as an extra benefit over the plain tube in terms of heat augmentation. A combination of helical insert and rod had provided 10% higher over the plain tube. Martín et al. [7] hypothesized heat transfer enhancement by using the TRNSYS simulator in a wire-coil inserted solar hot water system. Madhu Sruthi Emani et al. [8] analyzed the benefits of different compound techniques of passive heat augmentation inserts in a non-circular duct and found that performance parameters are influenced by helix angle, channel aspect ratio, and diameter of the wire coil. Jaisankar et al. [9, 10] conducted several experiments to predict heat removal and flow friction attributes of solar water heaters under forced and laminar circulation with a full helical twist, Left–Right twist of different ratios, and its modified forms of varying length consolidated that the gross thermal presentation of Left–right insert surpasses helical twist inserted systems. Similarly, twist combined with rod allowed higher heat flow than twist and spacer combination. Rajesh Kumar and Prabha Chand [11] predicted the performance of extended surface solar air collectors with twisted tape inserts of different twist ratios and concluded that the maximum performance enhancement is obtained with a twist of minimum twist ratio (2). Juan Du et al. [[12] performed a numerical study in a tubular heat exchanger tube with transversely mounted sinusoidal ribs to determine its effect on convective heat transfer and flow pressure properties under constant heat flux laminar flow conditions. Finding reveals that the use of sinusoidal ribs in tubes possesses the potential promise in laminar flow heat augmentation.

The heat transfer and friction factor attributes of a horizontal double pipe heat exchanger with helical screw inserts of different spacer lengths and twist ratios have been experimentally investigated by E.Z.Ibrahim [13]. Results show that the Nusselt number and friction factor decrease with an increase in spacer length and twist ratio. The recent developments in the thermos-economic performance of solar flat plate collectors have been comprehensively studied by Elumalai Vengadesan et al. [14] including passive augmentation techniques using twisted tape inserts concluded that lower twist ratios of twist inserts improve the thermal performance of the system up to 25.5%.

R. Suresh Isravel et al. [15] studied the thermal characteristics of solar water heating systems using twisted tapes with modified rings and revealed that the improvement in the thermal performance is with a significant decrement in friction loss. Mohammed Almeshaal et al. [16] experimented thermosyphon water heater with different lengths of spacers and rod in the trailing edge of the helical twist insert of ratio 3 and concluded that any linear increment in rod and spacer reduces the magnitude of flow pressure. Balaji et al. [17] experimentally investigated and compared the mixed convection effects of a simple flat plate solar collector and a collector with thermal performance enhancers in the absorber tube operated under similar conditions. Results show that the highest thermal performance evaluation factors were 1.38 and 1.29 for rod and tube thermal performance enhancers, respectively. A comparative experimental study of heat transfer enhancement of solar water heaters using three different types of wire-coil inserts and twisted tapes under laminar flow conditions analyzed by Garcia et al. [18], reported that there was a noticeable different behavior according to the insert geometry and flow conditions. Further, compared to wire-coil inserts, the twisted tapes offer a moderate increase in pressure drop. Saman Rashidi et al.[19] carried out a review of the latest experimentation on the potential applications of various inserts including baffles, wire coils, vortex generators and twisted tapes in different solar thermal energy systems suggested i) More realistic solar irradiation instead of constant flux as simple boundary condition ii) Implementing transverse swirl flow devices and concluded that only very few researchers employed inserts in solar water heaters which have 80% of the solar thermal market of the world.

Most of the augmentation techniques using twist inserts of various designs have been analyzed by researchers are mostly focused on heat exchangers under turbulent flow conditions. Moreover, many of the experiments have been conducted only with simple twist designs like helical and left–right and their modified designs with higher twist ratios in the order of 4, 5, and 6 considering the pressure drop. Since swirl-induced thermal enhancement using twisted tapes inevitably nurses ΔP in the collector, an experiment was conducted using a novel twist design known as kenics, and the findings are reviewed with the motive of improving the thermal presentation of DSWH using compound designs of kenics twists under a laminar regime without compromising the head loss and fluid mass flow rate. Further, the results are compared with the performance of a simple DSWH tested together to establish the outcomes.

Materials and methods

Experimental setup

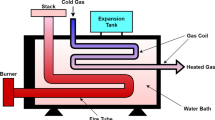

The experimental assemble consisting of simple DSWH systems with glass wool insulation are shown in Fig. 1. Temperature of water at entry and exit of all riser tubes, 1 m in length, are recorded by temperature recorders. T-type thermocouples brazed carefully on all absorber plates and on outer circumference of riser tubes equally placed all along the length of 1 m are used to record the respective local temperatures. The drop in pressure and fluid flow rate in the riser tubes has been recorded using pressure differential transducers and magnetic flow meters. Pyranometers records solar radiation by keeping it in open air conditions and the data collected are stored in Data logger. The detailed specifications of the measurement devices are given in Table 1.

In case of twisted tape collector, altered designs of kenics inserts combined with rod and spacer are introduced inside the riser, have same size as that of the simple collector. All experiments have been conducted simultaneously.

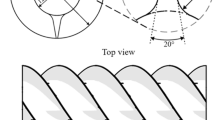

Twist inserts have been made manually by using copper strips of 0.003m thick, 1m length and 0.011 m width. The twist ratio (TR) 3 was obtained by twisting the strips through 180° to form a single helix. The Full kenics twist was formed by axially arranging array of such helical elements so that the leading edge of a helix element is at 90° to the trailing edge of the preceding helix and is continued for 1m length. Copper rod of 0.0004 m diameter, 0.125, 0.25, and 0.5 m length are brazed in succession with full twist in the design of kenics with rod (KR), marked as KR125, KR250, and KR500, respectively. Kenics with spacer (KS) is formed by maintaining empty space sequentially for aforesaid lengths, named KS125, KS250, and KS500, respectively, are given in Fig. 2.

Experimental procedure

This work has been executed at SLCET near Thanjavur, Tamilnadu, India (Latitude: 10°’N; longitude: 80°.11’E, 88m above MSL, 402.3 km to the North of equator) and testing has been conducted between March and May 2020 consecutively. The local weather conditions recorded during the trial days are; bright sunshine with a RH of in and around 68%, air dry bulb temperature 38°C, wind speed 2.7m/sec, max.

All DSWHs (plain tube, full length twist, & modified designs) were kept in open atmosphere; facing south direction slanting at 10° tilt angle, equal to local latitude to extract maximum energy. The readings were observed between 09.00 am and 04.00 pm IST during which the maximum solar intensity is obtained in all the trials. Fresh water is filled early morning in the storage tank and it is completely drained after the trial every day. The average temperature of water is estimated from the mean of entry, exit of individual risers. Likewise, the temperature of absorber plate and riser tube wall were estimated by taking the mean of temperatures recorded by thermocouples positioned at 45 points on the respective exteriors. Mass rate, fluid pressure difference, insolation, air temperature, entry, exit temperatures of water in riser tubes have been measured and aggregated for every 15-minutes. Similar trial runs have been executed for 4 successive days to substantiate the resemblance.

From the recorded parameters, it is observed that the solar insolation shows increasing trend and peaking at 1.00 pm tailed by declination till 4.00 pm. Identical inclination experienced for fluid mass rate, absorber plate, entry water, and air dry bulb temperatures. Based on above trend, the observation characteristic of solar water heater is split into two phases based on insolation; of ascending order as phase 1 followed by declining order as phase 2. For each phase flow friction, Nusselt number and thermal attributes are resolved individually.

Experimental data reduction

In order to understand the recorded results effectively, it is reduced by using the following relations

Heat removal

Quantity of heat removed (Q) risers are estimated from

The heat removal rate is connected to fluid mass rate, Cp and difference among fluid exit and entry temperatures. Further,

The inside convective heat removal coefficient between collector surface and flowing fluid hi has been calculated by linking equation 1 & 2 for the estimation of Nusselt number (experimental).

Thermo physical properties of water calculated at bulk mean temperature (Tm).

Frictional resistance

Fully developed friction factor for each riser of the collector estimated using

where ΔP is flow pressure reduction through risers.

Thermal attributes

The thermal characteristics of each DSWH is determined from Hottel and Whillier [20]

Product of transmittance-absorbance (τα), heat loss coefficient (UL) and heat removal factor (FR) are estimated from Duffie and Beckman [21].

The heat removal factor is estimated from

The spontaneous thermal performance is evaluated regularly at an interval of 15 min.

Experimental uncertainty

Experimental uncertainties of current data attrition resolved by Coleman-Steele [22] & ANSI/ASME [23] and observed to be within tolerable limits. The peak uncertainties realized for Re, \(\mathrm{ft}\), Nu and thermal performance are ± 1.8%, ± 3.5%, ± 2.1, and ± 1.32%, respectively. Mathematical models of derived quantities are developed by using the fundamental concepts of calculus and total differential. The experimentally measured quantities of m, h, P, L, and Di are used in mathematical models for estimating the derived quantities of Reynolds number, friction factor, and Nusselt number.

Results and discussions

Heat removal attributes of plain tube and full kenics twist collector

Sieder –Tate equation [24] is used for calculating the theoretical Nusselt number Nu of a simple DSWH in both phases. Since the Gratez number (Gz) value is less than 10, above said equation is used in the analysis.

For phase 1 & phase 2, experimental Nu is used in the above property relation and the peak discrepancy observed was ± 6%. The magnitude of solar insolation increments steadily in phase 1 boost the difference in temperature of the water from entry to exit. This phenomenon persuades driving potential; subsequently increases the fluid mass rate and kinetic energy. Hence steady improvement in Reynolds number and corresponding increase in Nusselt number has been observed. In phase 2, there is a gradual decrease in the intensity of solar insolation indicates that the heat absorption in the collector is also descending. Furthermore, it decreases difference of temperature among entry and exit of risers as result of diminishing driving force. It is obvious that, the declining Reynolds number this phase lowers the heat removal. In comparison with modified twist inserted collector and simple DSWH, higher heat enhancement is evaluated in full twist inserted collector. Presence of kenics twist inside the tube splits the fluid flow pattern inside the tube from circular to semicircular flow pattern on both side of the first helical element in the kenics. In the second helical element which is attached at an angle of 90° to the first element cuts the flow stream again, and this process is sustained throughout the length of the twist/riser tube. This kind of intermittent swap in swirl direction and fluid flow pattern gives rise to the fluid secondary motion, consistent fluid temperature and improved particle agitation; hence finer blending of fluid molecules. This causes the Nusselt number for full kenics inserted collector to increment about 4.4 times in comparison with simple DSWH.

Heat, friction characteristics of DSWH with modified twist designs

Current chapter discusses the heat augmentation in full kenics inserted collector and modified twist inserted collectors. Presence of spacer and rod sequentially between the twist elements influence significantly in heat transfer augmentation inside the riser tubes. The dependency of hi with Re are depicted in Fig. 3a, b. In general, observations from the experimental results that the hi value raises with increment in Reynolds number during phase 1 because of the progression in heat input to the collectors. The convective heat transfer coefficient for KR125 decreases by 0.95% and for KS125 is 3.8% compared to full kenic inserted collector. Similarly for collectors with KR250 and KS250 twist the decrement estimated is 5.54 and 6.68%, respectively. While the length of rod and spacer is increased to 0.5 m, named KR500 and KS500, the decrement in convective heat transfer coefficient evaluated is 11.2 and 18% correspondingly. As far as KR insert is concerned, existence of rod element sequentially in twist segment assist sustaining the fluid swirl to some extent. But in case of KS insert, the fluid particle swirl diffuses quickly in spacer segment; establish anew in twist regime. This phenomenon intensifies steadily while incrementing rod and spacer linearly and lessen the thermal enhancement proportionally. As a result of alternate establishment and confuse of fluid swirl, relatively greater decrement in Nusselt number in comparison with full twist collector.

Empirical correlations were established with 95% confidence level for both phases using Gauss elimination method.

where Nus is the swirl-induced Nusselt number. The Nusselt number approximated from the above correlations (10) and (11) for a respective phase fits the investigational values reasonably within ±18% depicted in Fig. 4a, b.

Flow friction attributes of DSWH and full twist collector

The frictional resistance experienced by the flowing fluid inside risers are determined by differential flow pressure transducers, fixed suitably between entry and exit. In general, it is observed that the flow pressure reduction is minimum at low fluid temperature, reaches peak at higher temperature since the fluid viscosity is inversely proportional to temperature. Equation (4) is used to calculate the experimental friction factor of simple DSWH and compared with fanning equation show an inconsistency within ±11.5 for both phases.

In case of twist inserted collector, higher value of ΔP is recorded as a result of improved particle mixing effect and raise in wetted surface of raiser tube. The novel design of kenics twist not only promotes fluid swirl in forward and reverse tangential direction but also split and reunite fluid flow. Accordingly, the flow velocity is significantly greater in full kenics inserted collector while comparing other collectors. The magnitude of ΔP estimated in full kenics inserted collector is closely thrice than simple DSWH. Increase in wetted surface and increment in hydraulic length of the fluid is the main cause of flow friction. Minimum fluid velocity is observed in the beginning of phase 1; progression of insolation intensity improves fluid flow velocity steadily, in turn raise the ΔP value, reduce \(\mathrm{ft}\). Since solar insolation steadily diminishes during phase 2, the fluid flow velocity and ΔP are affected as explained in the previous phase. Hence the magnitude of flow resistance raises correspondingly.

Influence of incorporating rod and spacer in flow ΔP

Existence of a rod section alternately along twists tend to decrement the wetted surface and hydraulic length. This is primarily because of the steady dissemination of fluid swirl in the rod regime which directly depend on rod length. The flow pressure reduction recorded in a collector with KR insert is significantly greater than KS inserted. This is mainly due to the continuation of the fluid swirl developed in twist regime and its persistence in rod section. In case of KS collector, due to the presence of empty space, the magnitude of swirl motion suddenly drops and hence the flow pressure loss for KR125, KR250, and KR500 are found to be decreased by 11, 22.4, and 33.6% when compared to full kenics collector. Likewise, the calculated flow ΔP for KS125, KS250, and KS500 are lower by 19, 28.6, and 47% the loss calculated for full kenics collector. In the same way, the friction in KR collector is high in comparison with KS collector. The friction factor for KR125, KR250, and KR500 is 2, 4.5, and 10% compared to full twist collector. For KS inserted collector, the flow friction factor for KS125, KS250 and KS500 are lesser by 5, 9, and 20%, respectively, compared to full kenics collector. The flow resistance factor calculated for collector with modified twist insert is a function of Re, TR and linear dimension of rod and spacer. The changes in flow pressure with corresponding Reynolds number is depicted in Fig. 5a b. Following empirical correlations are developed for both phases.

where \(\mathrm{ft}\) is the flow friction factor for modified twist designs KR and KS. The estimated \(\mathrm{f}\) t from Eqs. (12) and (13), compared with the experimental values and deviations are within ± 13% for both phases, as shown in Fig. 6a, b.

Thermal performance of the collector

The deviation of instantaneous efficiency with local time for simple DSWH, full kenics collector and KR, KS collectors are shown in Fig. 7. Observations show that there is decrement in instantaneous efficiency with increment in the ratio of temperature drop to solar insolation. The magnitude of overall heat loss coefficient, a measure of the performance of the system is depending upon the difference between entry, exit water temperature and local weather quality. Further, the spontaneous efficiency of all collectors progresses in phase 1, reaches maximum when the insolation intensity is peak and found to decrease till end of the trial, due to decrement in heat transfer since there is a decline in solar insolation intensity.

The spontaneous efficiency of full kenics collector is invariably greater than simple DSWH and KR, KS collectors. Introduction of twist elements modify the axial streamlined fluid flow in the plain collector into tangential direction intern improves the fluid surface that is wet and resident time in risers. This phenomenon amplifies the heat removal rate between inner riser surface and flowing fluid. Hence in simple DSWH, as a result of minimum wetted surface, we observe more thermal losses and record poor instantaneous efficiency.

In case of KR, KS collectors, the extension of tangential fluid swirl and particle turbulence surrounding rod regime improves the spontaneous performance substantially compared to simple DSWH. The length of the rod in the twist directly influences and is inversely proportional to the magnitude of reduction in the collector’s instantaneous efficiency.

Furthermore, in kenics insert with spacer, the magnitude of particle turbulence is quickly fade away in the empty space, leading to larger overall heat loss coefficient because of reduction in wetted surface and diminishing tangential swirl flow when compared to full kenics and collectors with modified inserts. Fluid particle blending agitation is indirectly and rate of decay of swirl depends directly on the spacer length. Hence the instantaneous efficiency of all collectors with spacer offers comparatively lower performance than collector with rod.

The collector heat removal rate, an important performance parameter which is defined as the ratio of actual useful energy absorbed to the energy absorbed if the entire collector were at the fluid entry temperature. The increase in the temperature of fluid through the collector decreases with increase in the fluid mass flow rate. Subsequently this phenomenon resulted in lower losses and maximizes the actual useful energy captured. The variation in heat removal rate with Reynolds number is depicted through Fig. 8. It is realized that the hotness of absorber plate of simple DSWH is elevated, minimum for collector with full kenics insert due to higher heat removal. Rate of heat removal from absorber plate, a direct indicator of the thermal performance of the collector is observed 0.99 for collector with full kenics insert and 0.62 for simple DSWH. It is obvious that, in plain tube, the only means of heat removal is convective heat removal since the inner tube surface in contact with flowing fluid is comparatively minimum in the absence of twist inserts.

It is observed in case of KR, KS collectors, the magnitude of \({\mathrm{F}}_{\mathrm{R}}\) gradually decays with incrementing rod and spacer linearly. The heat removal rate evaluated for KR250 and KS250 is 0.96 and 0.93, respectively. When the length is 500 mm the same is reduced to 0.89 and 0.88 correspondingly. This indicates that the fluid turbulence has a relatively strong influence on the mean plate temperature and heat removal rate in KS collector compared to KR collector.

Concluding remarks

Experimental analysis on heat transfer and flow friction attributes of simple DSWH with modified designs of kenics twist limited to laminar flow regime has been presented. The modified designs of twists offered an improved performance over the plain tube collector and summarized as given below.

-

Compared to simple DSWH, the improvement in instantaneous efficiency is in between 1.65 to 1.53 times and the decrease in ΔP compared to full length kenics insert is between 1.85 to 1.12 times. The instantaneous efficiency improvement is because of the presence of twist inserts which offer rapid turbulence, better particle mixing and ultimately leads to higher heat removal rate closure to 0.98.

-

The novel kenics twist design offered noticeable decrease in ΔP and ultimately lower the mass flow rate of the working fluid.

-

The enhancement of Nusselt number and convective heat transfer coefficient in comparison with a simple DSWH is between 4.35 to 3.62 times and 4.42 to 3.62 times, respectively.

Based on the above findings, it is concluded that the modified designs of kenics inserts offered significant improvement in the heat transfer along with parallel increment in the ΔP. Its magnitude varies indirectly with the length of rod and spacer.

Abbreviations

- A c :

-

Collector Aperture area, m2

- A i :

-

Inside surface area of the riser tube, m2

- A o :

-

Outside surface area of the riser tube, m2

- C p :

-

Specific heat kJ kg−1 oC

- D h :

-

Equivalent diameter of the riser tube with respect to the spacer diameter, m

- D o :

-

Outside riser tube diameter, m

- f :

-

Friction factor for plain tube collector, (dimensionless)

- ft:

-

Friction factor for twisted tape collector, (dimensionless)

- Gz:

-

Gratez number (dimensionless) Gz = DH/L RePr

- \(h\) :

-

Convective heat transfer coefficient (W m−2oC)

- hi:

-

Internal convective heat transfer coefficient (W m−2oC)

- H t :

-

Total intensity of solar radiation, W m−2oC

- k :

-

Thermal conductivity of water, W m−1oC

- k w :

-

Thermal conductivity of the riser tube wall, W m−1oC

- L :

-

Length of the riser tube, m

- m :

-

Mass flow rate kg s-1

- Nu:

-

Nusselt number for plain riser tube, dimensionless, \(\mathrm{Nu}=\frac{hiDi}{k}\)

- Nus :

-

Nusselt number for twisted tape inserted in the riser tube (Swirl flow)

- Pr:

-

Prandtl number, dimensionless, \({P}_{\text{r}}=\frac{\mu {C}_{\text{p}}}{k}\)

- Q :

-

Heat transfer rate, W

- Re:

-

Reynolds number based on the internal diameter of the riser tube, dimensionless

- S :

-

Length of rod and spacer (m)

- T m :

-

Bulk mean temperature of fluid in the riser tube, oC \(\left(\frac{{T}_{\mathrm{in}}+{T}_{\mathrm{out}}}{2}\right)\)

- T in :

-

Average outlet temperature of water, oC

- T out :

-

Average outlet temperature of water, oC

- T wo :

-

Average wall surface temperature outside

- U i :

-

Overall inside heat transfer coefficient (W m−2oC)

- U o :

-

Overall outside heat transfer coefficient (W m−2oC)

- U l :

-

Overall heat loss coefficient (W m−2oC)

- TR:

-

Twist ratio (length of one twist/diameter of the twist) (dimensionless)

- Η :

-

Collector efficiency

- F R :

-

Collector heat removal factor

- \({\tau \alpha }\) :

-

Transmittance-Absorptance product

- U l :

-

Overall heat loss coefficient

- T a :

-

Ambient temperature

- T p :

-

Absorber plate temperature

- H t :

-

Total solar radiation

- ρ :

-

Density of water (kg m−3)

- µ :

-

Dynamic viscosity of water at bulk mean temperature (Ns m−2)

- µ w :

-

Dynamic viscosity at wall temperature (Ns m−2)

- ΔP :

-

Pressure drop of water (N m−2)

References

Liu S, Sakr M. A comprehensive review on passive heat transfer enhancements in pipe exchangers. Renew Sustain Energy Rev. 2013;19:64–81. https://doi.org/10.1016/j.rser.2012.11.021.

Rahimi M, Shabanian SR, Alsairaf AA. Experimental and CFD studies on heat transfer and friction factor characteristics of a tube equipped with modified twisted tape inserts. Chem Eng Process Process Intensific. 2009;( 48):762–770. https://doi.org/10.1016/j.cep.2008.09.007

Wongcharee K, Eiamsa-ard S. Heat transfer enhancement by twisted tapes with alternate-axes and triangular, rectangular and trapezoidal wings. Chem Eng Process Process Intensific. 2011;(50):211–219. https://doi.org/10.1016/j.cep.2010.11.012

Guo J, Fan A, Zhang X, Liu W. A numerical study on heat transfer and friction factor characteristics of laminar flow in a circular tube fitted with center-cleared twisted tape. Int J Therm Sci. 2011;(50):1263–1270. https://doi.org/10.1016/j.ijthermalsci.2011.02.010

Sivashanmugam P, Suresh S. Experimental studies on heat transfer and friction factor characteristics of laminar flow through a circular tube fitted with helical screw-tape inserts. Appl Therm Eng. 2006;(26):1990–1997. https://doi.org/10.1016/j.applthermaleng.2006.01.008

Eiamsa-ard S, Promvonge P. Enhancement of heat transfer in a tube with regularly-spaced helical tape swirl generators. Solar Energy. 2005;78(4):483–494. https://doi.org/10.1016/j.solener.2004.09.021

Herrero Martín R, Pérez-García J, García A, García-Soto FJ, López-Galiana E. Simulation of an enhanced flat-plate solar liquid collector with wire-coil insert devices. Solar Energy. 2011; 85(3):455–469. https://doi.org/10.1016/j.solener.2010.12.013

Emani MS, Ranjan H, Bharti AK, Meyer JP, Saha SK. Laminar flow heat transfer enhancement in square and rectangular channels having: (1) A wire-coil, axial and spiral corrugation combined with helical screw-tape with and without oblique teeth and a (2) spiral corrugation combined with twisted tapes with oblique teeth. Int J Heat Mass Transfer. 2019;144:118707. https://doi.org/10.1016/j.ijheatmasstransfer.2019.118707

Jaisankar S, Radhakrishnan TK, Sheeba KN. Experimental studies on heat transfer and friction factor characteristics of forced circulation solar water heater system fitted with helical twisted tapes. Solar Energy. 2009;83(11):1943–1952. https://doi.org/10.1016/j.solener.2009.07.006

Jaisankar S, Radhakrishnan TK, Sheeba KN. Experimental studies on heat transfer and thermal performance characteristics of thermosyphon solar water heating system with helical and Left–Right twisted tapes. Energy Convers Manage. 2011;52(5):2048–2055. https://doi.org/10.1016/j.enconman.2010.11.024

kumar R, Chand P. Performance prediction of extended surface absorber solar air collector with twisted tape inserts. Solar energy 2018;(169):40–48.

Du J, Hong Y, Huang S-M, Ye WB, Wang SF. Laminar thermal and fluid flow characteristics in tube with sinusoidal ribs. Int J Heat Mass Transf 2018;120:635–651.

Ibrahim EZ. Augmentation of laminar flow and heat transfer in flat tubes by means of helical screw-tape inserts. Energy Convers Manage. 2011;52:250–7.

Vengadesan E, Senthil R. A review on recent developments of thermal performance enhancement methods of solar flat plate collectors. Sol Energy. 2020;206:935–61.

Isravel RS, Raja M, Saravanan S, Vijayan V. Thermal augmentation in parabolic trough collector solar water heater using rings attached twisted tapes. Materials Today Proc 2019;21(1):127–129. https://doi.org/10.1016/j.matpr.2019.05.375

Almeshaal M, Arunprasad V, Palaniappan M, Kolsi L. Experimental study of a solar water heater fitted with spacer at the leading edge of Left-Right screw tapes. Case Stud Therm Eng. 2020;22:100777. https://doi.org/10.1016/j.csite.2020.100777

Balaji K, kumar GP, Vadivel SD, Vigneswaran VS, Inian S. Experimental Investigation on flat plate solar collector using frictionally engaged thermal performance enhancer in the absorber tube. Renew Energy 2019;142:62–72.

Garcia A, Herrero-Martin R, Solenao JP, Perez-Garcia J. The role of insert devices on enhancing heat transfer in a flat plate solar collector. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2017.12.090.

Rashidi S, Kashefi MH, Hormozi F. Potential application of inserts in solar thermal energy systems—a review to identify the gaps and frontier challenges. Solar Energy 2018;171: 929–952.

Hottle HC, Whiller A. A Evaluation of flat-plate solar collector performance. Trans Conf Use Solar Energy. 1958;2(1):74–104.

Duffie JA, Beckman WA. Solar engineering of thermal process. New York: Wiley Interscience; 1980.

Coleman HW, Steele WG. Experimental and uncertainty analysis for engineers. New York: Wiley Interscience; 1989.

ANSI/ASME. Measurement uncertainty. PTC 19; 1986, p. 1–1985.

Sieder EN, Tate GE. Heat transfer and pressure drop of liquids in tubes. Ind Eng Chem. 1936;28:1429–39.

Acknowledgements

The authors gratefully acknowledge the financial support by the Department of Science and Technology (SR/FTP/ETA-071/2009), Ministry of Science and Technology, Government of India.

Author information

Authors and Affiliations

Contributions

JA contributed to development of experimental setup, experimentation, data analysis, investigation, content writing. SJ contributed to supervision, conceptualization, methodology. JS contributed to development of mathematical models, language check, data verification. AB contributed to data curation, draft preparation.

Corresponding author

Ethics declarations

Conflict of interest

The authors certify that there is no conflict of interest with the Department of Science and Technology, Ministry of Science and Technology, Government of India.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ananth, J., Jaisankar, S., J, S. et al. Design and experimentation on domestic solar water heaters using kenics twist inserts. J Therm Anal Calorim 148, 943–953 (2023). https://doi.org/10.1007/s10973-022-11814-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11814-6