Abstract

The ionic liquid 1-butyl-3-methylimidazolium dicyanamide ([Bmim][Dca]) is a novel solvent suitable for a wide range of applications in the petrochemical industry. However, the thermal safety of [Bmim][Dca] IL has not been fully considered when developing new uses, especially in areas involving high-temperature work. Starting from the initial decomposition temperature of [Bmim][Dca] IL, this article tries to find the highest temperature suitable for its intrinsic safety and provides a basis for its industrial production. The thermal stability of [Bmim][Dca] IL and its pyrolysis gas detection were obtained by simultaneous thermogravimetric analyser (STA) and thermogravimetric analysis coupled with Fourier infrared spectroscopy (TG-FTIR), respectively. Furthermore, the constant temperature experiments by STA show that the mass loss of [Bmim][Dca] IL at a specific temperature for 10 h is approximately 2% at 160 °C, about 15% at 190 °C, and more than 30% at 210 °C. The mass loss in the dynamic heating experiment is divided into two steps at each heating rate. The pyrolysis gas detection experiments by TG-FTIR show that extremely toxic gas such as HCN will be produced at 154 °C (T0.01/10 h). The real-time photography system by STA observed significant colour changes in samples at this temperature. Therefore, extrapolated temperature (TMOT,10 h,e) was defined to obtain a more accurate maximum operation temperature. Comparative experimental results show that the TMOT,10 h,e obtained by the extrapolation method has high reliability. The results of this study would provide a relevant basis for safer control based on the thermal hazard assessment of [Bmim][Dca] IL.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ionic liquids (ILs) are a particular class of materials that are organic salts with superior properties, containing organic cations and organic or inorganic anion counterparts [1,2,3,4]. The stable and effective use of ILs in synthesis, processing, and application is required for high efficiency and safety in modern industries [5].

1-butyl-3-methylimidazolium dicyanamide ([Bmim][Dca]) has been studied in many fields. In separation processes, it is expected to be used as solvents in the design of the separation process for selective recovery of fluorinated refrigerant gas [6]. Hybrid materials based on [Bmim][Dca] IL and polymers represent an emerging and exciting approach to increasing conductivity [7]. Moreover, in the field of protein science, compared with hydrophobic ILs, hydrophilic ILs such as [Bmim][Dca] tend to replace the relatively weak protein water hydrogen bond through the stronger protein IL hydrogen bond on the protein surface. This more excellent breaking of protein water hydrogen bond leads to more significant water loss for protein hydration in the presence of hydrophilic ILs, thus reducing protein stability [8]. Besides, the more attractive research is [Bmim][Dca] IL can leach gold under light conditions by mixing with iodoform (CHI3), and has high efficiency [9]. Herein, to solve the problem of the safe use of the [Bmim][Dca] IL in those applications, the multi-path method based on dynamic and isothermal techniques was used to evaluate the thermal stability and potential hazard.

Determining comparable thermal stability characteristics is a prerequisite for solving this problem. Currently, the different evaluation methods used to assess the stability of substances are challenging to evaluate thermal performance consistently. Based on the decomposition of substances, the commonly used parameters to describe the stability of substances are Tonset, T0.01/10 h, TFP, and TMOT. Usually, the thermal stability of ILs is characterised by Tonset [10], which is the extrapolated onset temperature measured by the instrument under dynamic heating conditions. Due to the existence of thermal inertia, the extrapolated starting temperature at different heating rates has a big difference. The ASTM standard [11, 12] has limited the range of the temperature rise rate of related experiments, but there is still a non-ignorable diversity in Tonset between this range. T0.01/10 h is an essential parameter obtained in the long-term thermal stability experiment of IL [4]. Starting from the actual industrial conditions, the data would be relatively conservative. Because under the experimental conditions, the 1% mass loss may be caused by the absorption of moisture in the air due to the hydrophilicity of IL, or it may be the organic solvent for purification inevitably carried by the IL during the production process. Therefore, purification in laboratory environments is particularly significant, especially for water treatment. TFP, in particular the flash point concept of ILs, may be different from ordinary organic liquids [13]. The flash point temperature of ILs is often due to the ignition of their decomposition products, while normal organic liquids are due to the ignition of their vapour. Therefore, it can be inferred that the flash point of the IL is higher than its decomposition onset temperature. TMOT, a kinetic model based on the maximum operation temperature, evaluates temperature and time-dependent stability [14,15,16]. Generally speaking, the evaluation procedure of TMOT is based on dynamic TGA to determine kinetic parameters. The decomposition of ILs may be accompanied by spontaneous combustion processes [17]. Therefore, there may be no suitable kinetic model for the decomposition kinetics of ILs to estimate the apparent activation energy of the decomposition reaction. For the reaction system whose reaction mode f(α) is unknown, the model-free method can be used. For instance, Flynn–Wall–Ozawa (F-W–O) method and Kissinger–Akahira–Sunose (K-A-S) method are two multiplex scanning methods that can be adopted. At present, Kissinger–Akahira–Sunose (K-A-S) model-free analysis was used to calculate the apparent activation energy Ea adopting the iso-conversion method.

Since most ILs may contain hydrophilic groups [18], they tend to absorb moisture when placed in the air. In the previous studies, the research on the thermal decomposition of IL did not eliminate this effect, which would lead to erroneous conclusions. To get more accurate experimental data, [Bmim][Dca] IL was placed at a constant temperature of 80 °C for one week to remove its moisture and organic volatiles before all experiments. Various experiments are used to determine the above temperature, and TG combined with FTIR analyses the gaseous products to assess whether the gaseous products at the above temperature are potentially harmful. Finally, the maximum operation temperature most suitable for using the IL was determined, and the preventive measures for producing gaseous products at excessively high temperatures were determined.

Experimental section

Experiment reagent

1-butyl-3-methylimidazolium dicyanamide ([Bmim][Dca]) was procured from Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences. The samples with 99 mass% purity were stored in a medicine cabinet at 4 °C. Before the experiment, the samples were placed in a vacuum oven at 80°Cfor one week to remove moisture and volatile organic solvents.

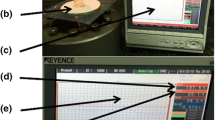

The simultaneous thermogravimetric analyser (STA)

A simultaneous thermogravimetric analyser (STA 7200RV, Hitachi, Japan) was used to observe the mass change in [Bmim][Dca] IL decomposition reaction [19]. It can simultaneously measure thermogravimetric (TG) and differential thermal analysis (DTA) within a wide temperature range. Before each experiment, STA was calibrated by calcium oxalate pentahydrate to ensure both temperature and heat flow accuracy. The investigation is divided into two parts: the linear heating experiment and the constant temperature experiment.

A 1-mL experimental disposable syringe was used for sample transfer. After absorbing the liquid sample, move the syringe to the top of the alumina crucible. Then, slowly drop the sample to the bottom of the crucible and disperse it evenly. In the linear heating experiment, roughly 3.0 ± 0.1 mg samples were loaded in the alumina crucible for each experiment, and the flow rate of purge gas was controlled at 80.0 mL min−1 under a nitrogen atmosphere. In addition, the temperature range was selected from 30.0 to 600.0 °C with a heating rate of 0.5, 1, 2, 4, and 8 °C min−1.

In constant temperature experiment, the temperature is, respectively, controlled as 150, 160, 170, 180, 185, 190, 195, 200, 210 °C. Other conditions are the same as the linear heating experiment.

Thermogravimetric analysis coupled with Fourier-transformed infrared spectrometry (TG-FTIR)

Thermogravimetric analysis coupled with Fourier-transformed infrared spectrometry (TGA 2, Mettler Toledo, Switzerland; Nicolet iS20 FTIR, Thermo Fisher Scientific, USA) was used to continuously analyse the evolved gases generated by the decomposition of the samples [20]. All the experimental conditions in TGA parts were the same as those described in the STA experiments. The FTIR spectrometer was set to transmission mode, and the FTIR spectra were analysed at a 4 cm−1 resolution with 8 scans in the range of 4000 − 400 cm−1.

Results and discussion

Thermal decomposition and constant temperature mass loss

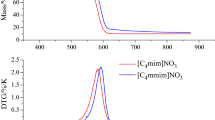

Both dynamic heating experiments and constant temperature experiments are used to evaluate the stability of [Bmim][Dca] IL. Among them, the dynamic heating experiment of [Bmim][Dca] IL at different heating rates is shown in Fig. 1. Figure 1a is the thermogravimetric curve, which describes the mass loss of the sample. Figure 1b is the DTG curve, which describes the mass loss rate of the sample. Obviously, the decomposition of [Bmim][Dca] IL is divided into two steps. In the first stage of decomposition, the mass loss rate of the IL was about 52%, and in the second stage of decomposition, the mass loss rate of [Bmim][Dca] IL was about 27%. Finally, at around 600 °C, about 21% of the residue remained. The constant temperature experiment of IL at different ambient temperatures is shown in Fig. 2. According to the experimental results, the mass loss of [Bmim][Dca] IL is approximately 2% at 160 °C for 10 h, about 15% at 190 °C, and more than 30% at 210 °C. In addition, the results of constant temperature experiments at all temperatures have linear characteristics.

Determination of extrapolated onset temperature (T onset)

According to the results of the dynamic heating experiment in Sect. Thermal decomposition and constant temperature mass loss, the Tonset at different heating rates is sorted in Table 1. As the temperature rise rate (β) increases, the value of Tonset increases from 241.9 to 296.0 °C. Although the Tonset has a larger interval with different temperature raise rates, it is still within the normal range, which is caused by the instrument’s limitations.

Determination of the temperature decomposed by 1% within 10 h (T 0.01/10 h)

According to the results of the constant temperature experiment in Sect. Thermal decomposition and constant temperature mass loss, the mass loss of constant temperature for 10 h at different temperatures is sorted in Table 2. As the constant temperature (T) increases from 150 to 210 °C, the mass-loss rate after 10 h gradually increases from 0.56 to 30.84%. To derive the temperature decomposed by 1% within 10 h, the interpolation Eq. (1) is used, combined with the results of constant temperature experiments.

Finally, the specific value is calculated: T0.01/10 h = 153.8 °C.

Determination of maximum operation temperature (TMOT)

Based on the Coats–Redfern approximation [21], the K-A-S equation can be given as Eq. (2):

Obviously, \(\ln \left( {\frac{\beta }{{T^{2} }}} \right)\) and 1/T is linear.

To obtain a reasonably accurate TMOT value of [Bmim][Dca] IL and ensure that IL decomposition does not occur at this temperature, the thermogravimetric experimental data of dynamic heating are used to execute this prediction model: Eq. (3):

where TMOT is the maximum operation temperature in the required period (tmax), Ea,1% is the apparent activation energy of decomposition at α = 1%, k0 is the frequency factor, R is the universal gas constant, m0 is the initial mass, and m denotes the mass of the substance. To obtain a representative TMOT, the prediction of decomposition has to ensure a lower decomposition than 1% in mass. Therefore, when choosing to decompose the 1% TMOT prediction, the formula can be simplified as Eq. (4):

The apparent activation energy Ea,1% was calculated by the Kissinger–Akahira–Sunose (K-A-S) method. Based on a set of experiments performed at various heating rates, Ea,1% can be determined from the slope of straight lines according to Eq. (5):

The frequency factor k0 can be obtained using the calculated apparent activation energy at 1% decomposition according to the Arrhenius law (experimental dynamic data at 4 °C·min–1 heating rate were used) (Eq. (6)):

Taking into account the experimental contingency at the initial stage of the reaction, the method of calculating the apparent activation energy under the intermediate conversion rate and then extrapolating the conversion rate to 1% was adopted. Figure 3 shows the Kissinger–Akahira–Sunose (K-A-S) plot of [Bmim][Dca] IL in the conversion rate range of 10–45%. In the first step of the decomposition, the apparent activation energy (Ea) changes linearly, as shown in Fig. 4. Perform a linear fit to the apparent activation energy of 10–35% and extrapolate it to the initial stage of the reaction. The fitting data by the K-A-S method under different conversion rates are shown in Table 3. According to the fitted linear equation, it can be concluded that when the conversion rate is 1%, the value of Ea,1%,e is around 105.0 kJ mol–1. Then, according to Arrhenius law, the value of frequency factor k0 was calculated around 3,874,647 s–1. In addition, the direct method used the K-A-S fitting curve at 1% conversion to directly obtain the apparent activation energy data. The value of Ea,1%,d is around 98.9 kJ mol–1, and the value of k0 is around 957,841 s–1. Part of the calculation results of TMOT of the two methods is shown in Table 4. In particular, TMOT,10 h,e is the maximum operation temperature calculated by the extrapolation method for a specified working time of 10 h, and TMOT,10 h,e is calculated using the direct method. The value of TMOT,10 h,e is around 144.3 °C, and TMOT,10 h,d is around 139.1 °C. Furthermore, to determine the safe use of [Bmim][Dca] IL during any other period, detailed results of the maximum operation temperature are shown in Fig. 5.

Constant temperature experiment-evolved gases detection

To determine which characteristic temperature has industrial guidance for the use of [Bmim][Dca] IL, the constant temperature experiment was used to identify the gas products of [Bmim][Dca] IL at different temperatures. Each group of experiments is a 10-h experiment at a constant temperature. (The experimental temperature setting value is the characteristic temperature in the above discussion). The Fourier transform infrared spectroscopy and sample morphology at constant temperature for 10 h are shown in Fig. 6. At lower temperatures, [Bmim][Dca] IL behaves stably. At 144 °C, the extrapolated maximum operation temperature (TMOT,10 h,e), the infrared spectrum of the sample does not appear with any characteristic peaks. However, at 154 °C, the calculated value of T0.01/10 h, the infrared spectrum of the sample begins to show characteristic peaks. In the real-time photography system, it was found that at 144 °C after ten hours of constant temperature experiment, IL is still colourless and transparent. At 154 °C, although IL did not react violently, the colour of IL had begun to change, and the colourless and transparent liquid became light yellow. This phenomenon further proves that the IL cannot maintain stability at this temperature.

The detection results of the gas released by the sample by the Fourier infrared spectroscopy under 154 °C are as follows. The peak wave number at 3338.33 and 3275.95 cm–1 are because of the N–H stretching vibrations. The peak wave number at 2965.68 cm–1 is attributed to the antisymmetric stretching vibration of C–H. Wave numbers at 1461.74 cm–1 are due to bending vibrations of C–H. The observed absorbance bands belong to HCN with bands at 713.85 cm–1. Based on the identified wavenumbers, the thermal decomposition gaseous products include poisonous gas HCN[22]. On 5 July 2013, the California Office of Environmental Health Hazard Assessment (OEHHA) classified hydrogen cyanide (HCN) and cyanide salts (CN salts) as known in Proposition 65 List of Reproductive Toxic Chemicals. Therefore, the production of this toxic substance can be detected at a temperature of 154 °C, which is an alarm for the safe use of [Bmim][Dca] IL.

Conclusions

[Bmim][Dca] IL is stable in dynamic measurements (0.5 °C min–1) up to temperatures of 241.9 °C. The value of Tonset will increase significantly with the increase in heating rate. The process of mass loss of [Bmim][Dca] IL in the dynamic experiment was divided into two steps. Seventy-nine per cent of the mass was lost in the nitrogen atmosphere and converted to gas products.

In a constant temperature experiment of up to 10 h, it is found that the mass loss of [Bmim][Dca] IL is approximately 2% at 160 °C, about 15% at 190 °C, and more than 30% at 210 °C. The interpolation method is used to calculate T0.01/10 h = 153.8 °C. Besides, the most valuable data, such as Ea,1%,e, are around 105.0 kJ mol–1, and the maximum operation temperature (°C) TMOT,10 h,e is 144.3 °C by the extrapolation method. The stability of [Bmim][Dca] IL at this temperature was proved in the constant temperature experiment for up to 10 h.

Herein, the Tonest, T0.01/10 h, TMOT,10 h,e, and TMOT,10 h,d could be ordered as Tonest > T0.01/10 h > TMOT,10 h,e > TMOT,10 h,d. From the experimental results of gas product analysis, [Bmim][Dca] IL can release highly toxic gas such as HCN at T0.01/10 h, and the colour of the sample becomes darker; at TMOT,10 h,e, [Bmim][Dca] IL had no obvious physicochemical changes within 10 h. Therefore, the values of Tonest and T0.01/10 h are pretty radical, while the values of TMOT,10 h,d are too conservative. The extrapolation method for calculating the maximum operation temperature has the highest reliability. Based on TMOT,10 h,e data and related calculations, [Bmim][Dca] IL can be used up to 132.6 °C for 24 h, 68.8 °C for 8000 h. Considering the scenarios in the actual application process, it is recommended not to use it at a temperature above 132.6 °C (TMOT,24 h) for a long time to avoid the generation of toxic gases and the decomposition of [Bmim][Dca] IL.

References

Ngo HL, LeCompte K, Hargens L, McEwen AB. Thermal properties of imidazolium ionic liquids. Thermochim Acta. 2000;357–358:97–102.

Salgado J, Villanueva M, Parajó JJ, Fernández J. Long-term thermal stability of five imidazolium ionic liquids. J Chem Thermodyn. 2013;65:184–90.

Gao Y, Cheng L, Gao R, Hu G, Zhao J. Deep desulfurization of fuels using supported ionic liquid-polyoxometalate hybrid as catalyst: A comparison of different types of ionic liquids. J Hazard Mater. 2021;401:123267.

Cao Y, Mu T. Comprehensive investigation on the thermal stability of 66 ionic liquids by thermogravimetric analysis. Ind Eng Chem Res. 2014;53:8651–64.

Weber M. Some safety aspects on the design of sparger systems for the oxidation of organic liquids. Process Saf Prog. 2006;25:326–30.

Asensio-Delgado S, Viar M, Pardo F, Zarca G, Urtiaga A. Gas solubility and diffusivity of hydrofluorocarbons and hydrofluoroolefins in cyanide-based ionic liquids for the separation of refrigerant mixtures. Fluid Phase Equilib. 2021;549:1–9.

Fernandes LC, Correia DM, Pereira N, Tubio CR, Lanceros-Méndez S. Highly sensitive transparent piezoionic materials and their applicability as printable pressure sensors. Compos Sci Technol. 2021;214:1–8.

Ghanta KP, Mondal S, Mondal S, Bandyopadhyay S. Contrasting Effects of Ionic Liquids of Varying Degree of Hydrophilicity on the Conformational and Interfacial Properties of a Globular Protein. J Phys Chem B. 2021;125:9441–53.

Feng F, Liu J, Zhao M, Yu L, Wang H, Lu C, Zhang Q, Zhao J, Sun Y, Cen J, Li X. Study of an environmentally friendly method for the dissolution of precious metal with ionic liquid and iodoalkane. Metals. 2021;11:1–12.

Del Sesto RE, McCleskey TM, Macomber C, Ott KC, Koppisch AT, Baker GA, Burrell AK. Limited thermal stability of imidazolium and pyrrolidinium ionic liquids. Thermochim Acta. 2009;491:118–20.

ASTM Standard E537. Standard Test Method for The Thermal Stability Of Chemicals By Differential Scanning Calorimetry. Annu B ASTM Stand. 2020; 1–8.

ASTM Standard E698. Standard Test Method for Arrhenius Kinetic Constants for Thermally Unstable Materials Using Differential Scanning Calorimetry and the Flynn/Wall/Ozawa Method 1. Annu B ASTM Stand. 2018; 1–8.

Chen CC, Liaw HJ, Chen YN. Flammability characteristics of ionic liquid 1-Decyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide. J Loss Prev Process Ind. 2017;49:620–9.

Knorr M, Icker M, Efimova A, Schmidt P. Reactivity of ionic liquids: studies on thermal decomposition behavior of 1-Butyl-3-methylimidazolium Tetrafluoro-borate. Thermochim Acta. 2020;694:178786.

Meißner A, Efimova A, Schmidt P. Impacts of TGA furnace parameters for prediction of long-term thermal stability of ionic liquids. Thermochim Acta. 2021;704:178917.

Navarro P, Larriba M, Rojo E, García J, Rodríguez F. Thermal properties of cyano-based ionic liquids. J Chem Eng Data. 2013;58:2187–93.

Chen CC, Chen CY, Wu JH, Kang X. Fire and explosion hazards of ionic liquid 1-methyl-1-propylpyrrolidinium bis(trifluoromethanesulfonyl)imide. J Loss Prev Process Ind. 2019;60:233–2340.

Ando T, Kohno Y, Nakamura N, Ohno H. Introduction of hydrophilic groups onto the ortho-position of benzoate anions induced phase separation of the corresponding ionic liquids with water. Chem Commun. 2013;49:10248–50.

Wang YR, Liu SH, Cheng YC. Thermal analysis and hazards evaluation for HTP-65W through calorimetric technologies and simulation. J Therm Anal Calorim. 2021;144:1483–92.

Wang WT, Liu SH, Wang Y, Yu CF, Cheng YF, Shu CM. Thermal stability and exothermic behaviour of imidazole ionic liquids with different anion types under oxidising and inert atmospheres. J Mol Liq. 2021;343:117691.

Liu N, Chen H, Shu L, Statheropoulos M. Error evaluation of integral methods by consideration on the approximation of temperature integral. J Therm Anal Calorim. 2005;81(1):99–105.

Chen M, Liang B, Guo Y, Li C, He X, Hu J, et al. Pyrolysis mechanism of polyimide containing bio-molecule adenine building block. Polym Degrad Stab. 2020;175:109124.

Acknowledgements

The authors would like to express their sincere thanks to the National Natural Science Foundation of China under contract number 52104177 and the Anhui Provincial Natural Science Foundation of China under contract number 1908085ME125 as the Anhui University of Science and Technology Graduate Innovation Fund of China under contract number 2021CX2096.

Author information

Authors and Affiliations

Contributions

W-TW contributed to conceptualization—lead, data curation—lead, formal analysis—lead, investigation—lead, methodology—lead, software—equal, writing—original draft—equal, writing—review and editing—lead. S-HL contributed to funding acquisition—equal, methodology—equal, project administration—equal, resources—equal, supervision—equal, writing—review and editing—equal. CS contributed to methodology—equal, software—equal, writing—review and editing—equal. Yang-Fan Cheng contributed to investigation—supporting, supervision—equal, methodology—equal, validation—supporting, writing—review and editing—supporting.

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, WT., Liu, SH., Su, C. et al. Multi-path method based on dynamic and isothermal techniques to evaluate the thermal stability and hazard of 1-butyl-3-methylimidazolium dicyanamide. J Therm Anal Calorim 148, 4897–4904 (2023). https://doi.org/10.1007/s10973-022-11726-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11726-5