Abstract

The objective of this research is to examine how ultrasonication time affects agglomeration, stability, thermal conductivity, and viscosity of CuO nanofluid. Using different reaction conditions, distinct shaped CuO nanoparticles are synthesised and dispersed in an EG: DW (70:30) ratio with 0.3 vol%. Microscopic and TEM images are used to analyze colloidal solutions with varying sizes and shapes of nanoparticles. After 30 days of preparation, the zeta potential is measured to ensure that the suspension is stable. The Bridgman equation is used to compute thermal conductivity using sound velocity values. Viscosity of colloidal suspension is measured by viscometer. All of the studies are performed at 30° ± 2 °C room temperature for ultrasonication times ranging from 30–120 min. At an optimal sonication time of 80 min, there is less agglomeration and more stable particle dispersion. In comparison to other morphological suspensions, CuO spherical shape suspended nanofluid has the lowest viscosity and maximum thermal conductivity, as well as the most stable fluid. At the optimal sonication period, measured results demonstrate thermal increase and decreased viscosity, which could have implications for heat transfer applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Improvement in heat transfer is highlighted for energy-saving purposes which could promote the excellence of human life and achieve sustainable progress [1]. High thermal load is a critical problem in infrastructure, transportation, manufacturing, space, defense sectors that are becoming a constraint for improving output [2]. There are several factors that explain production in these industries, one of which is the ability to cool the system being used rapidly. In order to maintain the operating efficiency and reliability of new products, cooling down thermo-physical machines are required, thus increasing the heat load and heat fluxes generated by raising the power and the product size [3]. Thus, in the last decade, a more effective cooling mechanism has been significantly in demand. As a result, more companies are starting to invest raising capital in research into more effective heat transfer processes. The standard method for enhancing heat transfer in any thermal system involves increasing the heat transfer surface area while also increasing the flow rate of the flowing fluid [4, 5]. There is a way to improve heat transfer by increasing the working fluid's thermal conductivity. To date, water, ethylene glycol, oil, etc. have been used as a heat transfer fluid which then has poor thermal conductivity than solids [6]. Adding solid particles to base fluid with higher thermal conductivity would improve thermal efficiency than conventional fluid. Multiple researchers previously studied the practical use of milli/micrometer-sized solid particles suspended in fluid and resulted in settling, agglomeration, erosion, and reduced efficiency of the thermophysical machine [7,8,9]. Therefore, the emergence of high heat flow processes has generated significant demand for new heat transfer technologies [10, 11]. Overcoming the microparticle suspension barrier, Choi and Eastman from Argonne National Laboratory examined nanoscale metallic particle and carbon nanotube thermal enhancement suspensions and first introduced the concept of 'nanofluid,' which is nanometer-sized particles suspended in base fluid as a result of which heat transfer is enhanced by suspending metallic nanoparticles in conventional heat transfer fluids [7, 12, 13]. They worked on nanoparticles of metal and metal oxides in several different conventional fluids and described their properties to enhance nanomaterials suspended in fluid called "nanofluids" [14,15,16]. Suspension stability, thermal conductivity, and viscosity are main areas for work to improve the properties of thermal engineering systems [17, 18].

Nanofluids are produced by One-step method in which particles synthesis process occurs in the base fluid at the same time and Two-step method has nanoparticles synthesis and fluid generation in separate stages [19]. The single-step fluid generation method has more issues of agglomeration compared to the Two-step method. The nanoparticles are agglomerated in both methods, when drying, processing, and transportation of nanofluid take place. Nanoparticles are accumulating because of Van der Walls forces taking place among nanoparticles. So, these clusters are trying to settle down in base fluid [20, 21].

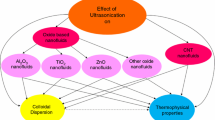

This agglomeration problem does not only affect the flow of fluid in micro/nanochannels, but also affects the thermal and viscous properties of fluid [22, 23]. There are some techniques to overcome this issue such as adding surfactants which repel particles and try not to agglomerate in dispersion. Ultrasonication process also reduces the clogging of particles and increases stability and thermophysical properties of fluid [24]. The use of ultrasonication process is breaking down the large clusters of nanoparticles into the smaller ones to ensure long-term stabilization, enhance thermal conductivity, and maintaining higher velocity of fluids with minimal agglomeration and sedimentation. Therefore, it can be inferred that stable fluid synthesis is a crucial step in conducting experimental research on the mechanisms of thermo-physical nanofluid. A primarily ultrasonic process is used for particle de-agglomeration, particle synthesis, and accumulation, particle size reduction, dispersal of particles into the functioning fluids. There are certain ultrasonic parameters which affect the stability and thermal properties of the nanofluid. The principal parameters are like [25],

-

Ultrasonic instrument type; bath or probe.

-

Time to ultrasonication.

-

The power of ultrasonication.

The stability of nanofluid plays a significant role in controlling the properties of the fluid for any thermophysical applications. The ultrasonic process separates aggregated particles in fluid and makes the suspension homogeneously. With higher surface energies of nanomaterials, they tend to get easily agglomerated [10]. Ultrasonic technique improves the properties of stable dilution in the surface and structure. As an extremely limited comparative research on optimum ultrasonic time affecting the nanofluid's stability and thermophysical properties is reported.

The primary goal of nanofluid research is to produce nanofluid that is stable over long time for industrial uses. For the preparation of aqueous nano-suspensions, ultrasonication is a widely used approach for dispersing aggregated nanoparticles [26, 27]. Hence, nanofluid stability is still a struggling field that directly affects the outcome of increasing viscosity and disappointing researchers to use these nanofluids in any system. There are very limited works reported on the effect of ultrasonic time on the preparation of nanofluids and on thermo-physical properties [25]. Amrollahi et al. [28] published literature on the impact of ultrasonication on carbon nanotube sediment dispersed in ethylene glycol base fluid and concluded thermal enhancement with ultrasonication time. Yang et al. [29] looked at the effect of sonication energy and time on nanotube-oil fluid thermal conductivity and found that as the energy and time of sonication increased, the thermal conductivity decreased. They also investigated the sonication-energy effects of nanotube-oil suspensions on the steady-shear viscosity and found that the viscosity decreased with increased sonic energy. Kwak and Kim [30] reported a time-dependent study of the sonication for nanofluid CuO-EG (Ethylene glycol). They sonicated fluid for 10–30 min and as a result, calculated zeta potential is optimum 9 h sonication time; particles are coalesced again after longer sonication time. Yang et al. [29] noted that nanofluid viscosity was gradually decreasing as dispersion energy increased for dispersion of carbon nanotube and resulted in time for sonication being proportional to energy dispersion. Therefore, the influence of sonication time on thermal and viscous properties is still in a state of dispute. More research on how the thermal and rheological properties can vary with the process/time of ultrasonication should be done.

The present study deals with copper oxide nanoparticles that are suspended in ethylene glycol: distilled water ratio (70:30) for 0.3% particle volume fraction varying ultrasonic time (30–120 min). For the ultrasonication process, a bath sonicator (Powersonic, UB-405) with a frequency of 40 kHz and a power of 350 W is used. The ultrasonic effect for various shaped suspended nanoparticles (spherical, cubelike, rectangular, nano bar, nanorod) was shown here as well. Zeta potential measurements are used to evaluate nanofluid stability, thermal conductivity of nanofluids is evaluated from sound velocity experiments. It has been noted that diluted different sizes and shaped CuO nanoparticles as a heat transfer fluid enhance the thermal conductivity and decrease the viscosity with respect to the time of sonication. The motive behind the present work is to highlight the treatment of ultrasonic time for most critical parameter stability for nanofluid and thermophysical properties for different shapes. All of the above criteria have been considered in this study in order to enable nanofluid research go to the next stage in its prospective usage as a heat exchanger liquid.

Importance of ultrasonication process

Nanofluid preparation two-step method has disadvantage of particle agglomeration in fluid. At the beginning of synthesis process, nanoparticle agglomeration tendency becomes higher when base fluid is with high density and this agglomeration is visible from bare eyes also. The size-shape and particle distribution of nanoparticles in fluid critically affect the stability and thermal properties of fluid because of agglomeration and settling down [31]. This problem can be solved by reducing the size of agglomeration for homogeneous fluid. Many methods are used to stabilize nanofluid for example electrostatic repulsion [32] or steric stabilization [33]. These particles do not have strong bonding between them so the ultrasonication process is extremely helpful to deagglomerate particles in fluid. Meyer et al. [34] reviewed that Dynamic Light Scattering (DLS) is the most used method for nanofluid dispersion and stability measurement of fluid but this method is only applicable for highly diluted volume fraction and depends on the opacity of dispersed particles. Since sonication is useful for different particle size-shape and different concentration better than a DLS device can handle. Examined results show that viscosity of fluid is directly correlated with ultrasonication time for uniform dispersion and this will allow the optimized sonication energy for dispersion of particles on fluid [25]. Nanofluid stability and reduced viscosity are dependent on good dispersion. Increased ultrasonication time/energy helps to reduce particle agglomeration, enhanced thermal conductivity, and reduced viscosity as a result of uniform dispersion [35].

The ultrasonication radiation effect on stable nanofluid preparation depends on time, temperature, frequency, and power of sonication [36]. In this method, strong shear forces between particles can be broken by acoustic cavitation generated by sonication [37, 38]. This acoustic cavitation will enhance diffusion rate, highly concentrated and uniform suspension of micro/nano particles in base fluid [39]. Moreover, there are some works reported on the effects of sonication on the thermal properties of nanofluids [40] but limited works are reported on ultrasonication process on different size and shape of suspended nanoparticles to enhance thermal performance. Selena Pradhan et al. [41] examined the highest particle concentrated standard solution which did not have sedimentation issues of nanoparticles and got noticeably clear and polydisperse particle size distribution. This highly concentrated solution has higher particle collision frequency and higher agglomeration probability. Similar outcomes for TiO2 nanoparticles have been reported [41]. Therefore, the effect of sonication time on particle size distribution was presented for a standard solution with higher concentrations of 1 g L–1 of particles [41].

The only key obstacle is nanofluid stability, which reduces the efficiency of smart fluids in engineering applications. Due to interaction forces, particle aggregation is a typical problem that affects the dispersion, rheology, and overall performance of nanosuspensions. The interaction between particles and suspension is crucial to the stability of nanofluids. B. Derjaguin, L. Landau, E. Verwey, and J. Overbeek proposed the DLVO hypothesis in the 1940s [42]. This theory gives a general description of the forces that impact colloids in suspension stability. The theory is essential for explaining colloidal interactions and separations induced by the balance of two opposing forces, particularly electrostatic repulsion and van der Waals attraction forces. Both electrostatic double-layer forces and van der Waals forces are involved in the overall interactions between two particles. Due to an energy barrier between the particles, the electrostatic double-layer forces prevent them from approaching one another, according to the theory. As a result of the repelling forces between particles, a stable dispersion can be created, which can resist to agglomeration. If the repulsion is insufficient, aggregation formation will be quite likely. The van der Waals forces can attract particles toward each other to overcome the barrier and form an agglomeration if the particle surfaces collide with enough energy [43].

The size of agglomerates in nanofluids can have a big influence on their thermal conductivity and viscosity, resulting in different heat transfer capabilities. Ultrasonication is a typical technique for breaking up agglomerates and increasing nanoparticle dispersion in base fluids. Bubbles are produced and deflated during sonication, and the shock from this cavitation process breaks up agglomerates. With a longer sonication period, the agglomerate size in the nanofluids is reduced. Smaller agglomerates indicate a more uniform distribution of nanoparticles, which is likely to contribute to the increase in thermal conductivity. When the agglomerates were broken, the viscosity of the nanofluids reduced [44].

Kiruba et al. [45] resulted enhancing stability with ultrasonication process for zinc oxide nanofluid and they have measured ultrasonic velocity and density values for six different molar concentrations of ZnO nanofluids. Yadav et al. [46] reported ultrasonication attenuation is directly proportional to thermal performance of suspension. They have worked on ultrasonication velocity factor for polymer colloidal solutions with suspended particles. Alvarez-Arenas et al. [47] investigate the ultrasonic characteristics of solid–liquid suspensions with micro-sized particles. They discovered that as ultrasonic attenuation increases, the velocity of micro-sized particles decreases.

Method and characterization

Synthesis of nanomaterials

CuO nanostructures of various shapes (nanoparticle, cubelike, rectangular, nano bar, and nanorod) were formed using a basic synthetic method that involved precipitating copper salts with concentrated NaOH solutions at ambient temperature. CuO nanocrystals of various shapes were created using a standard precipitation approach for regulating synthesis conditions. The precipitation process was used to make copper oxide nanocrystals with varying crystal growth heating temperatures. To create a 0.1 M concentration, the copper chloride precursor was dissolved in 100 mL distilled water. In the following step, (0.5 M) the NaOH solution was dropped into the aqueous solution and vigorously stirred with a magnetic stirrer for 2 h until the pH reached 14. In the mother solution, black precipitates were produced. The mother liquor is stored at various temperatures like 60, 80, 110, 160, 180 °C. Following that, the finished product was filtered (Whatman No. 1 filter papers) and rinsed with deionized water to eliminate any potential ionic remains, until the pH reached 7. Following that, the washed precipitates were heated at various reaction temperatures before being calcined at 450 °C for 4 h. Synthesis method and characterization for different shaped nanoparticles are already reported by us in detailed [48, 49]. Morphological tests of CuO nanoparticles show that as the temperature of the reaction increases (60–180 °C) the Brownian motion of droplets increased, so the rate of particle collision increased, and particle size increased.

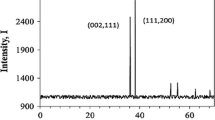

In nanomaterials characterisation techniques, X-ray diffraction (XRD) (model-Bruker) was used to evaluate phase and compound identification of the material. X-ray diffraction analysis [48] with minor residues of Cu(OH)2 residual, XRD revealed that all diffraction peaks are indexed to be monoclinic crystal structure of all CuO structures. The broadening of the diffraction peaks suggests a crystallite domain size on the nanometer scale. The XRD graph shows that crystallite phases with increased structural properties were formed in synthesis condition after calcinations temperature (450 °C/4 h). As a result, at a sufficiently high calcination temperature of 450 °C/4 h, the intensity of the CuO diffraction peak becomes stronger, indicating that due to agglomeration, copper oxide crystallization is complete and more inclusive. Additionally, scanning electron microscopy (SEM) (model-ZEISS) and transmission electron microscopy (TEM) (model-ZEISS) are also used to get information about morphological studies of homogeneous samples [48, 49] SEM gives information about composition and surface morphologies while TEM focuses on internal compassion of samples and crystallization, stress, or even magnetic domains also.

Preparation of nanofluid

We produced CuO nanofluid using a two-step process in which synthesised nanoparticles are suspended in a 0.3 vol % in EG: DW (70:30) base fluid volume ratio. CuO nanoparticles are suspended in ethanol as a solution and ultrasonicate it for 10–15 min and then using a micropipette to pour few drops on carbon-coated copper grids before a minute and then touch the grid to a bit of filter paper to get rid of remaining material and fluid. Microscopic and TEM images are shown in Fig. 1 including crystallite size of nanoparticles. This mentioned crystallite size is measured from XRD graph [48].

The current research focuses on the synthesis of different CuO nanoparticles using DW-EG mixtures as a base fluid. CuO nanoparticles with DW-EG mixes at 70:30 ratio exhibits higher stability and thermophysical properties at 0.3 vol % particle concentration when compared to other examined base fluid combinations of DW and EG. These nanoparticles are suspended in base fluid by magnetically stirrer until the solution becomes clear which was observed till 2 h at constant 40ºC and then different ultrasonic times (30–120 min) was chosen to disperse the nanoparticles in the base fluid, by a bath-type sonicator (Powersonic, UB-405; 40 kHz, 350 W). Below Eq. (1), is a formula for calculating the amount of dispersed nanoparticles in base fluid as a function of concentration.

As a function of concentration, the above Eq. (1) calculates the amount of nanoparticles that will disperse into the base fluid. [50]. Where ϕ is the percentage of concentration, Wp is mass of CuO particles, Wbf is the mass of base fluid and ρbf is the density of base fluid mixture. Here, ρp is the true density of nanoparticles and it was determined from the monoclinic crystal structure [45, 48, 49], its value is 6310 kg m–3 for all shapes of CuO.

The microscopic images of the nanofluids containing different shapes of CuO nanoparticles are taken using the optical microscope (Carl Zeiss Axio Scope. AI). A drop of nanofluid sample is placed on the glass slide and then gently covered with the coverslip before capturing the images. The microscopic images are taken for 80 min sonication time nanofluid which is shown in Fig. 1. These images conclude the best stability with spherical particles. As crystallite size increases from spherical to nanorod, the agglomeration also increases hence, stability in fluid decreases which can clearly be concluded from below Fig. 1.

In all different shaped CuO samples, the nanoparticles' crystallite size is not much variable but shapes are totally different from each other. Varying the temperature of the nucleation and growth cycle may also be a valuable method of regulating the form of nanoparticles in the solution state. Under the circumstances of high temperature [54, 55], orientated attachment [56], accumulation [57, 58], component diffusion, and phase transition are popular phenomena among existing particles resulting from a minimization of the free energy of the reaction mechanism and nanoparticles [59].

Characterization of nanofluid

The Zetasizer, Model # ZS 90 (Malvern Instruments, Worcestershire, UK) was used to determine the suspension stability of CuO nanoparticles in base fluid. Samples were drained from the beaker using a micro-pipette and filled in capillary zeta cells before being placed inside the Zetasizer machine for zeta potential measurement. This apparatus uses a combination of dynamic light scattering, laser Doppler micro-electrophoresis, and static light scattering to determine collision stability using the zeta potential of the suspension.

The ultrasonic nanofluid interferometer apparatus (Mittal Enterprises, New Delhi) uses Debye's theory to measure thermal conductivity from ultrasonic sound velocity. Phonons (hydroacoustic vibrations) produced in a continuous medium promote heat transfer in fluids. The wavelength of ultrasonic waves generated by a Piezo-Electric transducer is measured with a digital micrometer with a high accuracy of ± 0.001 mm in this apparatus. The temperature controller device keeps the temperature of filled nanofluids between RT and 90 °C. During the measurement, the temperature of the sample was kept constant by flowing water around it using a special thermostat. The sound velocity (\({\nu }_{\mathrm{S}}\)) of nanofluid is determined by the formula below using the frequency (\(f\)) and wavelength (\(\lambda\)) [60],

Bridgman develops a formula to calculate the relationship between sound velocity and thermal conductivity of any liquid, which is dependent on the heat transfer mechanism. It explains how liquid molecules are grouped in a lattice and how energy is transferred at the speed of sound from one lattice plane to the next in the filled fluid. Bridgman's modified equation is used to compute thermal conductivity from data of sound velocity in the submitted work [61],

where \(k_{{{\text{b}} }}\) is the calculated thermal conductivity from the modified Bridgman equation, N (Avogadro's number) is 6.02 × 1023, V is the molar volume calculated from the molar mass and density of the nanofluid, and value of Boltzmann’s constant \(K_{{\text{B}}}\) is 1.3807 × 10–23 J K–1. \(\rho_{{{\text{nf}}}}\) defines the density of nanofluid and Mnf is the molar mass of nanofluid. χbf and χp are the molar fractions of the base fluid and nanoparticles, respectively. Here, Mbf and Mp are molar masses of the base fluid and nanoparticles, respectively. An Anton-Paar (model DMA 45) digital density meter and a circulating fluid temperature bath (Brookfield TC-500) are used to determine the density of the fluid. The bath is used to keep the sample at different temperatures while measuring density.

The viscosity of nanofluid is measured using a Cannon Fenske-type capillary viscometer immersed in a bath that regulates the 30° ± 2 °C room temperature. Before each series of experiments with nanofluids, the accuracy of the instruments was checked by measuring the viscosity of distilled water at 20 °C for viscometer calibration. Furthermore, all measurements are repeated three times for all samples (with a maximum standard deviation of 2%) and averaged the results to improve accuracy. Because the measured values reveal minimal variations (less than 1%), they are averaged and used as the final values for nanofluids.

Results and discussions

Zeta potential

Here, zeta potential is measured for different shaped CuO nanoparticles suspended in EG: DW (70:30) base fluid with respect to varying sonication time. Stability is a critical parameter for nanofluid which is characterized by Zetasizer (Model #ZS90, Malvern Instruments, Worcestershire, UK) by varying sonication time of fluid (30–120 min) for all nanoparticle’s shapes after 30 days of preparation. According to Vandsburger [62], aqueous dispersions with zeta potential values lower than ± 30 mV generally present limited stability, zeta potentials ± 30–45 mV indicate that the fluid is physically stable and values larger than that threshold show excellent stability. So, in presented work, fluid with spherical and cubelike CuO nanoparticles are most stable with varying sonication time. Rectangular and Nanobar shaped particles show good stability and nanorods are very least stable compared to all fluids. For all nanofluids show most stable nature at 80 min which is optimised sonication time which is shown in below Fig. 2. As particle size and shape change, they will start to agglomerate which is also clearly visible in microimages of nanofluid (Fig. 1). These crystals will try to settle down in fluid and stability will decrease because of agglomeration and sedimentation of suspended particles in fluid.

Zeta potential values for different shaped CuO nanoparticles (Spherical, Cubelike, Rectangular, Nanorod, and Nanobar) suspended in EG: DW (70:30) with 0.3 vol% nanofluid for varying sonication time (30–120 min). Shaded region shows optimum sonication time (80 min). At 30° ± 2 °C room temperature, all of the measurements were collected. Because all experiments are performed three times for all samples, the error bars represent the data's specified uncertainty

The agglomeration and sedimentation are critical problems in preparation and usability of nanofluid as a nano-lubricant owing to string van der Waals interaction which disrupts the large-scale commercialization. The particles will colloid if the attractive force is greater than the repulsive force, and the suspension will be unstable. If repulsive forces are greater than attraction forces, particles will remain stable in fluid and form homogeneous solutions. [40]. These results are concluded as, the larger the value of zeta potential, greater the repulsive force between nanoparticles shows better stability of fluid. At 80 min ultrasonication time for most of all samples have maximum zeta potential values. Many works reported that, for a longer duration of sonication process, the zeta potential values can reach at maximum stability condition. But in most cases like here presented work, at higher ultrasonication time resulted in coalescence of the nanoparticles again as mentioned in [63]. Sadeghi et al. [64] presented data that stability of fluid continuously improved with increasing sonication period. However, Mahbubul et al. [63] noted that stability of fluid gets saturated at certain sonication time (60 min) not at maximum period. They have found that zeta potential is time-dependent property as time passes, colloidal suspension stability becomes lower and zeta values subsequently decrease. The time-dependent existence of the zeta potential may be one explanation behind the comparatively low zeta potential values that several studies have obtained compared to the described here.

Thermal conductivity of nanofluid

Thermal conductivity is calculated from above mentioned Bridgman equation method for all shaped CuO nanoparticles suspended nanofluid for varying sonication time (30–120 min). In below Fig. 3, value of thermal conductivity ratio is carried from thermal conductivity of nanofluid and thermal conductivity of base fluid. As nanoparticles shape changes from spherical to nanorod, the thermal efficient path for heat transport and thermal conductivity increases which are noted with respect to sonication time increases. Here, spherical suspended particles have excellent stability and nanorod has minimum stability with respect to sonication time (Fig. 2). As a result, the value of thermal conductivity ratio is enhanced with respect to ultrasonication time and zeta potential value. This is because ultrasonic rays break particles agglomeration, generating a larger surface area thus increasing thermal conductivity.

As the ultrasonication time increases 30 to 120 min, thermal enhancement takes place till sonication time is 80 min which is maximum fluid stability by zeta values (Fig. 2). After that, the value of thermal conductivity ratio started decreasing gradually. Thermal enhancement is noticed because of Brownian motion of nanoparticles and intermolecular interaction between particle and fluid increases with sonication time till 80 min. After that, particles started clustering in fluid which is the reason for decrease in heat transfer and thermal conductivity. Heat transfer is a surface phenomenon, and the surface of particles is used for thermal energy interaction. At the time of agglomeration of particles, the effective surface to volume ratio decreases and so the effective heat transfer area decreases which cause thermal conductivity of fluid decreases [65] (Fig. 3).

Ratio of thermal conductivity values with respect to base fluid for different shaped CuO nanoparticles (Spherical, Cubelike, Rectangular, Nanorod, and Nanobar) suspended in EG: DW (70:30) with 0.3 vol% nanofluid for varying sonication time (30–120 min). All the measurements were taken at 30° ± 2 °C room temperature

Few works reported on thermal conductivity of nanofluid as a function of sonication time to investigate its effect. Asadi et al. [20] worked on the effect of ultrasonication time on stability and thermal performance of MWCNT-water nanofluid. They observed the increasing phenomena of thermal conductivity till 60 min and after that, it started decreasing. They concluded the reason behind enhancement in thermal conductivity by prolonging the ultrasonication time which breaks the large clusters into smaller ones and surface volume ratio will be increased. Nishant et al. [65] studied heat transfer coefficient of CuO and TiO2 nanofluid with respect to effect of sonication time. It is noted that thermal conductivity increases with respect to sonication time till 60 min and start decreases after 70 min. A possible explanation for this phenomenon is clustering of nanoparticles and their settling in base fluid. Amrollahi et al. [28] examined MWCNT with 0.5 mass% concentration in ethylene glycol fluid. Their study shows thermal conductivity enhancement because of adding gum Arabic surfactant with sonication time. Ruan and Jacobi [44] explained the thermal conductivity of nanofluid increased with sonication time till 160 min. After 22 h of sonication, thermal enhancement reaches up to 23% of base fluid.

Viscosity of nanofluid

The addition of nanoparticles to fluids increases their viscosity significantly. The viscosity of nanofluids is affected by the nature, shape, size, and composition of nanoparticles, as well as the impact of base fluids and surfactants, as well as temperature. [66]. Here, viscosity is measured for all CuO nanoparticles shapes which are suspended in base fluid. As surface area increases by increasing particle shapes, fluid will become more viscous as shown in Fig. 4. As mentioned earlier in Fig. 1 spherical particles show maximum stability with de-agglomeration as compared to others. As particles get agglomerated cubelike to nanorod, suspension gets less stable, hence viscosity will be increased. In the process of ultrasonication, when frequency is given (40 kHz, 350 W) in a bath sonicator, bubbles are formed and collapse to each other which breaks up the agglomerated particles. As the sonication time increases 30 to 120 min, the agglomeration breaks down and viscosity of fluid is decreasing.

Viscosity values of different shaped CuO nanoparticles (Spherical, Cubelike, Rectangular, Nanorod, and Nanobar) suspended in EG: DW (70:30) with 0.3 vol% nanofluid for varying sonication time (30–120 min). All the measurements were taken at 30° ± 2 °C room temperature. Dashed line represents viscosity value of mixture of EG: DW (70:30) at same temperature

As particle concentration increases, surface to volume ratio also increases, it causes more attractive surface interaction and viscosity starts to increase. Furthermore, shorter ultrasonication duration leads to less energy dispersion. Thus before 80 min ultrasonication duration, the energy is not sufficient to break the agglomeration, so particles are still in cluster form till 80 min. With the 80 min of sonication time, it is gaining optimal energy to distribute the nanoparticles uniformly and lose the agglomeration with resulting lower viscosity. Viscosity of the fluid decreases after 80 min of the sonication time and after that it mainly keeps constant.

Researchers worked on the same concept of influence of ultrasonication time to enhance stability, thermal conductivity, and viscosity of titania nanofluid [67]. Shahsavar et al. [68] reported work on the effect of ultrasonication on thermal enhancement of nanofluids containing carbon nanotubes with higher concentration of particles. Hence, with the help of sonicated fluid shows stable suspension, thermal enhancement, and decreased viscosity this will be very much helpful parameters for heat transfer fluid. These properties are also examined by Garg et al. [25] for different types of fluid suspended in distilled water. Ruan and Jacobi [44] have worked on viscosity properties for 0.5 mass% CNTs. Starr et al. [69] studied experiments with higher viscosity with ultrasonication time duration of 60 min in the comparison with 0–30 min which shows clustered nanoparticles exhibited lower viscosity compared to uniformly dispersed suspension. Amount of suspended particles, ratio of base fluid and particles, clustering, and mainly ultrasonication time have significant impacts on nanofluid viscosity.

Conclusions

In this paper, the effect of ultrasonic duration (30–120 min) on the stability, thermal conductivity, and viscosity of an EG:DW (70:30) based nanofluid containing various-shaped CuO nanoparticles (spherical, cubelike, rectangular, nano bar, nanorod) with 0.3 vol. % is examined. The nanofluid stability improved with the time duration of the sonication, according to the current study. It establishes a direct link between ultrasonication time and thermophysical parameters. The agglomeration of particles breaks down as the period for ultrasonication increases, and heat conductivity rises. At an optimal sonication process time of 80 min, nanofluid demonstrates steady behavior. Furthermore, because of its low surface area, CuO nanofluid loaded with a spherical shape has the lowest viscosity and highest thermal conductivity compared to dispersions prepared with various morphologies such as cubelike, rectangular, nano bar, and nanorod. Remarkably, the synthesis approach enabled the efficient production of copper oxide nanoparticles with minimal re-aggregation, resulting in nanofluids with great stability. As a result, the ultrasonic process that influences colloidal phenomena, as well as noteworthy changes in nanofluid's thermophysical characteristics, is observed in this study. It can be concluded that sustaining commercialization efforts for heat transfer applications in the field of nanofluids can be achieved by calibrating ultrasonic time with long-term stability, lower viscosity, and enhanced nanofluid thermal conductivity.

References

Saidur R, Leong KY, Mohammed HA. A review on applications and challenges of nanofluids. Renew Sustain Energy Rev Elsevier. 2011;15:1646–68.

Garg P, Alvarado JL, Marsh C, Carlson TA, Kessler DA, Annamalai K. An experimental study on the effect of ultrasonication on viscosity and heat transfer performance of multi-wall carbon nanotube-based aqueous nanofluids. Int J Heat Mass Transf. 2009;52:5090–101.

El-Genk MS, Tournier J-M. Noble gas binary mixtures for gas-cooled reactor power plants. Nucl Eng Des. 2008;238:1353–72.

Das SK, Choi SU, Yu W, Pradeep T. Nanofluids: science and technology. Hoboken: John Wiley & Sons; 2007.

Berrada N, Hamze S, Desforges A, Ghanbaja J, Gleize J, Mare T, et al. Surface tension of functionalized MWCNT-based nanofluids in water and commercial propylene-glycol mixture. J Mol Liq. 2019;293:111473.

Gomez-Villarejo R, Aguilar T, Hamze S, Estellé P, Navas J. Experimental analysis of water-based nanofluids using boron nitride nanotubes with improved thermal properties. J Mol Liq. 2019;277:93–103.

Das SK, Choi SU, Patel HE. Heat transfer in nanofluids—a review. Heat Transf Eng Taylor & Francis. 2006;27:3–19.

Choi SU, Eastman JA. Enhancing thermal conductivity of fluids with nanoparticles. Argonne National Lab., IL (United States). 1995.

Sivashanmugam P. Application of nanofluids in heat transfer. An overview of heat transfer phenomena, InTechOpen; 2012.

Eastman JA, Choi US, Li S, Thompson LJ, Lee S. Enhanced thermal conductivity through the development of nanofluids. Argonne National Lab., IL (United States); 1996.

Minea AA, Estellé P. Numerical study on CNT nanofluids behavior in laminar pipe flow. J Mol Liq. 2018;271:281–9.

Eastman JA, Choi SUS, Li S, Yu W, Thompson LJ. Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles. Appl Phys lett. 2001;78:718–20.

Chen H, Witharana S, Jin Y, Kim C, Ding Y. Predicting thermal conductivity of liquid suspensions of nanoparticles (nanofluids) based on rheology. Particuology. 2009;7:151–7.

Lee S, Choi S-S, Li SA, Eastman JA. Measuring thermal conductivity of fluids containing oxide nanoparticles. J Heat Transf. 1999. https://doi.org/10.1115/1.2825978.

Buongiorno J, Venerus DC, Prabhat N, McKrell T, Townsend J, Christianson R, et al. A benchmark study on the thermal conductivity of nanofluids. J Appl Phys. 2009;106:094312.

Wong KV, Castillo MJ. Heat transfer mechanisms and clustering in nanofluids. Adv Mech Eng. 2010;2:795478.

Kole M, Dey TK. Thermal conductivity and viscosity of Al2O3 nanofluid based on car engine coolant. J Phys D Appl Phys. 2010;43:315501.

Xuan Y, Li Q. Heat transfer enhancement of nanofluids. Int J Heat Fluid Flow. 2000;21:58–64.

Zeroual S, Estellé P, Cabaleiro D, Vigolo B, Emo M, Halim W, et al. Ethylene glycol based silver nanoparticles synthesized by polyol process: characterization and thermophysical profile. J Mol Liq. 2020;310:113229.

Asadi A, Alarifi IM, Ali V, Nguyen HM. An experimental investigation on the effects of ultrasonication time on stability and thermal conductivity of MWCNT-water nanofluid: finding the optimum ultrasonication time. Ultrason Sonochemistry. 2019;58:104639.

Riahi A, Khamlich S, Balghouthi M, Khamliche T, Doyle TB, Dimassi W, et al. Study of thermal conductivity of synthesized Al2O3-water nanofluid by pulsed laser ablation in liquid. J Mol Liq. 2020;304:112694.

Munyalo JM, Zhang X. Particle size effect on thermophysical properties of nanofluid and nanofluid based phase change materials: a review. J Mol Liq. 2018;265:77–87.

Banisharif A, Aghajani M, Van Vaerenbergh S, Estellé P, Rashidi A. Thermophysical properties of water ethylene glycol (WEG) mixture-based Fe3O4 nanofluids at low concentration and temperature. J Mol Liq. 2020;302:112606.

Hong T-K, Yang H-S, Choi CJ. Study of the enhanced thermal conductivity of Fe nanofluids. J Appl Phys. 2005;97:064311.

Garg J, Poudel B, Chiesa M, Gordon JB, Ma JJ, Wang JB, et al. Enhanced thermal conductivity and viscosity of copper nanoparticles in ethylene glycol nanofluid. J Appl Phys. 2008;103:074301.

Leena M, Srinivasan S. Synthesis and ultrasonic investigations of titanium oxide nanofluids. J Mol Liq. 2015;206:103–9.

Shah J, Ranjan M, Gupta SK, Sonvane Y. Ultrasonication effect on thermophysical properties of Al2O3 nanofluids. In: AIP conference proceedings. AIP Publishing LLC; 2018. p. 020008.

Amrollahi A, Hamidi AA, Rashidi AM. The effects of temperature, volume fraction and vibration time on the thermo-physical properties of a carbon nanotube suspension (carbon nanofluid). Nanotechnology. 2008;19:315701.

Yang Y, Grulke EA, Zhang ZG, Wu G. Thermal and rheological properties of carbon nanotube-in-oil dispersions. J Appl Phys. 2006;99:114307.

Kwak K, Kim C. Viscosity and thermal conductivity of copper oxide nanofluid dispersed in ethylene glycol. Korea-Australia Rheology Journal. Korean Society of Rheology/한국유변학회. 2005;17:35–40.

Chung SJ, Leonard JP, Nettleship I, Lee JK, Soong Y, Martello DV, et al. Characterization of ZnO nanoparticle suspension in water: effectiveness of ultrasonic dispersion. Powder Technol. 2009;194:75–80.

Thomas S, Sobhan CBP. A review of experimental investigations on thermal phenomena in nanofluids. Nanoscale Res Lett. 2011;6:377.

Mason JM, Hagemann UB, Arndt KM. Role of hydrophobic and electrostatic interactions in coiled coil stability and specificity. Biochem ACS Publ. 2009;48:10380–8.

Meyer JP, Adio SA, Sharifpur M, Nwosu PN. The viscosity of nanofluids: a review of the theoretical, empirical, and numerical models. Heat Transf Eng Taylor & Francis. 2016;37:387–421.

Suganthi KS, Anusha N, Rajan KS. Low viscous ZnO–propylene glycol nanofluid: a potential coolant candidate. J Nanoparticle Res. 2013;15:1986.

Ying C, Zhaoying Z, Ganghua Z. Effects of different tissue loads on high power ultrasonic surgery scalpel. Ultrasound Med & Biology. 2006;32:415–20.

Xia E-Q, Ai X-X, Zang S-Y, Guan T-T, Xu X-R, Li H-B. Ultrasound-assisted extraction of phillyrin from Forsythia suspensa. Ultrason Sonochem. 2011;18:549–52.

Hartmann NB, Jensen KA, Baun A, Rasmussen K, Rauscher H, Tantra R, et al. Techniques and protocols for dispersing nanoparticle powders in aqueous media—is there a rationale for harmonization? J Toxicol Environ Health Part B Taylor & Francis. 2015;18:299–326.

Park J, An K, Hwang Y, Park J-G, Noh H-J, Kim J-Y, et al. Ultra-large-scale syntheses of monodisperse nanocrystals. Nature Mater Nat Publ Group. 2004;3:891–5.

Noroozi M, Azmi BZ, Moksin MM. The reliability of optical fiber-TWRC technique in liquids thermal diffusivity measurement. Infrared Phys & Technol. 2010;53:193–6.

Pradhan S, Hedberg J, Blomberg E, Wold S, Wallinder IO. Effect of sonication on particle dispersion, administered dose and metal release of non-functionalized, non-inert metal nanoparticles. J Nanoparticle Res. 2016;18:285.

Verwey EJW, Overbeek JTG, Van Nes K. Theory of the stability of lyophobic colloids: the interaction of sol particles having an electric double layer. Amsterdam: Elsevier Publishing Company; 1948.

Ilyas SU, Pendyala R, Marneni N. Stability of Nanofluids. In: Korada VS, Hisham B Hamid N, editors. Engineering applications of nanotechnology [Internet]. Cham: Springer International Publishing; 2017 [cited 2022 Jan 13]. p. 1–31. Available from: http://springerlink.bibliotecabuap.elogim.com/https://doi.org/10.1007/978-3-319-29761-3_1

Ruan B, Jacobi AM. Ultrasonication effects on thermal and rheological properties of carbon nanotube suspensions. Nanoscale Res Lett. 2012;7:1–14.

Kiruba R, Gopalakrishnan M, Mahalingam T, Jeevaraj A. Ultrasonic studies on zinc oxide nanofluids. J Nanofluids Am Sci Publ. 2012;1:97–100.

Yadav RR, Mishra G, Yadawa PK, Kor SK, Gupta AK, Raj B, et al. Ultrasonic properties of nanoparticles-liquid suspensions. Ultrasonics. 2008;48:591–3.

Álvarez-Arenas TG, Segura LE, de Sarabia ERF. Characterization of suspensions of particles in water by an ultrasonic resonant cell. Ultrasonics. 2002;39:715–27.

Shah J, Ranjan M, Gupta SK, Satyaprasad A, Chaki S, Sonvane Y. Reaction temperature dependent shape-controlled studies of copper-oxide nanocrystals. Mater Res Express. 2018;5:065037.

Shah J, Kumar S, Ranjan M, Sonvane Y, Thareja P, Gupta SK. The effect of filler geometry on thermo-optical and rheological properties of CuO nanofluid. J Mol Liq. 2018;272:668–75.

Senthilraja S, Vijayakumar K, Gangadevi R. A comparative study on thermal conductivity of Al2O3/water, CuO/water and Al2O3–CuO/water nanofluids. Dig J Nanomater Biostruct. 2015;10:1449–58.

Zhao H, Zhou XX, Pan LY, Wang M, Chen HR, Shi JL. Facile synthesis of spinel Cu 1.5 Mn 1.5 O 4 microspheres with high activity for the catalytic combustion of diesel soot. RSC Adv. 2017;7:20451–9.

Sun CC. Thermal expansion of organic crystals and precision of calculated crystal density: a survey of cambridge crystal database. J Pharm Sci. 2007;96:1043–52.

Kedzierski MA. Viscosity and density of CuO nanolubricant. Int J Refrig. 2012;35:1997–2002.

Wu Z, Yang S, Wu W. Shape control of inorganic nanoparticles from solution. Nanoscale R Soc Chem. 2016;8:1237–59.

Chen G, Xu C, Huang X, Ye J, Gu L, Li G, et al. Interfacial electronic effects control the reaction selectivity of platinum catalysts. Nat Mater Nat Publ Group. 2016;15:564–9.

Ullah MH, Kim I, Ha C-S. One-step synthetic route for producing nanoslabs: Zn-oriented polycrystalline and single-crystalline zinc oxide. J Mater Sci. 2006;41:3263–9.

Hanus LH, Sooklal K, Murphy CJ, Ploehn HJ. Aggregation kinetics of dendrimer-stabilized CdS nanoclusters. Langmuir ACS Publ. 2000;16:2621–6.

Nguyen CT, Desgranges F, Galanis N, Roy G, Maré T, Boucher S, et al. Viscosity data for Al2O3–water nanofluid—hysteresis: is heat transfer enhancement using nanofluids reliable? Int J Therm Sci. 2008;47:103–11.

Feigl CA, Barnard AS, Russo SP. Modelling polar wurtzite ZnS nanoparticles: the effect of sulphur supersaturation on size-and shape-dependent phase transformations. J Mater Chem. 2012;22:18992–8.

Shah J, Ranjan M, Davaria V, Gupta S, Sonvane Y. Temperature-dependent thermal conductivity and viscosity of synthesized α-Alumina nanofluids. Appl Nanosci. 2017;7:803–13.

Rashin MN, Hemalatha J. A novel ultrasonic approach to determine thermal conductivity in CuO–ethylene glycol nanofluids. J Mol Liq. 2014;197:257–62.

Vandsburger L, Swanson EJ, Tavares J, Meunier J-L, Coulombe S. Stabilized aqueous dispersion of multi-walled carbon nanotubes obtained by RF glow-discharge treatment. J Nanoparticle Res. 2009;11:1817.

Mahbubul IM, Chong TH, Khaleduzzaman SS, Shahrul IM, Saidur R, Long BD, et al. Effect of ultrasonication duration on colloidal structure and viscosity of alumina–water nanofluid. Ind & Eng Chem Res. 2014;53:6677–84.

Sadeghi R, Etemad SG, Keshavarzi E, Haghshenasfard M. Investigation of alumina nanofluid stability by UV–vis spectrum. Microfluid Nanofluid. 2015;18:1023–30.

Nishant K, Sonawane SS. Influence of CuO and TiO2 nanoparticles in enhancing the overall heat transfer coefficient and thermal conductivity of water and ethylene glycol based nanofluids. Res J Chem Environ. 2016;20:8.

Zeroual S, Loulijat H, Achehal E, Estellé P, Hasnaoui A, Ouaskit S. Viscosity of Ar-Cu nanofluids by molecular dynamics simulations: effects of nanoparticle content, temperature and potential interaction. J Mol Liq. 2018;268:490–6.

Alias H, Ani MFC, Sa’ad SF, Ngadi N. Heat transfer of alumina-deionized water nanofluids in concentric tube heat exchanger. In: AIP Conference Proceedings. AIP Publishing LLC; 2017. p. 020001.

Shahsavar A, Salimpour MR, Saghafian M, Shafii MB. An experimental study on the effect of ultrasonication on thermal conductivity of ferrofluid loaded with carbon nanotubes. Thermochim Acta. 2015;617:102–10.

Starr FW, Douglas JF, Glotzer SC. Origin of particle clustering in a simulated polymer nanocomposite and its impact on rheology. J Chem Phys. 2003;119:1777–88.

Acknowledgments

Special thanks to Dr. Yogesh Sonvane, Assistant Professor, Department of Applied Physics, SVNIT, Surat, India, Dr, Sanjeev K. Gupta, Assistant Professor, St. Xavier's College, Ahmedabad, India, and Dr. Saket Kumar, IIT Gandhinagar, Gujarat, India for useful discussion and the provision of equipment required for testing.

Author information

Authors and Affiliations

Contributions

JS contributed to Investigation, Conceptualization, Visualization, Data curation, Formal analysis, Writing—original draft, Writing—review & editing. MR contributed to Supervision, Formal analysis, Methodology, Writing—reviewing & editing. PT contributed to Supervision, Data curation, Formal analysis. PE contributed to Supervision, Formal analysis, Writing—review & editing.

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shah, J., Ranjan, M., Thareja, P. et al. Tailoring stability and thermophysical properties of CuO nanofluid through ultrasonication. J Therm Anal Calorim 147, 10319–10328 (2022). https://doi.org/10.1007/s10973-022-11266-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11266-y