Abstract

Slow pyrolysis experiments were performed at 500 °C on Russian feedstock (hydrolysis lignin, peat, mixed sewage sludge, and pine and spruce woods, for comparison). The pyrolysis products were analyzed through gas chromatography, and more than 130 components were identified and grouped according to their chemical family. A qualitative analysis of the pyrolysis products showed that the highest amount of molecules (more than 40%) released during the pyrolysis of hydrolysis lignin belongs to the phenol chemical family. They result from the lignin degradation. The peat pyrolysis led to a large amount (more than 50%) of sugars. The molecules detected during the pyrolysis of the mixed sewage sludge are similar to that of the spruce sample and almost the same as that of the pine sample, because the selected sewage sludge is a mixture of municipal and industrial waste from pulp and paper industry. Comparisons between the data obtained for these Russian feedstock and that of the literature concerning quite similar materials exhibit differences which may be the consequence of the feedstock and of the experimental conditions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biomass may be considered as a promising energy resource that can help to overcome the current dependence on fossil fuels. Biomass can indeed be used to produce high-valued by-products or to generate energy through efficient and appropriate thermal degradations. One of the most developed thermochemical conversion processes is pyrolysis, which is known since ancient times and which is usually performed under low and isothermal temperatures and a non-oxidative atmosphere. The final products of the pyrolysis process are a solid residue, called bio-coal, a condensable organic part and non-condensable gases.

Applying slow pyrolysis to Russian feedstock (hydrolysis lignin, peat, mixed sewage sludge), the products obtained were analyzed through gas chromatography. For comparison, similar analyses were performed on Russian pine and spruce.

Hydrolysis lignin is a by-product of the production of fuels and chemicals through either percolation (Scholler process) or low temperature hydrolysis of wood (Bergius process) [1]. The Scholler process was used from 1920 to 1945. This hydrolysis process was carried out with sulfuric acid on wood chips to produce glucose and fuel [2]. The Bergius process was developed during World War I. It converts brown coal (also called lignite) into crude oil through hydrolysis with hydrochloric acid [3]. These processes were stopped at the end of World War II, because of their lack of profitability. After World War II and until the twenty-first century, acid hydrolysis of wood and agricultural waste was carried out to produce ethanol, fodder yeast and sugars (hexoses and pentoses) in the former USSR [1]. The current stock of hydrolysis lignin in Russia approximately represents 30 million tons and increases by 1.5 million tons each year [1].

Peat may be classified between renewable and non-renewable energy sources. Its recovery period exceeds 200 years. However, peat consumption in Russia lags far below its annual natural growth, which allows to consider peat as a renewable energy source. Peat deposits have a significant importance in the mineral resources of Russia. They are widespread almost all over the Russian territory, and they are mainly explored in Northwestern Russia. Peat is recognized as a unique natural potential of organic origin. It is an energy, industrial and agrochemical resource, necessary for both the development of energy and industry. It contains little fractions of sulfur and mercury, it has a high moisture content and a low ash content, and its lower calorific value is close to that of lignin (approximately 17.8 MJ kg−1). Sulfur and mercury have a significant impact on human health, and sulfur also contributes to acid rain by reacting with water and forming sulfuric acid [4]. A low ash content is required to limit waste management after combustion, and a low moisture content is required to maximize the efficiency of combustion [5].

The mixed sewage sludge which is considered in the present study is composed of municipal (80%) and industrial waste (20%), the industrial part coming from paper and pulp industry and being collected after the bleaching paper process. Sewage sludge is an organic–mineral complex, the organic part of which is biomass and adsorbed and partially oxidized pollutants of sewage, as well as nitrogen and phosphorus-containing compounds. The main components of the sewage sludge mineral part are silicon oxide, aluminum oxide, iron oxide and phosphorus, which may be in the form of low-soluble heavy metal phosphates, as well as calcium [6, 7]. The main part of wastewater from cities, pulp and paper plants, petrochemical industry and other industries is treated with biological methods, using activated sludge. Paper industry is a sector which generates large volumes of wastewater and sludge [8, 9].

The selected feedstock are currently not significantly valorized in Russia, even if their available amounts are high. Further valorizations of hydrolysis lignin, peat and sewage sludge could reduce energy resource shortages and environmental problems. Hydrolysis lignin is not being extensively valorized, because only no profitable uses have been found up to now. Its high moisture content, the presence of residual acid, the complexity of its composition and its extreme heterogeneity make it difficult to use as a fuel. Peat has a high moisture content. Moreover, the gases released during peat combustion are greenhouse gases, as in the case of fossil fuels. The main way to treat sewage sludge in Russia is its mechanical dehydration and storage in sludge reservoirs, where waste decontamination and biodegradation take place for a long time. This method does not meet modern environmental and technical requirements and leads to long-term and often irreversible removal of significant land resources. These processes also present significant risks of groundwater pollution in the zone of influence of waste storage sites. In many countries, combustion is considered as one of the main routes to dispose this waste further characterized by a high organic content [10,11,12]. The main advantage of combustion is a significant reduction of the waste mass and volume, which is especially important in the conditions of shortage of available space for landfills and dumps [13]. Many hazardous organic compounds decompose during combustion. The use of the generated heat for power generation and ash and slag residues for the production of some materials can partially offset the cost of waste disposal.

Analytical pyrolysis combined with gas chromatography offers great opportunities to study and describe complex polymers such as hydrocarbons and lignin in biomass. This method allows obtaining detailed information on molecular changes and only requires small amounts of materials [14]. Moreover, it allows determining the proportions of different types of lignin: S (syringyl), G (guaiacyl) and H (p-hydroxyphenyl), without intersection with other components [15]. Pyrolysis gas chromatography is widely used to study the pyrolysis process and the components released during the thermal degradation. This method can be used to identify the composition of pyrolysis products using mass spectra libraries [16]. Some authors used pyrolysis gas chromatography–mass spectrometry methods (Py–GC/MS) to describe thermal degradation processes [17,18,19,20].

Considering the pyrolysis of wood components, cellulose and hemicellulose decompose to hexoses, pentoses and their derivatives, including furans and light (low molecular weight) oxygen-containing components [21,22,23,24]. Lignin decomposes to phenolic components including guaiacol, catechol and other phenols [25, 26]. A pyrolysis mechanism of a β-O-4 lignin dimer model (1-(4-hydroxy-3-methoxyphenyl)-2-(2-methoxyphenox)-1-ethanol) was described in [27]. These pyrolysis products react and finally form aromatic hydrocarbons [25]. For example, sugars are transformed into furans and then into aromatic hydrocarbons [28, 29]. Pyrolysis products with low molecular weight such as acids and ketones are exposed to oligomerization, aromatization, hydrogen transfer and oxygen-free reactions, also forming aromatic hydrocarbons [25, 30].

In the present study, the products obtained applying slow pyrolysis to Russian feedstock are analyzed using gas chromatography methods. More molecules are identified than in many papers of the literature, even if the pyrolysis conditions and analyses are quite similar. The properties of the lignocellulosic materials depend on the place and conditions where they grow. The properties of sewage sludge depend on the treatment it received. These elements may explain the differences with these results of the literature.

Materials and methods

Russian feedstock characteristics

In the present study, three Russian feedstock (hydrolysis lignin, peat and mixed sewage sludge) and two Russian woody biomass (pine and spruce) are considered.

Hydrolysis lignin was provided by the Bionet Company which produces hydrolysis lignin pellets from the Onega lignin dump, located in the Arkhangelsk region, Northwest Russia.

Peat was extracted from topsoil (up to 1.5 m) near the town of Mezen, Arkhangelsk region, Northwest Russia. The Mezen district belongs to the natural zone of forest tundra. Excess moisture combined with favorable thermal conditions for the growth of mosses causes an intensive process of waterlogging. The Mezen district is characterized by a combination of sparse forests with treeless tundra areas and the prevalence of peaty gley and weakly podzolized soils [31].

The mixed sewage sludge is composed of municipal (80%) and industrial (20%) waste, the industrial part coming from paper industry and being collected after the bleaching paper process. This industrial waste is formed during the primary mechanical treatment of wastewater and wastewater treatment with activated sludge. The mixed sewage sludge was partially dehydrated by decanter centrifuges and transported to the thermal power plant, before being stored in hoppers. The primary sampling of sewage sludge was carried out from the hopper.

Table 1 shows the proximate analyses and combustion properties of the feedstock. The volatile matter (VM) and fixed carbon (FC) contents were obtained by thermogravimetric analysis under nitrogen between 20 and 900 °C with a heating rate of 5 °C min−1. Moisture (M) was obtained placing a sample in an oven at 105 °C during 1 h and measuring the difference between the initial and final sample masses. Ash content (Ash) was determined burning the sample at 550 °C under air and weighing the final mass. The higher heating value was determined using a calorimeter IKA C 2000 Basic version 2, and the lower heating value (LHV) was determined from the higher heating value through classical calculations.

The proximate analyses obtained for pine and spruce samples are in good agreement with data from the literature for several woody biomass [32,33,34,35,36]. Biomass samples contain a high percentage of volatile organic compounds. The volatile matter and ash contents of the mixed sewage sludge agree with data from the papers [9, 12], who considered municipal sewage. The moisture percentage of the sewage sludge under consideration in the present study is very low, as it was partially dehydrated (see above). The ash contents of the different Russian feedstock, excluding pine, are higher than that of biomass present in Western Europe, for which values are lower than 1–2%. The proximate analysis of hydrolysis lignin is very close to those of spruce and pine, because it is a by-product of woods through Bergius’s process. Many papers devoted to sewage sludge are available leading to different values of the proximate analyses. In the present study, its ash content (12.3%) is quite low when compared to values of the literature ranging from 24 to 55% as dry and ash-free [37, 38]. Because of a low ash content, sewage sludge has a net calorific value (LHV) higher than that found in the literature with data ranging from 10 to 15 MJ kg−1 [37, 39]. Some paper sewage sludge has a LHV equal to 22.9 MJ kg−1, when collected after the clarifier [40]. The lower heating value of peat is slightly lower than that indicated in [41].

The ultimate analyses are presented in Table 2 for the different Russian feedstock. Carbon (C), hydrogen (H), nitrogen (N) and sulfur (S) contents were determined with an EuroVectorEA-3000 analyzer, and oxygen (O) was calculated by difference based on mass balance. The H/C and O/C atomic ratios are computed from these contents.

Hydrolysis lignin contains the highest carbon percentage among the five selected feedstock, while sewage sludge has the lowest carbon percentage. Sewage sludge has also the lowest oxygen percentage, but the highest nitrogen and sulfur percentages. Spruce has the highest oxygen percentage. The hydrogen percentages do not vary so much between the five selected feedstock.

The ultimate analyses of pine and spruce agree with data of the literature [32,33,34,35,36]. The ultimate analysis of peat agrees with values given indicated in [43], for several peats extracted in Canada and Sweden. The ultimate analysis of the sewage sludge agrees with data of the literature concerning several industrial and municipal sewage sludge [12, 39, 44].

According to [42], the values of the H/C and O/C ratios of hydrolysis lignin and peat characterize materials containing mainly lignin. Because peat is the first step of biomass coalification process, its ultimate analysis classifies this sample as a woody peat with a low rank of coalification to lignite (see [45,46,47]) and this peat could be considered as degraded wood [46]. Coalification allows atomic H/C ratio to decrease, leading to values ranging from 1.46 to 0.88 for wood peat and coalified peat, respectively, the coalification process depending of the extraction depth [43, 47]. The ultimate analyses for sewage sludge were expected to be close to those of lignocellulosic materials considering its origin.

Table 3 gives the biochemical composition of the Russian feedstock.

As hydrolysis lignin is a by-product of the acid hydrolysis of wood that allows the breakdown of saccharide polymers (hemicellulose and cellulose), lignin is the main polymer in this sample. Hemicellulose is more severely fragmented by acid hydrolysis, because its residual content is lower than cellulose. The composition of hydrolysis lignin highly varies, depending on the composition of the original biomass (wood species, agricultural or agri-food waste, etc.).

The extractive contents are relatively high for hydrolysis lignin and peat. Acid hydrolysis also acts on lignin forming small phenolic entities that are easily extracted by polar solvents such as water and ethanol. Peat contains a huge quantity of extractive and carbohydrate compounds due to the slow humus coalification, which also generates these compounds during the peat formation in the soil. High level of coalification leads to values of cellulose ranging from 3.3 to 13.5% [45]. In the present case, the cellulose content of 29.1% confirms the low level of coalification of the selected peat. The values of lignocellulosic compounds can highly vary for the same type of tree species, because they depend on the nature of the soil where the tree grew [32,33,34,35,36]. According to Glinska et al., the organic part of paper sewage sludge contents carbohydrates, lipids and proteins. Carbohydrates from paper sewage sludge mainly consists of cellulose [9]. As described by Gao et al., cellulose content in municipal sewage sludge ranges from 7 to 15%, depending on both the stage of the treatment process and the nature of the sludge (primary, secondary, activated or digested sludge) [12]. The cellulose content in the mixed sewage sludge under consideration is equal to 32.1%, as a mixture of industrial and municipal sludge.

Pyrolysis GC/MS conditions

The sample masses considered for pyrolysis gas chromatography were the following: hydrolysis lignin—134 µg, peat—147 µg, sewage sludge—147 µg, spruce—152 µg and pine—147 µg, respectively.

The samples were thermally degraded under a helium atmosphere using the pyrolyser EGA/PY-3030D (Frontier Lab) with a cryotrap. The pyrolysis products of the samples were analyzed by gas chromatography–mass spectrometry method using GCMS-QP2010Plus device (Shimadzu, Japan).

The pyrolysis conditions were as follows: helium atmosphere, single-shot (single pyrolysis) operation mode, isothermal pyrolysis temperature equal to 500 °C and cryotrap temperature equal to – 197 °C.

The chromatography conditions were as follows: capillary column HP-5MS, diameter equal to 0.25 mm, fixed phase thickness equal to 0.25 μm, column length equal to 30 m, sample introduction with a split ratio 1:100, input temperature equal to 280 °C, helium carrier gas, constant pressure gas flow control and flow through the column equal to 1 mL min−1. The temperature program started from 30 °C, and the temperature was maintained constant for 5 min and then increased with a rate of 5 °C min−1 to 230 °C and with a rate of 15 °C min−1 to 320 °C. The final temperature was taken equal to 320 °C and kept constant for 5 min. The temperature of the transfer line with the mass detector was held at 280 °C, the temperature of the ion source was held at 230 °C, the ionization energy was 70 eV, the detector voltage was 0.9 kV (according to the automatic configuration), and the mass detector worked in the mass spectra scanning mode (TIC Scan) in the mass range 15‒600 Da.

The chromatograms of pyrolysis products of the Russian feedstock under consideration contain a large number of peaks (Fig. 2 in Appendix 1). The main pyrolysis products are analyzed when their peaks have a sufficiently high signal-to-noise ratio for reliable identification. The identification of each pyrolysis product was performed by comparing the obtained chromatographic peak mass spectra with the Wiley-2010 and Nist-2011 mass spectra libraries. An agreement degree with the library spectra higher than 80% was chosen for positive identification. The residence time and mass spectra of pyrolysis products of plant components presented in [49, 50] were also used. The peak area of total ion current was used to estimate the relative content of identified components in the flue gas.

Results and discussion

The chromatograms were obtained by total ion current using a GC–MS. They are shown in Appendix 1, Fig. 2. The vertical axis represents the full ion current response of the detector, while the horizontal axis represents the time of analysis. The chromatograms allow the identification of many molecules whose identification is given in Appendix 2.

The pyrolysis first proceeds via a dehydratation stage with the formation of water. Then devolatilization stages occur associated with the decomposition of sugars and lignin, leading to the emissions of CO2, H2O and volatile organic compounds (VOC). These stages take place in a temperature range of 220–350 °C, depending on the biomass [51]. The percentage ratios of CO2, H2O and VOC are presented for each feedstock in Table 4.

Carbon dioxide and water come from the hydrolysis of cellulose and hemicellulose. Because hydrolysis lignin contains low amounts of carbohydrates, water could not be detected and quantified in the experimental conditions of the present study, which involve small sample masses. Water was probably below the quantification limit. As mentioned by several authors, the proportions highly depend on the pyrolysis processes, mainly temperatures and temperature ramps that separate pyrolysis from fast pyrolysis [10, 12].

The main components and peak areas on ion chromatograms corresponding to these components are given in Appendix 2, which lists the compounds identified by the mass spectrometer. The residence time for each molecule, the proportion of each molecule in the unit area and the name of the chemical family to which the molecule belongs are shown in Appendix 2. Components with short residence time are formic acid, furfural and others. These components are mainly released during the hemicellulose degradation. Acid and furan components come from the thermal degradation of cellulose and hemicellulose [52]. Hydrocarbons are the result of various reactions such as C–C bond breaking and dehydration of carbohydrates and products of their decomposition. The main pyrolysis products are phenols. They result from the lignin degradation—an aromatic component of woody biomass. It is known that when increasing the pyrolysis temperature, the number of formed phenols increases. As experiments were carried out at a sufficiently high temperature (500 °C), a large number of components of the phenol group were found.

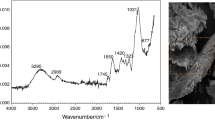

Many papers are available concerning the classification of individual molecules of VOC emitted during different pyrolysis processes of woody biomass under different experimental conditions [52,53,54,55,56,57,58,59]. The volatile organic components were divided according to the chemical families defined in [59]. However, guaiacols being methoxy-substituted phenols, these authors grouped guaiacols and phenols in the same family of phenol. The results of this classification are shown in Fig. 1, which allows estimating the ratio of different chemical families in pyrolysis products for the feedstock under consideration.

High oxygenate molecules dominate in VOC for all feedstock, being both aliphatic and aromatic, due to the break of covalent C–C and C–O bonds of lignocellulosic polymers (lignin, hemicellulose and cellulose). Sugars and phenols are well recognized as tracers of the thermal degradation of hemicellulose, cellulose and lignin, respectively. These results strongly agree with literature data concerning several woody biomass. If these chemical families always constitute the main VOC components, their own proportions depend both on the nature of the sample and on the pyrolysis operating conditions [54, 55, 60,61,62].

The highest amount of molecules (more than 40%) released during the thermal degradation of hydrolysis lignin belongs to the phenol chemical family. In addition, a significant part of the molecules released during the thermal degradation of hydrolysis lignin are alcohol, acid, aldehyde and ether groups.

The percentage of phenols observed for peat is the lowest (6%) when compared to the other feedstock. Sugars represent a significant part (over 50%) of the products from peat, because peat was extracted from the upper soil layer (up to 1.5 m) and, consequently, is very slightly fossilized. The peat pyrolysis is characterized by the formation of more furans produced during the pyrolysis of the carbohydrate part of the sample (cellulose and hemicellulose). These results agree with previous data concerning the pyrolysis of woody peat samples [60, 61].

The molecules detected during the pyrolysis of the mixed sewage sludge for the groups of phenols, ketones, furans and sugars are close in percentage to that of the spruce sample and almost the same as that of the pine sample. Gao et al. proved that the main VOC emitted during the pyrolysis of several municipal sewage sludge are in decreasing contents: phenols, alcohols, ketones and nitrogen-containing compounds such as pyrroles, pyridines, pyrazines, amines and amides [12]. The proportions indicated in Fig. 1 (see also the last column of Table 4) are similar to those concerning pyrolysis studies cited in this review, except for nitrogen- and sulfur-containing molecules. In the present case, as sewage sludge is a mixture of municipal sludge and paper industry waste, it contains a relative high amount of nitrogen (see Table 2) and few nitrogen-containing compounds were detected: complex pyrazine (2-amino-9-(3,4-dihydroxy-5-hydro), pyrrole (1H indole), nitrile (4-methyl-2-oxopentanenitrile) and complex (oxazolidine, 2,2-diethyl-3-methyl-) (see Appendix 2). As the sulfur content was quite high (3.6%), sulfur-containing molecules were expected, as indicated by Gao et al. in [12], but none of these compounds were identified in the conditions of the present study.

When compared to other samples, pine and spruce are characterized by a higher number of aldehydes pyrolysis products from carbohydrates (cellulose and hemicellulose), as well as fatty and resin acids.

Alkanes, alkenes and aromatics groups are found in small amounts in pyrolysis products, whatever the feedstock under consideration.

The results obtained for hydrolysis lignin in the present study can be compared to that of the papers by Kim et al. [57] and Windt et al. [54]. Both papers investigated untreated lignin, in contrast to the present paper, where hydrolysis lignin was used. In the paper by Windt et al., pyrolysis experiments were performed at 800 °C with a heating rate of 120 °C s−1, while in that by Kim et al. the pyrolysis experiments were performed at 800 °C with a heating rate of 20 °C min−1. The pyrolysis conditions also differ: In Windt et al., the pyrolysis was performed under N2 and N2/acetylene mixture, and in Kim et al., the pyrolysis was performed under N2 and CO2. Table 5 presents a comparison of the results of pyrolysis product identification.

In the papers by Windt et al. and by Kim et al., the pyrolysis experiments were performed at a higher temperature (800 °C) than in the present study (500 °C) and smaller numbers of molecules were identified (14–15 against 103). As hydrolysis lignin is the result of acid hydrolysis of lignocellulosic compounds, a slightly different composition of volatile organic compounds can be expected. Despite the absence of phenol function in the hydrolysis lignin, the thermolysis of the ether functions associated with aromatic rings can give C6H5O radicals and gives by completion phenols and guaiacols. Many sugars from cellulose and hemicellulose still remain in the hydrolysis lignin products.

The results of peat pyrolysis were compared to that of [58], where the pyrolysis was performed under N2 and CO2 conditions. Moreover, the temperature of the pyrolysis performed in this paper is much higher (700 °C and 900 °C) than in the present study (500 °C) and the heating rate was low (10 °C min−1). Table 6 presents a comparison of the pyrolysis product identification.

The results are significantly different for each family. The reason for such differences may lie in the peat composition. In the paper by Lee et al., peat has a lower carbon content (25.48%) than that (52%) of the peat sample considered in the present study. This means that the peat considered by Lee et al. is more fossilized. The absence of compounds resulting from the degradation of lignocellulosic compounds such as sugars, guaiacols, phenols and aldehydes suggests that the peat considered by Lee et al. initially contains few organic compounds and that carbon mineralization is present in the natural environment from which it was extracted.

Concerning sewage sludge and paper sludge, comparisons with available results from the literature are more complicated due to the differences between the materials. In [63], the authors analyzed the products obtained during the pyrolysis of digested sewage sludge using Py–GC/MS and Py–FTIR. Six temperatures were considered between 300 and 900 °C. The N fraction of this sewage sludge was found equal to 9.96% much higher than that of the mixed sewage sludge considered in the present study (1.9%, see Table 2). Zuo et al. analyzed in [64] the pyrolysis products of three sewage sludge through TG–MS and Py–GC/MS. Four temperatures were considered among which 500 °C. A hydrothermal carbonization was applied to pulp and paper mill sludge in [65], the authors considering three temperatures among which 550 °C. The results of these papers are summarized in Table 7.

Because of a very high N fraction (9.96%), Zhou et al. observed a very high proportion of nitrogen-containing compounds (56.7%). This high N fraction may be explained by the treatment applied to the raw sewage sludge which could concentrate nitrogenous compounds. Zuo et al. observed a high proportion of aliphatic compounds (alkane, alkene). They did not observe aromatic hydrocarbons. They did not give the details of the oxygenated organic compounds (named AOC with a proportion of 8%). In the present study, there oxygenated organic compounds are only represented by phenols. Zuo et al. also observed a small proportion of steroids and of heterocyclic nitrogenated compounds (named HNC with a proportion of 7%). When analyzing the products from the pyrolysis of pulp and paper mill sludge, Wang et al. observed a high proportion of phenols [65]. They also observed a small proportion of nitrogen-containing compounds (2%). The N fraction of the material was approximately equal to 5%. The mixed sewage sludge considered in the present has proportions of the different chemical families lying between that of the literature.

Conclusions

In the present study, the products obtained when applying slow pyrolysis to Russian feedstock (hydrolysis lignin, peat and sewage sludge) were investigated by gas chromatography methods. The pyrolysis experiments were carried out at a temperature of 500 °C. These conditions provided identification of a large number of components by the mass spectrometer and peak areas on ion chromatograms corresponding to these components. More molecules with a clearly visible peak on the chromatogram were indeed identified in the present study than in many papers of the literature. The gases emitted during the pyrolysis process were first determined as CO2, H2O and volatile organic components.

The highest amount of molecules (more than 40%) released during the thermal degradation of hydrolysis lignin belongs to the phenol chemical family, which result from the lignin degradation. Sugars represent a significant part (over 50%) of the peat degradation, because peat was very slightly fossilized being extracted from the upper soil layer (up to 1.5 m). The peat pyrolysis is characterized by the formation of more furans produced during the pyrolysis of the carbohydrate part of the sample (cellulose and hemicellulose), which agrees with the literature data. The mixed sewage sludge leads mainly to sugars (more than 52%). The data obtained in the present study globally agree with that of the literature. The differences may be partly explained by the origin of the feedstock or by their treatment conditions or even by the experimental conditions.

References

Rabinovich ML, Fedoryak O, Dobele G, Andersone A, Gawdzik B, Lindström ME, Sevastyanova O. Carbon adsorbents from industrial hydrolysis lignin: the USSR/Eastern European experience and its importance for modern biorefineries. Renew Sustain Energy Rev. 2016;57:1008–24. https://doi.org/10.1016/j.rser.2015.12.206.

Ragg PL, Fields PR. The development of a process for the hydrolysis of lignocellulosic waste. Philos Trans R Soc Lond A. 1987;321:537–47. https://doi.org/10.1098/rsta.1987.0030.

Wang Z. Bergius process. In: Wang Z, editor. Comprehensive organic name reactions and reagents. Hoboken, NJ: Wiley; 2010. p. conrr074. https://doi.org/10.1002/9780470638859.conrr074.

Schlesinger WH, Bernhardt E. The global cycles of sulfur and mercury. In: Schlesinger WH, Schlesinger WH, editors. Biogeochemistry: an analysis of global change. 3rd ed. Cambridge: Academic Press; 2013. p. 469–86.

Beith R, Liu H. Biomass fuels for small and micro combined heat and power (CHP) systems: resources, conversion and applications. In: Beith R, editor. Small and micro combined heat and power (CHP) systems: advanced design, performance, materials and applications. Cambridge: Woodhead Pub. Ltd; 2011.

Manara P, Zabaniotou A. Towards sewage sludge based biofuels via thermochemical conversion—a review. Renew Sustain Energy Rev. 2012;16:2566–82. https://doi.org/10.1016/j.rser.2012.01.074.

Schnell M, Horst T, Quicker P. Thermal treatment of sewage sludge in Germany: a review. J Environ Manage. 2020;263: 110367. https://doi.org/10.1016/j.jenvman.2020.110367.

Glińska K, Ismail MSB, Goma-Camps J, Valencia P, Stüber F, Giralt J, Fabregat A, Torrens E, Olkiewicz M, Bengoa C. Recovery and characterisation of cellulose from industrial paper mill sludge using tetrakis and imidazolium based ionic liquids. Ind Crops Prod. 2019;139: 111556. https://doi.org/10.1016/j.indcrop.2019.111556.

Glińska K, Lerigoleur C, Giralt J, Torrens E, Bengoa C. Valorization of cellulose recovered from WWTP sludge to added value levulinic acid with a Brønsted acidic ionic liquid. Catalysts. 2020;10:1004. https://doi.org/10.3390/catal10091004.

Fan H, Zhou H, Wang J. Pyrolysis of municipal sewage sludges in a slowly heating and gas sweeping fixed-bed reactor. Energy Convers Manage. 2014;88:1151–8. https://doi.org/10.1016/j.enconman.2014.05.043.

Fonts I, Gea G, Azuara M, Ábrego J, Arauzo J. Sewage sludge pyrolysis for liquid production: a review. Renew Sustain Energy Rev. 2012;16:2781–805. https://doi.org/10.1016/j.rser.2012.02.070.

Gao N, Kamran K, Quan C, Williams PT. Thermochemical conversion of sewage sludge: a critical review. Prog Energy Combust Sci. 2020;79: 100843. https://doi.org/10.1016/j.pecs.2020.100843.

Magdziarz A, Werle S. Analysis of the combustion and pyrolysis of dried sewage sludge by TGA and MS. Waste Manage. 2014;34:174–9. https://doi.org/10.1016/j.wasman.2013.10.033.

del Río JC, Gutiérrez A, Martínez MJ, Martínez AT. Py–GC/MS study of Eucalyptus globulus wood treated with different fungi. J Anal Appl Pyrolysis. 2001;58–59:441–52. https://doi.org/10.1016/S0165-2370(00)00184-4.

Ohra-aho T, Tenkanen M, Tamminen T. Direct analysis of lignin and lignin-like components from softwood kraft pulp by Py–GC/MS techniques. J Anal Appl Pyrol. 2005;74:123–8. https://doi.org/10.1016/j.jaap.2004.11.010.

Chen W-H, Wang C-W, Kumar G, Rousset P, Hsieh T-H. Effect of torrefaction pretreatment on the pyrolysis of rubber wood sawdust analyzed by Py–GC/MS. Biores Technol. 2018;259:469–73. https://doi.org/10.1016/j.biortech.2018.03.033.

Chen L, Wang X, Yang H, Lu Q, Li D, Yang Q, Chen H. Study on pyrolysis behaviors of non-woody lignins with TG–FTIR and Py–GC/MS. J Anal Appl Pyrol. 2015;113:499–507. https://doi.org/10.1016/j.jaap.2015.03.018.

Liang F, Wang R, Hongzhong X, Yang X, Zhang T, Hu W, Mi B, Liu Z. Investigating pyrolysis characteristics of moso bamboo through TG–FTIR and Py–GC/MS. Bioresour Technol. 2018;256:53–60. https://doi.org/10.1016/j.biortech.2018.01.140.

Hidayat S, AbuBakar MS, Yang Y, Phusunti N, Bridgwater AV. Characterisation and Py–GC/MS analysis of Imperata cylindrica as potential biomass for bio-oil production in Brunei Darussalam. J Anal Appl Pyrolysis. 2018;134:510–9. https://doi.org/10.1016/j.jaap.2018.07.018.

Vyazovkin S, Sbirrazzuoli N. Isoconversional kinetic analysis of thermally stimulated processes in polymers. Macromol Rapid Commun. 2006;27:1515–32. https://doi.org/10.1002/marc.200600404.

Ponder GR, Richards GN, Stevenson TT. Influence of linkage position and orientation in pyrolysis of polysaccharides: a study of several glucans. J Anal Appl Pyrol. 1992;22:217–29. https://doi.org/10.1016/0165-2370(92)85015-D.

Paine JB, Pithawalla YB, Naworal JD. Carbohydrate pyrolysis mechanisms from isotopic labeling. J Anal Appl Pyrol. 2008;83:37–63. https://doi.org/10.1016/j.jaap.2008.05.008.

Shen DK, Gu S, Bridgwater AV. The thermal performance of the polysaccharides extracted from hardwood: cellulose and hemicellulose. Carbohyd Polym. 2010;82:39–45. https://doi.org/10.1016/j.carbpol.2010.04.018.

Patwardhan PR, Brown RC, Shanks BH. Product distribution from the fast pyrolysis of hemicellulose. Chemsuschem. 2011;4:636–43. https://doi.org/10.1002/cssc.201000425.

Liu C, Wang H, Karim AM, Sun J, Wang Y. Catalytic fast pyrolysis of lignocellulosic biomass. Chem Soc Rev. 2014;43:7594–623. https://doi.org/10.1039/C3CS60414D.

Stefanidis SD, Kalogiannis KG, Iliopoulou EF, Michailof CM, Pilavachi PA, Lappas AA. A study of lignocellulosic biomass pyrolysis via the pyrolysis of cellulose, hemicellulose and lignin. J Anal Appl Pyrol. 2014;105:143–50. https://doi.org/10.1016/j.jaap.2013.10.013.

Shen Q, Fu Z, Li R, Wu Y. A study on the pyrolysis mechanism of a β-O-4 lignin dimer model compound using DFT combined with Py–GC/MS. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10130-1.

Carlson TR, Jae J, Lin Y-C, Tompsett GA, Huber GW. Catalytic fast pyrolysis of glucose with HZSM-5: the combined homogeneous and heterogeneous reactions. J Catal. 2010;270:110–24. https://doi.org/10.1016/j.jcat.2009.12.013.

Cheng Y-T, Huber GW. Chemistry of Furan conversion into aromatics and olefins over HZSM-5: a model biomass conversion reaction. ACS Catal. 2011;1:611–28. https://doi.org/10.1021/cs200103j.

Wang K, Kim KH, Brown RC. Catalytic pyrolysis of individual components of lignocellulosic biomass. Green Chem. 2014;16:727–35. https://doi.org/10.1039/C3GC41288A.

Zádorová T, Skála J, Žížala D, Vaněk A, Penížek V. Harmonization of a large-scale national soil database with the World Reference Base for Soil Resources 2014. Geoderma. 2021;384: 114819. https://doi.org/10.1016/j.geoderma.2020.114819.

Phyllis2—wood, pine (#787). (n.d.). https://phyllis.nl/Biomass/View/787. Accessed 16 March 2021.

Phyllis2—wood, spruce (#2402). (n.d.). https://phyllis.nl/Biomass/View/2402. Accessed 16 March 2021.

Phyllis2—peat moss (#2551). (n.d.). https://phyllis.nl/Biomass/View/2551. Accessed 16 March 2021.

Phyllis2—wood, spruce (#176). (n.d.). https://phyllis.nl/Biomass/View/176. Accessed 16 March 2021.

Phyllis2—peat (#1407). (n.d.). https://phyllis.nl/Biomass/View/1407. Accessed 16 March 2021.

Phyllis2 - paper sludge (#915). (n.d.). https://phyllis.nl/Biomass/View/915. Accessed 16 March 2021.

Phyllis2—paper sludge (#916). (n.d.). https://phyllis.nl/Biomass/View/916. Accessed 16 March 2021.

Phyllis2—sewage sludge (#1170). (n.d.). https://phyllis.nl/Biomass/View/1170. Accessed 16 March 2021.

Phyllis 1800. Wood spruce, Phyllis2 Database. (n.d.). https://www.ecn.nl/phyllis2/Biomass/View/1800.

Carrott PJM, Suhas MMLR, Carrott CI, Guerrero LA. Delgado, Reactivity and porosity development during pyrolysis and physical activation in CO2 or steam of kraft and hydrolytic lignins. J Anal Appl Pyrol. 2008;82:264–71. https://doi.org/10.1016/j.jaap.2008.04.004.

Van Krevelen DW, Te Nijenhuis K. Properties of polymers their correlation with chemical structure; their numerical estimation and prediction from additive group contributions. Amsterdam: Elsevier Science & Technology Books. 2009. http://international.scholarvox.com/book/88812025. Accessed 7 Aug 2020.

Björnbom E, Björnbom P, Karlsson O. Effect of the raw material on the liquefaction of wet peat with carbon monoxide. Fuel Process Technol. 1988;17:263–76. https://doi.org/10.1016/0378-3820(88)90039-2.

Phyllis2—paper sludge (#2746). (n.d.). https://phyllis.nl/Biomass/View/2746. Accessed 16 March 2021.

Levesque M, Dinel H. Applicability of thermal methods for characterization of peats and plants. Geoderma. 1978;20:201–13. https://doi.org/10.1016/0016-7061(78)90010-1.

Hatcher P, Lerchiii H, Kotra R, Verheyen T. Pyrolysis g.c.–m.s. of a series of degraded woods and coalified logs that increase in rank from peat to subbituminous coal. Fuel. 1988;67:1069–75. https://doi.org/10.1016/0016-2361(88)90372-9.

Orem WH, Neuzil SG, Lerch HE, Cecil CB. Experimental early-stage coalification of a peat sample and a peatified wood sample from Indonesia. Org Geochem. 1996;24:111–25. https://doi.org/10.1016/0146-6380(96)00012-5.

Godin B, Ghysel F, Agneessens R, Schmit T, Gofflot S, Lamaudière S, Sinnaeve G, Goffart J-P, Gerin PA, Stilmant D, Delcarte J. Détermination de la cellulose, des hémicelluloses, de la lignine et des cendres dans diverses cultures lignocellulosiques dédiées à la production de bioéthanol de deuxième génération. Biotechnol Agron Soc Environ. 2010;14:549–60.

Ralph J, Hatfield RD. Pyrolysis–GC–MS characterization of forage materials. J Agric Food Chem. 1991;39:1426–37. https://doi.org/10.1021/jf00008a014.

Wheeler EA. Methods in lignin chemistry. SY Lin’CW Dence (eds.), 578 pp., illus., 1992. Springer Series in Wood Science. Springer Verlag, Berlin, Heidelberg, etc. ISBN 3-540-50295-5. Price DM 480.00 (hardcover). IAWA J. 1993;14:152. https://doi.org/10.1163/22941932-90001308.

Maryandyshev P, Chernov A, Lyubov V, Trouvé G, Brillard A, Brilhac J-F. Investigation of thermal degradation of different wood-based biofuels of the northwest region of the Russian Federation. J Therm Anal Calorim. 2015;122:963–73. https://doi.org/10.1007/s10973-015-4798-3.

Wang K, Masiol M, Thimmaiah D, Zhang Y, Hopke PK. Performance evaluation of two 25 kW residential wood pellet boiler heating systems. Energy Fuels. 2017;31:12174–82. https://doi.org/10.1021/acs.energyfuels.7b01868.

Hosoya T, Kawamoto H, Saka S. Solid/liquid- and vapor-phase interactions between cellulose- and lignin-derived pyrolysis products. J Anal Appl Pyrol. 2009;85:237–46. https://doi.org/10.1016/j.jaap.2008.11.028.

Windt M, Meier D, Marsman JH, Heeres HJ, de Koning S. Micro-pyrolysis of technical lignins in a new modular rig and product analysis by GC–MS/FID and GC×GC–TOFMS/FID. J Anal Appl Pyrol. 2009;85:38–46. https://doi.org/10.1016/j.jaap.2008.11.011.

Heigenmoser A, Liebner F, Windeisen E, Richter K. Investigation of thermally treated beech (Fagus sylvatica) and spruce (Picea abies) by means of multifunctional analytical pyrolysis–GC/MS. J Anal Appl Pyrol. 2013;100:117–26. https://doi.org/10.1016/j.jaap.2012.12.005.

Hilbers TJ, Wang Z, Pecha B, Westerhof RJM, Kersten SRA, Pelaez-Samaniego MR, Garcia-Perez M. Cellulose–lignin interactions during slow and fast pyrolysis. J Anal Appl Pyrol. 2015;114:197–207. https://doi.org/10.1016/j.jaap.2015.05.020.

Kim J, Kim K-H, Kwon EE. Enhanced thermal cracking of VOCs evolved from the thermal degradation of lignin using CO 2. Energy. 2016;100:51–7. https://doi.org/10.1016/j.energy.2016.01.075.

Lee J, Yang X, Song H, Ok YS, Kwon EE. Effects of carbon dioxide on pyrolysis of peat. Energy. 2017;120:929–36. https://doi.org/10.1016/j.energy.2016.11.143.

Xin X, Pang S, de MiguelMercader F, Torr KM. The effect of biomass pretreatment on catalytic pyrolysis products of pine wood by Py–GC/MS and principal component analysis. J Anal Appl Pyrolysis. 2019;138:145–53. https://doi.org/10.1016/j.jaap.2018.12.018.

Durig JR, Calvert GD, Esterle JS. Development of a pyrolysis–gas chromatographic–Fourier transform infrared spectroscopic technique for the study of woody peats. J Anal Appl Pyrol. 1989;14:295–308. https://doi.org/10.1016/0165-2370(89)80005-1.

Calvert GD, Esterle JS, Durig JR. Pyrolysis-gas chromatography/mass spectrometry and pyrolysis–gas chromatography/Fourier transform infrared/flame ionization detection studies of particle size fractions of woody peat. J Anal Appl Pyrol. 1989;16:5–25. https://doi.org/10.1016/0165-2370(89)80032-4.

Cai W, Liu Q, Shen D, Wang J. Py–GC/MS analysis on product distribution of two-staged biomass pyrolysis. J Anal Appl Pyrol. 2019;138:62–9. https://doi.org/10.1016/j.jaap.2018.12.007.

Zhou P, Xiong S, Zhang Y, Jiang H, Chi Y, Li L. Study on the nitrogen transformation during the primary pyrolysis of sewage sludge by Py–GC/MS and Py–FTIR. Int J Hydrogen Energy. 2017;42:18181–8. https://doi.org/10.1016/j.ijhydene.2017.04.144.

Zuo W, Jin B, Huang Y, Sun Y. Thermal decomposition of three kinds of sludge by TG–MS and PY–GC/MS. J Therm Anal Calorim. 2015;121:1297–307. https://doi.org/10.1007/s10973-015-4651-8.

Wang S, Wen Y, Hammarström H, Jönsson PG, Yang W. Pyrolysis behaviour, kinetics and thermodynamic data of hydrothermal carbonization—treated pulp and paper mill sludge. Renew Energy. 2021;177:1282–92. https://doi.org/10.1016/j.renene.2021.06.027.

Acknowledgements

The authors thank M. Maugué, LGRE Mulhouse, for his technical assistance during the experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maryandyshev, P., Kangash, A., Trouve, G. et al. Analysis through gas chromatography of the products obtained from slow pyrolysis applied to Russian feedstock. J Therm Anal Calorim 147, 8485–8498 (2022). https://doi.org/10.1007/s10973-021-11152-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-11152-z