Abstract

Conventional surfactants such as CTAB (cetrimonium bromide), SDS (sodium dodecyl sulphate), SDBS (sodium dodecyl sulphonate) are combined with nanofluids to improve the stability and thermal conductivity of nanofluids. These nanofluids are mainly used for heat transfer applications where heating and cooling are usual courses of action which result in surfactants producing foams and polluting the heat transfer media, affecting the total system performance. Besides, the common surfactant molecules that augment the thermal resistance between the nanoparticles and base fluid also affect the thermophysical properties of the nanofluid. In this paper, [Bmim][Cl] (1-butyl-3-methylimidazolium chloride), a high purity ionic liquid (IL) with higher thermal stability was used to provide a comparative study on the stability and thermal properties with that of the conventional surfactants (CTAB, SDS, SDBS) on multiwalled carbon nanotubes (MWCNT)/propylene glycol (PG) nanofluid. The transient hot-wire based KD2-Pro and zeta potential results demonstrated that the inclusion of ionic liquid improved the thermal conductivity and stability of the formulated nanofluid. However, much like the conventional surfactants, the strong electrostatic repulsive force created by the ionic liquid was found to decrease when the temperature is increased. The outcome demonstrated the most extreme thermal conductivity upgrade of 33.7% at 303 K and maximum dispersion stability of more than one month without any aggregation for the nanofluid containing ionic liquid.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

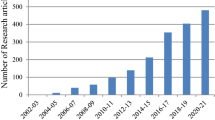

In general, the most ingenious way of improving base fluid’s thermal conductivity is to blend the MWCNT nanoparticles within it that can be called as ‘nanofluids’. Many researchers [1,2,3] have studied its inherent properties to be efficient for heat transfer application. Maintaining the stability of nanofluid is a significant task to deal with. One of the common ways of enhancing the nanofluid stability is through the inclusion of surfactants like CTAB, SDS, SDBS, Tween 20, Triton X-100, Gum Arabic, etc. Surfactants are substances used in nanofluids for their ability to lower the surface tension of liquids, making the molecules slipperier, so they are less likely to interact with nanoparticles and base fluids. They are also utilised to moderate the aggregation of nanoparticles in the mixture and its sedimentation, which fundamentally decreases the thermal properties of nanofluids. Most of the surfactants produce foams while homogenised with nanofluids which changed the original property of the nanofluids affecting the heat transfer media. Due to the excellent solvation properties of ionic liquids, they are chemically, thermally and electrochemically stable; and their low vapour pressure made them an attractive replacement for conventional surfactants. Ionic liquids are studied for many applications like batteries, solar cells, organic synthesis, catalysis, separation sciences, tissue preservation, alternative lubricants and biotransformation. Here in this paper, a new attempt is made to verify the performance of [Bmim][Cl] (ionic liquid) as the surfactant in MWCNT/PG nanofluid.

The latest research carried out by Pritam et al. [4] using CTAB, SDS, SDBS and acetic acid as surfactants proved that CTAB and SDS provided stable suspensions and optimal thermal conductivity improvement of 5.8%. Choi et al. [5] performed an experimental investigation with four surfactants that are typically utilised namely CTAB, SDS, SDBS and Triton X-100 in MWCNT/water nanofluid and concluded that high stability and heat transfer coefficient are achieved with SDBS surfactants. Since these surfactants produce harmful effects on the heat transfer media, ionic liquids which are incombustible at ambient conditions and are also recyclable are preferred to be used in its place [6]. Sheveylyova et al. [7] showed an 8% thermal conductivity enhancement by incorporating ionic liquids like [C4mim][BF4] and [C4mim][PF6] in MWCNTs; the results are almost similar to that of Nirto de Castro et al. [8]. Some of the latest experimental studies on the thermal properties of ionic liquid-based nanofluids are listed in Table 1. Al-Waeli et al. [9] used five different types of surfactants (CTAB, SDS, tannic acid + ammonia, SDBS, sodium deoxycholate) on water–silicon carbide nanofluid to determine its stability and thermophysical properties for use in photovoltaic–thermal systems. They concluded that the stability of the nanoparticle suspension is dependent on the variety of surfactant and the ultrasonication time. Their results showed that CTAB-based nanofluid achieved maximum stability of 93 days with an ultrasonication time of 6 h.

In the latest research done by Zhai et al. [16], the effect of PVP (polyvinylpyrrolidone) and SDS (sodium dodecyl sulphate) surfactants on Al2O3–EG nanofluid is investigated. It was found that the highest stabilisation and homogenisation were obtained for PVP used nanofluid. Akhgar and Toghraie [17] studied water–EG/TiO2–MWCNT hybrid nanofluid with CTAB surfactants of around 0.05 to 1% volume fractions at 293 to 323 K temperature. They demonstrated a maximum enhancement of 38.7% of thermal conductivity, and their experimental results are also consistent with two mathematical models proposed by them. SiC-based ionic liquids were studied by Chen et al. [18]. In their study, they experimentally analysed the thermophysical and optical properties of SiC-based ionic liquids as heat transfer fluids in direct absorption solar collectors. It was discovered that the thermal conductivity and specific heat of pure [Hmim][BF4] ionic liquid were increased to 10.2% and 5% at 298 K. Regarding its viscosity and density, data in the literature are contradictory. In an interesting study, Sanchez et al. [19] employed three experimental techniques namely UV–vis spectroscopy, particle size and zeta potential to determine the stability of NiO-eutectic mixture (diphenyloxide + biphenyl) nanofluid in the presence of BAC (benzalkonium chloride) and ODT (1-octadecanethol). All three methods proved that BAC surfactant is the best stabilising agent for NiO nanofluid. Gao et al. [20] used surfactants like APE-10, CTAB, OP-10, SDBS, SDS and TTAB to illustrate the impact of different surfactants on the dispersion effect and tribological performance of carbon nanotubes (CNT) with vegetable oils and proved that APE-10 with CNT nanofluids resulted in more extended stability (> 45 h) without any deposition.

Even though most researches done on MWCNT nanofluids with conventional surfactants resulted in excellent stability and thermal conductivity, no study compared the effect of [Bmim][Cl] (ionic liquid) with conventional surfactants. This paper presents a systematic report on the effect of using ionic liquid instead of conventional surfactants in MWCNT/propylene glycol nanofluid at different temperatures. It mainly aims at finding the best substance for maintaining the stability and thermal conductivity of MWCNT/propylene glycol nanofluids at least for 30 days. Four types of fluid at 0.9% mass concentration are prepared, and their thermophysical properties like thermal conductivity, viscosity density and specific heat capacity are tested and compared with other relevant researches.

Materials and methodology

Materials

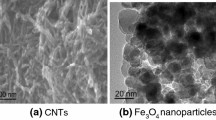

Multiwalled carbon nanotubes with an outer diameter of 13 nm were purchased from Sigma Aldrich, Merck Group LTD, USA. Due to the strong atomic bonds of MWCNTs, its thermal conductivity value is higher, which led to the selection of MWCNT nanoparticles in this study. On the other hand, blending of nanoparticles with ionic surfactants (CTAB, SDS, SDBS) have been extensively used in many production processes, including heat transfer fluids and shale oil processing due to their significant synergistic effects [21]. Moreover, the imidazolium-based ionic liquids have proved immense significance due to their fascinating properties such as dispersion [22], suspension [23], ability to transport [24] and solubility [25]. Furthermore, the provenance of ionic liquids with nanoparticles reported by previous researchers is summarised in Table 1. Conventional surfactants like CTAB, SDS and SDBS are used in this study, whereas [Bmim][Cl] ionic liquid is also used as a surfactant to enhance the dispersion stability of the proposed nanofluid. The detailed information of the surfactants is displayed in Table 2. The physical form of the surfactants can be distinguished from Fig. 1 showing that conventional surfactants (Fig. 1a–c) are in powder form that cannot be easily dissolved with nanofluids, whereas [Bmim][Cl] (Fig. 1d) is in liquid form that can be easily dissolved with nanofluids that can lead to excellent dispersion stability. Propylene glycol solution with a purity of 99.5% has the ideal working fluid qualities as it is non-corrosive and has very low volatility and toxicity; thus, it is chosen as the base fluid to produce the nanofluid. The thermophysical characteristics of the base fluid and nanoparticles are presented in Tables 3, 4, respectively. To verify the morphological properties of the MWCNT nanoparticles, field emission scanning electron microscope (FESEM) was used. The raw image of MWCNT nanoparticle is presented in Fig. 2.

Preparation of nanofluids

The significant challenges in synthesising a nanofluid are to maintain its dispersibility, thermal stability, chemical manipulation and its compatibility. To obtain a stable nanofluid, the thermal energy of the prepared nanofluid should be less than the van der Waals interaction. Usually, repulsive forces increase thermal energy, whereas attractive forces decrease thermal energy. The general approach used to overcome these challenges is to add surfactants. In this study, the two-step method was used where the commercial MWCNT nanoparticles were taken first, and those nanoparticles were dispersed into a propylene glycol base fluid. The preparation process of the proposed nanofluid is depicted in Fig. 3. The MWCNTs and propylene glycol solution were mixed using a magnetic stirrer for 30 min at 1000 rpm without heating. Using Sonics VCX-750 Vibra-Cell, 750 Watts, 50 kHz Ultrasonic probe with 60% amplitude, 303 K temperature (maintained by water bath) and 01 01 pulse rate as parameters, the nanoparticles and base fluids were homogenised for 4 h to obtain a better suspension. Based on the previous literature [29, 30], an optimum mass concentration of 0.9% MWCNT nanoparticle was chosen to prepare four samples with different surfactants namely CTAB, SDBS, SDS and [Bmim][Cl] ionic liquid to analyse the impact of typical surfactants and ionic liquid on the stability and thermophysical properties of MWCNT/propylene glycol nanofluid.

Since surfactants could affect the original nature of the nanofluids, their concentration should be in less proportion when compared to nanoparticles [31]. In each sample, surfactant was added in a proportion of 1:10 with respect to the nanoparticles by mass. The same parameters were followed for all the nanofluids synthesised. Table 5 presents the amount of nanoparticles, surfactants and base fluids used for the preparation of the studied fluids.

Characterisation

Surface morphology of MWCNT nanoparticles

FESEM (field emission scanning electron microscope, Zeiss Supra 55VP) was utilised to record the images of the studied nanoparticles. It can be used to characterise samples down to a resolution of 1 to 4 nm with voltage ranging from 100 V to 30 kV. Also, EDX analysis was performed to determine the elemental composition of the nanoparticle with the same FESEM equipment that has a maximum detection limit of 0.5%. Indeed, unstable materials at room temperature can also be analysed through its incredible cryo transfer system.

Thermal conductivity

Thermal conductivity of the formulated nanofluids with a mass concentration of 0.9% over temperatures ranging from 303 to 343 K was determined by KD2-Pro thermal property analyser (Decagon Devices, USA). After turning on the KD2-Pro device, the sensor needle (KS-1 sensor) has to be inserted into the nanofluid to be measured as shown in Fig. 4. Then, the sample is heated with a water bath where the temperature of the sample and water flow is regulated to measure the thermal conductivity of the sample at certain temperature. Before taking the final measurements, 15 min is allowed for samples and needles to equilibrate with the atmospheric temperature. In order to avoid the redistribution of moisture into the sample, the heat input is given as small as possible.

Density

In this study, the density of the prepared nanofluids is analysed by a density meter (DMA 1001, Anton Paar) that works on the principle of “Pulsed Excitation Method”. It can be used to measure the samples at a range of 0 g cm−3 to 3 g cm−3 with a pressure scale of 0 to 10 bar at a precision of 0.0001 g cm−3. This device consists of a U-shaped glass where the sample has to be injected without any gas bubbles. With a series of impulses, the U-tube is excited to oscillate for attaining a constant amplitude. Then, the resulting oscillation properties are converted into understandable algorithms by the device that generates the required density values.

Viscosity

At the present work, Brookfield viscometer is utilised to measure the fluid’s resistance to flow which is called as viscosity. It consists of a synchronous motor to maintain a constant rotational speed. Firstly, the spindle protector has to be mounted on the viscometer. The coupling screw is lifted to attach the spindle to the lower shaft of the viscometer. The spindle has to be inserted in a diagonal path across the fluid surface to avoid unnecessary air bubbles. Lower and centre the spindle in the studied fluid until the ‘meniscus’ of the fluid is at the centre of the immersion groove on the spindle’s shaft. Finally, the motor switch is turned on to power the synchronous motor and the viscosity is measured once the readings got stabilised.

Specific heat capacity

A differential scanning calorimetry (DSC 4000, PerkinElmer) is used to measure the specific heat capacity of the formulated samples. Here, the samples are descended (12 mg ± 0.1) into ceramic crucibles and placed in the device. The heating rate was adjusted to 10 °C min−1 and the final temperature was fixed to 343 K subjected to a nitrogen flow rate of 40 mL min−1. To know the baseline of the heat flux, calibration was performed with an empty crucible. After calibration, a standard sapphire was utilised to measure the heat flux for reference. To ensure the accuracy of the results, the same procedure is repeated for three times with all the samples.

Stability test

To ensure the dispersion stability of nanofluids, visual inspection and zeta potential technique were followed. For visual inspection, the samples were poured into highly transparent vials and their sedimentation is monitored at regular intervals of time. Usually, the nanoparticles will get deposited at the bottom of the vials after preparation which is considered as less stable. On the other hand, Litesizer 500, Anton Paar is used to measure the zeta potential value of the synthesised nanofluid. It is a technique to measure the charge generated between the surface of the solute and solvent. High charge represents high stability and low charge represents less stability. In this research, stability measurement was done using the visual inspection method and zeta potential technique where the results showed that nanofluid using [Bmim][Cl] obtained better stability when compared with nanofluids containing other conventional surfactants.

FTIR Spectroscopy

FTIR spectra were conducted with a range of 4000 to 500 cm−1 using a Spectrum Two FT-IR spectrometer (PKI-L160000A, PerkinElmer) at atmospheric temperature. In order to find the functional groups attached to the prepared nanofluids, this device was utilised. The vibrational energy and infrared light energy lead to the absorption of electromagnetic beam by the sample when it matches with each other. Certain spectrums can be generated by modifying the beam frequency where the molecules are absorbed resulting in broad peaks. These peaks are analysed to find the specific bonds in the material.

Uncertainty analysis

The analysis of uncertainty is the estimation of the interval of unsureness, that is associated with an experimental outcome based on scattered observations in the raw data which is used to measure the outcome. The literature has shown that no calculation is perfect from incertitude and albeit meticulously designed. Thus, it is vital to use the correct measurement to minimise ambiguity, as the application and structure of science are highly dependent upon the measurement. The uncertainty of each quantity is calculated by Gaussian distribution method [32] which is stated as follows.

In the above equation, the uncertainty is represented by \(U_{{\text{x}}}\) while σn and \(x_{{\text{n}}}\) indicate the standard deviation and mean of the experimental data. Thermal conductivity, density, viscosity and specific heat capacity were measured at least three times at each stage. The uncertainty percentage of the measured thermal conductivity, viscosity, density and specific heat capacity equipment is listed in Table 6.

Results and discussion

The most complex task in nanofluids is its successful preparation and stability since property enhancement of nanofluids relies on nanofluid dispersion. In this study, a two-stage method was used to prepare stable nanofluids. The propylene glycol base fluid with 0.9% mass concentration of MWCNT nanoparticle was sonicated with surfactants and ionic liquid in an ultrasonic probe (Sonics 750 Watts, 20 kHz) with 60% amplitude, 01 01 pulse rate for 4 h to prepare four samples. In order to enhance the stability, the synthesised nanofluids are subjected to ultrasonic processing where the nanoparticle is broken down to tiny agglomerates.

FESEM and EDX analysis

The morphology of the studied MWCNT nanoparticles was investigated using field emission scanning electron microscope (FESEM) at different magnification as shown in Fig. 5a, b. From the figure, the cylindrical structures of the nanoparticles were confirmed which can be considered as an important characteristic of multiwalled carbon nanotubes. These interlinked rolled up (cylindrical) sheets are significant for preventing the bond breakage with the solvent. Energy-dispersive X-ray (EDX) analysis was also conducted to characterise the unique energy and atomic percentage of each element present in the MWCNTs. EDX is one of the non-destructive characterisation techniques where it showed the type of elements and the percentage of concentration of each element on the MWCNT sample, which is displayed in Fig. 5c, d. The energy of the X-rays is presented in X axis reflecting the identification of elements like C, O and N. In contrast, the Y axis represents the number of counts or peak height leading to the determination of each element’s concentration.

FTIR spectrometry

In this research, PKI-L160000A Spectrum Two FTIR spectrometer was used to determine the existence of functional groups in all the studied surfactants. The molecules of the surfactants were irradiated with electromagnetic radiation so that energy was absorbed by these molecules at a situation when the frequency of the electromagnetic radiation coincided with the frequency of vibrational bonds in the molecules, which can be characterised with IR spectrum regions to identify the bond strength and types precisely. The FTIR graph of the studied surfactants is presented in Fig. 6.

In all the surfactants, prominent peaks occurred at the fingerprint region (1500–500 cm−1) except CTAB which showed a unique peak only at 2916 cm−1, whereas [Bmim][Cl] obtained its high peaks at 1163 cm−1 while SDBS and SDS reached theirs at 1182 cm−1 and 1217 cm−1 wavenumbers, respectively. Even though SDBS and SDS exhibited a large number of absorption peaks from 500 to 1700 cm−1 region, they showed only few peaks after 1700 cm−1. On the other hand, [Bmim][Cl] also illustrated the formation of peaks after 3000 cm−1. From the results, these peaks illustrate the existence of hydroxyl groups, carboxyl groups and hydrogen bonds on the surface of the ionic liquid, which is essential to enhance the stability of nanofluids.

Zeta potential analysis

Agglomeration and sedimentation are the significant problems of nanofluids that affect the heat transfer performance of the fluid. According to Maxwell, particle size is an essential factor to attain stable and high conductive nanofluids. To achieve a non-agglomerated and monodispersed nanoparticle in propylene glycol base fluid, MWCNTs were dispersed ultrasonically with an ultrasonic probe for 4 h. The stability measurement was done by the zeta potential method where nanofluid containing [Bmim][Cl], CTAB, SDBS and SDS reached a zeta potential of − 38.2 mV, − 35 mV, − 33.6 mV, − 31 mV, respectively, on the first day, which indicated that nanofluid containing ionic liquid provides better stability when compared with nanofluids containing another conventional surfactant. The obtained results are better than the previous study results carried out by Sezer et al. [33] which showed the highest zeta potential value of 26.7 mV with MWCNT nanofluids blended with Acacia gum surfactant while other surfactants such as SDS and PVP were observed to have zeta potential value of 16.5 mV and 19.8 mV, respectively. The zeta potential measurement of the prepared samples is indicated in Fig. 7.

Sedimentation observation

For the prepared nanofluids, sedimentation analysis was performed through visual inspection method at different intervals of time. Figure 8 indicates the deposition of MWCNT nanoparticles with different surfactants at 0.9% mass concentration for a maximum period of one month. As discussed earlier, the proportion of surfactant added with respect to MWCNT nanoparticle for nanofluid preparation was 1:10 by mass. There was no deposition in the prepared samples after immediate preparation. However, agglomeration was observed for nanofluid with SDS surfactant (S1) from the second week, which resulted in clear visibility of propylene glycol at week four. In contrast, SDBS-based nanofluid (S2) showed aggregation from the third week. Meanwhile, nanofluid containing ionic liquids (S4) demonstrated maximum stability of one month when compared with the other three nanofluids, and CTAB-based nanofluid (S3) obtained less suspension until week four. Except for nanofluid with ionic liquids, all other samples showed nanoparticles sedimentation during the fourth week.

Thermal conductivity

Conventional fluid’s intrinsically low thermal conductivity imposes a profound barrier on heat transfer. Many industries have a growing need to produce innovative heat transfer fluids with significantly higher thermal conductivity compared to the currently available materials due to increasing global competition. In this research, KD2-Pro thermal conductivity meter is used to analyse the thermal conductivity of the prepared samples at temperatures ranging from 303 to 343 K. Figure 9 illustrates the thermal conductivity measurement of the prepared nanofluids as a function of temperature. It is observed that nanofluid contained ionic liquids resulted in more thermal conductivity (0.28 W m−1 K−1) when compared with the other three nanofluids. It is inferred that the thermal conductivity of [Bmim][Cl] is greater compared to the other three surfactants. The data obtained are consistent with Kakavandi et al. [34] and Hua et al. [14]. Based on the obtained results, no considerable changes have been found despite the usual thermal conductivity increase with temperature rise for the tested samples. It is clear at this point that interfacial effects and the clustering of nanoparticles play significant roles in determining the effective thermal conductivity of nanofluids, together with temperature, particle size and concentration. Meanwhile, nanofluid with ionic liquids showed a maximum thermal conductivity enhancement of 33.7% over the base fluid at 303 K. Figure 10 depicts the comparison of the prominent findings of this study with the previous literature works.

The obtained results concur with that of the previous experimental research conducted by Yellapu et al. [35] whose thermal conductivity ranged from 0.154 to 0.254 W m−1 K−1 for functionalised MWCNTs dispersed with petroleum-based heat transfer fluids, at temperatures varying from room temperature to 423 K. As a result, the ionic liquid can be a potential substitute for conventional surfactants.

Viscosity and Density

Thermal fluid’s viscosity is a significant physical characteristic that influences the friction between the surface molecules. It also plays a vital role in dictating the effectiveness of heat dissipation of a fluid. A Redwood viscometer was utilised to determine the viscosity of the four samples with temperature ranging from 303 to 333 K. Figure 11 shows the impact of temperature on the viscosity of the prepared samples, which varied from 0.040 to 0.1 kg m−1 s−1. From the results, it is apparent that the viscosity of all the three samples is decreasing at a faster rate when their temperature is increased. Still, the viscosity of the SDBS-based nanofluids decreased at a slower rate when compared with the others. The mixture of [Bmim][Cl] with propylene glycol also followed the same trend of decrease in viscosity with increase in temperature, which could be caused by the increase in the kinetic energy of the solvent ions. Unsurprisingly, viscosity decreased, and thermal conductivity increased for temperature, which is similar to the results of Rahimi et al. [36] where MWCNT-Mgo/water hybrid nanofluid experimented.

Nanofluid density is also an essential thermophysical property since it affects the hydrothermal properties, namely pumping power, friction factor and Reynolds number. The results of the measured density of the prepared samples with temperature ranging from 303 to 343 K are represented in Fig. 12. The obtained results demonstrate that the density of the prepared nanofluids decreased with temperature rise. Since the density of the ionic liquid is higher than propylene glycol, ionic liquid-based nanofluid showed a maximum density of 1157 kg m−3 which gradually decreased with the increase in temperature, as observed in other samples. Indeed, there were no significant changes in the density of the nanofluid contained ionic liquids when the temperature was raised from 303 to 343 K.

Specific heat capacity

Specific heat capacity can vary due to many effects such as Schottky anomalies, magnetic spin-wave contributions, the density of states at Fermi level and vibrionic properties in a sample because of the influence of temperature. Specific heat capacity measurements are useful in providing information on a solid’s bulk behaviour, thus helping to dictate whether an observed result from specific techniques (e.g. resistivity measurements) is part of the bulk material or caused by some other marginal segments. The specific heat capacity of the prepared samples is displayed in Fig. 13. It demonstrates that the specific heat capacity of CTAB-based nanofluid showed a slight decrease with increase in temperature where nanofluid contained ionic liquids resulted in maximum specific heat capacity of 2.34 kJ kg−1 K−1. This may be due to the gain of thermal energy produced by interfacial interactions between MWCNT nanoparticle and the ionic liquid molecules. For other nanofluids, their specific heat capacity is attributed to the prevailing trend of specific heat capacity increase for temperature increase which is consistent with the previous literature [37, 38]. According to the graph, the nanofluid contained ionic liquids showed a considerable improvement in the specific heat capacity because of the influence of temperature which confirmed the significant effect of temperature on the heat capacity of the studied nanofluids. This could also be attributed to the high surface energy provided by the high surface area per unit volume of MWCNT nanoparticles that would facilitate high heat absorption.

Conclusions

For heat transfer applications, stability of nanofluid is significant to attain the actual thermophysical properties. This study intended to precisely quantify certain thermophysical properties of MWCNT/PG nanofluids stabilised with four different surfactants. Moreover, the concentration of surfactant in the as-prepared nanofluid is retained at a low level to preserve the Newtonian behaviour. At the same time, the dispersion stability of the as-prepared samples was evaluated by the visual inspection and zeta potential method over a month. Finally, the significant results of the present study are summarised as follows.

-

The impact of [Bmim][Cl], SDS, SDBS and CTAB surfactant on the stability of 0.9% mass concentration MWCNT/PG nanofluid is determined.[Bmim][Cl] as a stabiliser is revealed to be the best surface acting agent and homogeniser (4 weeks). The stability over the period is determined by the following high to low series. MWCNT–[Bmim][Cl]–PG > MWCNT–CTAB–PG > MWCNT–SDBS–PG > MWCNT–SDS–PG nanofluid. MWCNT–[Bmim][Cl]–PG nanofluid has been observed to illustrate maximum stability.

-

The incorporation of surfactants contributed to a decrease in thermal resistance and provoked Brownian motion, which favoured the increase in thermal conductivity. However, the usage of low concentration of surfactants has not revealed a significant change in viscosity and density.

-

Ionic liquid was found to play a significant role in the thermophysical property enhancement of MWCNT/PG nanofluids due to its wider temperature range (> 400 °C) that prevents the breakage of bonds.

-

Experimental characterisation of MWCNT/propylene glycol nanofluid demonstrated that ionic liquid-based nanofluid showed a maximum thermal conductivity of 33.7% at 303 K over the base fluid. Moreover, density and viscosity decreased up to an optimum temperature of 343 K, which is consistent with the previous studies.

-

Also, the specific heat capacity of the as-prepared samples revealed an increase with an increase in temperature and the highest increase in specific heat capacity was found to be 2.34 kJkg−1K−1 for ionic liquid-based nanofluids.

The usage of ionic liquids could render MWCNT/PG nanofluids with high dispersion stability ideal for applications involving fluid pumping without major frictional losses. In conclusion, the fascinating features of ionic liquids could ensure its application in heat transfer fluids, operating at different temperature ranges.

Abbreviations

- Al2O3 :

-

Aluminium oxide

- Au:

-

Gold

- BmimCl:

-

1-Butyl-3-methylimidazolium chloride

- CTAB:

-

Cetrimonium bromide

- EDX:

-

Energy-dispersive X-ray

- FESEM:

-

Field emission scanning electron microscope

- OD:

-

Outer diameter of MWCNTs

- FTIR:

-

Fourier transform infrared spectroscope

- h :

-

Heat transfer coefficient (W m−2 K−1)

- IL:

-

Ionic liquid

- INF:

-

Nanofluid containing ionic liquid

- k :

-

Thermal conductivity (W m−2 K−1)

- LiNO3 :

-

Lithium nitrate

- MWCNT:

-

Multiwalled carbon nanotubes

- PG:

-

Propylene glycol

- S1:

-

MWCNT + PG + SDS

- S2:

-

MWCNT + PG + SDBS

- S3:

-

MWCNT + PG + CTAB

- S4:

-

MWCNT + PG + IL

- SDBS:

-

Sodium dodecyl benzene sulphonate

- SDS:

-

Sodium dodecyl sulphate

- T :

-

Temperature (K)

- mass:

-

M (gram)

- ID:

-

Inner diameter of MWCNTs

- μ :

-

Dynamic viscosity (kg m−1 s−1)

- ρ :

-

Density (kg m−3)

- Ø :

-

Mass concentration (%)

- Cp:

-

Specific heat capacity (kJ kg−1 K−1)

- nf:

-

Nanofluid

- np:

-

Nanoparticle

- bf:

-

Base fluid

References

Moradi A, Toghraie D, Isfahani AHM, Hosseinian A. An experimental study on MWCNT–water nanofluids flow and heat transfer in double-pipe heat exchanger using porous media. J Therm Anal Calorim. 2019;137:1797–807. https://doi.org/10.1007/s10973-019-08076-0.

Ilyas SU, Pendyala R, Narahari M. Experimental investigation of natural convection heat transfer characteristics in MWCNT-thermal oil nanofluid. J Therm Anal Calorim. 2019;135:1197–209. https://doi.org/10.1007/s10973-018-7546-7.

Mukesh Kumar PC, Chandrasekar M. Heat transfer and friction factor analysis of MWCNT nanofluids in double helically coiled tube heat exchanger. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09444-x.

Das PK, Mallik AK, Ganguly R, Santra AK. Stability and thermophysical measurements of TiO2 (anatase) nanofluids with different surfactants. J Mol Liq. 2018;254:98–107.

Choi TJ, Jang SP, Kedzierski MA. Effect of surfactants on the stability and solar thermal absorption characteristics of water-based nanofluids with multi-walled carbon nanotubes. Int J Heat Mass Transf. 2018;122:483–90.

Minea AA, Murshed SMS. A review on development of ionic liquid based nanofluids and their heat transfer behavior. Renew Sustain Energy Rev. 2018;91:584–99.

Shevelyova MP, Paulechka YU, Kabo GJ, Blokhin AV, Kabo AG, Gubarevich TM. Physicochemical properties of imidazolium-based ionic nanofluids: density, heat capacity, and enthalpy of formation. J Phys Chem C. 2013;117:4782–90. https://doi.org/10.1021/jp3059432.

de Castro CAN, Langa E, Morais AL, Lopes MLM, Lourenço MJV, Santos FJV, et al. Studies on the density, heat capacity, surface tension and infinite dilution diffusion with the ionic liquids [C4mim][NTf2], [C4mim][dca], [C2mim][EtOSO3] and [Aliquat][dca]. Fluid Phase Equilib. 2010;294:157–79.

Al-Waeli AHA, Chaichan MT, Kazem HA, Sopian K. Evaluation and analysis of nanofluid and surfactant impact on photovoltaic-thermal systems. Case Stud Therm Eng. 2019;13:100392.

Paul TC, Mahamud R, Khan JA. Multiphase modeling approach for ionic liquids (ILs) based nanofluids: improving the performance of heat transfer fluids (HTFs). Appl Therm Eng. 2019;149:165–72.

Oster K, Hardacre C, Jacquemin J, Ribeiro APC, Elsinawi A. Understanding the heat capacity enhancement in ionic liquid-based nanofluids (ionanofluids). J Mol Liq. 2018;253:326–39.

Wang B, Wang X, Lou W, Hao J. Ionic liquid-based stable nanofluids containing gold nanoparticles. J Colloid Interface Sci. 2011;362:5–14.

Liu J, Wang F, Zhang L, Fang X, Zhang Z. Thermodynamic properties and thermal stability of ionic liquid-based nanofluids containing graphene as advanced heat transfer fluids for medium-to-high-temperature applications. Renew Energy. 2014;63:519–23.

Xie H, Zhao Z, Zhao J, Gao H. Measurement of thermal conductivity, viscosity and density of ionic liquid [EMIM][DEP]-based nanofluids. Chin J Chem Eng. 2016;24:331–8.

Luo C, Li Y, Li N, Wang Y, Su Q. Thermophysical properties of lithium nitrate + 1-ethyl-3-methylimidazolium diethylphosphate + water system. J Chem Thermodyn. 2018;126:160–70.

Zhai Y, Li L, Wang J, Li Z. Evaluation of surfactant on stability and thermal performance of Al2O3-ethylene glycol (EG) nanofluids. Powder Technol. 2019;343:215–24.

Akhgar A, Toghraie D. An experimental study on the stability and thermal conductivity of water-ethylene glycol/TiO2-MWCNTs hybrid nanofluid: developing a new correlation. Powder Technol. 2018;338:806–18.

Chen W, Zou C, Li X. An investigation into the thermophysical and optical properties of SiC/ionic liquid nanofluid for direct absorption solar collector. Sol Energy Mater Sol Cells. 2017;163:157–63.

Sánchez-Coronilla A, Martín EI, Navas J, Aguilar T, Gómez-Villarejo R, Alcántara R, et al. Experimental and theoretical analysis of NiO nanofluids in presence of surfactants. J Mol Liq. 2018;252:211–7.

Gao T, Li C, Zhang Y, Yang M, Jia D, Jin T, et al. Dispersing mechanism and tribological performance of vegetable oil-based CNT nanofluids with different surfactants. Tribol Int. 2019;131:51–63.

Jin J, Li X, Geng J, Jing D. Insights into the complex interaction between hydrophilic nanoparticles and ionic surfactants at the liquid/air interface. Phys Chem Chem Phys. 2018;20:15223–35. https://doi.org/10.1039/C8CP01838C.

Albert J, Müller K. A group contribution method for the thermal properties of ionic liquids. Ind Eng Chem Res. 2014;53:17522–6. https://doi.org/10.1021/ie503366p.

Yunus NM, Abdul Mutalib MI, Man Z, Bustam MA, Murugesan T. Thermophysical properties of 1-alkylpyridinum bis(trifluoromethylsulfonyl)imide ionic liquids. J Chem Thermodyn. 2010;42:491–5.

Kurnia KA, Quental MV, Santos LMNBF, Freire MG, Coutinho JAP. Mutual solubilities between water and non-aromatic sulfonium-{,} ammonium- and phosphonium-hydrophobic ionic liquids. Phys Chem Chem Phys. 2015;17:4569–77. https://doi.org/10.1039/C4CP05339G.

Ziyada AK, Wilfred CD, Bustam MA, Man Z, Murugesan T. Thermophysical properties of 1-propyronitrile-3-alkylimidazolium bromide ionic liquids at temperatures from (293.15 to 353.15) K. J Chem Eng Data. 2010;55:3886–90. https://doi.org/10.1021/je901050v.

Kotov N, Raus V, Dybal J. Non-covalent interactions in bmimCl/co-solvent mixtures: a FTIR spectroscopy and computational study. J Mol Liq. 2019;285:688–96.

Bakthavatchalam B, Habib K, Saidur R, Shahabuddin S, Saha BB. Influence of solvents on the enhancement of thermophysical properties and stability of MWCNT nanofluid. Nanotechnology. 2020;31:235402.

Miranda A, Barekar N, McKay BJ. MWCNTs and their use in Al-MMCs for ultra-high thermal conductivity applications: a review. J Alloys Compd. 2019;774:820–40.

Xian HW, Sidik NAC, Saidur R. Impact of different surfactants and ultrasonication time on the stability and thermophysical properties of hybrid nanofluids. Int Commun Heat Mass Transf. 2020;110:104389.

Li X, Zeng G, Lei X. The stability, optical properties and solar-thermal conversion performance of SiC–MWCNTs hybrid nanofluids for the direct absorption solar collector (DASC) application. Sol Energy Mater Sol Cells. 2020;206:110323.

Bakthavatchalam B, Habib K, Saidur R, Saha BB, Irshad K. Comprehensive study on nanofluid and ionanofluid for heat transfer enhancement: a review on current and future perspective. J Mol Liq. 2020;305:112787.

Azarfar S, Movahedirad S, Sarbanha AA, Norouzbeigi R, Beigzadeh B. Low cost and new design of transient hot-wire technique for the thermal conductivity measurement of fluids. Appl Therm Eng. 2016;105:142–50.

Sezer N, Koç M. Stabilization of the aqueous dispersion of carbon nanotubes using different approaches. Therm Sci Eng Prog. 2018;8:411–7.

Kakavandi A, Akbari M. Experimental investigation of thermal conductivity of nanofluids containing of hybrid nanoparticles suspended in binary base fluids and propose a new correlation. Int J Heat Mass Transf. 2018;124:742–51.

Yellapu G, Vishal CVC, Kandoth MP, Saha P, Bojja RR, Gandham S, et al. Functionalized multi-walled carbon nanotubes based Newtonian nano fluids for medium temperature heat transfer applications. Therm Sci Eng Prog. 2019;12:13–23.

Rahimi A, Rahjoo M, Hashemi SS, Sarlak MR, Malekshah MH, Malekshah EH. Combination of dual-MRT lattice Boltzmann method with experimental observations during free convection in enclosure filled with MWCNT–MgO/water hybrid nanofluid. Therm Sci Eng Prog. 2018;5:422–36.

Li X, Chen W, Zou C. An experimental study on β-cyclodextrin modified carbon nanotubes nanofluids for the direct absorption solar collector (DASC): specific heat capacity and photo-thermal conversion performance. Sol Energy Mater Sol Cells. 2020;204:110240.

Marcos MA, Podolsky NE, Cabaleiro D, Lugo L, Zakharov AO, Postnov VN, et al. MWCNT in PEG-400 nanofluids for thermal applications: a chemical, physical and thermal approach. J Mol Liq. 2019;294:111616.

Acknowledgements

We thank Universiti Teknologi PETRONAS (UTP) for their financial assistance through YUTP grant (Grant no. 015LC0-118). The authors were also grateful to CORIL (Centre of Research in Ionic Liquids), UTP for their adequate support on analysing the samples.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bakthavatchalam, B., Habib, K., Wilfred, C.D. et al. Comparative evaluation on the thermal properties and stability of MWCNT nanofluid with conventional surfactants and ionic liquid. J Therm Anal Calorim 147, 393–408 (2022). https://doi.org/10.1007/s10973-020-10374-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10374-x