Abstract

The present study describes the thermal properties of a series of porous microspheres synthesised from the dimethacrylate derivative of m-xylene, i.e. (4,6-dimethyl-1,3-phenylene)dimethylene bis(2-methylprop-2-enoate) and divinylbenzene via an aqueous suspension polymerisation in the presence of toluene and decan-1-ol as porogenic diluents. Various molar ratios of monomers were applied in the syntheses (1:4, 1:1, 4:1). The TG/DSC/FTIR analyses were performed in inert (helium) and oxidative (synthetic air) atmospheres. They revealed that the properties of the copolymeric microspheres were dependent on both their chemical composition and the testing atmosphere. The microspheres were stable up to 229–296 °C (in helium) and 302–308 °C (in synthetic air), as determined on the basis of the temperature of 1% mass loss. However, the most thermally stable were those synthesised at the molar ratio of the dimethacrylate derivative of m-xylene to divinylbenzene equal to 1:4. In helium, the copolymeric beads decomposed in one, two or three stages, whereas in synthetic air in two ones. The basic decomposition volatiles were carbon monoxide, carbon dioxide and organic carbonyl products, including esters, carboxylic acids and aldehydes as well as unsaturated and aromatic compounds.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Porous polymeric microspheres are used in various medical and biological applications, such as blood flow indicators, adsorbents in extracorporeal therapy, cell culture and peptide synthesis media as well as carriers of biologically active substances [1,2,3]. Regular microspheres are also applied as column packings in different chromatography techniques [4,5,6,7,8,9]. In reversed-phase high-performance liquid chromatography (HPLC), the most common are styrene–divinylbenzene porous microspheres [10, 11]. They do not contain any functional groups and are hydrophobic. In order to obtain more polar polymers that generally exhibit higher selectivity, monomers with various functional groups, e.g. methacrylate [12, 13], pyrrolidone [14,15,16], amine [17, 18] and thio [18], can be applied.

Another drawback of the porous polymeric packings is the fact that they swell in organic solvents [11]. This is particularly inconvenient when solvent gradients are used. Our previous studies indicated that promising packings for chromatography column are those synthesised from two tetrafunctional monomers. They guarantee a high cross-linking degree and thus a smaller degree of swelling. As the tetrafunctional monomers divinylbenzene (DVB) and dimethacrylate derivatives of naphthalene [15, 19,20,21,22], diphenyl sulphone [20, 21, 23], benzene [23], diphenylmethane [24] and ethylene glycol [6] as well as bis(maleimido) derivative of diphenylmethane [20, 21] were used.

Additionally, the high cross-linking degree improves thermal stability of the obtained materials [25, 26]. It was also found that an aromatic cross-linker provides better thermal resistance compared with an aliphatic one which is particularly important in the case of gas chromatography as well as catalysis [15, 16].

This paper describes the thermal properties of the highly cross-linked microspheres synthesised from DVB and dimethacrylate derivative of m-xylene (DMX), i.e. (4,6-dimethyl-1,3-phenylene)dimethylene bis(2-methylprop-2-enoate), via an aqueous suspension polymerisation in the presence of toluene and decan-1-ol as pore-forming agents. The particular attention was paid to the influence of various molar ratios of monomers on these properties. They were evaluated on the basis of thermogravimetry coupled online with FTIR spectroscopy (TG/FTIR) and differential scanning calorimetry (DSC) under inert (helium) and oxidative (synthetic air) conditions.

Experimental

Materials

Poly(vinyl alcohol), α,α′-azobisisobutyronitrile (98%), DVB and decan-1-ol were obtained from Sigma-Aldrich (Germany), whereas toluene, acetone and methanol from POCh (Poland). The DMX monomer was prepared in our laboratory in accordance with the procedure described below. The following compounds (analytical reagent grade) were used for its synthesis: m-xylene, paraformaldehyde, hydrochloric acid (36–38%), ice acetic acid, ethanol (POCh, Poland), N,N-dimethylformamide (DMF), hydroquinone and potassium methacrylate (Sigma-Aldrich, Germany).

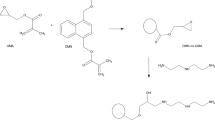

Synthesis of DMX

The synthesis was carried out in a 500-cm3 round-bottomed flask equipped with a thermometer, a mechanical stirrer and a heater. 27 g of m-xylene, 27.5 g of paraformaldehyde, 90.5 cm3 of hydrochloric acid and 65 cm3 of ice acetic acid were placed in the flask and heated at 85–90 °C for 6 h. Then, the mixture was cooled to room temperature, and the obtained dichloromethylene derivative of m-xylene was washed several times with water and then crystallised from ethanol. Next, 40.6 g of this compound was diluted in DMF and heated with 50.4 g of potassium methacrylate in the presence of hydroquinone as an inhibitor. The process was carried out at the boiling temperature of DMF and with vigorous stirring. The reaction product was poured into cold water. The precipitated DMX was crystallised from ethanol (m.p. = 140–145 °C).

Preparation of copolymers

Copolymerisation of DMX with DVB was conducted by an aqueous suspension polymerisation. To prepare a reaction medium, 195 cm3 of distilled water and 6.5 g of poly(vinyl alcohol) as the suspension stabiliser were stirred for 6 h at 80 °C in the three-necked flask equipped with a stirrer, a water condenser and a thermometer. Then, 15 g of mixture containing an appropriate mole fraction of DMX to DVB monomers (1:4, 1:1, 4:1) and 0.075 g of α,α′-azobisisobutyronitrile (0.5 mass% based on monomers) in the solution of 22.5 cm3 of pore-forming diluents (toluene and decan-1-ol (80:20 v/v)) were added while stirring in the aqueous medium. Copolymerisation was performed for 16 h at 80 °C. Porous microspheres formed in this process were filtered, washed with hot water and extracted in a Soxhlet apparatus with boiling acetone, toluene and methanol.

Testing methods

The chemical structure of the prepared copolymers was investigated by means of attenuated total reflectance Fourier transform infrared (ATR-FTIR). The infrared spectra were recorded with a Bruker Tensor 27 FTIR spectrometer (Germany) in the absorbance mode. The measurements were taken at room temperature. The main parameters were as follows: a resolution of 4 cm−1, the wavenumber region of 4000–600 cm−1 and 32 scans per spectrum.

Thermogravimetry (TG) together with differential scanning calorimetry (DSC) was carried out with a Netzsch STA 449 F1 Jupiter instrument (Germany) within the range of 30–1000 °C in helium or synthetic air atmospheres (flow = 20 cm3 min−1). The heating rate was held 10 °C min−1. The analyses were conducted in Al2O3 crucibles and copolymer samples weighted about 10 mg. At the same time, the gaseous FTIR spectra were collected by a Bruker Tensor 27 FTIR spectrometer (Germany) connected online with a Netzsch STA apparatus by the Teflon transfer line with a diameter of 2 mm heated to 200 °C. The spectra were gathered in the range of 4000–600 cm−1 with 16 scans per spectrum and a resolution of 4 cm−1.

In order to obtain more detailed DSC data, the investigations were additionally performed with a Netzsch 204 calorimeter (Germany) operating in the dynamic mode. The dynamic scans were carried out at the heating rate of 10 °C min−1 from 20 to 550 °C under argon atmosphere (flow = 20 cm3 min−1) in two cycles. The first cycle was done from 20 to 120 °C in order to remove any adsorbed moisture, mainly water, while the second one in the range of 20–550 °C. The samples of the tested materials (~ 7.5 mg) were placed in aluminium pans with a pierced lid. An empty aluminium pan was applied as a reference.

Results and discussion

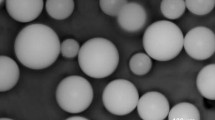

The aqueous suspension copolymerisation was applied to obtain the cross-linked porous microspheres of poly(DMX-co-DVB) with diameters in the range of 50–250 μm (Fig. 1). Various molar ratios of these tetrafunctional monomers were used in the syntheses. The designations of the obtained products are given in Table 1.

The ATR-FTIR analysis confirmed the assumed chemical structure of the copolymers. Namely, in the obtained spectra one can see bands typical of the ester group (at 1727–1724 cm−1 (ν C = O) and at 1134–1110 cm−1 (ν C–O–C)), methyl and methylene groups (at 2963–2932 cm−1 (νasym C–H) and at 2875–2874 cm−1 (νsym C–H)) and benzene ring (at 1605–1602 cm−1 (ν C–C) and at 833–709 cm−1 (δ C–H)). The bands at 1467–1450 cm−1 can originate from the vibrations of both methyl and methylene groups as well as benzene ring (Fig. 2).

In order to evaluate the thermal behaviour of the obtained porous copolymeric beads, the TG and DSC methods were applied. The studies were carried out in helium and synthetic air. Figures 3 and 4 show the TG and differential TG (DTG) curves obtained for these copolymers, while Table 1 gives the main parameters assessed on their basis. Furthermore, an analysis of volatiles emitted during the copolymers decomposition was conducted by TG/FTIR. The registered FTIR spectra are displayed in Figs. 5–11. In turn, the received DSC curves are presented in Figs. 12 and 13.

As it follows from DTG curves obtained in helium atmosphere, the decomposition of the copolymer with the lowest DMX-derived units content (poly(DMX-co-DVB)_1:4) proceeded in one step (with Tmax at 414 °C), whereas the decomposition of two remaining ones occurred in two or three steps. On the curve of poly(DMX-co-DVB)_1:1 copolymer peaks with Tmax at 378 °C (corresponding to 53% mass loss) and at 421 °C (corresponding to 37% mass loss) can be observed. On the other hand, the curve of poly(DMX-co-DVB)_4:1 copolymer exhibits peaks with Tmax at 351, 373 and 415 °C. These peaks are poorly resolved, but it is possible to approximate the mass losses corresponding to the decomposition steps. Thus, for the first and second steps the total mass loss equals ~ 70% and for the third one ~ 14%. From the comparison of all DTG data, it appears that the number of decomposition steps increased with the increase in DMX content. It can be assumed that the step with Tmax at 414–421 °C is associated with the decomposition of DVB-derived units, while the steps with Tmax at 351–378 °C can be ascribed to the decomposition of DMX-derived ones. Moreover, it was observed that the newly obtained materials are decomposed in around 90%. The highest residual mass (13.8%) was detected in the case of the copolymer containing the largest amount of DMX-based units.

Taking into account the T1, T20 and T50 values, one can say that the incorporation of a larger amount of DMX-based units in the material structure deteriorates the thermal stability of the synthesised copolymers. A particularly significant drop is observed in the case of T1 values (from 296 °C for poly(DMX-co-DVB)_1:4 to 229 °C for poly(DMX-co-DVB)_4:1) and T20 values (from 393 °C for poly(DMX-co-DVB)_1:4 to 345 °C for poly(DMX-co-DVB)_4:1). This is caused by the presence of a significant content of less thermally stable ester groups. Generally, it can be stated that the decomposition of methacrylate-derivative materials begins with the degradation of the ester groups [27]. As a result, CO2, CO, aldehydes and alcohols can be formed. The cross-linked network of the copolymers which contain aromatic rings decomposes at higher temperatures. To confirm these assumptions, the analysis of decomposition volatiles was conducted.

The FTIR spectrum registered during the decomposition of poly(DMX-co-DVB)_1:4 (Tmax at 414 °C) presented in Fig. 6 shows the absorption peak (at 1765 cm−1—ν C = O) which can be attributed to the carbonyl products. The other peaks indicate the presence of aldehydes (at 2725 cm−1—ν C–H of the aldehyde group), esters (at 1124 cm−1—ν C–O of the ester group) and carboxylic acids (at 3240 cm−1—ν O–H of the carboxylic group). Bands at 2974–2885 cm−1 assigned to the C–H stretching vibrations of the methyl and methylene groups are also visible. Moreover, one can see the peaks at 3093 and 3058 cm−1 which can come from aromatic and unsaturated products (ν C–H). The creation of unsaturated compounds is also manifested by the peaks at 1631 cm−1 (ν C = C), 3017 cm−1 (ν = CH–) and 989 and 910 cm−1 (δoop C–H of the vinyl group). In turn, the bands at 1600 cm−1 (ν C–C of the benzene ring) and 836 and 795 cm−1 (δoop C–H of the disubstituted benzenes) confirm the existence of aromatic compounds. In turn, the absorption peak at 3591 cm−1 is due to the O–H stretching vibrations, while that at 1060 cm−1 is characteristic of the C–OH stretching vibrations. Both these peaks point to the presence of alcohols. Also, in the spectrum there appear bands typical of H2O (at ~ 4000–3600 cm−1), CO2 (at 2359–2310 cm−1 and 669 cm−1) and CO (at 2176 and 2113 cm−1).

The FTIR spectra from the first (Tmax at 378 °C) and second (Tmax at 421 °C) decomposition steps of poly(DMX-co-DVB)_1:1 are shown in Fig. 7. Similarly to the spectrum of poly(DMX-co-DVB)_1:4 they display the adsorption peaks originating from CO2, CO, H2O, carbonyl and aromatic compounds, alkenes and alcohols. The incorporation of a larger amount of DMX units resulted in the appearance of additional peaks, at 1508 and 1458 cm−1. The former is due to the C–C stretching vibrations of the benzene ring, whereas the latter can be attributed to both the C–H deformation vibrations of the methyl group and the C–C stretching vibrations of the benzene ring. Comparing the intensity of the absorption bands at 1772 and 1125 cm−1, one can state that in the second decomposition step there is a significantly smaller amount of carbonyl compounds, including esters. Moreover, in this step slighter amounts of unsaturated products are detected.

In the FTIR spectra received for poly(DMX-co-DVB)_4:1 copolymer (Fig. 8), one can see almost the same bands as for poly(DMX-co-DVB)_1:1 one. This indicates that as a rule, the decomposition of these materials was connected with the evolution of the same compounds. The differences occur only in the amounts of the generated products (different peak intensities). The differences in the peak intensities are also present in the particular steps of poly(DMX-co-DVB)_1:4 copolymer decomposition. In the second step, one can notice smaller amounts of CO2, alcohols and carbonyl compounds, among others esters in comparison with the first one. In turn, in the third step one can observe a further decrease in the amounts of the above mentioned substances as well as unsaturated compounds, while the amount of aromatic ones increases (the increase of peaks at 821–750 cm−1).

In the synthetic air atmosphere, all the investigated copolymeric beads are decomposed in two steps. The DTG curves (Fig. 4) exhibit two partially overlapped peaks with Tmax at 323–336 and 478–486 °C, with a higher intensity of the lower-temperature one. These peaks correspond to ~ 47–53 and 43–48% mass losses. The first decomposition step can be connected with the thermal degradation of methacrylate bonds and immediate oxidation of newly created products, while the second one is probably associated with the oxidation process of the remaining cross-linked part which can be confirmed by the detailed analysis of FTIR spectra (Figs. 9–11). On the basis of this analysis, it can be stated that all copolymers in the first step are decomposed with the emission of CO2, CO, H2O, organic carbonyl products (mainly esters and aldehydes) as well as unsaturated and aromatic ones. In turn, in the second step their degradation was associated with the evolution of only CO2 and CO, but their amounts were higher.

Similarly to the situation in helium atmosphere, the larger amount of DMX-based units, the worse thermal stability of the synthesised copolymers (lower T1, T20 and T50). However, in the case of T1 and T20 values the differences were relatively small (Table 2). When it comes to the residual masses, it can be said that the studied materials were more degraded in synthetic air than in helium (~ 5–8 vs. ~ 9–14%).

As it was mentioned earlier, the thermal behaviour of the copolymers was also monitored by the means of the DSC analysis. The DSC curves of the copolymers under study measured in helium are shown in Fig. 12. In the case of poly(DMX-co-DVB)_4:1 copolymer, the first endothermic peak with the maximum at 332 °C can be attributed to the decomposition of mainly ester bonds originating from the functional monomer (DMX). Unsaturated compounds produced in this reaction can undergo the cross-linking process. As a result, an exothermic peak with the maximum at 360 °C appears. After that, the decomposition of the cross-linked part of the copolymeric matrix based mainly on DVB takes place which is represented by endothermic peaks with the maxima at 400 and 421 °C [19]. On the DSC curve of poly(DMX-co-DVB)_1:1 copolymer, only two superimposed endothermic peaks are observed. The first one with the maximum at 384 °C is associated with the thermal degradation of functional groups originated from DMX, whereas the second one with the maximum at 420 °C can be a result of the decomposition process of the cross-linked part of the copolymer. During the examination of poly(DMX-co-DVB)_1:4, two peaks of opposite energetic effects occur. As it was reported [25], copolymers based mainly on DVB contain a significant amount of unreacted bonds; so the exothermic peak with the maximum at 219 °C can be ascribed to the cross-linking reaction of double bonds located inside microspheres. In turn, an endothermic peak with the maximum at 404 °C is connected with the thermal degradation of entire polymer matrix. Due to the fact that this copolymer is considerably enriched in DVB-derived units, only one peak is visible on the DSC curve.

In the oxidative atmosphere for all the copolymers under study, the DSC curves possess a similar course (Fig. 13). Two exothermic peaks can be observed. Their maxima are in accordance with the decomposition maxima determined on the basis of DTG curves. The first one with the maximum at 329–344 °C can be associated with oxidative degradation of mostly ester bonds. The second one (maximum at 480–486 °C) can be ascribed to oxidative processes that take place in the cross-linked part of the copolymers.

Conclusions

Porous copolymers poly(DMX-co-DVB) were synthesised via the radical suspension polymerisation in the presence of the toluene and decan-1-ol mixture as porogenic diluents. To introduce a significant amount of methacrylate groups, the molar ratios of DMX to DVB (1:4, 1:1, 4:1) were increased in the syntheses. The utilisation of dimethacrylate derivative of m-xylene (DMX) is advantageous because it allows to obtain copolymers of more polar character compared with hydrophobic styrene–divinylbenzene commonly used in various chromatographic techniques. What is more, the copolymers derived from DMX are generally also more thermally stable in relation to the earlier described materials based on DMN [15, 17, 19]. This is especially beneficial because it broadens the range of their applications of techniques requiring a high thermal resistance. The temperatures of 1% mass loss of the copolymers under study were contained in the range of 229–296 °C (in helium) and 302–308 °C (in synthetic air). Unfortunately, the significant increase in the DMX amount in the polymerisation mixture caused the deterioration of the thermal stability of the synthesised copolymers. The degradation patterns showed two degradation steps in synthetic air. On the other hand, in helium atmosphere the number of degradation steps increased from 1 to 3 along with the increasing DMX-derived units. The analysis of decomposition volatiles pointed out that the formation of CO2, CO, organic carbonyl compounds (esters, carboxylic acids and aldehydes) and aromatic and unsaturated products took place. These types of substances were also detected for the familiar copolymeric beads [14, 15, 17, 19]. The thermal behaviour of the copolymers under study determined by the DSC method is generally in accordance with the decomposition patterns determined on the basis of DTG curves.

References

Jagur-Grodzinski J. Biomedical application of functional polymers. React Funct Polym. 1999;39:99–138.

Malik DJ, Webb C, Holdich RG, Ramsden JJ, Warwick GL, Roche I, Williams DJ, Trochimczuk AW, Dale JA, Hoenich NA. Synthesis and characterization of size-selective nanoporous polymeric adsorbents for blood purification. Sep Purif Technol. 2009;66:578–85.

Fan S, Luan Y, Wang J, Gao H, Zhang X, Wang G. Monodispersed poly (4-vinylpyridine) spheres supported Fe(III) material: an efficient and reusable catalyst for benzylic oxidation. J Mol Catal A Chem. 2015;404–405:186–92.

Benson JR, Woo DJ. Polymeric columns for liquid chromatography. J Chromatogr Sci. 1984;22:386–99.

Unsal E, Irmak T, Tuncel M. Monodisperse poly (styrene-co-divinylbenzene) particles (3.2 μm) with relatively small pore size as HPLC packing material. Chromatographia. 2004;60:553–60.

Maciejewska M, Osypiuk J, Gawdzik B. Preparation and characterization of the chromatographic properties of ethylene glycol dimethacrylate/divinylbenzene polymeric microspheres. J Polym Sci A Polym Chem. 2005;43:3049–58.

Puziy AM, Poddubnaya OI, Gawdzik B, Sobiesiak M, Reinish CA, Tsyba MM, Segeda TP, Danylenko MI. Nanostructured carbons for solid phase extraction. Appl Surf Sci. 2010;256:5216–20.

Sobiesiak M, Podkościelna B. Preparation and characterization of porous DVB copolymers and their applicability for adsorption (solid-phase extraction) of phenol compounds. Appl Surf Sci. 2010;257:1222–7.

Grochowicz M, Szajnecki Ł, Gawdzik B. 4VP-TRIM composite polymer particles and their application as adsorbents. Adsorpt Sci Technol. 2015;33:609–16.

Yu B, Tian C, Cong H, Xu T. Synthesis of monodisperse poly (styrene-co-divinylbenzene) microspheres with binary porous structures and application in high-performance liquid chromatography. J Mater Sci. 2016;51:5240–51.

Liu Q, Wang L, Xiao A. Research progress in macroporous styrene-divinylbenzene co-polymer microspheres. Des Monomers Polym. 2007;10:405–23.

Fila K, Bolbukh Y, Goliszek M, Podkościelna B, Gargol M, Gawdzik B. Synthesis and characterization of mesoporous polymeric microspheres of methacrylic derivatives of aromatic thiols. Adsorption. 2019;25:429–42.

Fila K, Grochowicz M, Podkościelna B. Thermal and spectral analysis of copolymers with sulphur groups. J Therm Anal Calorim. 2018;133:489–97.

Maciejewska M, Rogulska M. Synthesis and characterization of VP–DMN polymeric sorbents. Adsorption. 2019;25:419–27.

Maciejewska M. Synthesis and thermal properties of parent and modified DMN–co-GMA copolymers. J Therm Anal Calorim. 2018;133:969–80.

Maciejewska M. Characterization of macroporous 1-vinyl-2-pyrrolidone copolymers obtained by suspension polymerization. J Appl Polym Sci. 2012;124:568–75.

Maciejewska M, Rogulska M. Insight into functionalized DMN-co-GMA copolymers: part I. Modification with diethylenetriamine. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08327-0.

Donia AM, Atia AA, Elwakeel KZ. Gold(III) recovery using synthetic chelating resins with amine, thio and amine/mercaptan functionalities. Sep Purif Technol. 2005;42:111–6.

Gawdzik B, Rogulska M, Grochowicz M, Osypiuk-Tomasik J. Studies of thermal properties of di(methacryloyloxymethyl)naphthalene–divinylbenzene (DMN–DVB) copolymer and its alkyl-bonded derivatives. J Therm Anal Calorim. 2019;138:4385–93.

Gawdzik B, Osypiuk J. Reversed-phase high-performance liquid chromatography on porous copolymers of different chemical structure. J Chromatogr A. 2000;898:13–21.

Gawdzik B, Osypiuk J. Characterization of the porous structure of polymeric packings for HPLC. Chromatographia. 2001;54:595–9.

Bolbukh YM, Kuzema PO, Tertykh VA, Gawdzik B. Effect of surface hydride, vinyl, and methyl groups on thermal stability of modified silica-divinylbenzene-di (methacryloyloxymethyl) naphthalene composites. Int J Polym Mater. 2007;56:803–23.

Gawdzik B, Maciejewska M. Studies on the selectivity of porous methacrylate polymers. Adsorpt Sci Technol. 2002;20:523–9.

Maciejewska M, Gawdzik B. Preparation and porous structure characterization of 4,4′-diphenylmethane dimethacrylate-divinylbenzene polymeric particles. J Appl Polym Sci. 2005;95:863–7.

Li Y, Fan Y, Ma J. Thermal, physical and chemical stability of porous polystyrene-type beads with different degrees of crosslinking. Polym Degrad Stab. 2001;73:163–7.

Li Y, Fan Y, Ma J. The thermal properties of porous polydivinylbenzene beads. React Funct Polym. 2002;50:57–65.

Grochowicz M. Investigation of the thermal behavior of 4-vinylpyridine-trimethylolpropane trimethacrylate copolymeric microspheres. J Therm Anal Calorim. 2014;118:1603–11.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rogulska, M., Gawdzik, B. & Maciejewska, M. TG/DSC/FTIR study of porous copolymeric beads based on the dimethacrylate derivative of m-xylene. J Therm Anal Calorim 141, 1351–1360 (2020). https://doi.org/10.1007/s10973-019-09143-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-09143-2