Abstract

Temperature dependencies of the DC conductivity of mixtures of kaolin and quartz were measured in the temperature range of 20–1200 °C. During heating, several processes take place in the sample—release of the physically bound water (PBW), dehydroxylation of kaolinite, the α → β transition of quartz, and the creation of Al–Si spinel. These processes were studied using differential thermal analysis, thermogravimetry, thermodilatometry, and DC conductivity measurement. At temperatures < 200 °C, H+ and OH− ions are the dominant charge carriers in the DC conductivity due to the release and dissociation of PBW. After the release of PBW, and up to the start of dehydroxylation (~ 500 °C), the DC conductivity is dominated by the transport of Na+ and K+ ions. During dehydroxylation, OH− ions, which are released from the kaolinite lattice, contribute to the DC conductivity. However, the association of OH− ions with mobile alkali metal ions into neutral complexes, as well as depletion of OH− source, results in a deceleration of the increase in the DC conductivity at 500 °C. After the dehydroxylation is completed, alkali metal ions become again the dominant charge carriers. At temperatures above the dehydroxylation region, the DC conductivity slightly decreases with the increasing quartz content. A narrow peak of the DC conductivity observed at 960 °C can be linked to the motion of Al3+ cations into new sites as the metakaolinite collapses. The DC conductivity of different mixtures did not differ significantly. Quartz and grog have lower conductivities than kaolin. Thus, the conduction was determined by the kaolin matrix (60 mass%).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Traditional kaolin-based ceramic materials usually contain a significant amount of quartz particles. The presence of quartz in ceramics, especially in porcelain, is a continuous object of ceramic research, e.g., [1,2,3,4]. Mechanical properties of ceramics are strongly influenced by its microstructure, in which quartz grains play an important role. For example, it is known that residual quartz grains have a negative influence on the strength of porcelain [1, 2]. It is generally believed that microcracks around quartz grains are the result of the release of mechanical stress caused by the difference in the thermal expansion of the quartz grains and that of the glass matrix during the cooling stage of the firing. It is also assumed that the formation of microcracks vanishes during the β → α transition of the quartz grains. This transition is accompanied by a 0.68% volume contraction during cooling [1, 2, 5,6,7]. Our previous results [8] showed that microcracking begins just after reaching the glass transition temperature.

The linear contraction of kaolin (96 mass% of kaolinite) during its heating reaches significant values, e.g., 7.2% at 1100 °C, 10.5% at 1200 °C, and 13.5% at 1300 °C [9]. To decrease this contraction and to increase the stability of the dimensions of the ceramic product during firing, quartz sand is added to the ceramic mixture [6, 10,11,12]. Moreover, quartz particles improve the compressive strength [13].

Recent ceramic technologies apply electrical field to support sintering, which increases the importance of understanding the DC and AC conductivities of raw ceramics. From the electrical point of view, quartz is a good electrical insulator with conductivity ~ 10−17 S m−1 [14, 15]. The object of the present work is to study the influence of quartz content in a quartz–kaolin mixture during heating up to 1100 °C. Differential thermal analysis, thermogravimetry, and thermodilatometry were used to study the thermal processes during heating of kaolin–quartz mixtures. Special attention was paid to the DC conductivity measurements during heating of the mixtures. To the authors’ knowledge, the influence of quartz addition on the DC conductivity of kaolin has not been studied before. Knowledge of conduction behavior of raw ceramic components at high temperatures enables a more accurate control of the composition of the material and furnace temperature in modern energy-saving methods of production of ceramics (e.g., flash sintering).

Experimental

Samples were prepared from kaolin (see Table 1) supplied by the mine in Sedlec (Czech Republic), grog (kaolin fired at 1100 °C for 2 h), and quartz. All components were milled and sieved to obtain powder with particle size below 100 µm. Dry mixtures were prepared from powders with different content of kaolin, grog, and quartz (see Table 2). To obtain a plastic mass, the dry mixtures were mixed with ~ 35 mass% of distilled water.

For the DC conductivity measurements, the plastic mass was pressed in a mold together with the electrodes. The sample had a rectangular shape of 10 × 10 × 20 mm, and two parallel platinum wires (Ø 0.4 mm) served as electrodes. The distance between the electrodes was 3 mm (see Fig. 1). This arrangement was chosen in order to minimize the surface electric current of the sample [16]. After free drying in the ambient atmosphere, the samples were preheated at 120 °C for 1 h and then heated up to 1100 °C with heating rate 5 °C min−1 in static air. The measuring circuit (serial connection of the voltage source, the sample, and the electrometer [17]) was fed with the DC power supply Tesla BS 525 with voltage of 10 V. Electrical current was measured and recorded using the electrometer Keithley 6514, which was directly connected to the computer.

Differential thermal analysis (DTA) and thermogravimetry (TG) were performed on rectangular samples with dimensions of 10 × 10 × 20 mm with the initial mass of ~ 3.5 g using the upgraded derivatograph (MOM Budapest) DTA/TG analyzer [18] in static air atmosphere. The samples were heated up to 1050 °C, with heating rate of 5 °C min−1. To ensure the same initial conditions for all used mixtures, all samples were preheated at 120 °C for 1 h and then placed in a desiccator where they were cooled to the room temperature before taking the measurements.

Thermodilatometric analysis (DIL) was carried out on samples with dimensions 8 × 8 × 20 mm using the horizontal push rod dilatometer Netzsch DIL 402C under a flow of 40 mL min−1 of N2 gas. The samples were preheated at 120 °C for 1 h, and then the measurements were performed in the temperature range from 120 to 1100 °C, with the heating rate of 5 °C min−1.

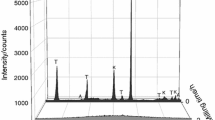

Microstructure observations were made using the FEI Quanta 200F electron microscope in the low vacuum mode (10 Pa) with an accelerating voltage of 15 kV. Micrographs were taken from the fracture area on both the raw and the fired samples.

Results and discussion

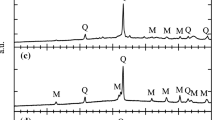

Simultaneous thermal analyses DTA and TG (Figs. 2 and 3) showed differences in the processes occurring in the samples during the heating. Major changes were observed in the temperature region from 500 to 650 °C where the kaolinite dehydroxylation takes place. The shift of the peak in the DTA curves to lower temperatures is obvious for all the prepared mixtures (KGQ0–KGQ40). This was caused by the reduced amount of kaolinite in the prepared mixtures (compared to the SLA sample). Dehydroxylation leads to a thermal decomposition of the kaolinite lattice, and the chemically bound OH groups are removed. As a result, the XRD amorphous metakaolinite phase is formed [19]. The mass loss during this process, corresponding to the mass of the OH groups in the sample, reaches 13.96% for the stoichiometric kaolinite [20]. The prepared mixtures exhibited a 7.28% ± 0.04% mass loss (independently on their composition) in the dehydroxylation region (see Fig. 3). The transition of α-quartz to β-quartz, which takes place at 573 °C, was superimposed on the DTA curves by dehydroxylation. The area of the endothermic minimum is the same for KGQ0–KGQ40, i.e., the enthalpy of dehydroxylation is driven only by the kaolinite part of the mixture. At around 950 °C, a sharp exothermic peak represents the transformation of metakaolinite to Al–Si spinel [21]. The heat effect of this reaction decreased for all samples compared to the SLA sample, which was caused by the lower amount of kaolinite in the prepared mixtures. The quartz addition had no major influence on the DTA results because of the difference between the enthalpy of kaolinite dehydroxylation (220 kJ mol−1, [22]) and the α → β transition of quartz (45 kJ mol−1, [23]), as well as a small part of quartz in the mixture.

The overall mass change of the samples dropped as the amount of kaolinite was reduced, but remained unchanged with respect to the quartz content. This means that the mass change was affected only by the kaolinite content of the samples.

Thermal expansion (Fig. 4) of the samples was observed up to 500 °C (550 °C for SLA). It was the most pronounced for the KGQ40 and the least for the KGQ0 sample. The sample with the highest content of kaolinite (SLA) exhibited a ~ 0.25% thermal expansion. As dehydroxylation proceeded, contraction of samples was observed, which was the most pronounced for the SLA sample. The moderate contraction ended at 850 °C, reaching 1% for SLA. A jump-like expansion at ~ 573 °C represents the α → β transition of quartz [24]. This feature became observable as the amount of quartz in the samples exceeded 10% (KGQ20, KGQ30 and KGQ40). Transformation of metakaolinite to Al–Si spinel resulted in a steep contraction of the samples’ dimensions. For the SLA sample, this contraction reached 1.5%. The prepared mixtures exhibited lower shrinkage due to the increased amount of quartz content. Quartz changes its crystalline structure from trigonal to hexagonal during the α → β transition, thus increasing its volume by 0.82% [6, 24]. The sample’s expansion became more pronounced as the amount of quartz increased and led to a decrease in the overall shrinkage above 600 °C. The overall linear shrinkage of the samples decreased from ~ 2.9% (SLA) to ~ 0.3% (KGQ40) at 1100 °C.

Differences were found in the final microstructure of the SLA and KGQ40 samples. Quartz grains were built into the kaolinite matrix in the sample KGQ40 (Fig. 5).

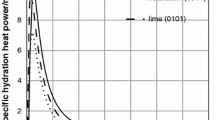

Temperature dependencies of the DC conductivities of the mixtures (Fig. 6) did not differ significantly. All samples exhibited the same characteristic features. Although the samples were preheated at 120 °C for 1 h, the effect of the water introduced during the sample preparation had not been eliminated, and it differed for various samples. In the low-temperature region (up to 200 °C), the dominant charge carriers are the products of the PBW dissociation, H+ and OH− ions. In the SLA samples, containing 100 mass% of kaolin, the DC conductivity and the content of PBW were the highest. In samples with the highest concentration of grog, the DC conductivity and the content of PBW were the lowest. At ~ 200 °C, when the PBW was removed, the minimum of the DC conductivity was reached. Above this temperature, the DC conductivity of all samples increased, and the temperature dependence of the conductivity showed 4 exponential sections, which can be described with the equation

where σ represents the DC conductivity, σ0 is the pre-exponential factor, Eσ is the conduction activation energy, k is the Boltzmann constant, and T is the thermodynamic temperature. In the temperature interval from 200 to 350 °C, the main charge carriers were loosely bound alkali ions (K+ and Na+) [25]. In this region, the activation energy of the DC conductivity (Eσ) varied non-systematically from 0.70 eV (SLA) to 0.75 eV (KGQ40), going through the maximum of 0.89 eV (KGQ10). These values corresponded well to the conduction activation energies of alkali ions in silicates. In the pre-dehydroxylation region (350–500 °C), the alkali metal ions were the main charge carriers. However, as the temperature approached 500 °C, these charge carriers were complemented by OH− ions released from the kaolinite structure. Therefore, the conduction activation energy increased in this region (Tab. 3). As dehydroxylation proceeded (500–730 °C), the amount of these ions decreased, thus leading to a deceleration in the increase in the DC conductivity, and a saddle point in the temperature dependence of the conductivity at 500 °C was observed. In addition to dehydroxylation, at 573 °C, the α → β transition of quartz took place. The electrical conductivity did not exhibit any abrupt changes near the α → β transition temperature [26]. Once the dehydroxylation was completed, the dominant charge carriers became alkali ions (K+ and Na+) and the conduction activation energy decreased due to a high defective metakaolinite in which these carriers moved. The conduction activation energies in the temperature interval (730–840 °C) varied from 0.39 eV (SLA) to 0.38 eV (KGQ40), going through the minimum of 0.21 eV (KGQ10) (Table 3). A small peak in the temperature dependence of the DC conductivity at ~ 980 °C manifested the transformation of metakaolinite to Al–Si spinel [25]. The small maximum of the DC conductivity was caused by short shifts of Al3+ ions when the metakaolinite lattice collapsed [25]. Above 1000 °C, only minor differences in the DC conductivities of the samples were observed; with the increasing quartz content, the conductivity slightly decreased.

The only minor differences between the temperature dependences of the DC conductivity of different mixtures resulted from the fact that the DC conductivity was determined by the kaolin fraction (60 mass%). The influence of quartz, which is a good insulator, and the grog, whose DC conductivity is by 2–3 orders of magnitude smaller than that of kaolin [27], was not observed in the current study because the quartz and the grog particles were embedded in the kaolin matrix. Thus, the kaolin matrix is a basic conductor in the samples.

Conclusions

Samples prepared from a mixture of kaolin (60 mass%), grog (0–40 mass%), and quartz (0–40 mass%) were investigated during heating using DTA, TGA, DIL, and DC conductivity measurements. It was found that

The amount of quartz and grog in the mixture does not influence the mass loss caused by dehydroxylation. The mass loss is determined only by the release of the OH groups from kaolinite.

The enthalpy of the dehydroxylation remains unchanged with respect to the amount of grog and quartz in the mixture. The enthalpy is determined only by the part of the kaolinite in the mixture. The same applies for the metakaolinite → Al–Si spinel transformation around 950 °C.

The sample expansion depends on the amount of grog and quartz significantly. The shrinkage above 500 °C decreases when the grog part or the quartz part increases.

The relationship between the DC conductivity and the temperature has almost the same course for each kaolin–grog–quartz composition. The electrical conductivity is driven mainly by the kaolin component.

The temperature dependence of the DC conductivity is very similar across all samples and has the following crucial features: the release of the physically bound water and its dissociation at low temperatures, 4 exponential sections, a saddle point at dehydroxylation, and a sharp peak at the metakaolinite-spinel transition.

Only small differences were observed between the DC conductivities of different samples. These resulted from the fact that quartz acts as an insulator and the conductivity of grog is by 2–3 orders of magnitude lower than that of kaolin.

References

Liebermann J. About the important correlation between microstructure properties and product quality of strength-stressed high-voltage insulators [Über den wichtigen zusammenhang von gefügeeigenschaften und produktqualität bei festigkeitsbeonspruchten hochsponnungsisolo. Keram Z. 2002;54:858–61.

Liebermann J. Avoiding quartz in alumina porcelain for high-voltage insulators, Part 2. Am Ceram Soc Bull. 2001;80:43–8.

Dal Bó M, Cantavella V, Sanchéz E, Gilabert FA, Boschi AO, Hotza D. An estimate of quartz content and particle size in porcelain tiles from young’s modulus measurements. Ceram Int. 2016;43:2233–8.

Selli NT, Tunali A. Role of the quartz particles on stain resistance of the polished porcelain tiles. Acta Phys Pol, A. 2014;125:506–8.

Oliveira APND, Vilches ES, Soler VC, Villegas FAG. Relationship between Young’s modulus and temperature in porcelain tiles. J Eur Ceram Soc. 2012;32:2853–8.

Hlaváč J. Technology of silicates. Praha: SNTL; 1981.

Knapek M, Húlan T, Minárik P, Dobroň P, Stubňa I, Stráská J, et al. Study of microcracking in illite-based ceramics during firing. J Eur Ceram Soc. 2016;36:221–6.

Chmelík F, Trník A, Štubňa I, Pešička J. Creation of microcracks in porcelain during firing. J Eur Ceram Soc. 2011;31:2205–9.

Hanykýř V, Havrda J, Trávníček Z. Specialized technology of ceramics II. Praha: VŠCHT; 1989.

Hanykýř V, Kutzendörfer J. Technology of ceramics. Praha: Silikátový svaz; 2008.

Pospíšil Z, Koller A. Fine ceramics: introduction and basics of technology. Praha: SNTL; 1981.

Pytlík P, Sokolář R. Building ceramics—technology, properties and application. Brno: Akademické nakladatelství CERM, s.r.o; 2002.

Yousefi E, Majidi B. Effects of free quartz on mechanical behaviour of kaolinite based geopolymers. Mater Technol. 2011;26:96–9.

Bleaney BI, Bleaney B. Electricity and magnetism. 3rd ed. London: Oxford University Press; 1976.

Halpren A, Erlbach E. Schaum’s outline of beginning physics II. New York: McGraw-Hill Education; 1998.

Štubňa I, Trnovcová V, Vozár L, Csáki Š. Uncertainty of the measurement of DC conductivity of ceramics at elevated temperatures. J Electr Eng. 2015;66:34–9.

Blumenthal RN, Seitz MA. Electrical conductivity in ceramics and glass. In: Tallan NM, editor. Experimental Tech. New York: M. Dekker; 1974.

Podoba R, Trník A, Podobník Ľ. Upgrading of TGA/DTA analyzer derivatograph. Építőanyag. 2012;64:28–9.

Ptáček P, Frajkorová F, Šoukal F, Opravil T. Kinetics and mechanism of three stages of thermal transformation of kaolinite to metakaolinite. Powder Technol. 2014;264:439–45.

Štubňa I, Varga G, Trník A. Investigation of kaolinite dehydroxylations is still interesting. Epa J Silic Based Compos Mater. 2006;58:6–9.

Ptáček P, Šoukal F, Opravil T, Nosková M, Havlica J, Brandštetr J. The kinetics of Al–Si spinel phase crystallization from calcined kaolin. J Solid State Chem. 2010;183:2565–9.

Frost RL, Vassallo AM. The dehydroxylation of the kaolinite clay minerals using infrared emission spectroscopy. Clays Clay Miner. 1996;44:635–51.

Hosieni KR, Howald RA, Scanlon MW. Thermodynamics of the lambda transition and the equation of state of quartz. Am Miner. 1985;70:782–93.

Prjanishnikov VP. System of silica. Leningrad: Strojizdat; 1971.

Podoba R, Štubňa I, Trnovcová V, Trník A. Temperature dependence of DC electrical conductivity of kaolin. J Therm Anal Calorim. 2014;118:597–601.

Wang D, Li H, Yi L, Matsuzaki T, Yoshino T. Anisotropy of synthetic quartz electrical conductivity at high pressure and temperature. J Geophys Res. 2010;115:B09211.

Trnovcová V, Podoba R, Štubňa I. DC conductivity of kaolin-based ceramics in the temperature range 20–600 & #xB0;C. Epitoanyag. 2012;2012:46–9.

Acknowledgements

This work was supported by the Constantine the Philosopher University grant agency [UGA VII/17/2018]. Authors are indebted to the ceramic plant PPC Insulators Čab (Slovakia) for the supply of kaolin.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ondruška, J., Csáki, Š., Štubňa, I. et al. Investigation of kaolin–quartz mixtures during heating using thermodilatometry and DC thermoconductometry. J Therm Anal Calorim 139, 833–838 (2020). https://doi.org/10.1007/s10973-019-08476-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08476-2