Abstract

The values of the standard molar energies of combustion of Tetra-N-phenylbenzidine and 4,4′-Bis(N-carbazolyl)-1,1′-biphenyl in solid phase were obtained experimentally using an isoperibolic semi-micro combustion calorimeter. The calorimeter was calibrated with benzoic acid NIST 39j and tested with 1,2,4-triazole. The molar enthalpies of combustion in oxygen, at T = 298.15 K and pº = 0.1 MPa were (− 18,522.4 ± 12.1) and (− 18,114.4 ± 12.5) kJ mol−1, respectively. The corresponding standard molar enthalpies of formation were derived as: (354.4 ± 12.9) and (518.1 ± 13.4) kJ mol−1. The vaporization enthalpies of the compounds were obtained by thermogravimetry, and these values were used to derive the enthalpies of formation in gaseous phase.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The depletion of fossil fuel sources and the relentless pollution that accompanies global warming show the need to have clean and economic renewable sources of energy. The sun is a renewable, clean and inexpensive source of energy. However, the technology available for its use is based on photovoltaic cells that use inorganic semiconductors and toxic materials such as silicon [1].

The pioneering work of Tang and VanSlyke generated an increasing investigation in the use of organic materials for solar cells, with new approaches in the construction and characterization of these materials, leading to the design of organic and hybrid devices such as organic diodes emitting light (OLEDs) and organic photovoltaic (OPVs) cells among others [2, 3]. These devices are promising because they can use organic compounds of low molar mass and can be manufactured of flexible thin layer and large surface area [4]. Polymers and conjugated oligomers derived from triphenylamine and carbazole can be used as organic semiconductors. These compounds are investigated because they offer a wide range of applications by the capacity in the transport of holes in devices OLEDs and OPVs [5,6,7].

Other compounds derived from carbazole and triphenylamine with recent interest in being used as transport of holes in devices OLEDs and OPVs are Tetra-N-phenylbenzidine (TPB) and 4,4′-Bis (N-carbazolyl)-1,1′-biphenyl (BCB), respectively. The reason for the interest in these molecules is centered on the nitrogen atom present in both molecules. This atom has the capacity of electron donor and activates the molecules to be combined with a large number of functional groups which allows the structures of the compounds to have a better solubility and a greater adjustment of their electronic and optical properties [8].

Several works have been dedicated to the improvement of these materials looking for high luminous efficiency, durability and improvement in the manufacturing processes. However, despite having several applications and being extensively studied, their thermochemical properties are insufficient to perform a complete thermodynamic study. These properties are of great importance because one of the main reasons for the degradation of OLEDs and OPVs is the change in structure of the organic layers caused by the heating Joule effect [9, 10].

In this paper, the thermochemical properties in solid and gaseous phase of TPB and BCB are presented. These properties were determined experimentally using combustion calorimetry and thermal analysis techniques such as differential scanning calorimetry and thermogravimetry.

Experimental

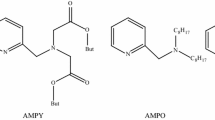

Differential scanning calorimetry

Figure 1 shows the structures of the compounds studied in this work. The compounds are Sigma-Aldrich with purity reported by the supplier equal to 97% for Tetra-N-phenylbenzidine and 99.9% for 4,4′-Bis (N-carbazolyl)-1,1′-biphenyl. Due to the low purity of TPB, it was purified by recrystallization using a 30% chloroform, 60% ethanol and 10% ethyl acetate mixture. For the BCB, it was not necessary to purify it and the purity reported by the supplier was corroborated.

In order to determine with accuracy of the thermodynamic properties of the compounds, the purities of TPB and BCB were verified by differential scanning calorimetry (DSC) and using the van’t Hoff equation, which relates the decrease in the melt temperature of the pure component to the amount of impurity involved. The purity, melting temperature and enthalpy of fusion of the compounds were assessed using a DSC Q2000 de TA Instrument of heat flow with a sensitivity of 0.2 μW and a temperature sensitivity of 0.1 K. This device was calibrated with the fusion of high-purity metallic indium, and from this fusion the calibration constant and the thermal resistance for temperature correction of DSC device were obtained. For the purity experiments of the compounds, about 3 mg of each sample was placed in a non-hermetic aluminum crucible and heated from 450 to 580 K at a 5 K min−1 scanning rate and always under a constant flow of 50 cm3 min−1 of dry nitrogen.

The heat capacities of the compounds were determined with a DSC 8000 Perkin Elmer of power compensation using the two steps method, with synthetic sapphire as reference over a 263.15–333.15 K temperature range. The masses of compounds in the purity and heat capacity experiments were measured in a UMX2 Mettler Toledo balance (accuracy: ± 0.1 µg).

Combustion calorimetry

The combustion experiments for TPB and BCB were carried out in an isoperibolic calorimeter. This device has a semi-micro oxygen bomb Parr 1109A with an internal volume 22 cm3. The calibration to determine the ε(calor) and the validation to verify the accuracy in the combustion energy of compounds containing C, H, O, N, of the calorimeter were using standard benzoic acid and 1,2,4-triazole, respectively. This procedure was described in a former paper [11]. However, because there was a change in the calorimetric vessel of the calorimeter of Ref. [11], the equipment was again calibrated with standard benzoic acid (RSM 39j, NIST). After eight combustion experiments, the new energy equivalent of the calorimeter accounted for in our calculations was ε(calor) = (2042.4 ± 2.7) J K−1.

In all combustion experiments, the masses of the samples, the cotton, auxiliary material, the crucible and platinum wire were weighed on a DV215CD Ohaus (accuracy: ± 0.01 mg). The corrections from apparent mass to effective mass were applied. In these experiments, the samples in pellets were burned in a platinum crucible of around 200 mg. For all the combustion experiments, 0.1 cm3 of demineralized water was placed in the bomb and charged with oxygen to p = 3.04 MPa. To remove the atmospheric air from the bomb, it was five times flushed by charging the bomb with oxygen to 2.0 MPa and returning to atmospheric pressure.

After loading the combustion semi-micro bomb with the sample of TPB or BCB, paraffin oil, cotton, wire and crucible of platinum into the calorimetric vessel, 400 g of distilled water was added. This amount of water was measured with a MS12001L Mettler Toledo balance (accuracy: ± 0.1 g). The isothermal jacket of the calorimeter system was maintained and regulated a constant temperature of 298.15 K, by a refrigerated circulator Polyscience 9502.

The first experiments showed that TPB and BCB do not undergo a complete oxidation leaving traces of carbon residue. Thus, several different experimental conditions were tested; also, auxiliary materials were used. After performing test experiments, it was found that paraffin oil was a convenient auxiliary substance. By using around 5 mg of paraffin oil, the samples ignition was total. The mass energy of combustion of paraffin oil is of −∆cu° = (648.606 ± 0.091) kJ mol−1 [12].

The temperature during the combustion experiments was followed by a 5642 Hart Scientific thermistor (diameter = 3.18 mm, length = 229 mm and resistance = 4 kΩ), calibrated over a temperature range from 273.15 to 333.15 K. Resistances were measured with a Keithley 2010 digital multimeter (sensitivity: 10−6 kΩ) and put on a personal computer for automatic data collection. The corrected temperature rise for each experiment of combustion was calculated by the Regnault–Pfaundler method, as described by Wadsö [13].

For the samples ignition was used a 2901 Parr ignition unity which provides 4.184 J. The circuit was closed with a platinum fuse wire (Cat. No.45C3, Parr) connected to the sample by a cotton thread. The mass energy of combustion of the cotton thread fused is of −∆cu° = (482.972 ± 0.120) kJ mol−1 [14].

As the samples have nitrogen in their structure, nitric acid was formed. The aqueous phase obtained in the bomb after combustion experiments of TPB and BCB was quantitatively transferred to a flask, and together with the rising bomb distilled water, it was diluted to a 100.0 cm3 volume. Subsequently, the amount of HNO3(aq) formed during the reaction was determined by titration with NaOH(aq), previously evaluated with potassium hydrogen phthalate.

The corrections to the standard state and the calculations of the thermodynamic quantities were made as described by Hubbard et al. [15]. Table 1 contains the summary of the provenance and purity of the material used.

Thermogravimetry

Thermogravimetric measurements were carried out on a TA Instruments TGA Q500 (Weighing Precision: 0.1 μg). The mass calibration of the TGA was performed in a range of 100 mg to 1 g using two calibration mass. The procedure consisted in registering in the equipment software the exact mass of the 100 mg mass in the cell to measure the combined mass between the mass and the cell. This was repeated for the calibration of the equipment with the 1 g mass. For the temperature calibration of the instrument an Alumel-Nickel alloy was used, the Curie Temperature values are 425.75 and 631.35 K, respectively. In such procedure, a magnet was placed under the furnace and a mass gain of approximately 2% was ensured. [16, 17].

The kinetic theory of gases indicates that in the sublimation process, the rate of mass loss (dm/dt) of the substance in an open surface is expressed as in Eq. (1) [18,19,20,21].

where M is the molar mass of the gas, R is the gas constant, T is the temperature, and A is the area the orifice. On the other hand, the integrated Clausius–Clapeyron equation relates the vapor pressure with enthalpy of sublimation as shown in Eq. (2).

substituting Eq. (1) into Eq. (2) followed by integration, and assuming that the enthalpy of sublimation is constant over the experimental temperature range, grouping the constant terms in a constant C′ and taking the logarithm Eq. (2) it is obtained:

here C′ = ln [A(M/2πRT)1/2] + C. The molar enthalpy of sublimation can be obtained from Eq. (3) by the slope of a plot of the left-hand expression (3) against 1/T. Also, this equation is applicable for calculating the enthalpy of vaporization [22,23,24,25,26].

The temperature scale of the instrument was calibrated by analyzing the melting temperature of sample of high-purity Indium, which has a melting temperature of (429.7485 ± 0.0034) K, as certified by NIST. For the calibration of mass measurements, standard masses obtained from NIST and certified with a mass of (315.1620 ± 0.0048) mg were used.

For the experiments of the compounds, approximately 9.5 mg of TPB and 16 mg of BCB were placed inside a cylindrical platinum cell with a height of 6.00 mm, a diameter of 6.35 mm and a cross-sectional area of 3.167 × 10−5 m2. The initial temperature and final temperature of sublimation experiments were 560–590 K and 610–640 K, respectively. The temperature scanning rate was of 10.0 K min−1 with a flow rate of 100 cm3 min−1 of nitrogen.

Results and discussion

1H and 13C spectra

To prove the identity of the compounds, the 1H and 13C spectra were determined by nuclear magnetic resonance (NMR). The spectroscopic data are shown below:

Tetra-N-phenylbenzidine: 1H NMR (CDCl3, 300 MHz) δ 7.02 (tt, J = 7.2, 1.5 Hz, 4H), 7.10–7.14 (m, 12 H), 7.22–7.28 (m, 8H), 7.43 (d, J = 8.4 Hz, 4H). 13C (CDCl3, 75 MHz) δ 122.8, 124.1, 124.3, 127.3, 129.3, 134.7, 146.8, 147.8.

4,4′-Bis(N-carbazolyl)-1,1′-biphenyl: 1H NMR (CDCl3, 500 MHz) δ 7.32 (ddd, J = 7.8, 6.9, 1.2 Hz, 4H), 7.45 (ddd, J = 8.4, 7.2, 1.2 Hz, 4H), 7.51 (d, J = 8.1 Hz, 4H), 7.68 (apr d, J = 8.7 Hz, 4H), 7.88 (apr d, J = 8.4 Hz, 4H), 8.17 (d, J = 7.5 Hz, 4H). 13C NMR (CDCl3, 75 MHz) δ 109.8, 120.1, 120.4, 123.5, 126.0, 127.4, 128.5, 137.2, 139.2, 140.8.

After performing a literary review, we found that the spectroscopic data of TPB are identical to those previously reported by Yuanhong et al. [27]. However, we did not find the NMR spectra for the BCB. Consequently, the 1H and 13C NMR spectra of the TPB and BCB are added in the supplementary material file of the manuscript (Figure A, B, C and D).

Purity and heat capacity

Table 2 gives the physical properties of the compounds and materials used in calculations of the standard mass energy of combustion. Also, melting temperature, fusion enthalpy and heat capacity results of the TPB and BCB obtained by DSC are presented. The uncertainty in the measurements corresponds to the standard deviation of a set of at least four measurements. From the results obtained by DSC, the melting temperature of the TPB was lower than for the BCB which implies that this compound has a greater cohesion in the solid phase. In contrast, the heat capacity for BCB is slightly smaller, which is consistent with a larger number of bonds and vibrational modes in the molecular structure of this compound. The results of the heat capacity experiments of TPB and BCB measured from 270.15–333.15 K are presented in the supplementary material file (Table A and B).

After performing a literary review of the thermodynamic properties of the study compounds, we found eight previous works that report the melting temperature for TPB and six works for BCB; these values are presented in Table 3. In this table, it can be seen that the values obtained with a fusiometer are different to the values obtained by DSC and can be due to the lack of accuracy of the values obtained using a fusiometer. Just one work on the melting temperature, fusion enthalpy and heat capacity of TPB, reported by Costa and Santos [10], used a SETARAM model DSC 141. The values reported by these authors using DSC are; Tfus = (504.6 ± 0.1) K, ΔfusH = (46.2 ± 0.3) kJ mol−1 and Cp = (557.52 ± 0.98) J mol−1 K−1. With the values reported by Costa and Santos and the results obtained in this work, it is observed that for the case of the heat capacity the values are similar and in the case of the melting temperature, fusion enthalpy the values are very close, without significant differences.

Energy of combustion and enthalpy of formation

The results typical for the combustion experiments of TPB and BCB are summarized in Tables 4 and 5, respectively. The values of the standard mass energy of combustion correspond to the combustion reactions equations; (4) for TPB and (5) for BCB.

From seven combustion experiments for each compound, the standard mass energy of combustion to T = 298.15 K, for TPB is −∆cu° = (37,955.9 ± 6.2) J g−1, and −∆cu° = (37,160.6 ± 11.6) J g−1 for BCB. The uncertainly in both cases is the standard deviation of the mean. They were calculated using the method described by Olofsson [43].

The values of standard molar energy of combustion \(\Delta_{\text{c}} U_{\text{m}}^{\text{o}}\), standard molar enthalpy of combustion \(\Delta_{\text{c}} H_{\text{m}}^{\text{o}}\) and the standard molar enthalpy of formation \(\Delta_{\text{f}} H_{\text{m}}^{\text{o}}\) of the compounds are shown in Table 6. The correction energetic of − 59.7 kJ mol−1 for the formation of 0.1 mol dm−3 HNO3(aq) solution from O2(g), N2(g), and H2O(l) was considered for the calculation of the standard mass energy of combustion [44]. The values for the standard molar enthalpies of formation of CO2(g), −(393.51 ± 0.13) kJ mol−1 and H2O(l), −(285.830 ± 0.042) kJ mol−1 at T = 298.15 K were taken from CODATA [45].

Comparing the values of the formation enthalpy in solid phase obtained in this work for the TPB and BCB shows that the difference between these values is 163.7 kJ mol−1. Based on this difference, it is considered that the TPB is more stable than the BCB. Therefore, the enthalpy value for hydrogenation of a C–C bond of a five-member BCB ring is 81.8 kJ mol−1.

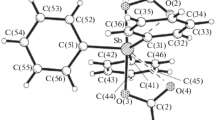

Enthalpy of vaporization and sublimation

In the previous TGA experiments of the compounds, it was observed that there was no mass loss before achieving the melting temperature of each compound. Thus, the enthalpies of vaporization of TPB and BCB were calculated from the slope of the straight line \({\text{ln }}\left( {({\text{d}}m/{\text{d}}t)T^{1/2} } \right)\) versus 1/T derived from Eq. (4) at the mean temperature for each experimental series, this graph is shown in Fig. 2. The uncertainty associated with each enthalpy of vaporization value is the standard deviation of the fit [46].

Linear dependence of equation \({\text{ln }}\left( {({\text{d}}m/{\text{d}}t)T^{1/2} } \right) = C' - \Delta_{\text{vap}} H_{\text{m}} /RT\) for the four experimental series of vaporization of the compounds. From the slope \(\Delta_{\text{vap}} H_{\text{m}} /R\), where R = 8.314/J mol−1 K−1, the \(\Delta_{\text{vap}} H_{\text{m}}\) is derived for the TPB and BCB to the 〈Texp〉

The enthalpies of vaporization of TPB and BCB were determined from four independent series of experiments, and each series of experiments includes 16 experimental points. Table 7 shows representative thermogravimetric data for each experimental series of each compounds studied. Detailed results of all the experiments evaporation are presented in tables C and D (in supplementary Material file).

Experimental molar enthalpies of vaporization were adjusted to the melting temperature using Eq. (6); subsequently, the enthalpy of sublimation was reduced to the temperature of 298.15 K, from of Eqs. (7) and (8) suggested by Chickos et al. [47].

Table 8 shows the molar enthalpies of vaporization of TPB and BCB at the experimental temperature, the molar enthalpies of vaporization and sublimation of the compounds at temperature of melting and the molar enthalpies of sublimation of both substances at T = 298.15 K.

In the work reported by Costa and Santos, they found that the sublimation enthalpy of the TPB is \(\Delta_{\text{sub}} H_{\text{m}} \left( {298.15 {\text{K}}} \right) = \left( {198.5 \pm 2.0} \right)\) kJ mol−1 in the range of 460–510 K using the combined Knudsen/quartz crystal effusion apparatus. Considering associated uncertainties to the values of the sublimation enthalpy of the TPB obtained by Costa and Santos [10] with those obtained in this work, the values are very close.

Enthalpy of formation in gas phase

The combination of the standard molar enthalpy of formation in the solid phase, presented in Table 6, with the molar enthalpy of sublimation, presented in Table 8, yields to the standard molar enthalpy of formation in gaseous phase at T = 298.15 K. For TPB value is \(\Delta_{\text{f}} H_{m}^{\text{o}} =\) (544.6 ± 13.4) kJ mol−1, and \(\Delta_{\text{f}} H_{m}^{\text{o}} =\) (718.4 ± 16.2) kJ mol−1 for BCB. The uncertainty in both cases is calculated through the root sum square method.

From these results it is concluded that the molar stabilization energy of TPB relative to BCB in gaseous phase increases to approximately 173.8 kJ mol−1, about 10 kJ mol−1 more than in the solid phase. Consequently, the hydrogenation enthalpy of the C–C bond of a five-membered ring of the BCB in the gaseous phase is 86.9 kJ mol−1.

Finally, Table 9 shows resume of all the results determined experimentally and the ones calculated from them.

Conclusions

Through experimental techniques such as differential scanning calorimetry, combustion calorimetry and thermogravimetry, the thermochemical properties of Tetra-N-phenylbenzidine and 4,4′-Bis(N-carbazolyl)-1,1′-biphenyl were determined.

It was verified that the formation of Tetra-N-phenylbenzidine from the hydrogenation of the C–C bonds of the five-membered rings of 4,4′-Bis(N-carbazolyl)-1,1′-biphenyl is enthalpically favored because the molar enthalpy of formation in the gaseous phase of the TPB is less positive.

Based on the results obtained by DSC, it is found that the BCB has a higher melting temperature than the TPB, this suggests that the BCB has better thermal stability. Additionally, the heat capacity of the BCB is lower than that of the TPB, which demonstrates that the formation of the BCB from the TPB decreases the vibration, rotation and translation movements of the molecule. By consequence, the BCB has a better capacity in the transport of holes in devices OLEDs and OPVs. Therefore, we are sure that the information reported in this paper will be of great help for future work in the application of these compounds in the form of thin films in the devices.

References

Nazeeruddin MK, Baranoff E, Grätzel M. Dye-sensitized solar cells: a brief overview. Sol Energy. 2011;85:1172–8.

Zhao X, Zhan X. Electron transporting semiconducting polymers in organic electronics. Chem Soc Rev. 2011;40:3728–43.

Kappaun S, Slugove C, List EJ. Phosphorescent organic light-emitting devices: working principle and iridium based emitter materials. Int J Mol Sci. 2008;9:1527–47.

Shirota Y, Kageyama H. Charge carrier transporting molecular materials and their applications in devices. Chem Rev. 2007;107:953–1010.

Knupfer M, Schwieger T, Fink J. Excitons in quasi-one-dimensional organic crystals. Phys Rev B. 2002;66:1–5.

Cias P, Slugovc C, Gescheidt G. Hole transporting in triphenylamine based OLED devices: from theoretical modeling to properties prediction. J Phys Chem. 2011;115:14519–25.

Low PJ, Paterson MAJ, Yufit DS, Howard JAK, Cherryma JC, Tackley DR, Brook R, Brown B. Towards an understanding of structure–property relationships in hole-transport materials: the influence of molecular conformation on oxidation potential in poly(aryl)amines. J Mater Chem. 2005;15:2304–15.

Quynh PBN, Sueng JB, Mi JK, Na YS, Gyeong WK, Dong CC, Jang HK, Kyu YC. Novel hole transporting materials based on 4-(9H-Carbazol-9-yl)triphenylamine derivatives for OLEDs. Molecules. 2014;9:14247–56.

Shizuo T, Hiromitsu T, Koji N, Akane O, Yasunori T. Thermal stability in oligomeric triphenylamine/tris(8-quinolinolato) aluminum electroluminescent devices. Appl Phys Lett. 1997;70:1929–31.

Costa JCS, Santos LMNBF. Hole transport materials based thin films: topographic structures and phase transition of triphenylamine derivatives. J Phys Chem C. 2013;117:10919–28.

Mentado J, Mendoza E. Calibration and testing an isoperibolic micro-combustion calorimeter developed to measure the enthalpy of combustion of organic compounds containing C, H, O, and N. J Chem Thermodyn. 2013;59:209–13.

Flores H, Amador P. Standard molar enthalpies of formation of crystalline stereoisomers of aldono-1,4-lactones. J Chem Thermodyn. 2004;36:1019–24.

Wadsö I. Calculation methods in reaction calorimetry. Sci Tools. 1966;13:33–9.

Good WD, Smith NK. Enthalpies of combustion of toluene, benzene, cyclohexane, cyclohexene, methylcyclopentane, 1-methylcyclopentene and n-hexane. J Chem Eng Data. 1969;14:102–6.

Hubbard WN, Scott DW, Waddington G. Standard states and corrections for combustion in a bomb at constant volume. In: Rossini FD, editor. Experimental Thermochemistry, vol. 1. New York: Interscience; 1956. p. 75–128.

Vieyra-Eusebio MT, Rojas A. Vapor pressures and sublimation enthalpies of nickelocene and cobaltocene measured by thermogravimetry. J Chem Eng Data. 2011;56:5008–18.

Ximello A, Flores H, Rojas A, Camarillo EA, Amador MP. Gas phase enthalpies of formation of nitrobenzamides using calorimetry and thermal analysis. J Chem Thermodyn. 2014;79:33–40.

Langmuir I. The vapor pressure of metallic tungsten. Phys Rev. 1913;2:329–42.

Ashcroft SJ. The measurement of enthalpies of sublimation by thermogravimetry. Thermochim Acta. 1971;2:512–4.

Verevkin SP, Zaitsau DH, Emeìyanenko VN, Heintz A. A new method for the determination of vaporization enthalpies of ionic liquids at low temperatures. J Phys Chem B. 2011;115:12889–95.

Verevkin SP, Ralys RV, Zaitsau DH, Emel’yanenko VN, Schick C. Express thermo-gravimetric method for the vaporization enthalpies appraisal for very low volatile molecular and ionic compounds. Thermochim Acta. 2012;538:55–62.

Wright SF, Dollimore D, Dunn JG, Alexander K. Determination of the vapor pressure curves of adipic acid and triethanolamine using thermogravimetric analysis. Thermochim Acta. 2004;421:25–30.

Pena R, Ribet JP, Maurel JL, Valat L, Lacoulonche F, Chauvet A. Sublimation and vaporisation processes of S(-) efaroxan hydrochloride. Thermochim Acta. 2003;408:85–96.

Phang P, Dollimore D, Evans SJ. A comparative method for developing vapor pressure curves based on evaporation data obtained from a simultaneous TG–DTA unit. Thermochim Acta. 2002;392–393:119–25.

Price DM. Vapor pressure determination by thermogravimetry. Thermochim Acta. 2001;367–368:253–62.

Price DM, Hawkins M. Calorimetry of two disperse dyes using thermogravimetry. Thermochim Acta. 1998;315:19–24.

Yuanhong Z, Yunsong W, Hongwei S, Liang L, Hongbin Z. Ullmann reaction in tetraethyl orthosilicate: a novel synthesis of triarylamines and diaryl ethers. Chem Commun. 2007;20:3186–8.

Meija J, Coplen TB, Berglund M, Brand WA, De Bièvre P, Gröning M, Holden NE, Irrgeher J, Loss RD, Walczyk T, Prohaska T. Atomic weights of the elements 2013 (IUPAC Technical Report). Pure Appl Chem. 2016;8:265–91.

Washburn EW. Standard states for bomb calorimetry. Bur Stand J Res. 1933;10:525–58.

Hai-Guang Z, Wen-Tao Y, Shi-Na Y, Chao C, Xu-Tang T. N, NN′N′-Tetraphenyl-1,1′-biphenyl-4,4′-diamine. Acta Cryst. 2006;E62:5236–8.

Good WD, Lacina JL, Collough JPM. Sulfuric acid: heat of aqueous solution by rotating-bomb calorimetry. J Am Chem Soc. 1960;82:5589–91.

Lamm VW, Jugelt W, Pragst F. Photochemische synthese von carbazolen und Indolo[3, 2-b]carbazolen. Journal f prakt Chemie. 1975;317:284–92.

Glossop PA, Millan DS, Price DA. Novel glucocorticoid receptor agonists. Patent Application. WO 2010;136940A.

Smith CJ, Tsang MWS, Holmes AB, Danheiser RL, Tester JW. Palladium catalyzed aryl amination reactions in supercritical carbon dioxide. Org Biomol Chem. 2005;3:3767–81.

Kazuo H, Iwaya K, Kaneko R. Condensations of 1,4-cyclohexanediones and secondary aromatic amines. II. N-phenylation of diarylamines. Bull Chem Soc Jpn. 1986;59:803–7.

Yu-Hua L, Chen C, Lian-Ming Y. Diazabutadiene: a simple and efficient ligand for copper-catalyzed N-arylation of aromatic amines. Tetrahedron Lett. 2006;47:9275–8.

Chen C, Lian-Ming Y. Arylation of diarylamines catalyzed by Ni(II)-PPh3 system. Org Lett. 2005;7:2209–11.

Proceedings of SPIE 6828, Light-Emitting Diode Materials and Devices II. 2008; https://doi.org/10.1117/12.783394.

Gong-chang Z, Xin-hua O, Ding-qiao Y, He-ping Z. A promising strategy for two-photon absorption materials by novel dicarbazole-conjugated C60/C70 fullerene derivatives. Opt Mater. 2010;32:637–42.

Gilman H, Honeycutt JB. Some aromatic and heterocyclic derivatives of carbazole. J Org Chem. 1957;22:226–7.

Andrews MD, Look K, Mosley A, Steudel A, Male N, Maxted N. Phosphorescent compositions and organic light emitting devices containing them. Patent Application. WO 2003;074628.

Steudel A, Male N, Watkins S. Electroluminescent device. Patent Application. WO 2005;027583A1.

Olofsson G. Assignment of uncertainties. In: Sunner S, Mansson M, editors. Combustion Calorimetry. Oxford: Pergamon; 1979. P. 137–59.

Wagman DD, Evans WH, Parker VB, Schumm RH, Halow I, Bailey SM, Churney KL, Nuttall RL. The NBS tables of chemical thermodynamic properties. J Phys Chem Ref Data. 1982;11(Suppl):2.

Cox JD, Wagman DD, Medvedev VA. CODATA Key values for thermodynamics. New York: Hemisphere; 1989.

Bevington PR, Robinson DK, editors. Data reduction and error analysis for the physical sciences. 3rd ed. New York: McGraw-Hill Higher Education; 2003.

Chickos JS, Hosseini S, Hesse DG, Liebman JF. Heat capacity corrections to a standard state: a comparison of new and some literature methods for organic liquids solids. Struct Chem. 1993;4:271–8.

Acknowledgements

The authors thank the Universidad del Mar for its financial support and CONACYT for the scholarship of Ernan Adalid Mendoza-Ruiz. Thanks to Dr. Silvano Cruz Gregorio for his support in obtaining the NMR spectra.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mendoza-Ruiz, E.A., Mentado-Morales, J. & Flores-Segura, H. Standard molar enthalpies of formation and phase changes of Tetra-N-phenylbenzidine and 4,4′-Bis (N-carbazolyl)-1,1′-biphenyl. J Therm Anal Calorim 135, 2337–2345 (2019). https://doi.org/10.1007/s10973-018-7395-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7395-4