Abstract

Many theoretical and experimental studies on heat transfer and flow behavior of nanofluids have been conducted, and the results show that nanofluids significantly enhance heat transfer. However, less attention has been paid to obtain the thermal conductivity of nanofluids and their stability using molecular simulations which are applied by investigators to explain the molecular mechanisms of nanoscale phenomena. In this work, the stability of water–ethylene glycol-based graphene oxide (GO) nanofluids was investigated by classical molecular dynamics simulations in which the kinetic energy, radial distribution function and intensity diagrams were obtained. The obtained results confirmed the stability of nanofluids. Also, the thermal conductivity of nanofluids was studied by reverse non-equilibrium molecular dynamics method at different ratios of water–ethylene glycol as base fluids and various amounts of graphene oxide as nanoparticles. The results show that the thermal conductivity of nanofluids increases with the amount of graphene oxide nanosheets. For example, the thermal conductivity of water–ethylene glycol (75/25%)-based nanofluid containing 3, 4 and 5% of GO nanosheets was increased by 24, 28 and 33%, respectively, at 46.7 °C. Finally, the theoretical models on heat transfer and flow behavior of nanofluids were employed to validate the molecular simulation results. The obtained thermal conductivity results are in good agreement with theoretical models.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanofluids are colloidal dispersions of nanoparticles in liquid which have great potential as coolants due to their improved thermophysical properties such as thermal conductivity and viscosity [1,2,3,4,5,6,7]. Such enhancements are attributed to addition of solid nanoparticles, rods, tubes or nanosheets to the base fluid. However, nanofluids can evade many serious flow characteristic problems such as pressure drop and severe cloggings due to rapid settling of millimeter- or micrometer-sized particles. In other words, these limitations of effective heat transfer can be considerably resolved by using nanofluids consist of nanoparticles with < 100 nm in diameter, suspended in base fluids [8,9,10,11].

By the birth of newly engineered nanofluids, many prevalent problems such as sedimentation of large particles, flow channels clogging, erosion of pipelines and continuously happening pressure drop in heterogeneous mediums gradually faded away. Nanoparticles in fluids despite the milli- and micro-sized particle slurries are relatively close in size to the molecules of the base fluid. As a result, these nanofluid suspensions remain remarkably stable with little gravitational settling over a long periods of time [2, 12,13,14]. In a close meaning, due to higher stabilization, according to the Stoke’s theory, particle sedimentation fades away and clogging of the heat sink is prevented [15].

Historically, nanofluid is a new dimensional fluid term in heat transfer emerged after the pioneering work by Choi [16] at Argonne National Laboratory of USA in 1995. Nanofluids have allocated the major part of interests because of the reports indicating the great enhancement in not only heat transfer but also in other fields of engineering such as mass transfer, wetting and spreading [17,18,19].

Also, other researchers [20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35] have been prepared dispersion of nanometer-sized solid particles like metals, oxides, polymeric particles, metallic oxide particles and also carbon materials such as carbon nanotubes, exfoliated graphite and graphene nanoribbons in base fluids. These fluids are engineered colloidal suspensions of nanoparticles in a base fluid [36,37,38]. By adding nanoparticles less than 1% volumetric concentration, sometimes thermal conductivity of the fluid may increase up to approximately two times [39]. Worldwide researches that have been conducted are clear evidence for this claim [3, 40]. Therefore, thermal properties and stability have been a hotly debated topic during the last two decades due to their promising heat transfer applications in nanotechnology arena [41].

Conventional fluids, such as water, ethylene glycol, engine oil, have poor heat transfer performance, and therefore, high compactness and effectiveness of heat transfer systems are necessary to achieve the required heat transfer [42]. Among the efforts for enhancement of heat transfer, the application of additives to liquids is more noticeable in recent years [43,44,45,46].

In this work, the application of graphene oxide nanosheets in the mixture of water and ethylene glycol (as the base fluid) is investigated, which is conventionally used in the cars’ radiators. For this purpose, molecular dynamics simulation is utilized. Molecular dynamics simulation [47, 48] was established in order to estimate some vital thermophysical properties in heat transfer, such as thermal conductivity, thermal capacity, shear viscosity, thermal diffusivity and density. Therefore, it can be applied to a system that consists of graphene oxide nanosheets and water–ethylene glycol-based fluid to obtain thermal properties. The reason for selection of graphene oxide as the nanoparticle and the mixture of water–ethylene glycol as the base fluid is briefly explained in the following.

In contrast to the theoretical studies on the heat transfer properties of graphene-based materials, the experimental works are rare about this issue. Graphene is a flat monolayer of carbon atoms tightly packed in a 2D structure and has exceptional thermophysical properties and mechanism in comparison with other nanoparticles and carbon nanotubes [23, 49]. Graphite is usual raw material for production of graphene nanosheets by some chemical methods. Therefore, graphite powder was applied to produce graphene oxide nanosheets which are appropriate nanoparticles for water-based nanofluids [49]. The small-sized conducting solid particles will enhance the surface area per unit volume (aspect ratio) and thereby cause an increase in heat transfer performance. In the selection of GO as nanosheet, two factors are involved. The first one is thermal conductivity, and the other more important factor is the dispersibility. GO is not a high conductive material but has acceptable thermal conductivity. Graphene oxide nanosheets are easily dispersed in used base fluid in this paper, and surfactants or other materials are not required [50].

In cold regions, due to long winter climate conditions, it is a common practice to use the mixture of ethylene glycol and water in different volume ratios as heat transfer fluid in building heating systems, industry coolants and automobile radiators as heat exchangers [15, 38, 51, 52]. Due to freezing of water at 0 °C, to avoid freezing of water, ethylene glycol is added in suitable proportions. Commonly used ratios of ethylene glycol–water mixtures are 60/40 and 50/50 percentage by volume. Ethylene glycol decreases the freezing point of water; thus, these fluids do not freeze in very cold operating temperatures even if temperature falls down to − 40 °C [53, 54]. Also, the addition of ethylene glycol to water elevates the boiling point of water up to 120 °C, and therefore, it extends the application of the fluid at wider operating temperature ranges [42].

As mentioned above, the studied nanofluid is formed by dispersion of graphene oxide nanosheets in water–ethylene glycol mixture. In this paper, the stability of water–ethylene glycol based graphene oxide nanofluids is investigated by classical molecular dynamics. Also, the thermal conductivity of nanofluids is studied via reverse non-equilibrium molecular dynamics (RNEMD) method. Finally, the theoretical models are employed to validate the obtained thermal conductivity results by molecular simulations.

Molecular dynamics (MD) simulation is a computational method that solves Newton’s equation of motion for a system of particles interacting with a given potential [55,56,57,58,59]. As molecular dynamics simulation directly and accurately calculates the movement of particles at atomic levels, it can afford scientists and engineers’ ways to predict macroscopic properties such as thermal conductivity and viscosity [56, 60].

In the literature, less attention has been paid to obtain the thermal conductivity of nanofluids and their stability at molecular-scale. Therefore, in this study the stability and thermal conductivity of nanofluid are investigated by classical molecular dynamics simulation and reverse non-equilibrium molecular dynamics simulation methods, respectively. To investigate the stability of the nanofluid, we tried to make a more comprehensive and different study than other research projects. The method of the study and using this combination of analyses (total energy, kinetic energy, radial distribution function and the obtained diagrams for dispersion quality of the nanofluids in the simulated systems) are very unique and new to the study of nanofluids stability, and no other similar research work exists. In order to assess the stability of the nanofluid, the simulation cases of this studies are investigated under different conditions. For this purpose, first of all, the simulations are actually implemented for the case of graphene oxide nanoparticles in the pure water and pure ethylene glycol liquid mediums. Then, the same trend is repeated for the mixtures of water–ethylene glycol with composition ratios of 25/75 and 40/60. After that, the RNEMD simulation method is performed at various volume ratios of water–ethylene glycol mixtures and various concentrations of graphene oxide nanosheets to investigate the nanofluids’ thermal conductivities. The nanofluids are simulated by considering both 75/25, 60/40 and 40/60 water–ethylene glycol mixtures as a base fluid and volume concentrations of 3, 4 and 5% of graphene oxide as a nanoparticle. The stability of the nanofluid is investigated in a composition of less than 2% of the graphene oxide nanosheets in the base fluid which can be done experimentally. Using high concentrations of GO nanofluids to investigate the thermal conductivity of the nanofluids has been performed to demonstrate clearly the positive impact of GO nanosheet in the thermal conductivity of the base fluid. Also, using low concentration of the GO nanosheets leads to increase in the number of atoms in the simulation box; thereby, the required time increases to perform the molecular dynamics simulations. Because the molecular dynamics simulations need a long time for processing.

Theoretical background

Classical molecular dynamics simulation for nanofluid stability

In the present work, the study on the stability of nanofluid was performed with the molecular dynamics simulation method. The simulations are performed under NVT (constant number, constant volume, constant temperature), NPT (constant number, constant pressure, constant temperature) and NVE (constant number, constant volume, constant energy) ensembles with the periodic boundary condition [61]. All the molecules are assumed to be arranged in the FCC lattice.

The simulations temperature is fixed at 26.7 °C controlled by Nosé-Hoover thermostat, and the pressure is set at 1.013 × 105 Pa [62]. Long-range electrostatic interactions are calculated by Ewald summation method [63]. All the simulation boxes were 44.5 × 44.5 × 44.5 Å3 in the x, y, z directions, respectively. The simulated systems consist of graphene oxide nanosheets dispersed in base fluids. The studied base fluids are defined as pure and mixtures of water and ethylene glycol liquids. The systems are initially equilibrated in the NPT ensemble to get the correct density. The time length of simulation is 2.5 ns. The next step is to reach the equilibrium with a NVT ensemble for the 2.5-ns simulation time. And finally the simulation is performed 2.5 ns using microcanonical (NVE) ensemble to calculate the structural and diffusion properties of the nanofluid components.

The stability of nanofluids is studied through the obtained kinetic energy, radial distribution functions and intensity diagrams.

RNEMD simulation for thermal conductivity of nanofluids

Prediction of the transport coefficients such as thermal conductivity can be done either by equilibrium or by non-equilibrium molecular dynamics. Both methods have their own advantages and disadvantages. Equilibrium molecular dynamics (EMD) calculates transfer coefficients using Einstein or Green–Kubo relations [64, 65]. In this approach, the system will remain at equilibrium condition. But, in reverse non-equilibrium molecular dynamics (RNEMD), a driving force (or field) is generated in the system by applying a perturbation. Then, the ensemble average of the resulting flux will be measured. Finally, transfer coefficients are calculated by dividing the flux by driving force [66].

There are many approaches that use RNEMD simulations. In most of them, a field is applied and a flux is measured. In RNEMD, the process is reversed. It means that a flux is imposed and a field is calculated. Müller-Plathe [67] proposed a simple and fast converging method in which the total energy and total linear momentum are conserved. In this method, the simulation box is divided into a number of slabs in the z direction with the same thickness. In order to impose a heat flux into the system, at first, two slabs are considered as hot and cold slabs. Then, an energy flux is produced through the velocity exchange between the coldest atom in the hot slab and the hottest atom in the cold slab. This mechanism leads to an energy transfer between the two slabs and creates a temperature gradient in the system. The instantaneous local kinetics temperature in slabs is calculated by the following equation:

where mi and vi are the mass and velocity of the atom i, nk is the number of the atoms in the slab k and kB is the Boltzmann’s constant.

After reaching the equilibrium, the thermal conductivity k is calculated by dividing the energy flux by temperature gradient:

where the vh and vc refer to the velocities of the hot and cold particles, the product of Lx and Ly is the area perpendicular to the heat transfer direction, t is the simulation time and m is the particle mass.

The current study calculates the thermal conductivity of nanofluid by using a reverse non-equilibrium molecular dynamics simulation in a periodic boundary conditions [67]. The RNEMD simulations are performed using LAMMPS simulation software [68]. LAMMPS integrates Newton’s equations of motion for collections of atoms, molecules, or macroscopic particles that interact via short- or long-range forces with a variety of initial and/or boundary conditions.

In a RNEMD simulation, a force field which includes the functional form and parameter sets needs to be specified in order to describe the interaction between atoms or molecules, which is also called the potential energy of a system of particles. Therefore, to model the nanofluid structures, the consistent valence force field (CVFF) is chosen [69]. It has been widely used to predict the behavior of small molecules and macromolecules. The CVFF uses Morse potential to calculate bond-stretching interactions. Also, the non-bonded terms describe the van der Waals (vdW) and long-range electrostatic interactions. Lennard-Jones (LJ) potential is used to explain the van der Waals (vdW) interactions between base fluid atoms and graphene oxide [47, 48, 57].

where εij is the depth of the potential well and σij is the distance at which the inter-atomic potential is zero and rij is the distance between atoms i and j, respectively [47, 48]. To improve the computational efficiency, only the neighboring atoms within a certain cutoff radius (rcut) are included in the force calculation because distant atoms have a negligible contribution. A cutoff radius of 18.5 Å is used to truncate the vdW interactions. The standard Lorentz–Berthelot combination rules [70], εij = (εiiεjj)1/2 and σij = (σii + σjj)/2, are used to derive the Lennard–Jones potential parameters between unlike atom-type force centers i and j from the values of the parameters between similar atom types.

The electrostatic interactions [47, 48] are represented by the following equation in which the dielectric constant, ε, is a function of distances between atoms.

where qi and qj are the effective charges on the charged atoms i and j, rij is the distance between atoms, and ε is the dielectric constant.

The system atoms are originally arranged in a tetragonal crystal system lattice. Simulations are performed in NVT ensemble where the total number of atoms N, the system volume V and temperature T are constant throughout the simulation [47, 48]. The simulation temperature is controlled by Nosé–Hoover thermostat [62].

The trajectories of the atom motion are generated by integrating the equation of motion using velocity Verlet algorithm [71]. The integration time step of 1 fs, and the periodic boundary conditions are applied in all directions. The total simulation time for each case is set on 2 ns in which first 1 ns is equilibration step and next 1 ns is to calculate the thermal conductivity. This simulation time is sufficient for obtaining converged simulation energies. The Ewald summation method [63] is used for long-range electrostatic interactions with a precision of 1 × 10−4, and all inter-molecular interactions in the simulation box are calculated within a cutoff distance of 18.5 Å.

All RNEMD simulations are performed at different compositions of water–ethylene glycol mixtures (75/25, 60/40 and 40/60) and volume concentrations of graphene oxide nanosheets (3, 4 and 5%). After 42 simulations, the thermal conductivity of nanofluids is obtained for each case.

Theoretical models

The theoretical relations are used for calculation of thermal conductivity of nanofluids in order to be compared with the trend of the results obtained by the molecular dynamics simulations.

The theoretical models to predict the thermal conductivity of solid suspension, which are suitable for water-based nanofluids containing less than 5% nanoparticles with a satisfactory precision, are given as follows:

a. Wasp’s model [72]

b. Yu and Choi’s model [73]

c. Bruggeman’s model [74]

where φ is the particle volume concentration, ks, kbfm and knf are the thermal conductivity of the solid particles, base fluid mixture and nanofluid, respectively. β is the ratio of the nanolayer thickness to the original particle radius. Normally, to calculate the thermal conductivity of the nanofluid, it is used as β = 0.1 [73]. Also, Bruggeman’s model [74] gives the effective thermal conductivity of nanofluid (keff), and the solution of above quadratic equation (Eq. 7) is given as [75]:

Results and discussion

Stability

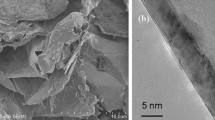

Molecular dynamics simulations are carried out to assess the stability of the nanofluid. As shown in Fig. 1, the graphene oxide that used in the simulations is designed according to relevant references [76,77,78] and has functionalized. In order to build the structure of graphene oxide nanosheet, the graphite supercell is designed and functional groups composed on that. The functional groups that are used include hydroxyls, carbonyls, epoxides and carboxyls.

The results obtained from the energy convergence step of the simulations are presented in Fig. 2a–d. The key results of this section are about the considerable differences of the total energy values in different cases of nanofluids. For the case of pure ethylene glycol as the base fluid and also in cases that ethylene glycol content in the base fluid has higher proportions, the total energy of the system is positive and is in the highest value. This aspect can be obviously seen in ethylene glycol-based graphene oxide nanofluid. However, in the cases in which the base fluid is pure water or the water content in the base fluid overcomes, the total energy of the system would be negative. The more explanations in this regard will be presented in the upcoming results.

Energy convergence for water/graphene oxide nanofluid at 26.7 °C (a), energy convergence for ethylene glycol/graphene oxide nanofluid at 26.7 °C (b), energy convergence for water–ethylene glycol (75/25) mixture containing graphene oxide at 26.7 °C, (c) and energy convergence for water–ethylene glycol (40/60) mixture containing graphene oxide at 26.7 °C (d)

For more investigation of the system energy, the results of the third step of the simulations are studied. The total kinetic energy diagrams for different conditions of the nanofluid are illustrated in Fig. 3a–d. Figure 3a, b shows the results of water/graphene oxide and ethylene glycol/graphene oxide nanofluid, respectively. The results obtained for the total kinetic energy of water–ethylene glycol in contact with graphene oxide nanosheet for the cases of 75/25 and 40/60 proportions of water to ethylene glycol are shown in Fig. 3c, d, respectively. The study of total kinetic energy in different conditions and the comparisons of the profiles obtained from the simulations and also the comparison of the average results of the simulation which is related to the most stable state of the total kinetic energy for each nanofluid in its relevant diagram indicates that when the base fluid is pure water these two curves are close to each other which implies the stability of water/graphene oxide nanofluid. Vice versa in the case of pure ethylene glycol as the base fluid, the gap between these two curves increases and consequently the stability of the nanofluid becomes weak. However, when the mixture of water and ethylene glycol was used as the base fluid, in the case of 25% ethylene glycol content the nanofluid is most stable in comparison with the case of 60% of the ethylene glycol content. In order to choose the most stable nanofluid between these two cases, it needs more scrutiny which is explained in the coming parts of the article.

The total kinetic energy diagrams for water/graphene oxide nanofluid (a), the total kinetic energy diagrams for ethylene glycol/graphene oxide nanofluid (b), the total kinetic energy diagrams for water–ethylene glycol (75/25) mixture containing graphene oxide (c), and the total kinetic energy diagrams for water–ethylene glycol (40/60) mixture containing graphene oxide (d)

Radial distribution function diagrams are another aspect of the work which could be used in the analysis to investigate the stability of the nanofluids. Figure 4a, b shows the mentioned radial distribution function for water/graphene oxide and ethylene glycol/graphene oxide nanofluids, respectively. In the same manner, radial distribution functions for the cases of the mixture of water and ethylene glycol as the base fluid with proportions of 75/25 and 40/60 of water to ethylene glycol containing fully dispersed graphene oxide nanoparticles are illustrated in Fig. 4c, d, respectively. Radial distribution functions are the primary linkage between macroscopic thermodynamics properties and inter-molecular interactions of fluids and fluid mixtures [79] and indicate the probability of presence of particles in specific distances. The first peak of radial distribution function is a sharp and highly elevated peak in the liquids that follows by a limited number of dissipating peaks which converges into horizontal line at the end. In contrast to liquids, solids have a regular structures with long-range order and therefore, the number of these peaks increases significantly. In the liquids suspended with fully dispersed particles, the radial distribution function diagrams are similar to those of the pure liquids. However, any clogging or precipitation of particles leads to increasing the number of peaks in the diagrams. As can be seen from the obtained radial distribution function diagrams, the water-ethylene glycol based graphene oxide nanofluid with ratio of 75/25 behaves similar to pure liquids which shows a good stability; while, for the cases of pure ethylene glycol or 60% ethylene glycol as the base fluids, numerous peaks appear in the radial distribution function diagrams which shows the poor stability of those nanofluids. Therefore, in contrast to water, ethylene glycol increases the instability of nanofluids.

Radial distribution function diagram for water/graphene oxide nanofluid (a), radial distribution function diagram for ethylene glycol/graphene oxide nanofluid (b), radial distribution function diagram for water–ethylene glycol (75/25) mixture containing graphene oxide (c) and radial distribution function diagram for water–ethylene glycol (40/60) mixture containing graphene oxide (d)

In order to confirm the accuracy of the simulation results, the diagram for dispersion quality of the nanofluids in the simulated systems was obtained (Fig. 5). As shown in Fig. 5, the intensity curves for nanofluids consisting of pure water and/or 75% water as the base fluids, are close together which show good stability. Also, a similar behavior is observed for nanofluids containing pure ethylene glycol and/or 60 % ethylene glycol as the base fluids which indicate poor stability. Therefore, in contrast to pure ethylene glycol based GO nanofluid, the pure water based GO nanofluid yields the highly stable nanofluid.

Thermal conductivity

Molecular dynamics simulations were performed in two main stages; the first was equilibration stage. Given a typical time step of 1 fs equilibration was run for 1 ns. As regards the constituent molecules of the nanofluid when put together, the interactions between these particles are performed that it causes an increasing in the level of energy and gets the system out of the balance. So, it should be tried to balance the simulation cell. After reaching the equilibrium, a 0.5 ns RNEMD simulation was performed with a time step of 1 fs to produce the z-component of the thermal conductivity under NVE-ensemble (second stage of the simulation).

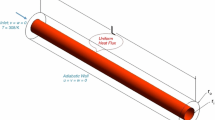

As explained before, in RNEMD method, the simulation box is divided into subdivisions in the z direction. In this research, the number of subdivided slabs is set to 50 so that the first slab is assigned to hot zone and the 26th slab to cold one, as depicted in Fig. 6. The thermal gradients results for nanofluid are presented in Fig. 7. The obtained thermal gradients in the interior of the simulation cells by molecular dynamics simulations were investigated. According to the simulation method, a thermal gradient between the side slabs and the middle slabs is going on, indicating the selection of the type of slab and moreover the selection of hot and cold slabs regarding the simulation method.

The obtained thermal conductivity by RNEMD simulations and experimental data [80] is compared in Fig. 8 for pure water and pure ethylene glycol. Also, similar results from RNEMD simulation and experimental data [80] for the base fluid (water–ethylene glycol) in three distinctive volume percentages are presented in Fig. 9. The results show that increasing rate of thermal conductivity versus temperature for water dominates the falling rate of thermal conductivity of ethylene glycol versus temperature. The increasing rate of the thermal conductivity of water and ethylene glycol was 2–3% with increasing 10° of temperature.

The thermal conductivity of nanofluids is estimated by theoretical models (as mentioned in “RNEMD simulation for thermal conductivity of nanofluids” section) with considering that the thermal conductivity of base fluid mixture (kbfm) is utilized from experimental data [80]. And, the obtained results by RNEMD simulations for thermal conductivity of nanofluids (with different compositions) are depicted in Fig. 10. The selection of simulation temperatures is made according to the used applications. This type of nanofluid is considered for a temperature lower than 70 °C. At temperatures nearby 80 °C, graphene oxide is reduced to graphene and sedimentation occurs. Therefore, the nanofluid loses its stability. As a result, by increasing the graphene oxide concentration, the deviation in the predicted value decreases as well. It is concluded that the Wasp’s, Yu and Choi’s and Bruggeman’s correlations could predict the thermal conductivity of the graphene oxide nanofluids. Results indicated that the thermal conductivity of nanofluids increases by increasing the amount of nanosheet’s volume concentration. Increasing thermal conductivity is desirable because of the enhancement in heat transfer capability. At the same time, this feature shows great potential and could widely be applied to enhance thermal efficiency in industrial heat transfer fluids. The molecular dynamics simulations results show that at 6.7 °C, the thermal conductivities of the nanofluids (water (75%)–ethylene glycol (25%) base fluid) with volume fraction of 3, 4 and 5% of nanosheets were increased by 14, 19 and 23%, respectively. Also, at 6.7 °C, the thermal conductivities of nanofluids (water (60%)–ethylene glycol (40%) base fluid) with volume fraction of 3, 4 and 5% of nanosheets were increased by 10, 25 and 28%, respectively. For the same temperature, the thermal conductivities of nanofluids (water (40%)–ethylene glycol (60%) base fluid) with volume fraction of 3, 4 and 5% of nanosheets were increased by 13, 17 and 30%, respectively. At 26.7 °C, the thermal conductivities of the nanofluids (water (75%)–ethylene glycol (25%) base fluid) with volume fraction of 3, 4 and 5% of nanosheets were increased by 26, 29 and 33%, respectively. Also, at 26.7 °C, the thermal conductivities of nanofluids (water (60%)–ethylene glycol (40%) base fluid) with volume fraction of 3, 4 and 5% of nanosheets were increased by 17, 33 and 37%, respectively. For the same temperature, the thermal conductivities of nanofluids (water (40%)–ethylene glycol (60%) base fluid) with volume fraction of 3, 4 and 5% of nanosheets were increased by 19, 22 and 37%, respectively. At 46.7 °C, the thermal conductivities of the nanofluids (water (75%)–ethylene glycol (25%) base fluid) with volume fraction of 3, 4 and 5% of nanosheets were increased by 24, 28 and 33%, respectively. Also, at 46.7 °C, the thermal conductivities of nanofluids (water (60%)–ethylene glycol (40%) base fluid) with volume fraction of 3, 4 and 5% of nanosheets were increased by 27, 37 and 40%, respectively. For the same temperature, the thermal conductivities of nanofluids (water (40%)–ethylene glycol (60%) base fluid) with volume fraction of 3, 4 and 5% of nanosheets were increased by 32, 40 and 47%, respectively. The thermal conductivity of nanofluids significantly increases with increasing of the temperature. The reason for increasing in the value of thermal conductivity through the increasing of the graphene oxide volume percent is clear. The addition of nanoparticles gives a better enhancement with temperature. As previously mentioned, some authors explain the enhancement of thermal conductivity of nanofluids with the temperature by Brownian motion typically; an increase in temperature increases the Brownian motion of particles [81]. Nanofluids should have important effects on both the particle Brownian motion and the diffusive heat conduction due to the difference in the particles' aspect ratio [82]. The results include both RNEMD and theoretical model data. All the results are collected in Fig. 11a–c in order to evaluate data confirmation. In a close meaning, from Fig. 11a–c, it can be seen that the RNEMD results were compared with the results of theoretical models for thermal conductivity of nanofluids. It is possible to give a general correlation for thermal conductivity of nanofluids in terms of concentration, temperature, and thermal conductivity of base fluid, based on simulation results, but so many simulations is required, and because of long-time processing of molecular dynamics simulations, it was not available in this paper; nevertheless, it is proposed to conduct the mentioned procedure to achieve theoretical correlation.

The obtained thermal conductivity by RNEMD simulations and experimental data [83] is compared in Fig. 12 for pure ethylene glycol based nanofluid containing 2% GO. The results indicate that the RNEMD results have less than 6.6% deviation from the experimental data [83].

Comparison between RNEMD thermal conductivities and experimental data [83] for 2% GO in pure EG-based nanofluid

Conclusions

In the present work, classical molecular dynamics simulation and RNEMD simulation methods are used to investigate the stability and thermal conductivity of the water–ethylene glycol based graphene oxide nanofluid, respectively. The obtained results confirm the stability of water/graphene oxide nanofluid while with adding the ethylene glycol to the base fluids and increasing its content, the stability of nanofluids decreases.

Also, the obtained results indicated that the thermal conductivity of nanofluids increases by increasing the amount of nanosheet’s volume concentration. The thermal conductivity enhanced by a 47% at 46.7 °C for water (40%)-ethylene glycol (60%) based GO (5%) nanofluid. The heat transfer mechanism between nanofluid components is very complex. More studies are needed to find the effects of types of nanoparticles on the improvement of the thermal conductivity of nanofluids.

Molecular dynamics simulation method, due to its novel capabilities in the field of simulation of material properties, could play a constructive role in providing the cost-effective and accurate solutions for investigators. With respect to the importance of heat transfer capability for the mentioned fluids, it is beneficial to use nanofluid as an alternative to improve the heat transfer characteristics of the base fluid. The studied nanofluids can be used in industral applications as the heat transfer fluid in cold regions.

Abbreviations

- k :

-

Thermal conductivity (W (m K)−1)

- k B :

-

Boltzmann constant

- k eff :

-

Effective thermal conductivity of nanofluid

- L x :

-

Width of simulation box in x-direction

- L y :

-

Width of simulation box in y-direction

- L x L y :

-

The area through which heat transport takes place

- m :

-

Particle mass

- N :

-

Total number of system atoms

- r ij :

-

Distance between atom i and atom j

- r cut :

-

Cutoff radius

- t :

-

Simulation time

- T :

-

System temperature

- U :

-

Potential energy

- V :

-

System volume

- v c :

-

The velocity of the cold particle

- v h :

-

The velocity of the hot particle

- ε :

-

Dielectric constant

- ε ij :

-

Energy parameter in L–J potential

- β :

-

The ratio of the nanolayer thickness to the original particle radius

- φ :

-

Particle volumetric concentration

- \(\sigma_{ij }\) :

-

Length parameter in L–J potential

- bfm:

-

Base fluid mixture

- eff:

-

Effective

- i :

-

Space dimension

- j :

-

Space dimension

- m:

-

Mixture

- nf:

-

Nanofluid

- s:

-

Solid nanoparticle

References

Dang LX, Annapureddy HVR, Sun X, Thallapally PK, Peter MB. Understanding nanofluid stability through molecular simulation. Chem Phys Lett. 2012;551:115–20. https://doi.org/10.1016/j.cplett.2012.09.025.

Lee S, Choi S-S, Li S, Eastman J. Measuring thermal conductivity of fluids containing oxide nanoparticles. J Heat Transf. 1999;121(2):280–9.

Eastman J, Choi S, Li S, Yu W, Thompson L. Anomalously increased effective thermal conductivities of ethylene glycol-based nanofluids containing copper nanoparticles. Appl Phys Lett. 2001;78(6):718–20.

Garg J, Poudel B, Chiesa M, Gordon J, Ma J, Wang J, et al. Enhanced thermal conductivity and viscosity of copper nanoparticles in ethylene glycol nanofluid. J Appl Phys. 2008;103(7):074301.

Liu M-S, Lin MC-C, Tsai C, Wang C-C. Enhancement of thermal conductivity with Cu for nanofluids using chemical reduction method. Int J Heat Mass Transf. 2006;49(17):3028–33.

Liu MS, Lin MC, Huang IT, Wang CC. Enhancement of thermal conductivity with CuO for nanofluids. Chem Eng Technol. 2006;29(1):72–7.

Sedighi M, Mohebbi A. Investigation of nanoparticle aggregation effect on thermal properties of nanofluid by a combined equilibrium and non-equilibrium molecular dynamics simulation. J Mol Liq. 2014;197:14–22. https://doi.org/10.1016/j.molliq.2014.04.019.

Aref AH, Entezami AA, Erfan-Niya H, Zaminpayma E. Thermophysical properties of paraffin-based electrically insulating nanofluids containing modified graphene oxide. J Mater Sci. 2017;52:2642–60.

Esfe MH, Esfandeh S, Rejvani M. Modeling of thermal conductivity of MWCNT–SiO2 (30:70%)/EG hybrid nanofluid, sensitivity analyzing and cost performance for industrial applications. J Therm Anal Calorim. 2017;131:1437–47.

Mashaei P, Shahryari M, Madani S. Numerical hydrothermal analysis of water–Al2O3 nanofluid forced convection in a narrow annulus filled by porous medium considering variable properties. J Therm Anal Calorim. 2016;126(2):891–904.

Raei B, Shahraki F, Jamialahmadi M, Peyghambarzadeh S. Experimental study on the heat transfer and flow properties of γ-Al2O3/water nanofluid in a double-tube heat exchanger. J Therm Anal Calorim. 2017;127(3):2561–75.

Sharma P, Baek I-H, Cho T, Park S, Lee KB. Enhancement of thermal conductivity of ethylene glycol based silver nanofluids. Powder Technol. 2011;208(1):7–19.

Xuan Y, Li Q. Heat transfer enhancement of nanofluids. Int J Heat Fluid Flow. 2000;21(1):58–64. https://doi.org/10.1016/S0142-727X(99)00067-3.

Xuan Y, Roetzel W. Conceptions for heat transfer correlation of nanofluids. Int J Heat Mass Transf. 2000;43(19):3701–7. https://doi.org/10.1016/S0017-9310(99)00369-5.

Tadjarodi A, Zabihi F, Afshar S. Experimental investigation of thermo-physical properties of platelet mesoporous SBA-15 silica particles dispersed in ethylene glycol and water mixture. Ceram Int. 2013;39(7):7649–55.

Choi SUS, Eastman JA. Enhancing thermal conductivity of fluids with nanoparticles. ASME-Publ-Fed. 1995;231:99–106.

Yu W, Xie H, Li Y, Chen L, Wang Q. Experimental investigation on the thermal transport properties of ethylene glycol based nanofluids containing low volume concentration diamond nanoparticles. Colloids Surf A. 2011;380(1):1–5.

Krishnamurthy S, Bhattacharya P, Phelan P, Prasher R. Enhanced mass transport in nanofluids. Nano Lett. 2006;6(3):419–23.

Wasan DT, Nikolov AD. Spreading of nanofluids on solids. Nature. 2003;423(6936):156–9.

Ding Y, Alias H, Wen D, Williams RA. Heat transfer of aqueous suspensions of carbon nanotubes (CNT nanofluids). Int J Heat Mass Transf. 2006;49(1):240–50.

Wen D, Ding Y. Effective thermal conductivity of aqueous suspensions of carbon nanotubes (carbon nanotube nanofluids). J Thermophys Heat Transf. 2004;18(4):481–5.

Shaikh S, Lafdi K, Ponnappan R. Thermal conductivity improvement in carbon nanoparticle doped PAO oil: an experimental study. J Appl Phys. 2007;101(6):064302.

Yu W, Xie H, Wang X, Wang X. Significant thermal conductivity enhancement for nanofluids containing graphene nanosheets. Phys Lett A. 2011;375(10):1323–8.

Khoshvaght-Aliabadi M, Eskandari M. Influence of twist length variations on thermal–hydraulic specifications of twisted-tape inserts in presence of Cu–water nanofluid. Exp Therm Fluid Sci. 2015;61:230–40. https://doi.org/10.1016/j.expthermflusci.2014.11.004.

Abbasi FM, Hayat T, Ahmad B. Peristaltic transport of copper–water nanofluid saturating porous medium. Phys E. 2015;67:47–53. https://doi.org/10.1016/j.physe.2014.11.002.

Nayak RK, Bhattacharyya S, Pop I. Numerical study on mixed convection and entropy generation of Cu–water nanofluid in a differentially heated skewed enclosure. Int J Heat Mass Transf. 2015;85:620–34. https://doi.org/10.1016/j.ijheatmasstransfer.2015.01.116.

Xu H, Gong L, Huang S, Xu M. Flow and heat transfer characteristics of nanofluid flowing through metal foams. Int J Heat Mass Transf. 2015;83:399–407. https://doi.org/10.1016/j.ijheatmasstransfer.2014.12.024.

Malvandi A, Safaei MR, Kaffash MH, Ganji DD. MHD mixed convection in a vertical annulus filled with Al2O3–water nanofluid considering nanoparticle migration. J Magn Magn Mater. 2015;382:296–306. https://doi.org/10.1016/j.jmmm.2015.01.060.

Wan Z, Deng J, Li B, Xu Y, Wang X, Tang Y. Thermal performance of a miniature loop heat pipe using water–copper nanofluid. Appl Therm Eng. 2015;78:712–9. https://doi.org/10.1016/j.applthermaleng.2014.11.010.

Azimi M, Mozaffari A. Heat transfer analysis of unsteady graphene oxide nanofluid flow using a fuzzy identifier evolved by genetically encoded mutable smart bee algorithm. Eng Sci Technol Int J. 2015;18(1):106–23. https://doi.org/10.1016/j.jestch.2014.10.002.

Derakhshan MM, Akhavan-Behabadi MA, Mohseni SG. Experiments on mixed convection heat transfer and performance evaluation of MWCNT–oil nanofluid flow in horizontal and vertical microfin tubes. Exp Therm Fluid Sci. 2015;61:241–8. https://doi.org/10.1016/j.expthermflusci.2014.11.005.

Malvandi A, Ganji DD. Effects of nanoparticle migration on hydromagnetic mixed convection of alumina/water nanofluid in vertical channels with asymmetric heating. Phys E. 2015;66:181–96. https://doi.org/10.1016/j.physe.2014.10.023.

Samira P, Saeed ZH, Motahare S, Mostafa K. Pressure drop and thermal performance of CuO/ethylene glycol (60%)–water (40%) nanofluid in car radiator. Korean J Chem Eng. 2015;32(4):609–16.

Kim S, Yoo H, Kim C. Convective heat transfer of alumina nanofluids in laminar flows through a pipe at the thermal entrance regime. Korean J Chem Eng. 2012;29(10):1321–8.

Bahiraei M, Hosseinalipour SM. Accuracy enhancement of thermal dispersion model in prediction of convective heat transfer for nanofluids considering the effects of particle migration. Korean J Chem Eng. 2013;30(8):1552–8.

Reddy M, Rao VV, Reddy B, Sarada SN, Ramesh L. Thermal conductivity measurements of ethylene glycol water based TiO2 nanofluids. Nanosci Nanotechnol Lett. 2012;4(1):105–9.

Buongiorno J. Convective transport in nanofluids. J Heat Transf. 2006;128(3):240–50.

Syam Sundar L, Venkata Ramana E, Singh MK, Sousa ACM. Thermal conductivity and viscosity of stabilized ethylene glycol and water mixture Al2O3 nanofluids for heat transfer applications: an experimental study. Int Commun Heat Mass Transf. 2014;56:86–95. https://doi.org/10.1016/j.icheatmasstransfer.2014.06.009.

Sundar LS, Farooky MH, Sarada SN, Singh MK. Experimental thermal conductivity of ethylene glycol and water mixture based low volume concentration of Al2O3 and CuO nanofluids. Int Commun Heat Mass Transf. 2013;41:41–6. https://doi.org/10.1016/j.icheatmasstransfer.2012.11.004.

Saeedinia M, Akhavan-Behabadi M, Nasr M. Experimental study on heat transfer and pressure drop of nanofluid flow in a horizontal coiled wire inserted tube under constant heat flux. Exp Therm Fluid Sci. 2012;36:158–68.

Zafarani-Moattar MT, Majdan-Cegincara R. Effect of temperature on volumetric and transport properties of nanofluids containing ZnO nanoparticles poly(ethylene glycol) and water. J Chem Thermodyn. 2012;54:55–67.

Peyghambarzadeh S, Hashemabadi S, Hoseini S, Jamnani MS. Experimental study of heat transfer enhancement using water/ethylene glycol based nanofluids as a new coolant for car radiators. Int Commun Heat Mass Transf. 2011;38(9):1283–90.

Duangthongsuk W, Wongwises S. An experimental study on the heat transfer performance and pressure drop of TiO2–water nanofluids flowing under a turbulent flow regime. Int J Heat Mass Transf. 2010;53(1):334–44.

Meibodi ME, Vafaie-Sefti M, Rashidi AM, Amrollahi A, Tabasi M, Kalal HS. The role of different parameters on the stability and thermal conductivity of carbon nanotube/water nanofluids. Int Commun Heat Mass Transf. 2010;37(3):319–23.

Demir H, Dalkilic A, Kürekci N, Duangthongsuk W, Wongwises S. Numerical investigation on the single phase forced convection heat transfer characteristics of TiO2 nanofluids in a double-tube counter flow heat exchanger. Int Commun Heat Mass Transf. 2011;38(2):218–28.

Duangthongsuk W, Wongwises S. Heat transfer enhancement and pressure drop characteristics of TiO2–water nanofluid in a double-tube counter flow heat exchanger. Int J Heat Mass Transf. 2009;52(7):2059–67.

Allen MP, Tildesley DJ. Computer simulation of liquids. Oxford: Oxford University Press; 1989.

Sadus RJ. Molecular simulation of fluids. Amsterdam: Elsevier Science; 2002.

Hajjar Z, Morad Rashidi A, Ghozatloo A. Enhanced thermal conductivities of graphene oxide nanofluids. Int Commun Heat Mass Transf. 2014;57:128–31.

Bhanvase BA, Sarode MR, Putterwar LA, Abdullah KA, Deosarkar MP, Sonawane SH. Intensification of convective heat transfer in water/ethylene glycol based nanofluids containing TiO2 nanoparticles. Chem Eng Process. 2014;82:123–31. https://doi.org/10.1016/j.cep.2014.06.009.

Reddy MCS, Rao VV. Experimental studies on thermal conductivity of blends of ethylene glycol–water-based TiO2 nanofluids. Int Commun Heat Mass Transf. 2013;46:31–6. https://doi.org/10.1016/j.icheatmasstransfer.2013.05.009.

Shamaeil M, Firouzi M, Fakhar A. The effects of temperature and volume fraction on the thermal conductivity of functionalized DWCNTs/ethylene glycol nanofluid. J Therm Anal Calorim. 2016;126(3):1455–62.

Peyghambarzadeh SM, Hashemabadi SH, Hoseini SM, Jamnani MS. Experimental study of heat transfer enhancement using water/ethylene glycol based nanofluids as a new coolant for car radiators. Int Commun Heat Mass Transf. 2011;38:1283–90.

Esfe MH, Arani AAA, Badi RS, Rejvani M. ANN modeling, cost performance and sensitivity analyzing of thermal conductivity of DWCNT–SiO2/EG hybrid nanofluid for higher heat transfer. J Therm Anal Calorim. 2017. https://doi.org/10.1007/s10973-017-6744-z.

Sankar N, Mathew N, Sobhan C. Molecular dynamics modeling of thermal conductivity enhancement in metal nanoparticle suspensions. Int Commun Heat Mass Transf. 2008;35(7):867–72.

Sun C, Lu W-Q, Liu J, Bai B. Molecular dynamics simulation of nanofluid’s effective thermal conductivity in high-shear-rate Couette flow. Int J Heat Mass Transf. 2011;54(11):2560–7.

Chang J, Kim H. Molecular dynamic simulation and equation of state of Lennard–Jones chain fluids. Korean J Chem Eng. 1998;15(5):544–51.

Erfan-Niya H, Izadkhah S. Molecular insights into structural properties around the threshold of gas hydrate formation. Pet Sci Technol. 2016;34(24):1964–71.

Gharebeiglou M, Erfan-Niya H, Izadkhah S. Molecular dynamics simulation study on the structure II clathrate-hydrates of methane + cyclic organic compounds. Pet Sci Technol. 2016;34(14):1226–32.

Kang H, Zhang Y, Yang M, Li L. Nonequilibrium molecular dynamics simulation of coupling between nanoparticles and base-fluid in a nanofluid. Phys Lett A. 2012;376(4):521–4.

Frenkel D, Smit B. Understanding molecular simulation: from algorithms to applications. London: Academic Press; 2001.

Nosé SI. A molecular dynamics method for simulations in the canonical ensemble. Mol Phys. 2002;100(1):191–8.

Ewald PP. Ewald summation. Ann Phys. 1921;64:253–371.

Green HS. The quantum mechanics of assemblies of interacting particles. J Chem Phys. 1951;19(7):955–62.

Kubo R. Statistical–mechanical theory of irreversible processes. I. General theory and simple applications to magnetic and conduction problems. J Phys Soc Jpn. 1957;12(6):570–86.

Müller-Plathe F. Reversing the perturbation in nonequilibrium molecular dynamics: an easy way to calculate the shear viscosity of fluids. Phys Rev E. 1999;59(5):4894.

Müller-Plathe F. A simple nonequilibrium molecular dynamics method for calculating the thermal conductivity. J Chem Phys. 1997;106(14):6082–5.

Plimpton S. Fast parallel algorithms for short-range molecular dynamics. J Comput Phys. 1995;117(1):1–19.

Dauber-Osguthorpe P, Roberts VA, Osguthorpe DJ, Wolff J, Genest M, Hagler AT. Structure and energetics of ligand binding to proteins: Escherichia coli dihydrofolate reductase-trimethoprim, a drug–receptor system. Proteins Struct Funct Bioinform. 1988;4(1):31–47.

Reid RC, Prausnitz JM, Poling BE. The properties of gases and liquids. New York: McGraw-Hill; 1987.

Swope WC, Andersen HC, Berens PH, Wilson KR. A computer simulation method for the calculation of equilibrium constants for the formation of physical clusters of molecules: application to small water clusters. J Chem Phys. 1982;76(1):637–49.

Wasp EJ, Kenny JP, Gandhi RL. Solid–liquid flow: slurry pipeline transportation.[Pumps, valves, mechanical equipment, economics]. Ser. Bulk Mater. Handl., vol 4. Clausthal: Trans. Tech. Publ.; 1977.

Yu W, Choi S. The role of interfacial layers in the enhanced thermal conductivity of nanofluids: a renovated Maxwell model. J Nanoparticle Res. 2003;5(1–2):167–71.

Bruggeman D. Calculation of various physics constants in heterogenous substances I: dielectricity constants and conductivity of mixed bodies from isotropic substances. Ann Phys. 1935;24(7):636–64.

Wang B-X, Zhou L-P, Peng X-F. A fractal model for predicting the effective thermal conductivity of liquid with suspension of nanoparticles. Int J Heat Mass Transf. 2003;46(14):2665–72.

Shen X, Lin X, Yousefi N, Jia J, Kim J-K. Wrinkling in graphene sheets and graphene oxide papers. Carbon. 2014;66:84–92.

Bagri A, Mattevi C, Acik M, Chabal YJ, Chhowalla M, Shenoy VB. Structural evolution during the reduction of chemically derived graphene oxide. Nat Chem. 2010;2(7):581–7.

Zhang J, Jiang D. Molecular dynamics simulation of mechanical performance of graphene/graphene oxide paper based polymer composites. Carbon. 2014;67:784–91.

Mansoori GA. Radial distribution functions and their role in modeling of mixtures behavior. Fluid Phase Equilibr. 1993;87(1):1–22.

ASHRAE. ASHRAE Handbook—fundamentals. Atlanta: American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.; 2009.

Mintsa HA, Roy G, Nguyen CT, Doucet D. New temperature dependent thermal conductivity data for water-based nanofluids. Int J Therm Sci. 2009;48(2):363–71.

Han Z. Nanofluids with enhanced thermal transport properties. University of Maryland at College Park: Ph.D. thesis; 2008.

Wei Y. Enhanced thermal conductivities of nanofluids containing graphene oxide nanosheets. Nanotechnology. 2010;21:055705.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Izadkhah, MS., Erfan-Niya, H. & Heris, S.Z. Influence of graphene oxide nanosheets on the stability and thermal conductivity of nanofluids. J Therm Anal Calorim 135, 581–595 (2019). https://doi.org/10.1007/s10973-018-7100-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7100-7