Abstract

We selected Camellia tenuifolia (Hayata) seed oil to compare the effects of mushroom extract and vitamin E on its stabilization properties. Camellia tenuifolia was selected for its higher oil content, but its proportions of unsaturated fatty acids and natural antioxidants as well as its oxidation stability are lower than those of Camellia oleifera oil. Our aim was to improve the oxidation stability, thermal stability, and photodegradation of C. tenuifolia seed oil and then compare the advantages of mixing traditional antioxidant (vitamin E) and mushroom natural antioxidant components (mushroom extract) in the oil. The focus was on the analysis of the effects of Pleurotus citrinopileatus (Singer) extract and vitamin E on the stabilization properties of C. tenuifolia seed oil, which involved some degradation research, such as evaluating the thermal, oxidation, and antioxidant effects as well as the irradiative (pulsed light) stability of the original oil and oil mixed with additives for comparing the differences by differential scanning calorimetry tests and isothermal microcalorimeter (TAM Air) analyses. We determined the effects of stabilization additives vitamin E and various PC extract doses by using pulsed light irradiation (0, 30, and 60 pulses) and found that the 3 mass% PC extract had the best antiphotodegradation characteristics, and the 0.1 mass% vitamin E indicated the outstanding oxidation stability for among all of the additives in this study. Overall, we obtained the following suitable conditions to stabilize camellia oil: addition of vitamin E, addition of 3 mass% PC extract, and a nitrogen atmosphere.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The seeds of Camellia tenuifolia (Hayata)/oleifera can be pressed to obtain high-quality oils (camellia seed oils) that are used extensively for cooking in Taiwan [1]. The fatty acid compositions of edible oils have been closely associated with changes in health. Camellia oil contains abundant unsaturated fatty acids consisting of oleic acid and linoleic acid. The unsaturated fatty acid content in the oil is more than 90 mass%, which is the highest amount reported thus far in edible oils [2]. Moreover, its monounsaturated fatty acid content is greater than that of olive oil, while its unsaturated fatty acid content complies with the international nutritional standards of meals high in omega-3 fatty acids. It is also rich in vitamin E, containing twice as much as olive oil, and it contains squalene and flavonoids [3].

Camellia oil is applied in a medicine for stomach aches and burns [4], and it is antimicrobial, antiviral [5], has skin healing properties [6], protects the liver against CCl4-induced oxidative damage [7], suppresses the cholesterol content in the body, and promotes resistance to oxidative stress [8]. We selected Camellia tenuifolia to compare the effects of Pleurotus citrinopileatus (Singer) (Pleurotaceae, Agaricomycetes) extract and vitamin E (vit E) on the stabilization properties. The main advantage of Camellia tenuifolia is its higher oil content, but its proportions of unsaturated fatty acids and natural antioxidants as well as its oxidation stability are lower than those of Camellia oleifera. Thus, our aim was to improve the oxidation stability, thermal stability, and photodegradation properties of Camellia tenuifolia seed oils and then compare mixing traditional antioxidant (vitamin E) and mushroom natural antioxidant components (mushroom extract) in the oil.

The mushroom extract was from the culinary-medicinal golden oyster mushroom Pleurotus citrinopileatus (PC), which is a popular species in many countries, especially in Asia [9, 10]. Many scientific studies indicate that this mushroom possesses biological and pharmacological activity, such as antitumor activity, antigenotoxicity, and antihyperglycemic effect [11,12,13]. Chen et al. [14] also examined the ergothioneine (EGT) content of the mushroom extracts from the fruiting bodies and mycelia of 20 edible and medicinal mushroom species and found that species of the genus Pleurotus contained substantial amounts of ergothioneine (2-mercaptohistidine trimethylbetaine), which is also one of the main reasons for using the mushroom extract as a natural antiaging additive [15,16,17]. Ergothioneine is an effective intrinsic antihydroxyl radical, antiperoxyl radical, and antiperoxynitrite radical antioxidant compared with classic molecules with antioxidant capacities, such as reduced glutathione, uric acid, and Trolox [18]. The mushroom extract also contains other antioxidants, such as flavonoids and phenols, which are also beneficial to human health.

Pulsed light is a high-energy short pulse current through an inert gas (xenon) of the bulb that stimulates a high-intensity white light; the broadband wave number of white light is from 190 to 700 nm, and it contains ultraviolet, visible, and infrared light [19]. It also has a short irradiation time with no radiation, no chemical residues, low energy pollution, and high efficiency [20]. Pulsed light irradiation causes the inactivation photochemical effect on microorganisms. When microorganisms absorb pulsed light, it changes the structure of DNA, the genetic information, causing damage, preventing cell replication and division, and finally causing microbial death [21]. This achieves sterilization but has insignificant effects on the nutritional value and quality of food [22]. Thus, it is gradually replacing the traditional disadvantages of sterilization under high-temperature and high-pressure conditions.

The focus of the study was on the effects of Pleurotus citrinopileatus extract and vitamin E on the stabilization properties of Camellia tenuifolia seed oil. We came up with a novel idea for adding natural, healthy, and physiologically active natural antioxidants, which will involve some degradation research, such as evaluating the thermal, oxidation, antioxidant effect, and irradiation (pulsed light) stabilities of the original oil as well as with the addition of additives for comparing the differences by differential scanning calorimetry (DSC) tests and isothermal microcalorimeter (TAM Air) analyses. We are also developing a novel approach to elucidate the degradation conditions, including the thermal, strong light exposure, and antioxidation properties, of the original camellia oil for proper storage and antidegrading conditions, such as the onset temperature (DSC)/time (TAM Air), the peak maximum temperature (DSC)/time (TAM Air), and the exothermic reaction by thermal analyses. The parameters and properties can be applied to design food processing, heat treatment, and storage conditions.

Materials and methods

Materials

Camellia tenuiflora seeds were obtained from a local market in the city of Taichung, Taiwan. Camellia oil was obtained by pressing dehusked camellia seeds at 65 °C with pre-roasting. The oil thus obtained was subjected to filtration using a filter cloth to remove physical impurities, and it was transferred to transparent glass bottles stored in the dark at 4 °C. The original fatty acid profile of camellia oil was studied by gas chromatography (GC) (Agilent 6890N, Wilmington, DE, USA) equipped with a flame ionization detector (GC-FID) and a Restek Rt-2340 NB Cap. column (105 m × 0.25 mm × 0.20 µm) analysis [23]. The camellia oil fatty acid profile was determined to be as follows: oleic acid (82.05 mass%), palmitic acid (7.70 mass%), linoleic acid (8.06 mass%), and stearic acid (2.19 mass%) (see Table 1).

Mushroom extract

Fruit bodies of Pleurotus citrinopileatus mushrooms were purchased from Xie-Yi Agricultural Products Company (Taichung, Taiwan) and then freeze-dried. Afterward, a coarse powder (60 mesh) was obtained using a mill (Retsch ultracentrifugal mill and sieving machine, Haan, Germany). The mushroom extract was prepared following the procedure of Lin et al. [24] with slight modifications. A subsample (10 g) was extracted by stirring with 200 mL of 75 °C water at 125 rpm for 60 min and filtering through Whatman No. 1 filter paper. The precipitate obtained was stirred again in 200 mL of 75 °C water and centrifuged. The combined supernatant was evaporated at 40 °C in vacuo. The obtained residue was dissolved in 10 mL of distilled water and stored at 4 °C for further use. Consequently, the concentration of mushroom extract was 0.365 g dry material mL−1 (see Table 2).

Mixture preparation

Pleurotus citrinopileatus extract (1, 3, and 5 mass% PC extract) and synthetic antioxidants (0.1 mass% vitamin E, T3634, Sigma-Aldrich, St. Louis, MO, USA) were added directly to camellia oil. A control sample was prepared using camellia oil without any antioxidant. All of the samples were kept at 4 °C. Figure 1 presents a flow diagram showing the effects of the PC extracts and vitamin E on the prevention of oxidation in the camellia oil.

Determination of antioxidant components

Ergothioneine, flavonoids, and total phenols were determined according to the methods described by Liang et al. [25], Zhishen et al. [26], and Taga et al. [27], respectively. The amounts of the components were calculated on the basis of the calibration curves of the corresponding authentic compounds; gallic acid and quercetin were used for the total phenols and flavonoids, respectively. The antioxidant properties were calculated as follows: chelating ability and scavenging activity (%) = [(ΔAbs of control − ΔAbs of sample)/ΔAbs of control] × 100. A value of 100% indicates the strongest chelating ability or scavenging activity. A higher absorbance indicates a higher reducing power.

Determination of the antioxidant properties

The reducing power was determined according to the method of Oyaizu [28]. The reducing power assayed is the ability of the extracts to form a colored complex with ferricyanide, which is an electron acceptor. The scavenging ability of 2,2-diphenyl-1-picrylhydrazyl (DPPH) radicals was determined on the basis of Shimada et al. [29]. The scavenging ability assayed is the ability of the extracts to react with DPPH radicals and reduce most DPPH radical molecules. The chelating ability was determined according to the method of Dinis et al. [30]. Ferrous ions play an important role as catalysts in the oxidative process, leading to the formation of hydroxyl radicals and hydroperoxide decomposition by the Fenton reaction. The chelating ability assayed is the ability of the extracts to inhibit the formation of complexes of ferrozine and ferrous ions.

Pulsed light irradiation

Samples were subjected to irradiation using a Xenon RC-801 pulsed light system (Xenon Corp.) employing a LH-840 lamp housing and B-type 16″ linear lamp (280–700 nm). The apparatus generated three pulses per second at 169 J pulse−1. An average dose was 11.50 kJ m−2 pulse−1 [31]. A 10 g sample mixture was placed in the Petri dish and irradiated with 0, 30, or 60 pulses.

Differential scanning calorimetry (DSC) tests

Calorimetric measurements were taken with a DSC (TA Q20) (TA Instruments, Newcastle, DE, USA). DSC analysis was performed on samples sealed in 20-μL aluminum pans; the test cell was sealed manually by a special tool equipped for TA’s DSC. In all DSC studies, nitrogen was the purge gas with a flow rate of 50 mL min−1. ASTM E698 was used to obtain thermal curves for analyzing the parameters. Samples of 1.4–1.8 mg were used for acquiring the experimental data [32,33,34,35,36]. Non-isothermal tests of the scanning rate selected for the programmed temperature ramp were 2, 4, 6, and 8 °C min−1, and after the oil underwent pulsed light irradiation treatment, the scanning rate selected for the programmed temperature ramp was 4 °C min−1 for the range of temperatures chosen from 30 to 450 °C for each experiment.

Measurement of the oxidation stability

The oxidation stability analysis experiments were performed using a TAM Air isothermal microcalorimeter (TA Instruments, Newcastle, DE, USA), which was equipped with eight twin calorimetric channels. One side of the microcalorimeter was used for the sample, and the other was used for a static reference. The generated signal was recorded in situ by a computer. Isothermal microcalorimeter measurements were taken using the ampoule method, and the instrument was brought to equilibrium temperature overnight in advance. The operating temperature range of the TAM Air thermostat was from 5 to 90 °C, with a stability of ±0.02 °C. The baseline was held at ~20 μW. We used the TAM Air software to control the thermostat [37, 38]. All 20-mL ampoules were cleaned prior to use. Next, approximately 1 mL of sample was placed in each ampoule and used for acquiring the experimental data. A TAM Air isothermal microcalorimeter was used to investigate the oxidation stability at 60.5 °C. The TAM Air isothermal microcalorimeter results for all samples were evaluated using PC extract and vitamin E with camellia oil under an isothermal temperature of 60.5 °C. We prepared approximately 1 g of each for each degradation process, blew away air using oxygen and nitrogen for 30 min under oxidizing and non-oxidizing conditions, respectively, never did any blowing under normal conditions, and then sealed all samples in glass ampoules. The original camellia oil (non-refined) was used as a control.

Results and discussion

The results of the materials analyses

Table 1 shows the fatty acid composition of camellia oil from GC analysis, which verified the fatty acid composition of the camellia oil and confirmed that the amount of oleic acid and linoleic acid was more than 90 mass% of the total unsaturated fatty acids. From Table 2, we obtained a Pleurotus citrinopileatus mushroom extraction yield of 36.5 mass%, and the antioxidant component of Pleurotus citrinopileatus mushroom extract, ergothioneine (0.59 mg mL−1), has the highest proportion in the extract. Moreover, comparing the data in Table 3 of the antioxidant properties with the chelating ability, reducing power, and scavenging activity, respectively, it is clear that vitamin E has outstanding antioxidant properties among all of the additives, and increasing PC extract doses increased the antioxidant properties.

DSC analysis

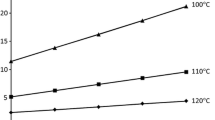

In Fig. 2, the DSC curves clearly show that the original camellia oil (non-refined) with various scanning rates of 2, 4, 6, and 8 °C min−1 undergoes a distinct exothermic reaction. The onset temperature, peak maximum temperature, and enthalpy of the exothermic reaction associated with the DSC transition were found in determining the thermal characteristics of the camellia oil. The detailed results of DSC analysis are listed in Table 4. From Table 4, it can be observed that the onset temperature was ca. 140 °C, which was previously reported for the exothermic reaction of camellia oil. The main exothermic reaction was thermal decomposition behavior by heat, which could be obtained from the original camellia oil’s (non-refined) peak maximum temperature of ca. 170 °C. Generally, edible oil used in food cooking will not exceed 300 °C, thus more than 300 °C of the endothermic reaction, so we did not do further research in this study.

Figure 2 shows that the original camellia oil (non-refined) did not have good thermal properties. In addition, DSC was used with four scanning rates (2, 4, 6, and 8 °C min−1) to analyze the original camellia oil and compare the exothermic reaction characteristics. The peak temperature is also influenced by the scanning rate. The DSC thermal curves of the original camellia oil show a delay in the peak temperature. The greater scanning rates (6 and 8 °C min−1) may lead to a wide DSC thermal curve, neglecting the slight exothermic reaction differences. Therefore, when analyzing the original camellia oil for thermal and irradiation (pulsed light) stability, we added additives to compare the differences in the DSC tests and found better conditions at the lower scanning rate. Thus, we selected a scanning rate of 4 °C min−1 as a follow-up to pulsed light irradiation to determine its effects on camellia oil-related research.

The effect of additive mixed in camellia oil with pulsed light irradiation

Camellia oil was either not irradiated (control) or irradiated with pulsed light with doses of 0, 30, and 60 pulses at ambient temperature. Table 5 and Figs. 3–7 show original camellia oil and that with additive (0.1 mass% vitamin E, 1 mass% PC extract, 3 mass% PC extract, and 5 mass% PC extract) for comparing the differences with various doses of pulsed light irradiation (0, 30, and 60 pulses) by DSC tests. Moreover, comparing Tables 1 and 2, we confirmed that after pulsed light irradiation, the quality of the oil was indeed affected, and as the irradiation dose increased, the onset temperature was pushed to a lower temperature.

Table 5 shows the results of mixing 0.1 mass% vitamin E additive in camellia oil with various doses of pulsed light irradiation (0, 30, and 60 pulses), and the results indicate that for 0.1 mass% vitamin E compared with the original oil, the onset temperature was promoted from 143 to 153 °C, indicating good antiphotodegradation characteristics. Table 5 and Fig. 6 show the 3 mass% PC extract additive mixed in oil under lower doses of pulsed light irradiation, such as 0 and 30 pulses, and this mixture exhibited excellent antiphotodegradation characteristics, which were better than those of 0.1 mass% vitamin E. In addition, Table 5 and Fig. 6 show that for 3 mass% PC extract additive mixed in oil under a lower dose of pulsed light irradiation, in the DSC tests for the range of temperatures from 30 to 300 °C, we did not see any exothermic reaction. This is probably because the PC extract contains ergothioneine, which has good UV resistance and is often added to cosmetics as a sunscreen agent or antioxidant [39].

Oxidation stability measurement results

TAM Air isothermal analysis was set up at 60.5 °C, the temperature at which the liquid chemicals of gasoline, diesel, and volatile organic solvents emit sufficient flammable vapor to bring the concentration of the flammable vapor in the head space above the liquid to the lower flammable limit. Thus, this temperature is usually adopted to classify liquid chemicals, such as gasoline, diesel, and volatile organic solvents, for the purpose of assessing their fire and explosion hazards, and a liquid chemical with a flash point below 60.5 °C is defined as a flammable liquid by the US Department of Transportation (DOT 49 CFR 173.120), requiring special protective procedures to be implemented while storing or transporting it [40].

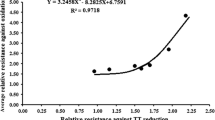

The results for the TAM Air measurement under a high isothermal temperature of 60.5 °C in different atmospheres of air, nitrogen, and oxygen for various additives mixed in original camellia oil were obtained, and then, we determined the oxidation stability of the oil. Figures 8–10 show that all of the samples under a nitrogen atmosphere have good stability, but under air and oxygen atmospheric conditions, a significant exothermic peak appears. Comparing the original camellia oil under air, nitrogen, and oxygen atmospheric conditions in Table 6, we found that under an oxygen atmosphere, the oil stability was destroyed more than in air or nitrogen, which showed that when the oil was exposed to air and oxygen, the oxygen oxidized the oil.

In addition, the oxidation stability measurement results in Table 6 and Figs. 8 and 10 show that the original camellia oil and that with additive (0.1 mass% vitamin E, 1 mass% PC extract, 3 mass% PC extract, and 5 mass% PC extract) indicate the differences in TAM analyses under air and oxygen atmospheres. This table and these figures also indicate that increasing PC extract doses increases the thermal and oxidation stabilities (the stabilities for 1, 3, and 5 mass% PC extract were 1725, 2375, and 2450 min and 2500, 2450, and 2500 min under air and oxygen atmospheres, respectively). Moreover, comparing Figs. 8 and 10, we confirmed that for 0.1 mass% vitamin E compared with the original oil, the onset time was raised from 1275 to 8325 min and from 1100 to 9625 min under air and oxygen atmospheres, respectively, which showed the outstanding antioxidation characteristics under a high isothermal temperature. In addition, Table 6 and Figs. 8 and 10 show that when the PC extract was added into the oil, it presented an antioxidant effect, but this effect was not as good as the effect of vitamin E. Then, by using the DSC and TAM Air calorimeters, we compared the thermal, oxidation, and antioxidant effects as well as irradiation (pulsed light) stabilities of the original oil and that with additives, which could establish the suitable conditions to stabilize camellia oil as follows: addition of vitamin E, addition of 3 mass% PC extract, and nitrogen atmosphere.

Conclusions

To evaluate the effects of Pleurotus citrinopileatus extract and vitamin E on the stabilization properties of Camellia tenuifolia seed oil, we developed a novel approach for adding natural, healthy, and physiologically active natural antioxidants to elucidate the degradation, including evaluating the thermal stability, stability after strong light exposure, and antioxidation properties of the original camellia oil to determine proper storage and stabilization conditions. We compared the effects of stabilization additives vitamin E and various PC extract doses by using pulsed light irradiation (0 and 30 pulses) and found that the 3 mass% PC extract had the best antiphotodegradation characteristics among all of the additives used in this study. In addition, the significant results of the oxidation stability measurements indicated that for the 0.1 mass% vitamin E additive compared with the original oil, the onset time of degradation was raised from 1275 to 8325 min and from 1100 to 9625 min under air and oxygen atmospheres, respectively, which showed the superior antioxidation characteristics of all of the additives under high isothermal temperatures. Overall, by conducting tests with the DSC and TAM Air calorimeters, we obtained the following suitable conditions to stabilize camellia oil: addition of vitamin E, addition of 3 mass% PC extract, and a nitrogen atmosphere. This study is a forward-looking and innovative research project on the effects of functional ingredients of Pleurotus citrinopileatus on improving food oil processing and storage conditions. In the future, our goal is to improve the processing technology for healthy foods and improve the use of functional ingredients in the food safety and food processing areas.

References

Su MH, Shih MC, Lin KH. Chemical composition of seed oils in native Taiwanese Camellia species. Food Chem. 2014;156:369–73.

Feas X, Estevinho LM, Vela P, Sains MJ, Seijas JA. Triacylglyceride. antioxidant and antimicrobial features of virgin Camellia olifers, C. reticulata and C. saanqua oils. Molecules. 2013;18:4573–8.

Li H, Zhou GY, Zhang HY, Liu JA. Research progress on the health function of tea oil. J Med Plants Res. 2011;5:485–9.

Zhang LL, Wang YM, Wu DM, Xu M, Chen JH. Comparisons of antioxidant activity and total phenolics of Camellia oleifera Abel fruit hull from different regions of China. J Med Plants Res. 2010;4:1407–13.

Akihisa T, Tokuda H, Ukiya M, Suzuki T, Enjo F, Koike K, Nikaido T, Nishino H. 3-epicabraleahydroxylactone and other triterpenoids from camellia oil and their inhibitory effects on Epstein-Barr virus activation. Chem Pharm Bull (Tokyo). 2004;52:153–6.

Jung E, Lee J, Baek J, Jung K, Lee J, Huh S, Kim S, Koh J, Park D. Effect of Camellia japonica oil on human type I procollagen production and skin barrier function. J Ethnopharmacol. 2007;112:127–31.

Lee CP, Shih PH, Hsu CL, Yen GC. Hepatoprotection of tea seed oil (Camellia oleifera Abel.) against CCl4-induced oxidative damage in rats. Food Chem Toxicol. 2007;45:888–95.

Xiao H, Yao Z, Peng Q, Ni F, Sun Y, Zhang CX, Zhong ZX. Extraction of squalene from camellia oil by silver ion complexation. Sep Purif Technol. 2016;169:196–201.

Wu CY, Mau JL, Liang ZC. The influence of cultivation conditions on mycelial growth and exopolysaccharide production of culinary-medicinal mushroom Pleurotus citrinopileatus Singer (Agaricomycetideae). Int J Med Mushrooms. 2008;10:279–92.

Lee LY, Huang GW, Liang ZC, Mau JL. Antioxidant properties of three extracts from Pleurotus citrinopileatus. LWT-Food Sci Technol. 2007;30:823–33.

Lin SY, Chien SC, Wang SY, Mau JL. Nonvolatile taste components and antioxidant properties of fruiting body and mycelium with high ergothioneine content from the culinary-medicinal golden oyster mushroom Pleurotus citrinopileatus (Agaricomycetes). Int J Med Mushrooms. 2016;18(8):689–98.

Chen PH, Weng YM, Yu ZR, Koo M, Wang B. Extraction temperature affects the activities of antioxidation, carbohydrate-digestion enzymes, and angiotensin-converting enzyme of Pleurotus citrinopileatus extract. J. Food Drug Anal. 2016;24:548–55.

Hu SH, Wang JC, Lien JL, Liaw ET, Lee MY. Antihyperglycemic effect of polysaccharide from fermented broth of Pleurotus citrinopileatus. Appl Microbiol Biotechnol. 2006;70:107–13.

Chen SY, Ho KJ, Hsieh YJ, Wang LT, Mau JL. Contents of lovastatin, γ-aminobutyric acid and ergothioneine in mushroom fruiting bodies and mycelia. LWT Food Sci Technol. 2012;47:274–8.

Dubost NJ, Ou B, Beelman RB. Quantification of polyphenols and ergothioneine in cultivated mushrooms and correlation to total antioxidant capacity. Food Chem. 2007;105:727–35.

Hartman PE. Ergothioneine as an antioxidant. Methods Enzymol. 1990;186:310–8.

Aruoma OI, Spencer JPE, Mahmood N. Protection against oxidative damage and cell death by the natural antioxidant ergothioneine. Food Chem Toxicol. 1999;37:1043–53.

Franzoni F, Colognato R, Galetta F, Laurenza I, Barsotti M, Di Stefano R, Bocchetti R, Regoli F, Carpi A, Balbarini A, Migliore L, Santoro G. An in vitro study on the free radical scavenging capacity of ergothioneine: comparison with reduced glutathione, uric acid and trolox. Biomed Pharmaco therap. 2006;60:453–7.

Gόmez- Lόpez VM, Ragaert P, Debevere J, Devlieghere F. Pulsed light for food decontamination: a review. Trends Food Sci Technol. 2007;18:464–73.

Dunn J, Ott T, Clark W. Pulsed-light treatment of food and packaging. Food Technol. 1995;49:95–8.

McDonald KF, Curry RD, Clevenger TE, Unklesbay K, Eisenstack A, Golden J, Morgan RD. A comparison of pulsed and continuous ultraviolet light sources for the decontamination of surfaces. IEEE Transac Plasma Sci. 2000;28:1581–7.

Ross AIV, Griffiths MW, Mittal GS, Deeth HC. Combining nonthermal technologies to control foodborne microorganisms. Int J Food Microbiol. 2003;89:125–38.

Metcalfe LD, Schmitz AA, Pelka JR. Rapid preparation of fatty acid esters from lipids for gas chromatographic analysis. Anal Chem. 1966;38:514–5.

Lin SY, Chien SC, Wang SY, Mau JL. Submerged cultivation of mycelium with high ergothioneine content from the culinary-medicinal golden oyster mushroom, Pleurotus citrinopileatus (higher Basidiomycetes). Int J Med Mushrooms. 2015;17:749–61.

Liang CH, Huang LY, Ho KJ, Lin SY, Mau JL. Submerged cultivation of mycelium with high ergothioneine content from the culinary-medicinal king oyster mushroom Pleurotus eryngii (higher Basidiomycetes) and its composition. Int J Med Mushrooms. 2013;15:153–64.

Taga MS, Miller EE, Pratt DE. Chia seeds as a source of natural lipid antioxidants. J Am Oil Chem Soc. 1984;61:928–31.

Zhishen J, Mengcheng T, Jianming W. The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem. 1999;64:555–9.

Oyaizu M. Antioxidative activity of browning products of glucosamine fractionated by organic solvent and thinlayer chromatography. Nippon Shokuhin Kogyo Gakkai. 1986;35:771–5.

Shimada K, Fujikawa K, Yahara K, Nakamura T. Antioxidative properties of xanthan on the autoxidation of soybean oil in cyclodextrin emulsion. J Agric Food Chem. 1992;40:945–8.

Dinis TCP, Madeira VMC, Almeida LM. Action of phenolic derivatives (acetaminophen, salicylate, and 5-amino salicylate) as inhibitors of membrane lipid peroxidation and as peroxyl radical scavengers. Arch Biochem Biophys. 1994;315:161–9.

Tsai SY, Hwang BF, Wang YH, Lin CP. Moisture desorption and thermal properties of polysaccharide from pulsed light irradiated Flammulina velutipes. J Therm Anal Calorim. 2017;127:469–81.

Boillat-Blanco N, Tafin UF, Jaton K, Trampuz A. Susceptibility testing of Mycobacterium abscessus by isothermal microcalorimetry. Diagn Microbiol Infect Dis. 2015;83:139–43.

Kabanova N, Stulova I, Vilu R. Microcalorimetric study of the growth of bacterial colonies of Lactococcus lactis IL1403 in agar gels. Food Microbiol. 2012;29:67–79.

Li KY, Tsai SY, Lin CP, Tsai YT, Shu CM. Smart technology for evaluating fire extinguishing effect of tert-butyl hydroperoxide. Ind Eng Chem Res. 2013;52(32):10969–76.

Lin CP, Tseng JM. Green technology for improving process manufacturing design and storage management of organic peroxide. Chem Eng J. 2012;180:284–92.

Tseng JM, Lin JZ, Lee CC, Lin CP. Prediction TMCH thermal hazard with various calorimetric tests by green thermal analysis technology. AIChE J. 2012;58(12):3792–8.

Liao SW, Hsieh CC, Li KY, Tsai SY, Tseng JM, Li JS, Lin CP. Storage lifetime management and thermal hazard assessment of thermally reactive material. J Therm Anal Calorim. 2014;116:205–14.

Lin HY, Tsai SY, Tseng YL, Lin CP. Gamma irradiation for improving functional ingredients and determining the heat treatment conditions of Cordyceps militaris mycelia. J Therm Anal Calorim. 2015;120:439–48.

Cheah IK, Halliwell B. Ergothioneine; antioxidant potential, physiological function and role in disease. Biochim Biophys Acta. 2012;1822:784–93.

Wang GB, Chen CC, Liaw HJ, Tsai YJ. Prediction of flash points of organosilicon compounds by structure group contribution approach. Ind Eng Chem Res. 2011;50:12790–6.

Acknowledgements

We are indebted to Asia University and China Medical University in Taiwan under contract number ASIA-105-CMUH-08 for financial support. In addition, the authors are indebted to SD Biotech Inc. in Taiwan for technical support on the pulsed light experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsai, SY., Hsu, YC., Lin, HY. et al. Comparison of the effect of Pleurotus citrinopileatus extract and vitamin E on the stabilization properties of camellia oil. J Therm Anal Calorim 130, 1281–1292 (2017). https://doi.org/10.1007/s10973-017-6423-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6423-0