Abstract

In order to deeply investigate the role of potassium in modifying thermal behavior and burning characteristics of reconstituted tobacco sheet (RTS), electrodialysis (ED) technology was employed at first to remove the main ions in the tobacco extract to reduce interference of endogenous ions. Characterization on thermal behavior of RTS treated with three organic (acetate, malate and citrate) potassium salts and three inorganic (chloride, sulfate and phosphate) potassium salts was then performed using thermogravimetric analyzer coupled with Fourier transforms infrared spectrometer (TG-FTIR) at the heating rate of 20 °C min−1. TG results illustrated that potassium decreased the peak temperature of carbohydrate pyrolysis, retarded the thermal degradation of the major components of RTS and meanwhile promoted the formation of stable char firmly depending on its chemical state. The organic potassium salts had a more significant effect on the process of char oxidation than inorganic ones with a new peak at around 570 °C. Analyses of evolved gaseous products distribution demonstrated a significant reduction of CO and CO2 during carbohydrates pyrolysis in the presence of potassium, especially organic potassium salts. Moreover, the maximum firecone temperature was also measured by Infrared thermography, and it had been found that the burning cone temperature of ED-modified RTS was averagely 13.27 °C higher than that of organic potassium treated RTS but averagely 16.57 °C lower than that of inorganic ones.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Reconstituted tobacco sheet (RTS) has now gained increasing worldwide acceptance by tobacco industry due to its advantageous economic impact on the manufacturing cost as well as its superiority in structural strength, combustion performance and tar delivery [1,2,3,4]. The introduction of RTS in a cigarette leads to a considerable reduction of tar, phenols, polynuclear aromatic hydrocarbons, etc., depending on the inclusion level of RTS [1, 5]. As contrasted to the economic considerations, the possibilities for combustion and smoke modification by RTS technology are perhaps even more profound.

It has been well established that the pyrolysis and combustion of tobacco are closely related to its chemical components, especially salts content [6,7,8]. Previous works confirmed that demineralized biomass had higher and lower yields of levoglucosan and glycolaldehyde, respectively, in comparison with the untreated biomass [9]. As a major constituent of tobacco (can even be present up to 10% w/w in tobacco), potassium plays an important role both in tobacco growth and cigarette pyrolysis [10]. Yamamoto et al. [11] demonstrated that both the exogenous and endogenous potassium contents reduced CO delivery by decreasing the peak temperature of the burning cone. Liu and Parry [12] demonstrated that nicotine-free-dry-particulate-matter, nicotine and carbon monoxide in the mainstream were decreased at almost equal level with the addition of potassium as malate, citrate and tartrate. Izawa et al. [13]. found that the presence of potassium malate accelerated the formation of various lower molecular compounds and explained the mechanisms in modifying the burning characteristics of cellulose by using curie-point pyrolysis. Yang et al. [14] pretreated corn straw by water or acid washing and found potassium favored the formation of C=O containing compounds and CO2. However, some controversial issues have arisen with different kinds of organic or inorganic potassium during thermal decomposition processes of biomass. Horler [10] illustrated the interacting effects between the inorganic and organic potassium and pointed out that it was the quantity of potassium percent as organic acid salts but not the total potassium content that was important in controlling burn rate. Zhao et al. [15] indicated that the anions played a crucial role on the catalytic effects for the pyrolysis kinetics of cigarette paper except for potassium cations. Yamamoto et al. [11] reported that potassium malate was more effective than nitrate for the reduction of carbon monoxide while the opposite conclusion in the case of nicotine. Therefore, it is important to reduce interference of other ions in studying the catalytic mechanism of potassium on tobacco pyrolysis.

In this study, electrodialysis (ED) technology was employed to remove the main ions in the tobacco extract to reduce interference of endogenous ions as much as possible. Then, the thermal behavior and volatile products produced during the pyrolysis and combustion process of reconstituted tobacco were deeply investigated in the presence of several potassium salts by thermogravimetric analysis coupled with Fourier transform infrared spectrometer (TG-FTIR). Analyses were carried out to provide a better understanding of the effects of the organic and inorganic potassium salts in modifying thermal behavior and burning characteristics of RTS.

Experimental

Materials

Tobacco extract and base web of RTS utilized in this study were obtained from China Tobacco Anhui Industrial Co., Ltd, Hefei, Anhui Province, China. Organic (acetate, malate, citrate) and inorganic (chloride, sulfate, phosphate) potassium salts were obtained commercially from Sinopharm Chemical Reagent Co., Ltd, with the purity above 99% and used directly without further purification in the experiment.

Sample preparation

RTS samples were manufactured by a paper-making process described elsewhere [2, 16,17,18]. To be brief, tobacco extract from paper-making process was demineralized with ED separation technology specified in our previous work [19]. Potassium organic and inorganic salts were, respectively, added to the demineralized tobacco extract with the same amount of potassium content as the untreated tobacco extract (control). Base web was impregnated completely in these tobacco extracts for 1 min and then dried for about 20 min at 65 °C to produce RTS samples. Potassium content of RTS samples shown in Table 1 suggests that the potassium content of samples treated with exogenous potassium organic and inorganic salts is consistent and agrees well with our preconceived level at about 2.7%.

For analytical experiments of burning cone temperature of cigarette, the cut samples were conditioned at 22 °C, 60% R.H. and made into cigarettes with identical design features. Samples were grounded to pass through a 60 mesh screen to provided increased homogeneity for comparative purposes, prior to pyrolysis experiments and chemical analysis.

Measurements

Ion chromatography analysis

The concentration of main ions (K+, Ca2+, Mg2+, Cl−, NO −3 , SO 2−4 and PO 3−4 ) in the tobacco extract and RTS samples was determined by Ion chromatography (ICS3000, Dionex Company, USA) [20].

TG-FTIR analysis

The TG-FTIR method has been widely applied on investigating the volatile products during biomass pyrolysis at low heating rate [21,22,23]. The instrument consists of a thermogravimetric analyzer (NETZSCH, STA 449C) connected with a Fourier transform infrared (FTIR) spectrometer (Thermo Scientific, 6700 FT-IR, Nicolet Instrument Co., USA) through a heated line by a thermogravimetric analysis interface (Nicolet Instrument Co., USA). Approximately 20 mg of RTS sample powder was placed evenly into a standard aluminum crucible paved in the thermogravimetric analyzer (TGA) and then heated with temperature ranging from 30 to 1000 °C at a heating rate of 20 °C min−1 under the atmosphere of 10% oxygen in nitrogen with a total flow rate of 100 mL min−1. Procured α-Al2O3 was used as reference material. The temperatures of the transferred line for the evolved gases and IR cell were maintained at 225 °C and 230 °C, respectively, to avoid the condensation of volatile products. The FTIR measurements were operated simultaneously in the continuous scan mode covering the wavenumber scope of 4000–500 cm−1 at a resolution of 4 cm−1 for the analysis of evolved gases.

Infrared thermography measurements

The temperature profiles of the burning fuel surface of cigarettes manufactured by RTS were monitored by Infrared thermography (IRT). The PYROVIEW 380MC Compact camera with PYROSOFT Professional software from DIAS Systems (DIAS Infrared GmbH, Germany) was employed. Details could be found elsewhere [24]. Cigarettes were smoked under ISO smoking conditions (35 mL puff volume, 2 s duration, 1 puff per minute), and experiments were carried out under normal air atmosphere.

Results and discussion

Effect of electrodialysis on thermal behavior of RTS

In many studies, acid demineralization was usually performed to remove inorganic constituents in order to describe their catalytic effect [25,26,27]. However, this technique may yield unreliable results because significant chemical degradation of the biomass can occur during acid demineralization, resulting in a structurally modified biomass that is not comparable with raw material [28]. Furthermore, aqueous extracts of tobacco is an integral part of RTS. Therefore, acid demineralization is not suitable to RTS, due to its physical and chemical damage of tobacco fiber and the loss of tobacco extracts. ED has a high efficacy of demineralization and has been employed to remove the main inorganic ions of aqueous tobacco extract [19]. According to the optimized parameters in the previous study [19], tobacco extract was desalted by ED to reduce the interference of endogenous ions. The content of main ions in RTS samples was specified in Table 2. Generally, ED could remove most of the aqueous ions effectively with removal rate above 80%, substantially reducing the endogenous ions interference.

TG, DTG and DSC curves obtained from the pyrolysis process for the control and ED-modified RTS are plotted in Fig. 1. Typically, the thermal degradation process of RTS can be divided into four stages [7, 29]: (1) evaporation of water; (2) pyrolysis of simple sugars and other carbohydrates; (3) combustion of residual char; and (4) decomposition of calcium carbonate. To be specified, the first stage occurs with a mass loss of about 3% in the temperature of 30–135 °C, mainly due to the loss of adsorbent water and volatile species [29, 30]. Then, a shoulder peak (135–190 °C) and a strong peak (190–370 °C) appear subsequently with respect to the pyrolysis of simple sugars and thermal decomposition of cell wall biopolymer (cellulose, hemicelluloses, lignin and pectin) [7, 29,30,31], respectively, leading to a total mass loss of 49.5%. The third stage taken place from 370 to 556 °C with 33.8% mass loss is actually resulted from the thermal oxidative decomposition of residual char [24, 29]. And an unobvious low peak at temperature higher than 556 °C can be attributed to the thermal decomposition of calcium carbonate and other salts [29]. Though with similar TG, DTG and DSC profiles as control, ED-modified RTS has several significant differences on the characteristic parameters, especially the process for thermal decomposition of carbohydrates and combustion of residual char, suggesting that the desalination of tobacco extract is of considerable influence and ED is necessary.

Effect of potassium organic and inorganic salts on TG/DTG curves of RTS

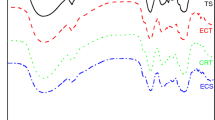

TG and DTG results of experiments conducted with potassium organic and inorganic are illustrated in Fig. 2. It is evident that all the potassium salts have a considerable effect on the process of RTS pyrolysis with the comparison of ED-modified RTS, especially on stage 2 and stage 3. Specific characteristic parameters are demonstrated in Table 3.

Organic potassium salts

As shown in Fig. 2a, c, organic potassium salts have a similar effect on the pyrolysis of RTS. On the thermal decomposition stage of carbohydrates, the initial temperature, final temperature and the peak temperature of the first strong peak (Tp1) at around 306 °C, all shift consistently toward lower temperature with the addition of organic potassium salts. The shift carbohydrate decomposition to lower temperature is due to the significant reduction in the apparent activation energy of carbohydrates pyrolysis by potassium [15, 32]. It is also noticeable that Tp1 of the three potassium organic salts decreases by an order of Potassium malate > Potassium citrate > Potassium acetate with very slightly difference at a reduction of 13.7, 22.7 and 29.1 °C, respectively, suggesting not only potassium cation but also the organic anions contribute to the drop of carbohydrates pyrolytic temperature but to a lesser extent. Moreover, the mass loss percentage and maximum mass loss rate slow down extraordinarily with the presence of organic potassium. The mass loss percentage for ED, potassium acetate, malate and citrate modified RTS is 55.33, 43.29, 41.08 and 43.36%, respectively (cf. Figure 2a), and the maximum mass loss rate (MLRmax1) even drops from 35.8% min−1 of ED-modified RTS to 10.73% min−1 of potassium acetate-treated RTS (cf. Table 3), indicating that the incorporation of organic potassium into RTS could suppress the major thermal decomposition reactions of carbohydrates pyrolysis.

However, as for the char oxidation stage (stage 3) in the DTG curves, remarkable differences could be found on the combustion process of residual char. The temperature of the second strong peak P2 moves toward higher temperature with adjacent temperature as control sample with a descending order of Potassium malate > Potassium acetate > Potassium citrate, whereas the relevant MLRmax2 drops remarkably from 18.21% min−1 to even 2.23% min−1 (potassium acetate in Table 3). It is worth noting that, at higher temperature (around 570–580 °C), a new strong peak P3 occurs with the average MLRmax3 at 11.88%·min−1 for organic potassium-modified RTS. The new peak accompanied by the evolution of CO2 and CO (cf. Figure 4) is also the char oxidation stage. This result elucidated that organic potassium salts improved the stability of char, due to the alteration of the ash morphology in a way that restricted the air flow and caused stronger bonding of the ash particles [12]. It should be noted that, in previous study [6], organic potassium only had a slight effect on peak temperature of char oxidation of tobacco. The considerable difference of char combustion process should be due to the interference of endogenous ions, suggesting that it is necessary that the removal of endogenous ions by ED in studying the role of potassium on RTS pyrolysis. Moreover, in agreement with the decrease in MLRmax1, a significant increase in the char residue at 500 °C was noted in this work on all organic potassium-modified RTS, particularly for potassium malate, signifying that organic potassium salts enhances stable char yields [6, 33]. This all contributed to the modification of burning characteristic and the reduced formation of total particular material of organic potassium-added cigarettes

Inorganic potassium salts

Figure 2c, d illustrates the influence of inorganic potassium salts on TG and DTG curves, respectively. The DTG curves with the addition of inorganic potassium salts show something different from the organic ones. In the stage of carbohydrates decomposition, inorganic potassium salts decrease the temperature of the initial point, end point and the first strong peak (Tp1) similar to organic potassium salts. The whole stage moving toward lower temperature indicates that potassium reduces the apparent activation energy of carbohydrates pyrolysis independent on its chemical state [15, 32]. Compared with ED-modified RTS, inorganic potassium also reduces the corresponding MLRmax1 greatly but not as much as organic potassium, which illustrates that inorganic potassium also hinders the decomposition reaction during the pyrolysis of carbohydrates and organic potassium has a more obvious influence than inorganic one. Besides, inorganic potassium also affects the combustion of residual char observably and the inorganic anion matters as well. For instance, the temperature of the second strong peak (Tp2) vary diversely from one another with a descending order of KCl > K2SO4 = ED > K3PO4. And it is worth noticing that MLRmax2 increases slightly for all inorganic potassium salts with an average increment of 3.13% min−1, suggesting that inorganic anions could accelerate the combustion of residual char. What is more, the residual mass at 500 °C all increase lightly compared with ED-modified RTS, which reveals that inorganic potassium also promotes char formation [34]. It should be noted that the residual mass at 1000 °C of potassium chloride-added RTS was significantly lower than one of the other inorganic potassium salts-added RTS, which may be due to the enhancement of alkali metal emission by chlorine [34].

Based on the above study, it can be found that all the organic and inorganic potassium salts have the similar influence on the carbohydrates pyrolysis stage by shifting the whole stage toward lower temperature and decreasing the maximum mass loss rate with the improvement of char yield, due to the catalytic effect of alkali metal on biomass pyrolysis [8]. What is important, inorganic potassium only affects the process of char oxidation on the characteristic parameters, whereas the organic ones totally change the process into two peaks. The considerable different action of inorganic and organic potassium salts on char yield and its oxidation process should be resulted from potassium chemical form. Wornat et al. [35]. have demonstrated that the carboxylates of organic potassium salts can thermally decompose to release carbon oxides with the alkali bonded to char matrix, resulting in decreasing the surface area of chars and a noticeable change in char morphology: Small ash particles appeared to be coated and more tightly bonded together by the melt of potassium, which contributes to the remarkable improvement of char yield and stability by organic potassium. It was also found in previous study that alkali in inorganic form volatilized more easily than one in the form of carboxylates at high temperature during coal pyrolysis [36, 37]. These results illustrated that organic anions had a crucial impact on the process of carbonization and char properties of potassium-modified RTS. Our work explained that it was the quantity of potassium percent present as organic acid salts but not the total potassium content that was important in controlling burn rate of cigarette [10]. Furthermore, the differences between control sample and exogenous potassium-modified RTS indicate that the added potassium does not behave in the same way as the inherent minerals [22] or the content of anions matters, indicating that interference of endogenous ions indeed exits, and deep investigation on the influence of content remains to be done.

Effect of potassium organic and inorganic salts on DSC curves of RTS

Differential scanning calorimetry (DSC) results of organic and inorganic potassium-modified RTS shown in Fig. 3 and Table 4 display a really identical conclusion with DTG curves. With the presence of organic potassium salts, the first exothermic peak, which mainly due to the thermal decomposition of carbohydrates, shrinks and the initial temperature, end temperature and peak temperature (Tp1) all go down significantly. With regard to the secondary exothermic stage which is ascribed to the combustion of residual char, the heat release (A2) of the secondary peak drops remarkably while a new peak with great peak area (A3) appears at about 596 °C. Therefore, it can be said that the addition of organic potassium salts totally changes the oxidation process of chars but has less significant effect on the thermal decomposition.

Similarly, the first exothermic stage moves toward lower temperature, and Tp1, maximum heat release rate (HRmax1) and heat release all decreased for inorganic potassium-added RTS. Besides, the HRmax2 and heat release (A2) of secondary exothermic stage rise moderately as the DTG curves suggest, confirming the close relation between the two exothermal process and degradation of carbohydrates and residual char.

Effect of potassium organic and inorganic salts on evolution patterns of COx

Typical 3D FTIR spectral output of gaseous products evolved from pyrolysis process of ED-modified reconstituted tobacco sheet is shown in Fig. 4 known as a waterfall spectrum. Nine main absorption regions can be easily recognized as 3780–3485 cm−1, 3100–2770 cm−1, 2400–2224 cm−1, 2220–2000 cm−1, 1900–1600 cm−1, 1600–1500 cm−1, 1500–1300 cm−1, 1100–930 cm−1 and 760–590 cm−1 in the spectrum, suggesting the difficulty to identify every species in the mixture of gaseous products for the interference of their IR absorbance. However, the detection of carbon dioxide in the absorption region of 2400–2226 cm−1 is undoubted, and it is also confirmed by the absorption peak at 672 cm−1 [38]. Also peaks at 2180 and 2108 cm−1 attributed to carbon monoxide have been conformed previously [39, 40]. CO and CO2 evolution profiles plotted in Figs. 5, 6 are constructed from the waterfall spectra by selecting a key characteristic IR absorbance at 2180 and 2280 cm−1, respectively, and have been normalized to the sample mass (intensity per 20 mg of sample) to make sure the comparisons are on the relative amount.

Carbon oxide, including CO and CO2, is a major thermal decomposition product of RTS. Comparison of COx evolution profiles with DTG and DSC curves indicated that CO evolution was firmly related with the exothermal process and the mass loss process of carbohydrates decomposition and residual char combustion. Figures 5 and 6 show the influence of potassium salts on CO and CO2, respectively. There are three basically consistent temperature ranges of about 190–350, 350–510 and 510–630 °C in CO evolution during RTS pyrolysis treated with organic potassium salts (cf. Figure 5a), while, for ED-modified RTS, CO evolves only in two temperature ranges of 225–365 and 365–529 °C. All organic potassium salts affect on the first peak of CO evolution by lowering the temperature and absorption intensity, while for the second peak the intensity drops remarkably, which illustrates organic potassium salts reduced CO evolution at low temperature (<500 °C). However, in agreement with DTG curve, organic potassium salts result in the formation of a new strong CO peak at a much higher temperature, due to the improvement of char stability. With regard to CO2 evolution, the same phenomenon and conclusion can be identified except an ambiguous peak appeared at around 700–800 °C, which is due to decomposition of calcium carbonate [29].

As for inorganic potassium, analysis of the two peaks existing in the CO2 and CO evolution profiles are very identical with the DTG and DSC curves. Inorganic potassium salts decline the yield for CO evolution both on the process of carbohydrate decomposition and char combustion. However, in the case of CO2 evolution, a reduction on the first peak but a slight rise on the second one appears regardless of the anions.

Judging from the peak areas (calculated using the program originpro9.0 32 bit [41]) of CO (cf. Table 5), it can be deduced that, dependently on anion species, potassium salts decrease the total CO release and the CO evolution during the thermal decomposition of carbohydrates. The significant inhibition of CO evolution during carbohydrates pyrolysis elucidates the role of alkali metals in CO reduction in mainstream smoke of cigarette. As for CO2, all potassium salts reduce its evolution during carbohydrates pyrolysis but increase its yield during char combustion. Furthermore, the total peak area of CO2 has a slight increase regardless of potassium species, except for potassium malate.

IR thermography of the firecone of RTS

The maximum and average firecone temperatures of potassium-modified RTS are shown in Table 6. Actually, the maximum firecone temperature of ED-modified RTS is higher than that of organic potassium treated RTS with an average reduction of 13.27 °C, which may be due to the heat release in wider temperature range as suggested in the DSC curves. The reduction of firecone temperature by organic potassium salts contributes to the reduced formation of TPM of organic potassium-added cigarette, whereas the maximum temperature of inorganic potassium-modified RTS conducts a different behavior with higher temperature by 16.57 °C averagely.

Conclusions

In this study, the interference of endogenous ions was reduced by electrodialysis method, and the effects of potassium organic and inorganic salts as burning additives on thermal behavior and gaseous products evolution of reconstituted tobacco were investigated using TG-FTIR. The results verified that ED was an efficient method with the ions removal rate over 80% and could reduce the interference endogenous ions on the pyrolysis behaviors of RTS significantly. Pyrolysis tests revealed that potassium could decrease the temperature of carbohydrates degradation by lowering the apparent activation energy. However, firmly depending on chemical state, potassium enhanced the formation of stable char and potassium, especially organic state, increased the peak temperature of char combustion greatly. Furthermore, DSC curves were influenced similarly by potassium, especially organic anions for the secondary exothermic peak. The analysis of COx evolution indicated that potassium significantly suppressed COx release during RTS thermal degradation. In addition, the maximum firecone temperature of RTS was considerably reduced by organic potassium salts. What is more important, comparative analysis of different potassium salts elucidated that anion was one of the most important factors in modifying the thermal behavior and burning characteristics of RTS by potassium.

References

Wang L, Wen YB, Sun DP, Mao Y, Yao YJ. Study on the decrease of harmful substance in paper-process reconstituted tobacco sheet. Adv Mater Res-Switz. 2011;314–316:2338–43. doi:10.4028/www.scientific.net/AMR.314-316.2338.

Gao WH, Chen KF, Yang RD, Yang F. Rheological property of reconstituted tobacco coatings. Ind Crop Prod. 2014;60:45–51. doi:10.1016/j.indcrop.2014.06.002.

Zhong WH, Zhu CJ, Shu M, Sun KD, Zhao L, Wang C, et al. Degradation of nicotine in tobacco waste extract by newly isolated Pseudomonas sp ZUTSKD. Bioresour Technol. 2010;101(18):6935–41. doi:10.1016/j.biortech.2010.03.142.

Gao WH, Chen KF, Yang RD, Yang F. Process for coating of reconstituted tobacco sheet with citrates. J Anal Appl Pyrolysis. 2015;114:138–42. doi:10.1016/j.jaap.2015.05.013.

Wu XX, Xu CH, Li M, Sun SQ, Li JM, Dong W. Analysis and identification of two reconstituted tobacco sheets by three-level infrared spectroscopy. J Mol Struct. 2014;1069:133–9. doi:10.1016/j.molstruc.2013.12.057.

Yin CY, Xu ZQ, Shu JS, Wang H, Li Y, Sun WF, et al. Study on the effect of potassium lactate additive on the combustion behavior and mainstream smoke of cigarettes. J Therm Anal Calorim. 2014;115(2):1733–51. doi:10.1007/s10973-013-3478-4.

Ge SL, Xu YB, Tian ZF, Zhou S, She SK, Hu YH, et al. Effect of urea phosphate on thermal decomposition of reconstituted tobacco and CO evolution. J Anal Appl Pyrolysis. 2013;99:178–83. doi:10.1016/j.jaap.2012.09.013.

Saddawi A, Jones JM, Williams A. Influence of alkali metals on the kinetics of the thermal decomposition of biomass. Fuel Process Technol. 2012;104:189–97. doi:10.1016/j.fuproc.2012.05.014.

Eom IY, Kim JY, Kim TS, Lee SM, Choi D, Choi IG, et al. Effect of essential inorganic metals on primary thermal degradation of lignocellulosic biomass. Bioresour Technol. 2012;104:687–94. doi:10.1016/j.biortech.2011.10.035.

Baskevitch N, Horler JW. Organic potassium. Its role in controlling the rate of burn and tar content of tobacco products. http://legacy.library.ucsf.edu/tid/uay11c00/pdf.

Yamamoto T, Umemura S, Kaneko H. Effect of exogenous potassium on the reduction in tar, nicotine and carbon-monoxide deliveries in the mainstream smoke of cigarettes. Beitr Tabakforsch. 1990;14(6):379–85.

Liu C, Parry A. Potassium organic salts as burn additives in cigarettes. Beitr Tabakforsch/Contrib Tob Res. 2014;20:341–7.

Izawa K, Matsukura M, Ishizu Y. Curie-point pyrolysis of cellulose in the presence of potassium malate. Agrc Biol Chem Tokyo. 1990;54(4):957–63.

Yang CY, Lu XS, Lin WG, Yang XM, Yao JZ. TG-FTIR study on corn straw pyrolysis-influence of minerals. Chem Res Chin Uiniv. 2006;22(4):524–32. doi:10.1016/S1005-9040(06)60155-4.

Zhao DQ, Dai Y, Chen KF, Sun YF, Yang F, Chen KY. Effect of potassium inorganic and organic salts on the pyrolysis kinetics of cigarette paper. J Anal Appl Pyrolysis. 2013;102:114–23. doi:10.1016/j.jaap.2013.03.007.

Prowse RL. Reconstituted (‘Sheet’) Tobaccos: a review of processes, product properties and future potential. http://www.legacy.library.ucsf.edu/tid/fpy74a99/pdf.

Gellatly G. Process for utilizing tobacco fines in making reconstituted tobacco. Google Patents 1983.

Kumar A, Gomes J. Method and apparatus for producing reconstituted tobacco sheets. Google Patents 2001.

Zhang ZH, Ge SL, Jiang CX, Zhao Y, Wang YM. Improving the smoking quality of papermaking tobacco sheet extract by using electrodialysis. Membr Water Treat. 2014;5(1):31–40.

Chen MS, Xu ZQ, Chen G, Wang H, Yin CY, Zhou ZL, et al. The influence of exogenous fiber on the generation of carbonyl compounds in reconstituted tobacco sheet. J Anal Appl Pyrolysis. 2014;105:227–33. doi:10.1016/j.jaap.2013.11.008.

Marcilla A, Beltran MI, Gomez-Siurana A, Martinez-Castellanos I, Berenguer D, Pastor V, et al. TGA/FTIR study of the pyrolysis of diammonium hydrogen phosphate-tobacco mixtures. J Anal Appl Pyrolysis. 2015;112:48–55. doi:10.1016/j.jaap.2015.02.023.

Jensen A, Dam-Johansen K, Wojtowicz MA, Serio MA. TG-FTIR study of the influence of potassium chloride on wheat straw pyrolysis. Energy Fuel. 1998;12(5):929–38. doi:10.1021/Ef980008i.

Wang HQ, Yang XF, Guo LH, Zeng HM, Qiu DW. PeBL1, a novel protein elicitor from Brevibacillus laterosporus strain A60, activates defense responses and systemic resistance in Nicotiana benthamiana. Appl Environ Microbiol. 2015;81(8):2706–16. doi:10.1128/Aem.03586-14.

Zhou S, Ning M, Xu YB, Hu Y, Shu JS, Wang CH, et al. Thermal degradation and combustion behavior of reconstituted tobacco sheet treated with ammonium polyphosphate. J Anal Appl Pyrolsis. 2013;100:223–9. doi:10.1016/j.jaap.2012.12.027.

Di Blasi C, Branca C, D’Errico G. Degradation characteristics of straw and washed straw. Thermochim Acta. 2000;364(1–2):133–42.

Muller-Hagedorn M, Bockhorn H, Krebs L, Muller U. A comparative kinetic study on the pyrolysis of three different wood species. J Anal Appl Pyrolysis. 2003;68–9:231–49. doi:10.1016/S0165-2370(03)00065-2.

Nowakowski DJ, Jones JM. Uncatalysed and potassium-catalysed pyrolysis of the cell-wall constituents of biomass and their model compounds. J Anal Appl Pyrolysis. 2008;83(1):12–25. doi:10.1016/j.jaap.2008.05.007.

Eom IY, Kim KH, Kim JY, Lee SM, Yeo HM, Choi IG, et al. Characterization of primary thermal degradation features of lignocellulosic biomass after removal of inorganic metals by diverse solvents. Bioresour Technol. 2011;102(3):3437–44. doi:10.1016/j.biortech.2010.10.056.

Wang WS, Wang Y, Yang LJ, Liu BZ, Lan MB, Sun WL. Studies on thermal behavior of reconstituted tobacco sheet. Thermochim Acta. 2005;437(1–2):7–11. doi:10.1016/j.tca.2005.06.002.

Sung YJ, Seo YB. Thermogravimetric study on stem biomass of Nicotiana tabacum. Thermochim Acta. 2009;486(1–2):1–4. doi:10.1016/j.tca.2008.12.010.

Fenner RA, Lyonshart J, Lephardt JO, Teng DM. Application of Fourier-transform infrared evolved gas-analysis (Ft-Ir-Ega) to the study of tobacco curing. Beitr Tabakforsch. 1988;14(2):85–91.

Liu Q, Wang SR, Luo ZY, Cen KF. Catalysis mechanism study of potassium salts on cellulose pyrolysis by using TGA-FTIR analysis. J Chem Eng Jpn. 2008;41(12):1133–42.

Crowther AC, Carrier SL, Preston TJ, Crim FF. Time-resolved studies of CN radical reactions and the role of complexes in solution. J Phys Chem A. 2008;112(47):12081–9. doi:10.1021/jp8064079.

Olsson JG, Jaglid U, Pettersson JBC, Hald P. Alkali metal emission during pyrolysis of biomass. Energy Fuel. 1997;11(4):779–84. doi:10.1021/Ef960096b.

Wornat MJ, Sakurovs R. Proton magnetic resonance thermal analysis of a brown coal: effects of ion-exchanged metals. Fuel. 1996;75(7):867–71. doi:10.1016/0016-2361(96)00016-6.

Quyn DM, Wu HW, Li CZ. Volatilisation and catalytic effects of alkali and alkaline earth metallic species during the pyrolysis and gasification of Victorian brown coal. Part I. Volatilisation of Na and Cl from a set of NaCl-loaded samples. Fuel. 2002;81(2):143–9. doi:10.1016/S0016-2361(01)00127-2.

Wu HW, Quyn DM, Li CZ. Volatilisation and catalytic effects of alkali and alkaline earth metallic species during the pyrolysis and gasification of Victorian brown coal. Part III. The importance of the interactions between volatiles and char at high temperature. Fuel. 2002;81(8):1033–9. doi:10.1016/S0016-2361(02)00011-X.

Colthup NB, Daly LH, Wiberley SE. Introduction to infrared and Raman spectroscopy. 3rd ed. Boston: Academic Press; 1990.

Buryan P, Staff M. Pyrolysis of the waste biomass. J Therm Anal Calorim. 2008;93(2):637–40. doi:10.1007/s10973-007-8700-9.

Li J, Liu YW, Shi JY, Wang ZY, Hu L, Yang X, et al. The investigation of thermal decomposition pathways of phenylalanine and tyrosine by TG-FTIR. Thermochim Acta. 2008;467(1–2):20–9. doi:10.1016/j.tca.2007.10.014.

http://www.originlab.com/index.aspx?go=Products/Origin/DataAnalysis/PeakAnalysis.

Acknowledgements

The financial supports from China Tobacco Anhui Industrial Corporation (No. 2014104 and 2014109) are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, M., Wei, B., Zhang, Z. et al. Effect of potassium organic and inorganic salts on thermal decomposition of reconstituted tobacco sheet. J Therm Anal Calorim 129, 975–984 (2017). https://doi.org/10.1007/s10973-017-6214-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6214-7