Abstract

Amino-functionalized SBA-15 was prepared using 1.0 and 2.5% chitosan solutions and a wet impregnation method. The adsorbents were characterized by XRD, TG, DSC, SEM, FTIR and nitrogen adsorption/desorption. The results showed that the insertion of chitosan into the holder did not destroy its typical hexagonal structure, maintaining its morphology and a uniform distribution of pores. The thermal stability of the CS and CS-SBA-2.5 materials was investigated using the Vyazovkin and Ozawa–Flynn–Wall kinetic models. The apparent activation energies (E α) obtained ranged around 161–335 kJ mol−1, and a conversion range of 0.2–0.8, with minimum variations, was observed for the two methods and both samples. However, the results showed that the E α, which is an important factor to future applications in adsorption of CO2, was not significantly altered by the presence of SBA-15.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The capture and sequestration of CO2 have been widely reported and extensively researched in recent years. The presence of this gas has implications on global warming and in the increase in emissions caused by the growing yearly consumption of oil, natural gas and coal [1, 2]. The technologies employed in order to solve this problem consist of gas capture, with permanent storage and subsequent regeneration of the adsorbent used for capturing. CO2 absorption using amine solution is the most commonly used technology, but it has disadvantages such as high energy consumption for regenerating the absorbing solution, high corrosion and degradation of the amine solution [3, 4]. Extensive research has been conducted for the development of adsorbent solids, such as mesoporous carbon [5], zeolites [6], surface oxides [7], metal–organic networks (MOF’s) [8], hasty nanostructures and nanosilica [9], and mesoporous materials, for the removal of CO2 [10–12].

Synthesized for the first time by Zhao et al. [13], SBA-15 (Santa Barbara Amorphous 15) mesoporous material has outstanding characteristics such as the wide distribution of pore diameters, as well as large wall thickness, which results in high hydrothermic stability when compared to mesoporous materials of the M41S family. With a hexagonally ordered mesophase, it has a high surface area (600–1000 m2 g−1), broad pore size (5–30 nm) and a width to length ratio of 1:1000, which provides a high surface area within of pores [14–16]. However, the lack of active sites limits many applications in catalysis and adsorption. In contrast, the presence of silanol groups on the surface allows for the implementation of surface modification through functionalization processes [17]. According to Jing et al. [10], two widely used methods for this purpose are physical wet impregnation of amine-containing species and chemical grafting of aminosilanes on the surface. The wet impregnation method consists of a simple procedure that can achieve very high amine loadings.

Yoo et al. [18] showed that CO2 capture increases with to the presence of multiple amines in a single silane molecule (MONO < DI < TREN ~ TRI). Hao et al. [19] investigated the obtainment of amino-functionalized SBA-15 materials synthesized by cocondensation of tetraethoxysilane (TEOS) with organosilane aminopropyltrimethoxysilane (APTMS) in a wide range of APTMS-to-TEOS molar ratios. The results showed an adsorption of up to 2.23 mmol g−1. The CO2 adsorption capacity PEI-modified SBA-15 materials was investigated by Yan et al. [20], showing the largest CO2 adsorption capacity (105.2 mg g−1) in the SBA-15 material with the largest pore volume. Vilarrasa-Garcia et al. [11] showed a high adsorption capacity for CO2 by functionalization with polymers containing amines.

Chitosan (CS) is a linear polymer with a high amount of distributed nitrogen (6.89%) and consists of 2-amino-2-deoxy-d-glucopyranose (GlcN) and 2-acetamido-2-deoxy-d-glucopyranose (GlcNAc), with units linked by (1–4) glycosidic bonds. It is obtained by the deacetylation of chitin, which in turn can be found in the exoskeleton of crustaceans such as shrimps, crabs and lobsters, or in cell walls of insects such as beetles and fungi, and also in mushrooms. This biopolymer has attracted much attention because of its specific properties of cationicity, high adsorption capacity, macromolecular structure, abundance and low cost [21–24]. Its main applications are in the adsorption of heavy metals [25, 26], in removal of dyes in water and sewage [23], as an excipient for drug release control [27], and in tissue engineering in regenerative medicine [28]. In the literature, some works already show the functionalization of other types of porous materials with chitosan, for the adsorption of CO2. In all cases, the adsorption capacity is increased with the introduction of this amine source [29, 30].

Considering the necessity of regenerating the adsorbent after the capture of CO2 [31] and the use of polymers in the functionalizing of mesoporous supports, it is important to obtain some information such as thermal stability and thermal kinetics degradation, as well as the distribution of the pyrolysis products. The kinetic interpretation of the degradation material provides information on the kinetic triplet: activation energy (E α), pre-exponential factor, and the reaction model or reaction mechanisms [32]. To determine this information, many studies use thermogravimetry (TG). For this, data from a series of measurements performed at different heating rates are used with a free energy model, and the values of precise activation energy are estimated [33]. The Vyazovkin and Ozawa–Flynn–Wall methods (free isoconversional kinetic models) are the most used for studying the thermal degradation of polymers. In these methods, the activation energy is dependent on the extent of conversion, and this dependence can be used to predict the mechanism and kinetics of the process, thereby forming the basis of the model-free kinetic methods [33].

In this study, SBA-15 mesoporous material was synthesized and functionalized with CS through the wet impregnation method. A kinetic study of the adsorbents obtained using the Vyazovkin and Ozawa–Flynn–Wall free energy methods was used to determine the important parameters such as activation energy that characterizes the adsorbents obtained. This information is important in the adsorbent regeneration process after use in CO2 capture.

Materials and methods

Materials

Tetraethylorthosilicate (TEOS) (98%) from Sigma-Aldrich was used as the silica source, and a triblock Pluronic (P123) copolymer of molecular mass 5750 g mol−1, from Sigma-Aldrich, was used as template structure. Hydrochloric acid (HCl) (37%, Merck), chitosan (CS) with a degree of deacetylation (DD) of 85% (±3) and molecular mass of 1.9 × 105 g mol−1 from Polymar Ltd., glacial acetic acid (C2H4O2) (99.7%) from Dynamics, sodium hydroxide (NaOH) (99%) from VETEC and ultrapure water (MilliQ) were also used.

Purification of CS

2% (v/v) acetic acid solution and 1.25 M sodium hydroxide solution were prepared in this step. The acetic acid solution was used to make the 1.5% CS solution, which was maintained under magnetic stirring for 24 h. Thereafter, a 1.25 M NaOH solution was added and mixed with the aid of a glass rod. The mixture was allowed to stand for about 30 min, and subsequently filtered and washed with ultrapure water until reaching a neutral pH [22].

Preparation of the SBA-15

The mesoporous SBA-15 support was synthesized using the hydrothermal method proposed by Zhao et al. [13]. The P123 was weighed and dissolved in ultrapure water with HCl by magnetic stirring and heated at a temperature of around 35–40 °C for 2 h. The TEOS silicon source was then slowly added and maintained under agitation for 24 h at the same temperature. After this period, the mixture was transferred to an autoclave and subjected to hydrothermal treatment under static conditions, at 100 °C, for 48 h. The material obtained was washed with a solution of hydrochloric acid in 2% ethanol, dried and calcined in a muffle furnace at a temperature of 550 °C for 6 h in air atmosphere.

Functionalization of the support

The SBA-15 mesoporous support was functionalized with CS through a wet impregnation method [34]. The excipient volume for 0.5 g of support was 0.9 mL of CS solution, where polymer solutions at concentrations of 1.0 and 2.5% were used. After the procedure, the materials were dried at room temperature for 24 h [1]. The samples were named CS-SBA-x, where x refers to the % CS concentration in the solution.

Characterization

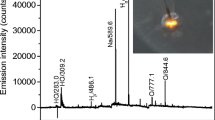

The adsorbents obtained were first characterized by X-ray diffraction (XRD) in a Rigaku Miniflex II diffractometer with CuKa radiation (λ = 0.1542 nm) and diffraction angles (2θ) ranging from 0,5–5°. The thermogravimetric (TG) and differential scanning calorimetry (DSC) curves were obtained using a Netzsch STA 449 F3 instrument in the 25–900 °C temperature range, with a heating rate of 10 °C min−1 and a nitrogen atmosphere, using about 5 mg of sample. The SEM images were taken using a Shimadzo TESCAN MIRA3 microscope with a magnification range of 10,000–15,000× under vacuum. Fourier transform infrared (FTIR) spectra were obtained with a Shimadzu IR Prestige-21 spectrophotometer in the range 4000–400 cm−1 at 4 cm−1 resolution. Samples were dispersed in KBr at a concentration of 1%. The nitrogen adsorption and desorption isotherms were measured at a temperature of—196 °C with Micromeritics model ASAP 2020 equipment. Prior to the adsorption measurement, the sample was degassed at a temperature of 70 °C for 3 h and then at 100 °C for 7 h under vacuum. The specific surface areas were determined using the Brunauer–Emmet–Teller (BET) equation. The pore size distributions were calculated using the adsorption of the nitrogen isotherms by the Barrett–Joyner–Halenda (BJH) method.

Activation energy: model-free methods

To obtain the kinetic data, thermogravimetric (TG) analyses were performed. To obtain these data, the Netzsch STA 449 F3 instrument, with about 5 mg of sample in an alumina crucible, was used. Analysis was performed from 25 to 900 °C, under N2 flowing at 60 mL min−1, at heating rates (β) of 5, 10 and 20 °C min−1. The measured changes are converted to a value called extent or degree of conversion (α), which is dimensionless, and α is defined as

where m t is mass of sample at time t, m 0 is the initial mass value and m f is the final mass value of the analysis. The result of this equation varies between 0 and 1 for the current mass change for the total mass variation that occurred during the entire process [35].

The thermal transformation kinetics of a single step reaction is described in Eq. 2.

where dα/dt is the rate of decomposition, T is the temperature, t is time, k (t) is the Arrhenius rate constant, which can be expressed by the Arrhenius equation:

where A is the pre-exponential factor (min−1), E α the apparent activation energy and R the gas constant. Substituting Eq. (3) into Eq. (2), we obtain:

By means of Eq. (4), we can see the dependence of E α on α [36].

The apparent activation energy is determined by the Vyazovkin and Ozawa–Flynn–Wall methods which are different mathematical approaches, where the former uses a nonlinear isoconversional method and the latter is limited to linear heating rate conditions. However, E α is determined by the slope of curve ln(β/Tα 2) and ln(β) versus 1/Tα for Vyazovkin and Ozawa–Flynn–Wall models, respectively, as shown in Eqs. (5) and (6) [37].

Results and discussion

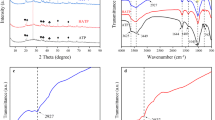

The diffraction patterns, at low angle, of the calcined SBA-15 and functionalized support are shown in Fig. 1. The characteristic profile of the SBA-15 mesoporous support is determined by the three reflections (100), (110) and (200) from the hexagonal p6-mm structure [38]. This shows the presence of long-range periodicity in the synthesized material [39].

It is important to highlight that, even with the inclusion of the CS, the position of the peaks is hardly changed, as we can see from the 2θ data in Table 1. In addition, the mesoporous structure is not damaged by the presence of CS. However, there is a decrease in the peak intensity, more pronouncedly in the CS-SBA-2.5 sample, which is indicative of the filling of the mesopores of SBA-15 by the polymer [10, 40]. The decrease in the lattice parameter (a 0) in samples with CS (Table 1) also reinforces the above statement.

Thermogravimetric (TG) and calorimetric (DSC) analyses of calcined SBA-15 and of the functionalized supports are shown in Fig. 2. The TG curves show loss of mass at the beginning of the temperature rise, and the DSC curves also show physically adsorbed water in the materials, through an endothermic peak [41]. A gradual mass loss due to degradation of CS can be seen through two stages. The corresponding losses for each solid are shown in Table 1. The first stage (between about 150 and 420 °C) indicates the onset of decomposition by depolymerization of CS chains by deacetylation, breaking of the glucosidic bonds and subsequent formation of some volatile products. The exothermic effect of this event seen in the DSC curves is due to the occurrence of cross-linking reactions during polymer degradation. The second mass loss in the presence of CS (between approximately 420 and 720 °C) is due to degradation of the new cross-linked material obtained in the first stage of decomposition, which involves the thermal destruction of the pyranose ring, generating formic acid, acetic acid and butyric acid, as well a series of lower fatty acids [42–44].

The FTIR spectra of the functionalized solids are shown in Fig. 3. The profile of both spectra shows characteristic peaks of the SBA-15 support, including a broad peak at 3450 cm−1 which is associated with defects due to the presence of silanol groups. The N–H stretching can also be seen in this band due to the presence of CS in the SBA-15 sample. On increasing the amount of CS from 1.0 to 2.5%, we noted a increase in the width of said peak which is typical of immobilization of amine groups in the SBA-15 network [45]. The bands at 1080 cm−1 and 811 cm−1 correspond to symmetric and asymmetric vibrations of the Si–O–Si bond. The bands at 463 and 967 cm−1 are due to the stretching and asymmetric vibrations in the silanol groups Si–O–Si, respectively. The presence of water is identified by the presence of a peak at 1635 cm−1. The broad band centered at 3440 cm−1 also indicates physically bound water in the solids through interactions by hydrogen bonds with S–OH groups. The bands which indicate the presence of CS can be seen from the transmittance peaks at 1548 cm−1 corresponding to the presence of NH2 generated by N–H vibrations. The peak at 1413 cm−1 indicates the stretching bonds of NCOO [40, 46].

The nitrogen adsorption–desorption isotherms of the samples are shown in Fig. 4. This analysis gives information on the specific surface area, pore size and the changes caused by the insertion of CS, which are shown in detail in Table 2.

The graphs show a typical type IV isotherm with H1 hysteresis characteristic of SBA-15 with high surface area, indicating a two-dimensional ordered hexagonal mesoporous structure. The first increase in volume adsorbed is observed at relative pressure p/p 0 < 0.1, associated with the completion of a monolayer and the beginning of multilayer adsorption on the surface. The second increase at 0.5 < p/p 0 < 0.7 refers to capillary condensation in the mesopore which has nitrogen multilayers adsorbed on the inner surface of the material [47]. The isotherm for the impregnated samples exhibits the same profile as the mesoporous structure SBA-15, which is not destroyed by the presence of the polymer, as also seen in the XRD of the functionalized solid. However, there was a decrease in the hysteresis loop with increasing inserted CS which, according to the literature, indicates filling of the mesoporous SBA-15 with the polymer [10].

Table 2 shows that with the functionalization there was a decrease in the specific surface area (S BET) and in the volume of the mesopores of the support. This confirms the presence of CS on the surface and inside in the mesopores after functionalization, in addition to showing that the surface area remains high, which is essential for adsorption applications [10]. However, the polymer´s long chain makes its entry into the micropores of the SBA-15 impossible. The pore distribution graphs show that the pore size is maintained in a narrow range and is little affected by the presence of CS [48, 49].

The SEM images of SBA-15 before and after being functionalized with CS are displayed in Fig. 5.

All pictures show structures with short stems of similar sizes, or resemble rods stacked in arrays, which is in agreement with reports in the literature [16, 50]. In Fig. 5b, c for SBA-15 functionalized with CS, we note that the morphology of the support remains relatively unchanged, and the absence of clusters corroborates the XRD results. This suggests that CS is distributed evenly inside the pores and on the surface of SBA-15, which agrees with the results of BET and BJH of the adsorbents [47, 51].

The TG curves of CS and CS-SBA-2.5 are shown in Fig. 6 at three different heating rates (5, 10 and 20 °C min−1) in order to make a kinetic study of the first stage (150 at 420 °C) of the thermal degradation of CS (see Fig. 2). This study promotes interesting information about the influence of the presence of the SBA-15 in degrading CS, in light of the necessity of regeneration of the adsorbents after the CO2 capture process.

The conversion curves as a function of temperature of the studied samples are shown in Fig. 7. We can observe a high degree of parallelism for straight lines, between 0.2 and 0.8 of conversion for both samples and for both methods studied, showing the occurrence of decomposition. We can observe a high correlation coefficient (R): 0.9999 for pure CS and 0.9998 for CS-SBA-15-2.5 for both methods, showing a good fit to the experimental data [52].

The dependence of activation energy on the extent of conversion in the range 0.2–0.8 is shown in Fig. 8. E α increases with increasing degree of conversion. For both samples and both methods, the energies ranged from 161 to 335 kJ mol−1. According to Mishra et al. [52], the small differences observed in the activation energy values in the two methods occur due to the different approaches used to calculate the integral temperature in these methods. According to Ou et al. [53], the range of degradation of CS studied corresponds to the initial deacetylation of chitosan (225–252 °C), followed by cleavage of glycosidic bonds present (252–280 °C) and subsequent cleavage of additional glycosidic bonds (280–350 °C). However, it can be seen that E α calculated by the two methods is not significantly altered by the presence of SBA-15. This information is of great importance for future application of the material under study, in the recovery process of CO2 after being adsorbed into the CS-SBA-15. Otherwise, the increased temperature needed for the CO2 recovery process could cause the decomposition of the CS and consequently prevent their reuse in the process of adsorption of the gas of interest. Serna-Guerrero et al. [54] described in detail this regeneration procedure.

Conclusions

The wet impregnation method used in this study for functionalizing the mesoporous SBA-15 support was effective, so that the presence of the polymer does not change its structure and characteristic morphology. This was verified by the characterizations of XRD and SEM, respectively. The presence of CS inserted in the support was observed in the FTIR and in the thermal techniques. However, the insertion of CS into the support promoted certain changes to its textural properties, such as reduction in specific surface area and reduction in pore volume. This indicates the presence of the polymer on the surface and inside the mesopores of SBA-15. As expected, the volume of micropores in the functionalized samples did not change, showing that it is impossible to insert the polymer into these spaces due to the size of the CS molecule. The two kinetic models applied showed quite similar results, with activation energies with values of 161–335 kJ mol−1 for a degree of conversion between 0.2 and 0.8 for pure CS and SBA-CS-2.5 samples for the two methods. However, the results have shown that the E α was not significantly altered by the presence of SBA-15 in CS.

References

Barbosa MN, Araujo AS, Galvão LPFC, Silva EFB, Santos AGD, Luz GE Jr, Fernandes VJ Jr. Carbon dioxide adsorption over DIPA functionalized MCM-41 and SBA-15 molecular sieves. J Therm Anal Calorim. 2011;106:779–82.

Hook M, Tang X. Depletion of fossil fuels and anthropogenic climate change—a review. Energy Policy. 2013;52:797–809.

Yan X, Komarneni S, Yan Z. CO2 adsorption on Santa Barbara Amorphous-15 (SBA-15) and amine-modified Santa Barbara Amorphous-15 (SBA-15) with and without controlled microporosity. J Colloid Interface Sci. 2013;390:217–24.

Ojala MS, Serrano NF, Uusi-Kyyny P, Alopaeus V. Comparative study: absorption enthalpy of carbon dioxide intoaqueous diisopropanolamine and monoethanolamine solutions and densities of the carbonated amine solutions. Fluid Phase Equilib. 2014;376:85–95.

Yu J, Guo M, Muhammad F, Wang A, Zhan F, Li Q, Zhu G. One-pot synthesis of highly ordered nitrogen-containing mesoporous carbon with resorcinol–urea–formaldehyde resin for CO2 capture. Carbon. 2014;69:502–14.

Snider MT, Verweij H. Gas sorption studies on Zeolite Y membrane materials for post-combustion CO2 capture in coal-fired plants. Microporous Mesoporous Mater. 2014;192:3–7.

Olivares-Marín M, Cuerda-Correa EM, Nieto-Sánchez A, García S, Pevida C, Román S. Influence of morphology, porosity and crystal structure of CaCO3 precursors on the CO2 capture performance of CaO-derived sorbents. Chem Eng J. 2013;217:71–81.

Chen D-S, Cheng J-M, Sun L-B, Liang Z-Q, Shao K-Z, Wang C-G, Xing H-Z, Su Z-M. A new porous 2D copper(II) metal–organic framework for selective adsorption of CO2 over N2. Inorg Chem Commun. 2013;38:104–7.

Liu J-L, Lin R-B. Structural properties and reactivities of amino-modified silica fume solid sorbents for low-temperature CO2 capture. Powder Technol. 2013;241:188–95.

Jing Y, Wei L, Wang Y, Yu Y. Synthesis, characterization and CO2 capture of mesoporous SBA-15 adsorbents functionalized with melamine-based and acrylate-based amine dendrimers. Microporous Mesoporous Mater. 2014;183:124–33.

Vilarrasa-Garcia E, Moya EMO, Cecilia JA, Cavalcante CL Jr, Jiménez-Jiménez J, Azevedo DCS, Rodríguez-Castellón E. CO2 adsorption on amine modified mesoporous silicas: effect of the progressive disorder of the honeycomb arrangement. Microporous Mesoporous Mater. 2015;209:172–83.

Kishor R, Ghoshal AK. APTES grafted ordered mesoporous silica KIT-6 for CO2 adsorption. Chem Eng J. 2015;262:882–90.

Zhao D, Huo Q, Feng J, Kim J, Han Y, Stucky GD. Nonionic triblock and star diblock copolymer and oligomeric surfactant syntheses of highly ordered, hydrothermally stable, mesoporous silica structures. J Am Chem Soc. 1998;120:6024–36.

Hoo P-Y, Abdullah AZ. Direct synthesis of mesoporous 12-tungstophosphoric acid SBA-15 catalyst for selective esterification of glycerol and lauric acid to monolaurate. Chem Eng J. 2014;250:274–87.

Liu R, Wang T, Jin Y. Catalytic dehydration of glycerol to acrolein over HPW supported on Cs+ modified SBA-15. Catal Today. 2014;233:127–32.

Meng M, Meng X, Liu Y, Liu Z, Han J, Wang Y, Luo M, Chen R, Ni L, Yan Y. An ion-imprinted functionalized SBA-15 adsorbent synthesized bysurface imprinting technique via reversible addition–fragmentation chain transfer polymerization for selective removal of Ce(III) fromaqueous solution. J Hazard Mater. 2014;278:134–43.

Zhang W, Wang H, Han J, Song Z. Multifunctional mesoporous materials with acid–base frameworks and ordered channels filled with ionic liquid: synthesis, characterization and catalytic performance of Ti–Zr-SBA-15-IL. Appl Surf Sci. 2012;258:6158–68.

Yoo C-J, Lee L-C, Jones CW. Probing intramolecular versus intermolecular CO2 adsorption on amine-grafted SBA-15. Langmuir. 2016;2015(31):13350–60. doi:10.1021/acs.langmuir.5b03657 (Access: August 01).

Hao S, Chang H, Xiao Q, Zhong Y, Zhu W. One-pot synthesis and CO2 adsorption properties of ordered mesoporous SBA-15 materials functionalized with APTMS. J Phys Chem C. 2011;115:12873–82.

Yan X, Zhang L, Zhang Y, Yang G, Yan Z. Amine-modified SBA-15: effect of pore structure on the performance for CO2 capture. Ind Eng Chem Res. 2011;50:3220–6.

Badawya MEI, Rabea EI, Taktak NEM. Antimicrobial and inhibitory enzyme activity of N-(benzyl) and quaternary N-(benzyl) chitosan derivatives on plant pathogens. Carbohydr Polym. 2014;111:670–82.

Pandis C, Madeira S, Matos J, Kyritsis A, Mano JF, Ribelles JLG. Chitosan–silica hybrid porous membranes. Mater Sci Eng, C. 2014;42:553–61.

Vakili M, Rafatullah M, Salamatinia B, Abdullah AZ, Ibrahim MH, Tanb KB, Gholami Z, Amouzgar P. Application of chitosan and its derivatives as adsorbents for dye removal from water and wastewater: a review. Carbohydr Polym. 2014;113:115–30.

Wang J, Chen C. Chitosan-based biosorbents: modification and application for biosorption of heavy metals and radionuclides. Bioresour Technol. 2014;160:129–41.

Allouche FN, Guibal E, Mameri N. Preparation of a new chitosan-based material and its application for mercury sorption. Colloids Surf A Physicochem Eng Asp. 2014;446:224–32.

Lin S, Wei W, Wu X, Zhou T, Mao J, Yun Y-S. Selective recovery of Pd(II) from extremely acidic solution using ion-imprinted chitosan fiber: adsorption performance and mechanisms. J Hazard Mater. 2015;299:10–7.

Contri RV, Soares RMD, Pohlmann AR, Guterres SS. Structural analysis of chitosan hydrogels containing polymeric nanocapsules. Mater Sci Eng, C. 2014;42:234–42.

Upadhyaya L, Singh J, Agarwal V, Tewari RP. The implications of recent advances in carboxymethyl chitosan based targeted drug delivery and tissue engineering applications. J Controlled Release. 2014;186:54–87.

Huang C-C, Shen S-C. Adsorption of CO2 on chitosan modified CMK-3 at ambient temperature. J Taiwan Inst Chem Eng. 2013;44:89–94.

Keramati M, Ghoreyshi AA. Improving CO2 adsorption onto activated carbon through functionalization by chitosan and triethylenetetramine. Phys E. 2014;57:161–8.

Belmabkhout Y, Serna-Guerrero R, Sayari A. Adsorption of CO2-containing gas mixtures over amine-bearing pore-expanded MCM-41 silica: application for CO2 separation. Adsorption. 2011;17:395–401.

Moriana R, Vilaplana F, Karlsson S, Ribes S. Correlation of chemical, structural and thermal properties of natural fibres for their sustainable exploitation. Carbohydr Polym. 2014;112:422–31.

Vyazovkin S, Sbirrazzuoli N. Isoconversional kinetic analysis of thermally stimulated processes in polymers. Macromol Rapid Commun. 2006;27:1515–32.

Le MUT, Lee S-Y, Park S-J. Preparation and characterization of PEI-loaded MCM-41 for CO2 capture. Int J Hydrog Energy. 2014;39:12340–6.

Vyazovkin S, Chrissafis K, Lorenzo MLD, Koga N, Pijolat M, Roduit B, Sbirrazzuoli N, Suñol JJ. ICTAC Kinetics Committee recommendations for collecting experimental thermal analysis data for kinetic computations. Thermochim Acta. 2014;590:1–23.

Janković B, Smičiklas I, Stajić-Trošić J, Antonović D. Thermal characterization and kinetic analysis of non-isothermal decomposition process of Bauxite red mud. Estimation of density distribution function of the apparent activation energy. Int J Hydrog Energy. 2013;123:46–59.

Santos AGD, Souza LD, Caldeira VPS, Farias MF, Fernandes VJ Jr, Araujo AS. Kinetic study and thermoxidative degradation of palm oil and biodiesel. Thermochim Acta. 2014;592:18–22.

Mendoza-Nieto JA, Vera-Vallejo O, Escobar-Alarcón L, Solís-Casados D, Klimova T. Development of new trimetallic NiMoW catalysts supported on SBA-15 for deep hydrodesulfurization. Fuel. 2014;110:268–77.

Yadavi M, Badiei A, Ziarani GM. A novel Fe3+ ions chemosensor by covalent coupling fluorene onto the mono, di- and tri-ammonium functionalized nanoporous silica type SBA-15. Appl Surf Sci. 2013;279:121–8.

Shahbazia A, Younesia H, Badiei A. Functionalized SBA-15 mesoporous silica by melamine-based dendrimer amines for adsorptive characteristics of Pb(II), Cu(II) and Cd(II) heavy metal ions in batch and fixed bed column. Chem Eng J. 2011;168:505–18.

Hernández-Morales V, Nava R, Acosta-Silva YJ, Macías-Sánchez SA, Pérez-Bueno JJ, Pawelec B. Adsorption of lead (II) on SBA-15 mesoporous molecular sieve functionalized with –NH2 groups. Microporous Mesoporous Mater. 2012;160:133–42.

Zeng L, Qin C, Wang L, Li W. Volatile compounds formed from the pyrolysis of chitosan. Carbohydr Polym. 2011;83:1553–7.

Marroquina JB, Rhee KY, Park SJ. Chitosan nanocomposite films: enhanced electrical conductivity, thermal stability, and mechanical properties. Carbohydr Polym. 2013;92:1783–91.

Xu K, Li K, Zhong T, Guan L, Xie C, Li S. Effects of chitosan as biopolymer coupling agent on the thermal and rheological properties of polyvinyl chloride/wood flour composites. Compos B. 2014;58:392–9.

Diagboya PN, Olu-Owolabi BI, Adebowale KO. Microscale scavenging of pentachlorophenol in water using amine and tripolyphosphate-grafted SBA-15 silica: batch and modeling studies. J Environ Manage. 2014;146:42–9.

Zhang X, Qin H, Zheng X, Wu W. Development of efficient amine-modified mesoporous silica SBA-15 for CO2 capture. Mater Res Bull. 2013;48:3981–6.

Seftel E-M, Cool P, Lloyd-Spetz A, Lutic D. Pt-doped semiconductive oxides loaded on mesoporous SBA-15 for gas sensing. C R Chimie. 2014;17:717–24.

Pang J, Zhao L, Zhang L, Li Z, Luan Y. Folate-conjugated hybrid SBA-15 particles for targeted anticancer drug delivery. J Colloid Interface Sci. 2013;395:31–9.

Gao Q, Zhu H, Luo W-J, Wanga S, Zhou C-G. Preparation, characterization, and adsorption evaluation of chitosan-functionalized mesoporous composites. Microporous Mesoporous Mater. 2014;193:15–26.

Guo W, Chen R, Liu Y, Meng M, Menga X, Huc Z, Song Z. Preparation of ion-imprinted mesoporous silica SBA-15 functionalized with triglycine for selective adsorption of Co(II). Colloids Surf A Physicochem Eng Asp. 2013;436:693–703.

Wang X, Ma X, Song C, Locke DR, Siefert S, Winans RE, Möllmer J, Lange M, Möller A, Gläser R. Molecular basket sorbents polyethylenimine–SBA-15 for CO2 capture from flue gas: characterization and sorption properties. Microporous Mesoporous Mater. 2013;169:103–11.

Mishra G, Kumar J, Bhaskar T. Kinetic studies on the pyrolysis of pinewood. Bioresour Technol. 2015;182:282–8.

Ou C-Y, Li S-D, Li CP, Zhang C-H, Yang L, Chen C-P. Effect of cupric ion on thermal degradation of chitosan. J Appl Polym Sci. 2008;109:957–62.

Serna-Guerrero R, Belmabkhout Y, Sayari A. Triamine-grafted pore-expanded mesoporous silica for CO2 capture: effect of moisture and adsorbent regeneration strategies. Adsorption. 2010;16:567–75.

Acknowledgements

The authors acknowledge the financial and structural support provided by the and the structural support provided by Catalysis, Environment and Materials Laboratory (LACAM), Optical Analysis and Magnetic Laboratory (LAMOp) of State University Rio Grande do Norte (UERN) and Catalysis and Petrochemicals Laboratory (LCP) of the Federal University of Rio Grande do Norte (UFRN). Funding was provided by National Council for Scientific and Technological Development (CNPq) and Coordination of Improvement of Higher Level Personnel (CAPES).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

dos Santos, A.P.B., Santos, A.G.D., Caldeira, V.P.S. et al. Kinetic study of type SBA-15 materials functionalized with chitosan. J Therm Anal Calorim 129, 391–399 (2017). https://doi.org/10.1007/s10973-017-6109-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6109-7