Abstract

We present the critical analysis of the utilization of CO2 adsorption calorimetry/volumetry and TPD-CO2 for the determination of the Mg–Al mixed oxide basicity. The aim of work is the description and the evaluation of both methods with respect to the fact when the same types of CO2 adsorption complexes are involved. Critical parts of basic sites determination are originally discussed for both methods. In TPD-CO2, the process of the purging of non-specifically physisorbed CO2 is stressed. In CO2 adsorption calorimetry, the differential heat of CO2 distinguishing CO2 adsorption on weak basic sites and non-specific CO2 physisorption is stressed. Both methods are applied on series of selected Mg/Al mixed oxides varying in Mg/Al molar ratio and alkali co-cation. We show that the generally used TPD-CO2 does not provide complete information about basic sites since some weak sites form unstable CO2 species and these species could not be involved in TPD experiments. All our TPD-CO2 experiments reflect at 0–485 °C those CO2 adsorbed in the range of the differential heat of CO2 above 30–32 kJ mol−1.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mg–Al mixed oxides represent attractive catalysts in many base-catalysed organic reactions [1] such as transesterification [2, 3], aldol and Knoevenagel condensation [4] and transformation of glycerol to acetol and acrolein [5]. Mg–Al mixed oxides are very often prepared by thermal treatment of layered double hydroxide precursors, also known as hydrotalcites. Mg–Al mixed oxides are formed by the release of interlayer water molecules (dehydration), followed by dehydroxylation of hydroxide layers and decomposition of interlayer carbonate resulting in the destruction of layered structure. Obtained Mg–Al mixed oxides show well dispersed Mg and Al cations, strong surface basicity, large surface area and a high quantity of defects resulting from incorporation of Al3+ cations in the MgO lattice [6]. Low cost of synthesis and high thermal stability represent other advantages of layered double hydroxide-related Mg–Al mixed oxide catalysts [7].

A lot of efforts have been focused on the analysis of surface basicity of Mg–Al mixed oxide catalysts (the strength of basic species, their concentration and accessibility). Basic sites can be classified in Mg–Al mixed oxides according to their different strength as weak, medium and strong. Weak basic sites are attributed to OH− groups on the catalyst surface. Medium strength basic sites are related to oxygen in both Mg2+–O2− and Al3+–O2− pairs. Strong basic sites correspond to isolated O2− anions [8–11]. While pure MgO possesses strong basic sites (O2−), Mg–Al mixed oxides contain surface basic sites of low, medium and strong basicity [6]. The presence of weak, medium and strong basic sites has been discussed based on temperature programmed desorption (TPD) of CO2 [6, 12], measurements of FTIR spectra after CO2 adsorption [6, 13, 14], adsorption calorimetry of CO2 [14, 15] and 1H MAS NMR [16]. The total concentration of basic sites presented in Mg–Al mixed oxides has been determined by Hammett titration method [17–19], TPD of CO2 [20–22], CO2 adsorption calorimetry [14, 23], testing reactions (e.g. self-condensation and cross-aldol condensation of aldehydes and ketones [24]). However, the reported basicity of approximately the same Mg–Al mixed oxides determined by different methods is very often different as it was discussed by Fraile et al. [25]. One reason is complex properties of Mg–Al mixed oxides depending on their preparation procedures. The second reason originates from the type of selected technique as well as from the set of experimental conditions that is the point of this work.

The highest basicity has evidently been reported for Mg–Al mixed oxides based on Hammett titration method (e.g. 1.3–3.5 mmol g−1 [17]), which is unequivocally given by the fact that the soluble basicity is also involved in this technique.

Total basicity of Mg–Al mixed oxides is mainly obtained from TPD-CO2. The most important parameter that could affect the obtained basicity is the temperature of CO2 adsorption and the set of experimental conditions used to purge (remove) the so-called excess of CO2, i.e. non-specific CO2 physisorption (temperature, time and flow of inert). Non-specific CO2 physisorption represents the weak interaction of CO2 with Mg–Al mixed oxides, and it has to be neglected when calculating the amount of basic sites. Thus, it has to be purged from the surface of Mg–Al mixed oxides before separate TPD-CO2 measurement. Unfortunately, this process could be associated with unwanted desorption of some CO2 from the weakest basic sites (such case is leading to undervalue basicity). CO2 adsorption and the process of the purging the non-specifically physisorbed CO2 are generally done at the same temperature. The value of used temperature is limited by TPD experimental set-up. For example, there are used varied values of temperatures, i.e. room temperature [21, 26], 30 °C [27], 50 °C [28, 29] and 100 °C [30]. It could be expected that the temperature as low as possible maximizes the amount of CO2 remaining to be adsorbed on the weakest basic sites.

In contrast, CO2 adsorption calorimetry brings the basicity based on the value of adsorption heat and involves all basic sites. The most important parameter that could affect the obtained basicity of Mg–Al mixed oxides is the value of adsorption heat, to which the amount of basic sites is calculated. In the literature, the amount of basic sites has been calculated at various intervals of differential heats of CO2 adsorption, i.e. up to 70 kJ mol−1 (weak basic sites 70 < Q diff < 120 kJ mol−1) [31], 30 kJ mol−1 (weak basic sites 30 < Q diff < 90 kJ mol−1) [15, 32] and 27 kJ mol−1 [33].

The aim of this study is to compare TPD of CO2 and CO2 adsorption calorimetry with respect to the fact, when the same types of basic sites are involved in both techniques. We discussed and compared the basicity obtained from both techniques. We also draw the general results useful for the determination of the amount of basic sites in Mg–Al mixed oxides as well as in other materials using CO2 as a probe. As the basicity of Mg–Al mixed oxides plays the critical role in its catalytic properties, the results of this work could also be useful to wide range of applications of these materials. This work follows to our previous works dealing with the utilization of Mg–Al mixed oxides in transesterification of rapeseed oil [34, 35]. Although the role of basicity on the catalytic behaviour of Mg–Al mixed oxides was mentioned in these works, the basicity was only determined based on TPD-CO2 and the aspects of the determination of basic sites with respect to the results of CO2 adsorption calorimetry was not reported yet.

Experimental

Material synthesis

Mg–Al hydrotalcite-like precursors with Mg/Al ratio 2.5, 3.0 and 4.0 were synthesized by co-precipitation method using NaOH/Na2CO3 or KOH/K2CO3 alkaline solution. A detailed procedure was described in [34, 35]. The samples were denoted by acronyms with used alkali (Na and K). All Mg–Al hydrotalcite-like precursors were calcined at 450 °C for 4 h in air flow in order to obtain Mg–Al mixed oxide materials. Mg–Al mixed oxides were denoted as Mg–Al–Na–X or Mg–Al–K–X. The value of X refers to Mg/Al molar ratio determined by chemical analysis in the obtained solid.

Material characterization

The chemical analyse was performed by using of XRF analysis (recorded with X-ray fluorescence spectrometer Philips PW1404). The structure of samples was determined by the powder X-ray diffraction (XRD). Patterns were recorded with Bruker AXS D8-Advance diffractometer using Cu Kα radiation (λ = 0.154056 nm) with a secondary graphite monochromator. Specific surface areas (S BET) of Mg/Al mixed oxides were measured at the boiling point of liquid nitrogen (−196 °C), and it was determined by the fitting of the experimental data to the BET isotherm.

Temperature programmed desorption of carbon dioxide (TPD-CO2) was carried out on Micromeritics AutoChem 2920 equipped with mass spectrometer (quadrupole analyser MS OmniStar). 100 mg of sample (grain of 0.25–0.5 mm) was placed in quartz reactor. Before TPD experiments, the samples were calcined in helium flow (25 mL min−1) at 450 °C (heating rate of 10 °C min−1) for 2 h. Two types of conditions were used. Usually, the samples were subsequently cooled down to 0 °C and saturated with pure CO2 (99.9 % purity, flow 25 mL min−1, 30 min). The non-specifically physisorbed CO2 was removed by flushing with helium at the same temperature as its adsorption was done (0 °C) for 30 min (25 mL min−1 He). The desorption of CO2 was measured by heating of the sample from 0 to 485 °C (heating rate of 10 °C min−1) in the flow of helium (25 mL min−1). Secondly, varied experimental conditions were used when we studied the role of experimental conditions to the type of TPD profile. The following changes were done. (1) CO2 saturation was done with the gas containing different concentration of CO2: pure CO2 (99.9 % purity), 50 % CO2 in He or 10 % CO2 in He. (2) CO2 saturation was done at 0, 25 or 34 °C. At the same temperature, non-specifically physisorbed CO2 was removed by flushing with helium (for 30 min, 25 mL min−1 He) and the heating program started (from 0 to 485 °C, heating rate of 10 °C min−1). (3) The heating of the sample was done up to 900 °C (from 0 to 900 °C, heating rate of 10 °C min−1). The desorbed products were analysed by a mass spectrometer (the molecular ion m/z = 44 was analysed). The total basicity was estimated from the area of CO2 peaks (the molecular ion, m/z = 44) with help of calibration using a known amount of CO2 desorbed from the decomposition of NaHCO3 as standard in the flow of helium (25 mL min−1).

The calorimetric/volumetric experiments were carried out using high-sensitive isothermal Tian–Calvet-type microcalorimeter (BT 2.15, SETARAM) combined with a homemade volumetric/manometric device equipped with capacitance pressure gauges (Pfeiffer Vacuum) allowing precise adsorbed amount determination [36]. 400 mg of sample was outgassed by increasing temperature (heating rate of 5 °C min−1) with simultaneous careful evacuation up to residual pressure 10−4 Pa at 450 °C. The adsorption isotherms and heats of adsorption were measured at 34 °C by step-by-step introduction of CO2 (99.9993 purity) into the measure and reference cells. Temperature of sample in the cells inside the microcalorimeter was kept at 34 °C, and the volumetric–manometric device was tempered at the same temperature. Adsorptive was introduced from the calibrated dose volume via a system of electrically operated vacuum valves. Once pressure in the dosing volume was stabilized, the valve separating dosing volume from sample cell was opened to allow the adsorptive to reach the sample. Each dose was accompanied by exothermic effect detected by the microcalorimeter. The system was equilibrated at each dose for ca. 180 min—the establishment of equilibrium was monitored by both the pressure and the heat-flow stabilization. The integral area of the peak in heat flow–time plot provided integral adsorption heat evolved at each adsorptive dose. The dependence of differential adsorption heat versus adsorbed amount was obtained by numeric differentiation of the integral adsorption heat dependence on adsorbed amount data. The calorimeter response was calibrated to the melting heat of mercury used as a standard.

Results and discussion

Structure and composition of Mg–Al hydrotalcites and related Mg–Al mixed oxides

Based on our previous research, we selected Mg–Al hydrotalcites and related Mg–Al mixed oxides varying in Mg/Al content and alkali co-cation. Composition, structure and textural properties have already been fully described [34, 35]. For Mg–Al–Na–2.3, Mg–Al–Na–2.7 and Mg–Al–Na–3.7 materials, we reported chemical analysis (mixed oxides), XRD patterns (hydrotalcites and mixed oxides), specific surface area (mixed oxides) and TG–DTA (hydrotalcites) results [34]. For Mg–Al–K–3.5 material, we reported chemical analysis (mixed oxide), XRD patterns (hydrotalcite and mixed oxide) and specific surface area (mixed oxide) [35].

Mg–Al–Na–3.7 mixed oxide exhibited higher specific surface area (189 m2 g−1) than Mg–Al–K–3.5 mixed oxide (174 m2 g−1) [35] and that the specific surface area of the Mg–Al–Na mixed oxides slightly increased (170–189 m2 g−1) with increasing Mg/Al molar ratio [34].

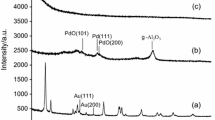

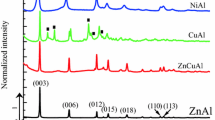

Powder XRD patterns of all Mg–Al hydrotalcites showed the diffraction lines at 2θ = 11.0°, 22.2°, 34.2°, 38.2°, 45.1°, 59.9° and 61.1° (for more details see [34, 35]), which are characteristic for hydrotalcite-like phases. No other crystalline phase was detected in these samples. Powder XRD patterns of Mg–Al mixed oxides showed characteristic diffraction lines observed at 2θ = 43.0° and 62.5° (for more details see [34, 35]). These diffraction lines can be ascribed to MgO-like phase or rather magnesia–alumina solid solution [37, 38]. It indicates that the layered hydrotalcite structures were successfully transferred to Mg–Al mixed oxide materials during the thermal treatment [39, 40].

The TG–DTA peaks obtained from the thermal analysis studies of Mg–Al hydrotalcites are presented elsewhere [34]. In all cases, three peaks were observed, the loss of interlayer water (125 °C), dehydration (200 °C) and the loss of OH− groups and decomposition of CO3 2− in the LDH structure (380–400 °C). The similar shape of the curves of all the samples suggested their similar XRD structures, and differences were only in the total mass loss.

Basic sites in Mg–Al mixed oxides

The amount of basic sites was evaluated from the differential heat of CO2 adsorption and the temperature programmed desorption of CO2 (TPD-CO2). In general, adsorption of CO2 on Mg–Al mixed oxide leads to the formation of bicarbonates formed on weakly basic OH groups, bidentate carbonates formed on Mg–O pairs and unidentate carbonates formed on strongly basic surface O2− anions [9]. The elimination of weakly adsorbed water (below 100 °C), interlayer water (100–200 °C) and dehydroxylation/decarbonation (310 °C) [41] can represent the problem in the determination of the amount of basic sites. Thus, the Mg–Al mixed oxides were online pre-treated before TPD-CO2 and CO2 adsorption calorimetry in the stream of helium at 450 °C. This operation guaranteed that the basicity was determined for the materials with the same properties. Temperature 450 °C is the same as it is generally used during the sample pre-treatment in such type of experiments.

Temperature programmed desorption of CO2

Figure 1 shows TPD-CO2 profiles of Mg–Al–K–3.5 mixed oxide calcined at 450 °C in He with and without CO2 pre-adsorption step at 0 °C. If CO2 was pre-adsorbed on Mg–Al mixed oxide, desorption peaks were observed in the range of 0–485 and 485–850 °C. On the other hand, if CO2 was not pre-adsorbed on Mg–Al mixed oxide, there was only observed the desorption peak at 485–850 °C. The desorption peak at 0–485 °C is generally attributed to CO2 desorbed from basic sites of Mg–Al mixed oxide [10, 12, 20]. It is in agreement with the fact that only CO2 pre-adsorption step led to the formation of CO2 desorption peak in the temperature range of 0–485 °C. Above 485 °C, a CO2 desorption peak was observed in both TPD-CO2 profiles. Moreover, the intensity of the desorption peak was the same and it corresponded to the amount of 127 μmol(CO2) g−1. Thus, the TPD peak located above 485 °C does not represent desorption of CO2 from the basic sites, but it is connected with CO2 released from the residual carbonate, which was not decomposed during calcination of the hydrotalcite-like precursor [38, 42].

In detail, we focused on the role of (1) the concentration of CO2 used during the CO2 saturation and (2) the temperature at which proceeds the process of the purging non-specifically physisorbed CO2. These experimental conditions represent those at which mainly differ the measuring of the basicity of Mg–Al mixed oxides among different laboratories.

Figure 2 shows TPD-CO2 profile of Mg–Al–Na–3.7 mixed oxide, when the CO2 saturation was done with the gas containing different concentration of CO2: pure CO2 (99.9 % purity), 50 % CO2 in He or 10 % CO2 in He. The basicity of Mg–Al–Na–3.7 mixed oxide was determined to be 145 μmol g−1 (10 % CO2 in He), 148 μmol g−1 (50 % CO2 in He) and 168 μmol g−1 (pure CO2). For pure CO2, there was observed slightly more intensive desorption peak with a maximum at 74 °C. Nevertheless, such differences are only negligible. It could be partly explained by the varied concentration of CO2 used in its adsorption that could result in different forced convection.

Figure 3 shows TPD-CO2 profiles of Mg–Al–Na–2.3 mixed oxide when the non-specifically physisorbed CO2 was purged from the sample at 0, 25 and 34 °C (temperature 34 °C was used to measure adsorption isotherms and heats of adsorption). It was done due to the fact that various temperatures are used in the literature (see “Introduction” section). It is clearly seen that the start of desorption peak as well as its maximum was connected with the chosen temperature. However, the amount of basic sites determined from the amount of desorbed CO2 was approximately the same, i.e. 295 μmol g−1 (0 °C), 278 μmol g−1 (25 °C) and 284 μmol g−1 (34 °C). No similar experiment was reported at the literature. Unfortunately, we are not able to bring the clear explanation of this phenomena. Nevertheless, the dependence of the maximum of the first desorption peak on the temperature used to purge the Mg–Al sample from the non-specifically physisorbed CO2 could explain the discrepancy in the reported maximum of the first desorption peak. In the literature, the maximum of first desorption peak, originated from the desorption of bicarbonates formed on weakly basic OH groups, has been reported to be present in wide range of temperature from 75 °C [26] to ca 175 °C [30], depending on the fact at which temperature CO2 pre-adsorption step was done. Thus, it could be supposed that the shift of the maximum of desorption peak is connected with the different TPD set-up (temperature, time and flow of inert) used to purge the non-specifically physisorbed CO2.

Figure 4 shows the TPD-CO2 profiles of Mg–Al–Na–2.3, Mg–Al–Na–2.7, Mg–Al–Na–3.7 and Mg–Al–K–3.5 mixed oxides (non-specifically physisorbed CO2 was removed by flushing with 25 mL min−1 of helium at 0 °C for 30 min). Total amount of desorbed CO2 detected in TPD-CO2 profiles of Mg–Al mixed oxides in the range of 0–485 °C is summarized in Table 1. The total amount of desorbed CO2 increased in order Mg–Al–K–3.5 < Mg–Al–Na–3.7 < Mg–Al–Na–2.7 < Mg–Al–Na–2.3. TPD profiles of all studied Mg–Al mixed oxides exhibited dominant desorption peak at 65–75 °C that could be attributed to the CO2 desorption from weak basic sites [10, 12]. In any of TPD profiles, strict separation of individual peaks above 140 °C reflecting the presence of medium (reported to be characteristic by desorption peak at 140–170 °C [6, 12, 43] or at 220 °C [10]) or strong (reported to be characteristic by desorption peak at 270–317 °C [6, 43, 44], 400–450 °C [10] or 550–600 °C [8]) basic sites was not observed. There was observed only a shoulder of the most intensive desorption peak at 75 °C up to 420 °C and a peak at 270 °C of low intensity that could be probably attributed to the presence of CO2 desorption from strong basic sites. This suggests that a low amount of medium and strong basic sites is present in the studied samples.

In the following, we checked the process of CO2 purging, i.e. if the signal of CO2 achieved a stable zero value. Figure 5 shows the dependence of the amount of desorbed CO2 on time during the process of the purging the non-specifically physisorbed CO2, which was operated in the flow of helium at temperature 0 °C for 30 min. It is clearly evident that in all cases, CO2 was purged up to 5 min. After that marginal CO2 amount was detected in the helium going through the sample containing adsorbed CO2. Thus, non-specifically physisorbed CO2 was purged from the sample before TPD-CO2 experiment. On the other hand, CO2 weakly adsorbed on the basic sites could also be involved in the purged amount of CO2. Such case could lead to decrease in the amount of CO2 desorbed during TPD-CO2. Subsequently, it could lead to decrease in the obtained value of the amount of basic sites obtained from TPD-CO2.

CO2 adsorption calorimetry

Figure 6 shows calorimetric curves of CO2 adsorption on all studied Mg–Al mixed oxides. Calorimetric curves are presented as the differential heat of adsorption being a function of sample coverage. Figure 7 shows corresponding CO2 adsorption isotherms at 34 °C.

Individual CO2 adsorption steps revealed heterogeneity of the basic sites in the presented Mg–Al mixed oxides. First adsorption steps are characterized by heats in the range of 150–140 kJ mol−1 and near zero CO2 equilibrium pressure, indicating strong CO2 bounds [13, 45]. Next doses are followed by gradual decrease in heats in the range of 140–25 kJ mol−1. The region of adsorption heats reflecting the presence of medium and weak basic sites is still matter of discussion. Medium and weak basic sites have been mostly reported to be characterised by adsorption heats in the region of 140 (120)–90 kJ mol−1 [14, 46] and 90–25 kJ mol−1 [24, 47], respectively. Lower value of adsorption heat is generally attributed to the non-specific CO2 physisorption [47, 48], and it could not be involved in the calculation of the amount of basic sites (those CO2 that has to be purged from the sample before TPD-CO2 experiment). This adsorption heat was denoted by dot line in Fig. 6 (with corresponding equilibrium pressure in Fig. 7).

The total amount of basic sites probed by CO2 adsorption is thus given by the amount of CO2 adsorbed until the heat drops to the 25 kJ mol−1 (Fig. 6) and pressure reaches ca. 77 mbar (Fig. 7). The limit in the calculation of the amount of basic sites is 25 kJ mol−1. This value can be attributed to the physical adsorption, and it has to be neglected when calculating the amount of basic sites [47, 48]. Table 1 gives the amount of basic sites calculated as the difference of the amount of CO2 between the initial adsorption heat and the energy of 25 kJ mol−1. The end of the run is reflected by the energy of 17 kJ mol−1, being the condensation heat of CO2, and equilibrium pressure 250–300 mbar.

Evaluation of the determination of the amount of basic sites

In this work, the determined amount of basic sites for Mg–Al mixed oxide varied between 165 and 303 μmol g−1 depending on the Mg–Al mixed oxides properties (Table 1). The most of works dealing with Mg–Al mixed oxides reports the basicity of Mg–Al mixed oxides between 100 and 500 μmol g−1 [9, 12, 44]. There are only few works, where the basicity of Mg–Al mixed oxides was reported above 500 μmol g−1 [49]. In contrast to Mg–Al mixed oxides, higher basicity has been reported for Mg–Al hydrotalcites, where the amount of basic sites has been reported at around 1.5 and 2.5 mmol g−1 depending to the Mg/Al ratio [50]. The varying basicity of samples with similar chemical composition is sometimes reported [25] which suggests different synthesis, sample pre-treatment stages and/or analysis conditions. Even though there are number of studies dealing with the basicity of Mg–Al mixed oxides, the influence of individual parameters on basicity of Mg–Al mixed oxides remains a matter of discussion representing motivation for our study.

Table 1 compares the amount of basic sites of Mg–Al–Na–2.3, Mg–Al–Na–2.7, Mg–Al–Na–3.7 and Mg–Al–K–3.5 mixed oxides determined by TPD-CO2 and CO2 adsorption calorimetry. In all cases, higher basicity has been reported by CO2 adsorption calorimetry (>25 kJ mol−1) than for TPD-CO2 (0–485 °C). This is in agreement with the fact that some part of CO2 weakly adsorbed on the basic sites could be purged before TPD together with non-specifically physisorbed CO2. From that point of view, the amount of basic sites calculated as the difference of the amount of CO2 between the initial adsorption heat and the energy of 25 kJ mol−1 represents the highest amount of basic sites that could be determined for Mg–Al mixed oxides. Combining our experimental results, quantities from TPD-CO2 correspond for all tested samples to equilibrium CO2 pressure 30 mbar and heat of adsorption 30–32 kJ mol−1. Although adsorption of CO2 (CO2 adsorption calorimetry; 34 °C; Fig. 6) was done at different temperature as CO2 desorption (TPD-CO2; 0 °C; Fig. 4), it has been clearly shown the same amount of basic sites was determined by TPD-CO2 at both 0 and 34 °C (Fig. 3). Thus, it could be concluded that the TPD-CO2 experiments reflect at 0–485 °C those CO2 adsorbed in the range of the differential heat of CO2 above 30–32 kJ mol−1.

Generally, it is hard to predict or check whether there is purging (before TPD-CO2) only the non-specifically physisorbed CO2 or whether there is also unwanted purging the CO2 weakly adsorbed on the basic sites. To unambiguously distinguish the stability of CO2 adsorption complexes, after the first run and evacuation of the sample at 34 °C for 1 h the second run of adsorption was realized. The starting values of heat within the second run were just between 50 and 60 kJ mol−1, i.e. CO2 surface complexes with the energy below the heat of adsorption 50–60 kJ mol−1 were weakly bound and represent unstable CO2 species formed only with the CO2 equilibrium pressure. Such pressure is approximately 5 mbar and higher, as denoted by dash line in Fig. 7. Thus, CO2 adsorption complexes with the heat of adsorption below 50–60 kJ mol−1 represent those complexes that could be unwanted purged with the non-specifically physisorbed CO2 before TPD-CO2 experiment (depending on experimental conditions of purging: temperature, time and flow of inert). From that point of view, the amount of basic sites determined by CO2 adsorption calorimetry by using of value 50–60 kJ mol−1 (unstable CO2 physisorption) and 25 kJ mol−1 (non-specific CO2 physisorption) represents the limiting values of the amount of basic sites that could be generally determined by TPD-CO2 depending on experimental conditions of CO2 purging (temperature, time and flow of inert). Table 1 shows significant differences in the amount of basic sites determined by CO2 adsorption calorimetry by using of values 50 and 25 kJ mol−1. Thus, when one compares the values of the amount of basic sites obtained from TPD-CO2 among the different laboratories (using different experimental conditions), this fact should be kept in mind. The values on the basicity of Mg–Al mixed oxides reported in the literature based on TPD-CO2 can differ with varying sample saturation/flushing.

Conclusions

We focused on the role of important experimental conditions on TPD-CO2 profiles. It was found that TPD peak located above 485 °C does not represent desorption of CO2 from the basic sites, but it is connected with CO2 released from the residual carbonate, which was not decomposed during calcination of the hydrotalcite-like precursor. We detected approximately the same amount of CO2 in Mg–Al mixed oxide, when we used 10 % CO2 in helium, 50 % CO2 in helium and pure CO2 during CO2 adsorption (145, 148 and 168 μmol g−1, respectively). The amount of basic sites was also not affected by the temperature (in the range from 0 to 34 °C) used to CO2 adsorption and purged the non-specifically physisorbed CO2. However, the start of desorption peak as well as its maximum was connected with the chosen temperature.

The amount of basic sites in Mg–Al mixed oxides was studied by TPD-CO2 and CO2 adsorption calorimetry. Some systematic differences originated from the principle of both methods have been stressed. It has been shown that the amount of basic sites determined by CO2 adsorption calorimetry by using of value 50–60 kJ mol−1 (“unstable CO2 physisorption”) and 25 kJ mol−1 (“non-specific CO2 physisorption”) represents the limiting values of the amount of basic sites that could be generally determined by TPD-CO2. The amount of basic sites calculated as the difference of the amount of CO2 between the initial adsorption heat and the energy of 25 kJ mol−1 represents the highest amount of basic sites that could be determined for Mg–Al mixed oxides. On the other hand, CO2 adsorption complexes with adsorption energy below 50–60 kJ mol−1 generally represent those CO2 that could be unwanted loosed in TPD-CO2, depending on the conditions of purging the non-specifically physisorbed CO2. In our case, the total amount of basic sites determined by TPD-CO2 corresponded for all studied Mg–Al mixed oxides to the value of adsorption energy 30–32 kJ mol−1 and pressure 30 mbar. Thus, in all our case the TPD-CO2 experiments reflect at 0–485 °C those CO2 adsorbed in the range of the differential heat of CO2 above 30–32 kJ mol−1. The overall number of basic sites was higher for samples with lower Mg/Al ratios. Results can be adopted for other oxides being sorbents and/or catalytic supports.

References

Xu ZP, Zhang J, Adebajo MO, Zhang H, Zhou C. Catalytic applications of layered double hydroxides and derivatives. Appl Clay Sci. 2011;53(2):139–50.

Prado RG, Almeida GD, Carvalho MMO, Galvão LM, Bejan CCC, Costa LM, et al. Multivariate Method for transesterification reaction of soybean oil using calcined Mg–Al layered double hydroxide as catalyst. Catal Lett. 2014;144(6):1062–73.

Zeng HY, Xu S, Liao MC, Zhang ZQ, Zhao C. Activation of reconstructed Mg/Al hydrotalcites in the transesterification of microalgae oil. Appl Clay Sci. 2014;91–92:16–24.

Abello S, Medina F, Tichit D, Perez-Ramirez J, Sueiras JE, Salagre P, et al. Aldol condensation of campholenic aldehyde and MEK over activated hydrotalcites. Appl Catal B Environ. 2007;70(1–4):577–84.

Meszaros S, Halasz J, Konya Z, Sipos P, Palinko I. Reconstruction of calcined MgAl- and NiMgAl-layered double hydroxides during glycerol dehydration and their recycling characteristics. Appl Clay Sci. 2013;80–81:245–8.

Di Cosimo JI, Diez VK, Xu M, Iglesia E, Apesteguia CR. Structure and surface and catalytic properties of Mg–Al basic oxides. J Catal. 1998;178(2):499–510.

Cavani F, Trifiro F, Vaccari A. Hydrotalcite-type anionic clays: preparation, properties and applications. Catal Today. 1991;11(2):173–301.

Alvarez MG, Segarra AM, Contreras S, Sueiras JE, Medina F, Figueras F. Enhanced use of renewable resources: transesterification of glycerol catalyzed by hydrotalcite-like compounds. Chem Eng J. 2010;161(3):340–5.

Di Cosimo JI, Apesteguia CR, Gines MJL, Iglesia E. Structural requirements and reaction pathways in condensation reactions of alcohols an MgyAlOx catalysts. J Catal. 2000;190(2):261–75.

Silva CCCM, Ribeiro NFP, Souza MMVM, Aranda DAG. Biodiesel production from soybean oil and methanol using hydrotalcites as catalyst. Fuel Process Technol. 2010;91(2):205–10.

Sree R, Babu NS, Prasad PSS, Lingaiah N. Transesterification of edible and non-edible oils over basic solid Mg/Zr catalysts. Fuel Process Technol. 2009;90(1):152–7.

Bolognini M, Cavani F, Scagliarini D, Flego C, Perego C, Saba M. Heterogeneous basic catalysts as alternatives to homogeneous catalysts: reactivity of Mg/Al mixed oxides in the alkylation of m-cresol with methanol. Catal Today. 2002;75(1–4):103–11.

Prescott HA, Li ZJ, Kemnitz E, Trunschke A, Deutsch J, Lieske H, et al. Application of calcined Mg–Al hydrotalcites for Michael additions: an investigation of catalytic activity-and acid-base properties. J Catal. 2005;234(1):119–30.

Shen JY, Tu M, Hu C. Structural and surface acid/base properties of hydrotalcite-derived MgAlO oxides calcined at varying temperatures. J Solid State Chem. 1998;137(2):295–301.

Leon M, Diaz E, Vega A, Ordonez S. A kinetic study of CO2 desorption from basic materials: correlation with adsorption properties. Chem Eng J. 2011;175:341–8.

Aramendia MA, Borau V, Jimenez C, Marinas JM, Ruiz JR, Urbano FJ. XRD and H-1 MAS NMR spectroscopic study of mixed oxides obtained by calcination of layered-double hydroxides. Mater Lett. 2000;46(6):309–14.

Xie WL, Peng H, Chen LG. Calcined Mg–Al hydrotalcites as solid base catalysts for methanolysis of soybean oil. J Mol Catal A Chem. 2006;246(1–2):24–32.

Tittabutt T, Trakarnpruk W. Metal-loaded MgAl oxides for transesterification of glyceryl tributyrate and palm oil. Ind Eng Chem Res. 2008;47(7):2176–81.

Navajas A, Campo I, Arzamendi G, Hernandez WY, Bobadilla LF, Centeno MA, et al. Synthesis of biodiesel from the methanolysis of sunflower oil using PURAL (R) Mg–Al hydrotalcites as catalyst precursors. Appl Catal B Environ. 2010;100(1–2):299–309.

Shumaker JL, Crofcheck C, Tackett SA, Santillan-Jimenez E, Morgan T, Ji Y, et al. Biodiesel synthesis using calcined layered double hydroxide catalysts. Appl Catal B Environ. 2008;82(1–2):120–30.

Alvarez MG, Chimentao RJ, Figueras F, Medina F. Tunable basic and textural properties of hydrotalcite derived materials for transesterification of glycerol. Appl Clay Sci. 2012;58:16–24.

Bastiani R, Zonno IV, Santos IAV, Henriques CA, Monteiro JLF. Influence of thermal treatments on the basic and catalytic properties of Mg, Al-mixed oxides derived from hydrotalcites. Braz J Chem Eng. 2004;21(2):193–202.

Cross HE, Brown DR. Entrained sodium in mixed metal oxide catalysts derived from layered double hydroxides. Catal Commun. 2010;12(3):243–5.

Prinetto F, Ghiotti G, Durand R, Tichit D. Investigation of acid-base properties of catalysts obtained from layered double hydroxides. J Phys Chem B. 2000;104(47):11117–26.

Fraile JM, Garcia N, Mayoral JA, Pires E, Roldan L. The influence of alkaline metals on the strong basicity of Mg–Al mixed oxides: the case of transesterification reactions. Appl Catal A Gen. 2009;364(1–2):87–94.

Carvalho DL, de Avillez RR, Rodrigues MT, Borges LEP, Appel LG. Mg and Al mixed oxides and the synthesis of n-butanol from ethanol. Appl Catal A Gen. 2012;415:96–100.

Wang D, Zhang X, Wei W, Sun Y. Mg/Al mixed oxides: heterogeneous basic catalysts for the synthesis of salicylamide from urea and phenol. Catal Commun. 2012;28:159–62.

Zhang Z, Zhang Y, Wang Z, Gao X. Catalytic performance and mechanism of potassium-supported Mg–Al hydrotalcite mixed oxides for soot combustion with O2. J Catal. 2010;271(1):12–21.

Valente JS, Prince J, Maubert AM, Lartundo-Rojas L, del Angel P, Ferrat G, et al. Physicochemical study of nanocapsular layered double hydroxides evolution. J Phys Chem C. 2009;113(14):5547–55.

Pavel OD, Tichit D, Marcu I-C. Acido-basic and catalytic properties of transition-metal containing Mg–Al hydrotalcites and their corresponding mixed oxides. Appl Clay Sci. 2012;61:52–8.

Meloni D, Monaci R, Solinas V, Auroux A, Dumitriu E. Characterisation of the active sites in mixed oxides derived from LDH precursors by physico-chemical and catalytic techniques. Appl Catal A Gen. 2008;350(1):86–95.

Leon M, Diaz E, Vega A, Ordonez S, Auroux A. Consequences of the iron-aluminium exchange on the performance of hydrotalcite-derived mixed oxides for ethanol condensation. Appl Catal B Environ. 2011;102(3–4):590–9.

Meloni D, Monaci R, Cutrufello MG, Rombi E, Ferino I. Adsorption microcalorimetry characterization of K-doped MgAl mixed oxide catalysts for soybean oil transesterification synthesized by impregnation and ball milling techniques. J Therm Anal Calorim. 2015;119(2):1023–36.

Hajek M, Kutalek P, Smolakova L, Troppova I, Capek L, Kubicka D, et al. Transesterification of rapeseed oil by Mg–Al mixed oxides with various Mg/Al molar ratio. Chem Eng J. 2015;263:160–7.

Kutalek P, Capek L, Smolakova L, Kubicka D. Aspects of Mg–Al mixed oxide activity in transesterification of rapeseed oil in a fixed-bed reactor. Fuel Process Technol. 2014;122:176–81.

Bulanek R, Frolich K, Frydova E, Cicmanec P. Study of adsorption sites heterogeneity in zeolites by means of coupled microcalorimetry with volumetry. J Therm Anal Calorim. 2011;105(2):443–9.

Liu Y, Lotero E, Goodwin JG, Mo X. Transesterification of poultry fat with methanol using Mg–A1 hydrotalcite derived catalysts. Appl Catal A Gen. 2007;331:138–48.

Kustrowski P, Chmielarz L, Bozek E, Sawalha M, Roessner F. Acidity and basicity of hydrotalcite derived mixed Mg–Al oxides studied by test reaction of MBOH conversion and temperature programmed desorption of NH3 and CO2. Mater Res Bull. 2004;39(2):263–81.

Constantino VRL, Pinnavaia TJ. Basic properties of Mg1–X(2+)Alx(3+) layered double hydroxides intercalated by carbonate, hydroxide chloride and sulfate anions. Inorg Chem. 1995;34(4):883–92.

Reichle WT, Kang SY, Everhardt DS. The nature of the thermal-decomposition of a catalytically active anionic clay mineral. J Catal. 1986;101(2):352–9.

Theiss FL, Ayoko GA, Frost RL. Thermogravimetric analysis of selected layered double hydroxides. J Therm Anal Calorim. 2013;112(2):649–57.

Garcia-Sancho C, Moreno-Tost R, Merida-Robles JM, Santamaria-Gonzalez J, Jimenez-Lopez A, Torres PM. Etherification of glycerol to polyglycerols over MgAl mixed oxides. Catal Today. 2011;167(1):84–90.

Grabowska H, Zawadzki M, Syper L, Mista W. Mg, Al-mixed oxide system: synthesis under hydrothermal conditions, physico-chemical characterisation and application as an efficient catalyst for imidazole methylation. Appl Catal A Gen. 2005;292:208–14.

Veloso CO, Perez CN, de Souza BM, Lima EC, Dias AG, Monteiro JLF, et al. Condensation of glyceraldehyde over Mg, Al-mixed oxides derived from hydrotalcites. Microporous Mesoporous Mater. 2008;107(1–2):23–30.

Shen JY, Kobe JM, Chen Y, Dumesic JA. Synthesis and Surface acid/base properties of magnesium–aluminum mixed oxides obtained from hydrotalcites. Langmuir. 1994;10(10):3902–8.

Auroux A, Gervasini A. Microcalorimetric study of the acidity and basicity of metal-oxide surfaces. J Phys Chem. 1990;94(16):6371–9.

Atkins PW. Physical chemistry. 6th ed. Oxford: Oxford University Press; 2000.

Leon M, Diaz E, Bennici S, Vega A, Ordonez S, Auroux A. Adsorption of CO2 on hydrotalcite-derived mixed oxides: sorption mechanisms and consequences for adsorption irreversibility. Ind Eng Chem Res. 2010;49(8):3663–71.

Hora L, Kelbichova V, Kikhtyanin O, Bortnovskiy O, Kubicka D. Aldol condensation of furfural and acetone over Mg–Al layered double hydroxides and mixed oxides. Catal Today. 2014;223:138–47.

Azzouz A, Arus VA, Platon N, Ghomari K, Nistor ID, Shiao TC, et al. Polyol-modified layered double hydroxides with attenuated basicity for a truly reversible capture of CO2. Adsorpt J Int Adsorpt Soc. 2013;19(5):909–18. doi:10.1007/s10450-013-9498-3.

Acknowledgements

The authors gratefully thank to the Czech Science Foundation (Project No. GA15-21817S).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Smoláková, L., Frolich, K., Troppová, I. et al. Determination of basic sites in Mg–Al mixed oxides by combination of TPD-CO2 and CO2 adsorption calorimetry. J Therm Anal Calorim 127, 1921–1929 (2017). https://doi.org/10.1007/s10973-016-5851-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5851-6