Abstract

The effect of three metallic ferrites, LaFeO3, ZnFe2O4, and BiFeO3, on the thermal degradation and flame retardancy of flexible poly(vinyl chloride) (PVC) was investigated using thermogravimetric analysis (TG), differential thermal analysis, and TG coupled with Fourier transform infrared spectrometry. In combination with X-ray photoelectron spectroscopy techniques, the charring and flame-retardant mechanism has been obtained. The results show that compared with LaFeO3 and ZnFe2O4, BiFeO3 promoted the dehydrochlorination reaction of PVC more effectively and generated a large amount of stable char residue in a condensed phase. In the char residue of PVC/BiFeO3, the Fe2p spectra are assigned to FeCl2 and FeOCl, which acts as effective catalysts for the ionic dehydrochlorination of PVC owing to their strong Lewis acidity. Bi exists as BiOCl, which has a lower melting point and boiling point and can more easily decompose to form BiCl3 gas at the flame temperature. The results demonstrated that BiFeO3 can not only effectively inhibit the production of smoke from PVC during combustion, but it also has an effect similar to that of Sb2O3 in flame-retardant PVC.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Poly(vinyl chloride) (PVC) with proven product performance, material process ability, thermal stability, and economic cost-effectiveness has been an excellent choice as insulation material for wire and cable systems. However, a large quantity of black smoke is produced when PVC is forced to burn, which is a big problem in its applications where the fire hazard is a concern. There has been a great volume of literature on applications and mechanisms of flame retardancy and smoke suppression of PVC [1–3]. As the complexity of the polymer composition and the combustion process, resulting in the researches on the mechanism of the flame retardant is difficult.

The study of the thermal decomposition of PVC is essential to address the flame retardancy issue. Thermogravimetric analysis (TG) method is an often used method for PVC degradation and can obtain a lot of information in the degradation process of PVC, such as the decomposition temperature and mass loss rate. [4, 5]. When combining TG with Fourier transform infrared spectrometry (TG-FTIR) analysis of the gas-phase products, very useful information can be obtained for studying the degradation mechanism of polymer [5, 6]. This system is a very powerful technique, TG measurement of the mass loss as a function of temperature, and FTIR test the composition of gas-phase products at the same time use of sensitive spectroscopic detector. Investigation on the thermal degradation mechanisms would provide insight into the effect of flame retardants on the polymer systems.

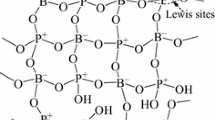

In our previous work [7], we prepared three typically metallic ferrites, LaFeO3, ZnFe2O4, and BiFeO3, as flame retardants and smoke suppressants for PVC. The results indicate that BiFeO3 is an excellent flame retardant and smoke suppressant for flexible PVC, and has better flame-retardant and smoke-suppressant properties than LaFeO3 and ZnFe2O4 [7]. However, the flame-retardant mechanism of the ferrites was not clarified in that work. Bismuth in BiFeO3 and antimony at the same group, and lanthanum in LaFeO3 have f electrons, which may result in different flame-retardant and smoke-suppressant properties as compared with the transition metal ferrite ZnFe2O4. Two different flame-retardant and smoke-suppressant mechanisms have been proposed for transition metal-containing inorganic salts [8, 9]. A Lewis acid mechanism suggests that linear cis-polyenes, which convert to benzene and other aromatics smoke precursors, are catalytically converted into trans-isomers that cannot readily convert to aromatics. These isomers are in turn converted to carbonaceous char or light aliphatics. The second mechanism is based on oxidation–reduction theory, where a low-valency metal compound reacts to form a higher valence compound and causes coupling of the alkyl groups [10].

The aim of this study was to investigate the thermal decomposition of neat PVC and PVC/ferrites using TG coupled with Fourier transform infrared spectrometry (TG-FTIR). Combine with the X-ray photoelectron spectroscopy (XPS) analysis result of the char residue to understand the flame-retardant mechanism of metallic ferrites in PVC.

Experimental

Materials

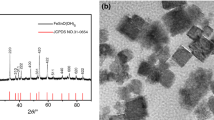

The metallic ferrites, LaFeO3, ZnFe2O4, and BiFeO3, used in this work were prepared in our previous work [7], and the average sizes of LaFeO3, ZnFe2O4, and BiFeO3 are approximately 134, 71, and 83 nm, respectively [7]. The materials used were PVC TL-1000 (apparent density = 0.45 g cm−3 and average polymerization degree = 970–1050) (Tianjin dagu chemical Co., LTD); dioctylphthalate (DOP) as a plasticizer (Baoding yisida Co., LTD); diisooctyl-2,2′-[(dioctylstannylene)bis(thio)] diacetate as a heat stabilizer; calcium stearate as a lubricant (Tianjin east China reagent factory); and NDZ-311 (Bis(P,P-bis-ethylhexyldiphosphat-o)ethanediolato titanate) as a coupling agent (Nanjing shuguang of silane chemical industry Co., Ltd).

Sample preparation

The test samples were prepared as follows: First, the samples were prepared by melting and mixing PVC with DOP, a heat stabilizer, lubricant, coupling agent, and a certain amount of the metallic ferrites, LaFeO3, ZnFe2O4, or BiFeO3. Subsequently, the specimens were blended in a two-roll mill at 130 °C for 10 min, followed by compression at 170–180 °C to form samples of suitable thickness and size for the corresponding tests. The basic formula was PVC: 100 parts per hundreds of resin (phr), DOP: 40 phr, heat stabilizer: 3 phr, lubricant: 1 phr, coupling agent: 1 phr, and 20 phr flame retardant.

Samples used for char residue analysis were prepared as follows. Firstly, approximately 1.0 g of each sample was put in a small porcelain crucible. The sample was then placed in a tube-type furnace and heated to 800 °C under N2 atmosphere. After allowing the sample to cool down, the char residue was collected for XPS analysis.

Characterization

TG and derivative thermogravimetric analysis (DTG) were performed on a WCT-2 analyzer with a heating rate of 10 °C min−1 under air flow rate of 60 mL min−1. The temperature range was from room temperature to 800 °C.

The TG-FTIR measurement was taken on a Netzsch TG 209 F1 thermogravimeter coupled with a Nicolet 6700 FTIR spectrometer. 10 mg of each sample was heated from 40 to 800 °C with a heating rate of 10 °C min−1 under nitrogen. The FTIR spectra were recorded within the 400–4000 cm−1 range.

XPS data were obtained using a PerkinElmer PHI 5300 ESCA system (PerkinElmer, USA) at 250 W (12.5 kV at 20 mA) under a vacuum better than 10−6 Pa (10−8 Torr).

Results and discussion

Thermogravimetric analysis

The thermal degradation behavior of the PVC/ferrites was monitored by TG in N2 atmosphere. The TG and DTG results are presented in Figs. 1, 2 and Tables 1, 2. Comparing calculated and experimental TG or DTG curves can reveal interactions between PVC and ferrites. The calculated TG curve (M cal) is predicted to be the mass average of the TG curves of all the mixture components, that is,

where x i is the mass fraction of compound i and M i is the TG curve of compound i. The using ferrites in experiment will not set off any mass loss reaction in the experimental temperature range, so the M (T) for the ferrites is 100 %. The calculated TG and DTG curves are also presented in Figs. 1, 2.

It is shown in Figs. 1 and 2, and Tables 1 and 2 that the thermal degradation of all the samples occurred in two steps, which is in good agreement with the results reported in the literature [11, 12]. The first degradation step in the temperature range of 200–390 °C can be attributed to the emission of hydrogen chloride and the degradation of DOP. The second degradation step in the temperature range of 310–760 °C is owing to the chain scission of the carbonaceous backbone and oxidation of the unstable char.

Figures 1 and 2, and Tables 1 and 2 show that the mass loss of all the samples in the first stage was in the range 46–72 %. The TG curves of PVC/LaFeO3 and neat PVC almost coincide at this stage, but the mass loss of PVC/LaFeO3 is reduced from 71.3 to 58.8 %, compared with neat PVC. Meanwhile, parameters such as the mass loss temperature range, the maximum mass loss rate (MV), and the temperature at maximum mass loss rate (TM) did not change significantly. In addition, the theoretical curve is very consistent with the experimental curve. These results indicate that LaFeO3 had only a dilution effect in the first stage.

When 20 phr ZnFe2O4 was added to PVC, the mass loss decreased from 71.3 to 46.2 %, and the initial decomposition temperature, T 5 % (defined as the temperature at which 5 % of the initial mass has been lost), decreased from 255 to 241 °C. Meanwhile, the maximum rate of the mass loss at the first stage (MV 1) of PVC/ZnFe2O4 was much larger than that of the neat PVC, whereas the temperature at the maximum rate of the first stage (TM 1) of PVC/ZnFe2O4 was much lower. This indicates that ZnFe2O4 can effectively catalyze the dehydrochlorination of PVC and promote the cross-linking and charring reactions. As compared with ZnFe2O4, BiFeO3 can more effectively promote the dehydrochlorination reaction in the first stage because the MV 1 value for PVC/BiFeO3 was as high as 73.3 % min−1, which was significantly higher than that of other samples, and the mass loss of PVC/BiFeO3 was 57.0 %, which is higher than that for PVC/ZnFe2O4. These results indicate that BiFeO3 can induce faster degradation of PVC and generate more HCl in the first stage. HCl as a gas-phase inhibitor can effectively inhibit the burning, and so PVC/BiFeO3 had the highest LOI.

In the second stage, the thermal degradation from 300 to 760 °C consists mainly of the cyclization of conjugated polyene sequences to form aromatic compounds, including cross-linking, aromatization, isomerization, and structural reorganization with the release of combustible gases [13]. At this stage, different from the other samples, PVC/ZnFe2O4 began to lose mass at 306 °C, and this mass loss continued up to 760 °C, with a maximum mass loss rate of 2.3 % min−1 at 442 °C. This suggests that the char residue of PVC/ZnFe2O4 generated in the first stage is unstable, probably because of cracking of the char residue, and the remainders were possibly CO2 and aliphatic fragments. According to the cationic cracking reactions that occur in the presence of Lewis acids, ZnFe2O4 can fragment the char residue at higher temperatures [14]. The results revealed the poor smoke-suppressing properties of ZnFe2O4. However, PVC/BiFeO3 at this stage lost mass up to 410 °C, at which point the mass loss obviously decreased. The sample at 800 °C had the highest amount of char residue, which indicates that PVC/BiFeO3 has better flame-retardant and smoke-suppressant properties.

TG-FTIR analysis

The gaseous thermal degradation products of the PVC samples were analyzed by TG-FTIR, and the evolved gases from the TG furnace were inspected by FTIR simultaneously, as shown in Fig. 3. The FTIR spectra show the changes in the dynamic FTIR spectra obtained from neat PVC and the PVC/ferrite composites at different pyrolysis temperatures in an inert atmosphere. Characteristic spectra were obtained by the calculation mentioned above with the DTG pattern at four temperatures: the undecomposed temperature, the temperature at the maximum rate of the first stage, the termination degradation temperature of the first stage, and the temperature at the maximum rate of the second stage.

Figure 3 indicates that the pyrolysis of PVC is complicated. The main gaseous products are HCl, CO2, H2O, and benzene. It can be seen that there is negligible change in the relative intensity of the PVC and PVC/ferrite characteristic peaks below 200 °C. For neat PVC at 304 °C, a new band appears at 2938 cm−1 that corresponds to the absorption of HCl, indicating the dehydrochlorination of PVC. At the same time, the appearance of the absorption at approximately 1520 cm−1 proves the existence of benzene, whereas the absorptions at 2875/2976, 1460, and 1380 cm−1 demonstrate the presence of a CH3 moiety. In addition, the absorption peaks at 1040–1311 cm−1 and 1641/1804/1868 cm−1 could be assigned to the ester group and C=O bonds, respectively, which could possibly be attributed to the presence of DOP. The evolution curve of H2O is shown as the integral area in the range 3615–4000 cm−1 versus temperature to avoid interference from the absorbance of other species [15–18]. As compared with neat PVC, the FTIR spectra of PVC/LaFeO3 at the maximum mass loss rate temperature (291 °C) show that only the absorption intensity decreases, consistent with the results of TG. PVC/LaFeO3 has a lower mass loss in the first stage, which suggests that the flame-retardant and smoke-suppressant properties of LaFeO3 may be mainly caused by the dilution and physical barrier effects.

As compared with neat PVC, there are three differences among the absorbance bands in the spectra of PVC/ZnFe2O4. First, corresponding to the TG results for PVC/ZnFe2O4, the maximum absorption of the FTIR spectra can be observed at a lower temperature (241 °C). Secondly, the absorption intensity of the C–O–C and C=O vibrations of PVC/ZnFe2O4 at this temperature obviously increases. Thirdly, the most intensive absorbance band of HCl in the spectra of PVC/ZnFe2O4 is slightly lower than that of neat PVC. However, the absorption intensity of HCl in the spectra of PVC/BiFeO3 at the maximum mass loss rate temperature (242 °C) is considerably higher than that of neat PVC, and HCl as a gas-phase inhibitor can effectively inhibit the burning. Therefore, PVC/BiFeO3 has better flame-retardant and smoke-suppressant properties.

In order to study the detailed effects of the production of HCl in the gas phase on the flame-retardant and smoke-suppressant properties of the samples, Fig. 4 shows the evolution curve of HCl. As shown in the figure, the absorption intensity and peak area of PVC/LaFeO3 are lower in the two degradation stages, and so LaFeO3 has a weaker gas-phase effect and a higher average effective heat of combustion (Av-EHC). PVC/ZnFe2O4 and PVC/BiFeO3 have higher absorption intensities than neat PVC in the first stage, but the peak areas are lower than those of neat PVC. These results indicate that the addition of ZnFe2O4 and BiFeO3, especially when using BiFeO3 as a flame retardant, could catalyze dehydrochlorination and promote the generation of HCl gas in large quantities within a narrow temperature range. This degradation process is helpful for improving the self-extinguishing properties of materials [15]. In addition to the generation of an HCl gas-phase inhibitor, the generation of a large amount of stable char residue in the condensed phases may be even more important in terms of flame-retarding and smoke-suppressing properties.

XPS analysis of char residue

XPS can provide further information about the elemental composition and content of char residue in detail, and so the char residues obtained from the tube-type furnace were analyzed. Figure 5 and Table 3 present the results of XPS measurements for quantitative analysis of the elements in the char residues. The spectrum of the neat PVC char residue shows signals due to the presence of carbon (284.6 eV, C1 s) and oxygen (531.0 eV, O1 s). A higher carbon content means that more carbon atoms accumulated in the char residue, and that there was a higher degree of cross-linking of the char residue [19, 20]. Except for the neat PVC, the carbon content of PVC/BiFeO3 was the highest among all the samples. This indicates that BiFeO3 is the most effective for increasing the char formation, which is consistent with the TG results.

For PVC/LaFeO3, new signals of chlorine (198.6 eV, Cl2p), iron (Fe2p), and lanthanum (La3d) were detected. As compared with PVC/Zn2FeO4 and PVC/BiFeO3, the atom content of these elements is higher. These results show that more flame-retardant LaFeO3 remained in the condensed phase. However, the signal of zinc was not detected in the char residue of PVC/Zn2FeO4. Previous work showed that the presence of reducing gases (pyrolysis and combustion products) could provide a lower temperature volatilization route. In this route, zinc compounds are reduced to zinc metal, which is volatized and reacts with O2 in air to form zinc oxide aerosols; free zinc metal would be an intermediate phase, and zinc oxide aerosols would be counted by the photometer as smoke [21], and so PVC/Zn2FeO4 has higher smoke density rating (SDR) and total smoke produced (TSP) values than PVC/BiFeO3 [7].

In order to further understand the ferrites in the form of char residue, XPS curves for Fe2p, La3d, and Bi4f were subjected to a fitting process. Figures 6–8 and Table 4 show the curve-fitting results of the Fe2p, La3d, and Bi4f spectra of the char residue for further analysis of the chemical states of the elements. The results show that there were two distinguished bands for the Fe2p spectra of PVC/LaFeO3 and PVC/ZnFe2O4, which are assigned to FeO (722.7 eV, Fe2p1/2, and 709.6 eV, Fe2p3/2) and FeOCl (726.6 eV, Fe2p1/2, and 713.5 eV, Fe2p3/2), respectively. FeO can effectively inhibit the production of smoke by PVC in the combustion process, mainly because it can catalyze the cracking reaction of H2 and H2O to generate H·. H· further reacts with water to generate OH·, and the soot can be oxidized by OH·, forming CO. The detailed reaction process is shown as follows [22]:

In the cone calorimetry test, the average CO yield (Av-COY) values of the flame-retardant PVC samples are higher than that of neat PVC. The two distinguished bands for the Fe2p spectra of PVC/BiFeO3 are assigned to FeCl2 (723.8 eV, Fe2p1/2, and 710.7 eV, Fe2p3/2) and FeOCl (726.3 eV, Fe2p1/2, and 713.2 eV, Fe2p3/2), respectively. FeOCl and/or FeCl2, which are formed along with the thermal decomposition of PVC, act as effective catalysts for the ionic dehydrochlorination of PVC owing to their strong Lewis acidity [22]. Dehydrochlorination of PVC under the influence of Lewis acidity occurs with the formation of trans-polyene structures followed by intermolecular cyclization, resulting in increased char formation and a decrease in smoke production.

In the char residue of PVC/LaFeO3, La exists in two forms, which are assigned to La2O3 (851.1 eV, La3d3/2, and 834.3 eV, La3d5/2) and LaCl3 (854.4 eV, La3d3/2, and 837.6 eV, La3d5/2). La2O3 and LaCl3 cannot catalyze the dehydrochlorination reaction, making it difficult to evaporate into the gas phase (the boiling points of these compounds are higher than 1000 °C; even the melting point of La2O3 is as high as 2315 °C). Therefore, in the three kinds of ferrites, LaFeO3 has the poorest flame-retardant and smoke-suppressant effect. Although Zn2+ will promote cationic cracking reactions and fragmenting of the char residue at higher temperatures [14], zinc compounds can react with HCl generated during the degradation of PVC, thus forming ZnCl2, which can effectively catalyze the dehydrochlorination reaction in the first degradation stage of PVC and increase char formation. Therefore, as compared with LaFeO3, Zn2FeO4 has good flame-retardant and smoke-suppressant effects. In the char residue of PVC/BiFeO3, Bi exists as BiOCl (165.2 eV, Bi4f5/2, and 159.9 eV, Bi4f7/2). BiOCl has a lower melting point and boiling point (218 and 461 °C, respectively) than La2O3 and LaCl3, and BiOCl can more easily decompose to form BiCl3 gas at the flame temperature. The reaction process is as follows:

These results show that BiFeO3 has an effect similar to that of Sb2O3 in flame-retardant PVC, and it can inhibit flame reactions via scavenging of free radicals in the gas phase, resulting in a lower av-EHC value.

Conclusions

TG, DTG, and TG-FTIR results showed that ZnFe2O4 and BiFeO3 can more effectively promote the dehydrochlorination reaction of PVC in the first stage, whereas LaFeO3 acted only as a physical barrier at this stage. BiFeO3 generated a large amount of stable condensed char residue. However, because of cationic cracking reactions, the char residue of PVC/ZnFe2O4 generated in the first stage was unstable. From TG and the analysis of XPS spectra, it was deduced that a large amount of carbonaceous material was generated in condensed phases during the combustion and degradation of PVC, and that this material was more important than the HCl generated in the first stage for improving the flame-retardant and smoke-suppressant properties of PVC. For all PVC/ferrite samples, the Fe elements in the char residue in the form of FeO, FeCl2, and FeOCl effectively inhibited the smoke production of PVC during combustion and catalyzed the ionic dehydrochlorination reaction of PVC. In the char residue of PVC/LaFeO3, La exists as La2O3 and LaCl3, which cannot catalyze the dehydrochlorination reaction, making it difficult to evaporate into the gas phase. Therefore, LaFeO3 has the poorest flame-retardant and smoke-suppressant effects. In the char residue of PVC/BiFeO3, Bi exists as BiOCl, which has an effect similar to that of Sb2O3 in flame-retardant PVC, and so BiFeO3 has the best flame-retardant and smoke-suppressant effect.

References

Levchik SV, Weil ED. Overview of the recent literature on flame retardancy and smoke suppression in PVC. Polym Adv Technol. 2005;16:707–16.

Rodolfo A Jr, Mei I, Helena L. Metallic oxides as fire retardants and smoke suppressants in flexible poly(vinyl chloride). J Appl Polym Sci. 2010;118:2613–23.

Qu HQ, Liu CH, Wu WH, Chen LZ, Xu JZ. Using cone calorimeter to study thermal degradation of flexible PVC filled with zinc ferrite and Mg(OH)2. J Therm Anal Calorim. 2014;115:1081–7.

Etienne S, Becker C, Ruch D, Germain A, Calberg C. Synergetic effect of poly(vinyl butyral) and calcium carbonate on thermal stability of poly(vinyl chloride) nanocomposites investigated by TG–FTIR–MS. J Therm Anal Calorim. 2010;100:667–77.

Awad WH, Wilkie CA. Investigation of the thermal degradation of polyurea: the effect of ammonium polyphosphate and expandable graphite. Polymer. 2010;5:2277–85.

Feng J, Hao JW, Du JX, Yang RJ. Using TGA/FTIR TGA/MS and cone calorimetry to understand thermal degradation and flame retardancy mechanism of polycarbonate filled with solid bisphenol A bis(diphenyl phosphate) and montmorillonite. Polym Degrad Stab. 2012;97:605–14.

Han LJ, Wu WH, Qu HQ, Han X, Wang AQ, Jiao YH, Xu JZ. Metallic ferrites as flame retardants and smoke suppressants in flexible poly(vinyl chloride). J Therm Anal Calorim. 2015;. doi:10.1007/s10973-015-4855-y.

Pi H, Guo SY, Ning Y. Mechanochemical improvement of the flame-retardant and mechanical properties of zinc borate and zinc borate-Aluminum trihydrate-filled poly(vinyl chloride). J Appl Polym Sci. 2003;89:753–62.

Qu HQ, Wu WH, Zheng YJ, Xie JX, Xu JZ. Synergistic effects of inorganic tin compounds and Sb2O3 on thermal properties and flame retardancy of flexible poly(vinyl chloride). Fire Saf J. 2011;46:462–7.

Starnes WH Jr, Pike RD, Cole JR, Doyal AS, Kimlin EJ, Lee JT, Murray PJ, Quinlan RA, Zhang J. Cone calorimetric study of copper-promoted smoke suppression and fire retardance of poly(vinyl chloride). Polym Degrad Stab. 2003;82:15–24.

McNeill IC, Memetea L, Cole WJ. A study of the products of PVC thermal degradation. Polym Degrad Stab. 1995;49:181–91.

Zhu H, Wang W, Liu TX. Effects of copper-containing layered double hydroxide on thermal and smoke behavior of poly(vinyl chloride). J Appl Polym Sci. 2011;122:273–81.

Qu HQ, Wu WH, Xie JX, Xu JZ. A novel intumescent flame retardant and smoke suppression system for flexible PVC. Polym Adv Technol. 2011;22:1174–81.

Pike RD, Starnes WH Jr, Jeng JP, Bryant WS, Kourtesis P, Adams CW. Low-valent metals as reductive cross-linking agents: a new strategy for smoke suppression of poly(vinyl chloride). Macromolecules. 1997;30:6957–65.

Yoshioka T, Akama T, Uchida M, Okuwaki A. Analysis of two stages dehydrochlorination of poly(vinyl chloride) using TG-MS. Chem Lett. 2000;29:322–3.

Beneš M, Milanov N, Matuschek G, Kettrup A, Placek V, Balek V. Thermal degradation of PVC cable insulation studied by simultaneous TG-FTIR and TG-EGA methods. J Therm Anal Calorim. 2004;78:621–30.

Wang XD, Zhang Q. Effect of hydrotalcite on the thermal stability, mechanical properties, rheology and flame retardance of poly(vinyl chloride). Polym Int. 2004;53:698–707.

Zhu HM, Jiang XG, Yan JH, Chi Y, Cen KF. TG-FTIR analysis of PVC thermal degradation and HCl removal. J Anal Appl Pyrol. 2008;82:1–9.

Feng JX, Zhang XM, Ma SQ, Xiong Z, Zhang CZ, Jiang YH, Zhu J. Syntheses of metallic cyclodextrins and their use as synergists in a poly(vinyl alcohol)/intumescent flame retardant system. Ind Eng Chem Res. 2013;52:2784–92.

Huang GB, Liang HD, Wang Y, Wang X, Gao JR, Fei ZD. Combination effect of melamine polyphosphate and graphene on flame retardant properties of poly(vinyl alcohol). Mater Chem Phys. 2012;132:520–8.

Qu HQ, Wu WH, Jiao YH, Xu JZ. Thermal behavior and flame retardancy of flexible poly(vinyl chloride) treated with Al(OH)3 and ZnO. Polym Int. 2005;54:1469–73.

Carty P, Metcalfe E, While S. A review of the role of iron containing compounds in char forming/smoke suppressing reactions during the thermal decomposition of semi-rigid poly(vinyl chloride) formulations. Polymer. 1992;33:2704–8.

Acknowledgements

The work was financially supported by the Natural Science Foundation of China (Grant No. 21306035 and Grant No. 21276059).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qi, Y., Wu, W., Han, L. et al. Using TG-FTIR and XPS to understand thermal degradation and flame-retardant mechanism of flexible poly(vinyl chloride) filled with metallic ferrites. J Therm Anal Calorim 123, 1263–1271 (2016). https://doi.org/10.1007/s10973-015-5084-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-5084-0