Abstract

The surfaces of natural beidellite clay were modified with cationic surfactant, tetradecyltrimethylammonium bromide, at different concentrations. The organo-beidellites were analysed using thermogravimetric analysis which shows four thermal oxidation/decomposition steps. The first step of mass loss is observed from room temperature to 130 °C due to the dehydration of adsorbed water. The second step of mass loss between 130 and 400 °C is attributed to the oxidation step of the intercalated organic surfactant with the formation of charcoal. The third mass loss happens between 400 and 500 °C which is assigned to the loss of hydroxyl groups on the edge of clays and the further oxidation step of charcoal. The fourth step is ascribed to the loss of structural OH units as well as the final oxidation/decomposition step of charcoal which takes place between 500 and 700 °C. Thermogravimetric analysis has proven to be a useful tool for estimating loaded surfactant amount.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The smectite group of clay minerals represent the most important phyllosilicates which are widely used in a range of applications because of their cation exchange capacities, high surface areas and resulting high adsorption capacities. Though both montmorillonite and beidellite belong to the smectite group, montmorillonite is one of the most studied clay minerals. There are numerous papers on the properties of organic surfactant-modified montmorillonites [1–8]. In common with montmorillonite, beidellite consists of 2:1 TOT layers with the ideal formula of [Si3.5Al0.5][Al2]O10(OH)2Ca0.25 [9, 10]. However, the property and the potential application of beidellite have received less attention [11]. The net negative surface charge on some beidellites mainly originates from the isomorphous substitution of Al3+ for Si4+ in the silicate tetrahedral sheets [9], while the charge of montmorillonite is usually from the octahedral substitution of Al3+ by Mg2+. Because of this substitution, the surface charge is regular as opposed to random as for montmorillonite.

To the best of our knowledge, compared with montmorillonite, there are fewer studies on organo-beidellites and their thermal properties have sparsely been reported in the literature. Hence, the present research is aimed to examine the thermal properties of organo-beidellites. Thermogravimetric measurement was used to characterize the thermal oxidation and decomposition of tetradecyltrimethylammonium bromide-modified beidellites prepared at different surfactant concentrations and to estimate the loaded surfactant amounts within organo-beidellites.

Materials and methods

The SBId-1 beidellite clay, obtained from Clay Minerals Repository USA, has a cation exchange capacity (CEC) of 129 meq/100 g [12]. The surfactant selected for this study, tetradecyltrimethylammonium bromide (denoted as TDTMA, C17H38NBr, FW: 336.39), was obtained from Sigma-Aldrich. All materials were used as received without purification (Fig. 1).

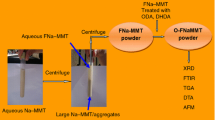

Synthesis of organo-beidellite was undertaken by the following procedure: beidellite sample was finely grounded with an agate mortar and then sieved through a 250-µm sieve. Four gram of beidellite was dispersed into 400 mL of deionized water. The clay suspension was stirred at 600 rpm for an hour using a magnetic stirrer. Stoichiometric amount of 25 % (0.25 CEC), 50 % (0.50 CEC), 75 % (0.75 CEC), 100 % (1.00 CEC) and 125 % (1.25 CEC) of TDTMA was slowly added to the clay suspension and stirred at 600 rpm at room temperature for another 3 h. The mixture was allowed to settle overnight and the supernatant was decanted. All organo-clays were washed with high-purity water until free of bromide anions as determined by AgNO3 test. All samples were dried at room temperature and stored in plastic sample containers in a vacuum desiccator. The prepared TDTMA-modified beidellites, with surfactant loadings corresponding to CEC values from 0.25 to 1.25, were denoted as 0.25CEC-TB, 0.5CEC-TB, 0.75CEC-TB, 1.00CEC-TB and 1.25CEC-TB, respectively.

Thermogravimetric analyses of the TDTMA-modified beidellites were carried out in a Netzsch TG-209-type thermobalance in a ceramic crucible up to 1,000 °C. The samples were heated in an atmosphere containing 20 % O2 and 80 % Ar (99.995 % purity) at a rate of 10 °C min−1.

Results and discussion

TG and DTG curves of the organo-beidellites are presented in Fig. 2. Generally, there are four main mass loss steps which are observed for each organo-beidellite. The first mass loss occurring from room temperature to about 130 °C is related to the loss of adsorbed water. The second mass loss, in the temperature range 130–400 °C, corresponds to the first thermal oxidation/decomposition step of TDTMA surfactant which was oxidized to H2O and CO2 with the formation of charcoal residue. The third mass loss at around 400–500 °C is presumably due to the loss of OH units at the edge of clay layers [13] as well as the oxidation step of charcoal, which persisted at about 420 °C and then was gradually oxidized by air [14], while the mass loss at around 500–700 °C is due to the final oxidation of the residue charcoal in the clay and the dehydroxylation of the structural OH units. A very small mass loss recorded at about 530 °C only for 0.25CEC-TB may also be due to the dehydroxylation in beidellite. The mass loss of structural OH units at high temperature shows that the clay is relatively stable at elevated temperatures [15]. The position of surfactant oxidation/decomposition temperature in the curves of the organo-beidellites is confirmed by comparison with the DTG curve of the pure TDTMA which shows a major intense peak at 267 °C with a mass loss of 95.0 % (see Fig. 1S in the supplementary material). The decomposition temperature and related % mass loss data from the thermogravimetric analysis in Fig. 2 are summarized in Table 1.

In some previous studies (under N2), more than one peak for the desurfactant process can be observed, which indicates that the surfactant is present in different environments within the organo-clays [13, 16, 17]. In this study, the analysis atmosphere is composed of 20 % O2 and 80 % Ar which is similar to that of air. Thus, the decomposition procedures of surfactant are very different. There are three steps for surfactant oxidation/decomposition. Compared with the decomposition temperature of pure TDTMA surfactant at about 267 °C, it is observed that the surfactant molecules within organo-beidellite are more thermal stable and the central peak position shifts slightly from 309 °C of 0.25CEC-TB to 274 °C of 1.25CEC-TB. The higher decomposition temperature may indicate that the mass loss is mainly from the exchanged TDTMA on the internal active sites of the clay.

An estimate of the real surfactant concentration (in units of CEC of the clay) of TDTMA onto beidellite was made for each organo-clay using TG data on the mass loss % of surfactant using a similar equation as created previously [16] which gives theoretical maximum and minimum values of the real adsorption amount of surfactant onto the clay.

Equation 1 is created based on the definition of cation exchange capacity. This equation can be converted to Eq. 2, where X is the loaded surfactant amount (in CEC); m is the total mass of organo-clay (g); M is the molecular mass of surfactant (g mol−1); S% is the mass loss percentage of surfactant in organo-clay; y is 0 (if all the Br ions remain) or 80 (no Br ion, the molecular weight of Br is 80), y = 0 or 80 is not possible to be reached, but it can be helpful in working out the range of X by calculating the theoretical maximum and minimum values. The CEC of beidellite at 129 meq/100 g and the molecular weight of TDTMA at 336.39 g mol−1 are used in the equation. The mass loss percentage of organo-clay is calculated based on the last three mass losses as described in Table 1. It should be noticed that the dehydroxylation mass loss in the fourth step is not deducted as it is much smaller than that of the surfactant. The results from these calculations are presented in Table 2.

Table 2 shows that there are some differences between the added amount and the loaded amount of surfactant in organo-beidellites. For example, in 0.25CEC-TB, the real adsorption amount is about 0.387–0.508 CEC of the clay which is more than the added amount. An increase in the added surfactant amount leads to an increase in the estimated real loading. For 0.50CEC-TB and 0.75CEC-TB, the loaded amounts of surfactants reached 0.609–0.798 CEC and 0.778–1.02 CEC, respectively. When the added amount of surfactant was increased further, the loaded amounts can reach 0.826–1.08 and 0.890–1.17 for 1.00CEC-TB and 1.25CEC-TB, respectively. Generally, the estimated real surfactant loading amount is higher than the added amount during the sample preparation procedure. When the added amount is close to or higher than one CEC, the calculated amount is very close to that of the added amount, and this may be due to the saturation of beidellite with surfactant. The amount of adsorbed water was gradually reduced from 4.80 to 2.67 %, indicating the increasing hydrophobicity of the organo-complex with increasing surfactant loadings.

Conclusions

TG and DTG have been used to characterize and compare the thermal decomposition behaviours of TDTMA-modified beidellites. There are mainly four mass losses of organo-beidellite, corresponding to dehydration surfactant oxidation, loss of OH units at the edge of clay layers/charcoal oxidation and dehydroxylation of the structural OH units/final oxidation of charcoal in the clay, respectively. TG/DTG is a powerful tool in estimating the loaded amount of surfactant. It is concluded that the developed equation can estimate the real surfactant loading into beidellite with accurate results. These findings are important on the quest from insights into the properties of organo-clays that may be useful for environmental remediation applications.

References

Park Y, Sun Z, Ayoko GA, Frost RL. Bisphenol A sorption by organo-montmorillonite: implications for the removal of organic contaminants from water. Chemosphere. 2014;107:249–56.

Park Y, Ayoko GA, Horvath E, Kurdi R, Kristof J, Frost RL. Structural characterisation and environmental application of organoclays for the removal of phenolic compounds. J Colloid Interface Sci. 2013;393:319–34.

Wu P, Dai Y, Long H, Zhu N, Li P, Wu J, et al. Characterization of organo-montmorillonites and comparison for Sr(II) removal: equilibrium and kinetic studies. Chem Eng J. 2012;191:288–96.

Liu B, Lu J, Xie Y, Yang B, Wang X, Sun R. Microwave-assisted modification on montmorillonite with ester-containing gemini surfactant and its adsorption behavior for triclosan. J Colloid Interface Sci. 2014;418:311–6.

Zhu J, Qing Y, Wang T, Zhu R, Wei J, Tao Q, et al. Preparation and characterization of zwitterionic surfactant-modified montmorillonites. J Colloid Interface Sci. 2011;360(2):386–92.

Ghayaza M, Le Forestier L, Muller F, Tournassat C, Beny J-M. Pb(II) and Zn(II) adsorption onto Na- and Ca-montmorillonites in acetic acid/acetate medium: experimental approach and geochemical modeling. J Colloid Interface Sci. 2011;361(1):238–46.

Xi Y, Martens W, He H, Frost RL. Thermogravimetric analysis of organoclays intercalated with the surfactant octadecyltrimethylammonium bromide. J Therm Anal Calorim. 2005;81(1):91–7.

Zhou Q, Frost RL, He H, Xi Y. Changes in the surfaces of adsorbed p-nitrophenol on methyltrioctadecylammonium bromide organoclay-An XRD, TG, and infrared spectroscopic study. J Colloid Interface Sci. 2007;314(2):405–14.

Newman ACD. Chemistry of clays and clay minerals. New York: Wiley; 1987.

Foth HD, Ellis BG. Soil fertility. 2nd ed. Boca Raton: CRC Press, LLC; 1997.

Paul B, Martens WN, Frost RL. Organosilane grafted acid-activated beidellite clay for the removal of non-ionic alachlor and anionic imazaquin. Appl Surf Sci. 2011;257(13):5552–8.

Aggarwal V, Li H, Teppen BJ. Triazine adsorption by saponite and beidellite clay minerals. Environ Toxicol Chem. 2006;25(2):392–9.

Park Y, Ayoko GA, Frost RL. Characterisation of organoclays and adsorption of p-nitrophenol: environmental application. J Colloid Interface Sci. 2011;360(2):440–56.

Ashton Acton Q. Advances in carbon research and application (2012 Edition). Atlanta: Scholarly Editions; 2012. p. 12.

Park Y, Ayoko GA, Kristof J, Horvath E, Frost RL. Thermal stability of organoclays with mono- and di-alkyl cationic surfactants. J Therm Anal Calorim. 2012;110(3):1087–93.

Xi Y, Frost RL, He H. Modification of the surfaces of Wyoming montmorillonite by the cationic surfactants alkyl trimethyl, dialkyl dimethyl, and trialkyl methyl ammonium bromides. J Colloid Interface Sci. 2007;305(1):150–8.

Park Y, Frost RL, Ayoko GA, Morgan DL. Adsorption of p-nitrophenol on organoclays. J Therm Anal Calorim. 2013;111(1):41–7.

Acknowledgements

The corresponding author thanks the Queensland University of Technology’s Vice Chancellor’s research grant. The authors also thank QUT for the provision of facilities and infrastructure used. Thermogravimetric analyses have been carried out in the frame of the TÁMOP-4.2.2.A-11/1/KONV-2012-0071 project supported by the European Union and the European Social Fund.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lim, Y.H., Zsirka, B., Horváth, E. et al. Thermogravimetric analysis of tetradecyltrimethylammonium bromide-modified beidellites. J Therm Anal Calorim 120, 67–71 (2015). https://doi.org/10.1007/s10973-015-4413-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4413-7