Abstract

In this paper, monodisperse high chroma colored silica nanoparticles (SiNPs) were efficiently prepared by layer-by-layer (LbL) self-assembled technique. Poly(sodium-p-styrenesulfonate) (PSS) and Poly(ethyleneterephthalate) (PEI) were respectively used as polyanion and polycationic electrolytes. The monodisperse SiNPs with negative charge on the surface were used as the matrix. Direct dye (C.I Direct Red 224) was deposited on the SiNPs surface by means of LbL electrostatic adsorption. PEI and C.I. Direct Red 224 were electrostatically adsorbed on the surface of SiNPs. Then PSS and PEI were adsorbed on SiNPs surface to make the red SiNPs positive negative, respectively. And multilayer film-coated high chroma red SiNPs were prepared by repeating the above steps 4 times. The effects of concentration of polyelectrolyte, supporting salt (NaCl), amount of C.I Direct Red 224 and deposition time on dye coupling rate were studied. The multilayer film-coated high chroma red SiNPs were characterized using Scanning Electron Microscopy (SEM), Nano ZS potential laser particle analyzer and UV–vis spectrophotometer. The nanoparticles show good dispersibility due to the mutual repulsion of the same charge, and deep color. In addition, dense nano-film formed prevents the detachment of the dye and prevent the dye from falling off. This high chroma red SiNPs is expected to become a probe of visual marker and amplify the signal in immunoassay.

Schematic representation of the preparation of high chroma colored silica nanoparticles Poly(sodium-p-styrenesulfonate) (PSS)/Poly(ethyleneterephthalate) (PEI) multilayer membrane by layer-by-layer self-assembly. The high chroma red nanoparticles were prepared for the first time using layer-by-layer self-assembly.

Highlights

-

The high-chroma colored SiNPs was prepared by electrostatic layer-by-layer self-assembly method.

-

Surface modification of red SiNPs during alternate assembly of polyelectrolytes.

-

Dense polyelectrolyte nano-films prevents dye from shedding.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Colored silica nanoparticles (colored SiNPs) because of its bright color, good water dispersibility, stability and harmless were widely used as biomarker in biosensors and immunochromatography assay for pathogen, protein and β-agonists detection [1,2,3,4,5]. In previous reports, monodisperse colored SiNPs were usually prepared by amino modification of silane coupling agent, then the organic reactive dyes were coupled to the surface-modified amino SiNPs [6,7,8]. In previous Stöber method [9], not only many organic solvents were used, but also the preparation time was too long. In recent years, our group had improved the synthesis method from the perspective of high efficiency, economic and environmental protection. The organic reactive dye was coupled to the surface of the SiNPs in the silane coupling agent aqueous solution, and a silica shell was used to prevent the dye from leaking, synthesizing the core-shell colored SiNPs [10]. The core-shell colored SiNPs have the characteristics of bright color, good dispersibility, smooth surface and abundant groups. However, using the silane coupling agent as a bridge to graft reactive dye, only one layer of dyeing can be performed, the resulting nanoparticles have low chroma, in the processes of dyeing and coating the silica shell are time-consuming. Therefore, it is necessary to develop novel dyeing method for synthesizing high-chroma colored SiNPs.

The layer-by-layer (LbL) self-assembly technology developed in 1900s adopts an economic and environmental-friendly water treatment process [11, 12]. By using electrostatic action, polyelectrolytes with opposite charges are alternately coated on nanoparticles, polymers and biomolecules to produces finely-controlled and multilayer thin-film nanocomposites, which are widely used in optoelectronic devices and biomaterials [13,14,15]. Moreover, many ionic dyes such as C.I. direct red 80 and Congo red, porphyrin and phthalocyanine were used to prepare the multilayer nano-films with polycations or polyanions to coated dye aggregates by LbL self-assembly method, which provides many excellent properties for optoelectronic applications [16,17,18,19,20,21]. The main driving force of LbL self-assembly is the electrostatic attraction between polyelectrolytes molecules [22,23,24,25,26], often accompanied by hydrogen bonding, hydrophobic interaction, charge transfer and so on [15, 27]. LbL self-assembly technology has become a powerful tool for micro-nano packaging. Utsav Chakraborty et al. [28] prepared dye-coated organic-inorganic hybrid LbL self-assembly film on polypropylamine hydrochloride (PAH) coated quartz substrate by methylene blue (MB) and inorganic clay mineral (MMT). Based on these results, it is reasonable to assume that using LbL technique to prepare high chroma colored SiNPs covered by multilayer nanofilms.

In this study, LbL technology was used for the first time to synthesize colored SiNPs. Direct dye (C.I. Direct Red 224) is adsorbed on the surface of negatively charged SiNPs by means of LbL self-assembly technology. The polycation electrolyte Poly(ethyleneterephthalate) (PEI) was used to immobile dye molecular on SiNPs forming nano-film-coated red SiNPs. And then, the polyelectrolyte PEI and Poly(sodium-p-styrenesulfonate) (PSS) were adsorbed successively, making red SiNPs full of negative charge again. Cycle in turn, a high-chroma colored SiNPs were prepared by LbL.

2 Experimental section

2.1 Chemicals and apparatus

Tetraethyl orthosilicate (TEOS), ammonia (NH3·H2O, 28.0%), sodium chloride (99.5%) were obtained from Aladdin Industrial Inc. (Shanghai, China). Poly(ethyleneterephthalate) (PEI, MW = 70000, 30 wt% aqueous solution), Poly(sodium-p-styrenesulfonate) (PSS, Mw ≈ 70000, powder), was obtained from Shanghai Macklin Biochemical Co., Ltd. (Shanghai, China). The C.I. Direct Red 224 and C.I. Direct Blue 199 were supplied by Zhejiang Shunlong Chemical Co., Ltd. (Zhejiang, China). Ethanol was obtained from Xilong Sientific Co., Ltd (Guangdong, China). All reagents were used without further purification. All water used was deionized water.

Scanning electron microscopy (SEM) was purchased from Hitachi Inc. (Tokyo, Japan); Malvern Nano ZS potential laser particle analyzer was provided by Malvern Instruments Co., Ltd. (Worcestershire, UK); UV 2600 UV–vis spectrophotometer was purchased from Shimadzu Co., Ltd (Shanghai, China); Full-wavelength microplate reader and Nicolet 380 Fourier transform infrared spectrometer (FTIR) were purchased from Thermo Fisher Scientific Inc. (Shanghai, China).

2.2 Synthesis of monolayer red SiNPs

The preparation of SiNPs is described in the Supporting Information. 0.1 g SiNPs were ultrasonic dispersed in a mixture of 15 mL H2O and 70 μL C.I. Direct Red 224 solution (0.1 g/mL), then 3.6 ~ 3.75 mL PEI (1 g/L, 0.1 mol/L NaCl) was added. The mixture was allowed to stand at room temperature for 25 min. The particles were centrifuged (3 min, 8000 rpm) and washed three times with water to obtain monolayer red SiNPs. Note that the centrifugation method is used to separate the free polyelectrolyte from the polyelectrolyte-coated red SiNPs after each polyelectrolyte adsorption.

2.3 Synthesis of PEI/PSS nanomultilayer film wrapped high chroma red SiNPs

The monolayer red SiNPs were dissolved in 15 mL of H2O, 100 μL of PEI was added under ultrasonic conditions. The mixture solution was deposited at room temperature for 10 min. The red SiNPs were centrifuged, washed, and then redispersed in 15 mL H2O, 3.6~3.75 mL PSS(1 g/L, 0.2 mol/L NaCl) was added under ultrasonic conditions, deposited for 25 min. The reaction mixture was centrifuged and washed several times with water. This whole process describes the assembly of monolayer dyes coated by bimolecular nano-films: (PEI/PSS)1 red SiNPs and repeated to obtain high chromaticity red SiNPs coated with different number of nano-bilayer films.

2.4 Characterizations

The size and morphology of SiNPs, (PEI/PSS)1.2.3.4 red SiNPs were characterized by SEM. Particle size distribution in each sample aqueous solution and the zeta potential of the pH of the sample was adjusted to 7 with 0.1 M HCl and 1 M NaOH solution were recorded by Nano ZS potential laser particle analyzer. The maximum absorption wavelength of C.I. Direct Red 224 and (PEI/PSS)1.2.3.4 red SiNPs are recorded by scanning with UV 2600 UV–vis spectrophotometer; The coupling efficiency of C.I. Direct Red 224 was measured by multiskan spectrum. Analysis of groups on the surface of (PEI/PSS)–PEI red SiNPs, (PEI/PSS)–PSS red SiNPs by FTIR.

3 Results and discussion

The procedure for preparation of the high chroma red SiNPs is illustrated in Fig. 1. Due to negative charge on surface of SiNPs, the polyelectrolyte multilayer film coated with dye molecules can be formed on the SiNPs by electrostatic LbL self-assembly method. PEI was used as a bridge to link dye molecules and SiNPs. When the positively charged PEI was electrostatically adsorbed to form a polyelectrolyte film in the aqueous solution of dye and SiNPs, the dye molecules were adsorbed on the surface of particles. To make the dyeing process smoother, positively charged PEI and negatively charged PSS were alternately deposited on the SiNPs. And the above experimental processes were repeated to prepare high chroma red SiNPs coated with four nano-bilayer films. In order to prevent the phenomenon of aggregation and adhesion of nanoparticles such as Fig. 1S, after each coating step, the free or unbound polyelectrolytes are removed by centrifugation to prevent the formation of aggregates between the polyelectrolytes. The –COOH on the surface make it is more conveniently to couple the antibody for immunoassay.

3.1 Effect of LbL conditions on the coupling rate of dyes

Based on the coupling efficiency of C.I. direct red 224 on SiNPs, the optimal preparation conditions were investigated. The amount of dye coupled to each partic1e was determined spectrophotometrically. The maximum absorption wavelength of C.I. Direct Red 224 measured by UV–vis spectrophotometer is at 517 nm. The supernatant was collected, and the coupling rate was calculated by multiskan spectrum at 517 nm to characterize the effect of self-assembly conditions on the coupling rate of dyes.

The surface of the SiNPs contains a large amount of—OH, the C.I. Direct Red 224 is rich in –SO3−1 (Fig. 2S), which dissociate many anions in the aqueous solution. The addition of polycation electrolyte PEI quickly adsorbs dye molecules to the surface of SiNPs under the action of static electricity. Figure 2a shows the effect of dye amount on the coupling rate. The coupling rate of dyes increases from 80.1% to 89.9% with the increase of C.I. Direct Red 28 aqueous solution (0.1 g/mL) from 40 to 80 μL. So the optimal addition amount of C.I. Direct Red 224 aqueous solution is 70 μL.

a The effect of amount of C.I. Direct Red 224 on its coupling efficiency on SiNPs (Insert: standard curve for C.I. Direct Red 224 concentration and absorbance); b The effect of PEI deposition time on dye coupling efficiency on SiNPs; c The effect of PSS deposition time on dye coupling efficiency on SiNPs; d The effect of PEI concentration on dye coupling efficiency on SiNPs; e The effect of PSS concentration on dye coupling efficiency on SiNPs; f The effect of supporting salt concentration on dye coupling efficiency in PEI; g The effect of supporting salt concentration on dye coupling efficiency in PSS

With the increase of the adsorption time, the PEI molecular skeleton becomes gradually complete. After adding polyanionic electrolyte PSS, repeat electrostatic deposition and adjust the molecular conformation to form a dense nanofilm, and tightly encapsulate the dye on the surface of the SiNPs. Figure 2b, c shows that when the electrostatic deposition time is 25 min, the coupling rate of dye reaches the peak, and then with the increase of time, the coupling rate decreases. This is due to the conformational adjustment of the polyelectrolyte and the formation of a stable polyelectrolyte membrane.

Figure 2d, e presents the effect of polyelectrolyte concentration on coupling rate. The coupling rate increases the peak with the increase of PEI from 0.5 mg/mL to 1 mg/mL, as shown in 2d. When the concentration of PEI increased to 2 mg/mL, flocculent precipitation observed with the naked eyes. When the concentration of the polyelectrolyte increases to a certain extent, adjacent ionic groups are shielded from each other, and the conformation in the solution is curled, causing the polyelectrolytes to be arranged closely and a thicker polyelectrolyte film is formed. Figure 2e shows that the dye coupling rate decreases gradually when PSS concentration increases from 1.0 to 5 mg/mL. This is because there are many –SO3−1 in both PSS and C.I. Direct Red 224, and the shielding effect between groups becomes more obvious with the increase of concentration. As a result, the optimum concentration of PEI and PSS are 1 mg/mL.

The effect of supporting salt concentration on the coupling rate is shown in Fig. 2f, g. In aqueous solution, the polyelectrolyte is fully extended under the action of mutual repulsion between the groups. Inorganic salts can change the ionic strength of polyelectrolytes. When a large amount of Na+ enters the solution, the charge shielding effect changes the electrostatic repulsion between polyelectrolyte segments, and the molecular conformation changes from stretching to curling. However, a certain concentration of inorganic salts can increase the compactness of the membrane and increase the coupling rate of dyes. Therefore, it can be concluded from the Fig. 4f that the best-supporting salt concentrations of PEI and PSS are 0.1 mol/L and 0.2 mol/L, respectively.

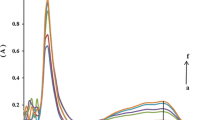

3.2 Effect of LbL layers on the absorbance value of the (PEI/PSS) n red SiNPs

Figure 3 shows at the concentration of 2.5 mg/mL, the UV–Vis absorbance value of the (PEI/PSS)1.2.3.4 red SiNPs obtained with different dyeing layers and the red SiNPs of the silane coupling agent (3-[2-(2-aminoethylamino)ethyl amino] propyl-trimethoxysilane,3APTMS) graft dye. It can be seen from the figure that at the maximum absorption wavelength 517 nm, the absorbance of the particles increases gradually with the increase of dyeing times, which is obviously higher than that of red SiNPs with 3APTMS branch dye. The absorbance of red SiNPs obtained by the first three dyeing showed an obvious increasing trend, and there was slight increase at the absorbance curves of red SiNPs after the third dyeing and the fourth dyeing. These results prove that the method of polyelectrolyte LBL self-assembly and adsorption of dyes for 4 times to prepare high chromaticity colored SiNPs is effective.

The ultraviolet absorbance value of 3APTMS- red SiNPs, (PEI/PSS)0-PEI red SiNPs, (PEI/PSS)1-PEI red SiNPs, (PEI/PSS)2-PEI red SiNPs, (PEI/PSS)3-PEI red SiNPs; Inset: photographs of 3APTMS- red SiNPs, (PEI/PSS)0-PEI red SiNPs, (PEI/PSS)1-PEI red SiNPs, (PEI/PSS)2PEI red SiNPs, (PEI/PSS)3-PEI red SiNPs

3.3 Characterizations of high chroma red SiNPs

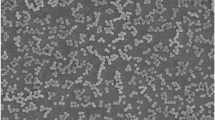

3.3.1 Morphological observation

The surface morphology of red SiNPs after polyelectrolyte self-assembly was characterized by SEM. Figure 4a–d show SEM photographys of SiNPs, (PEI/PSS)0-PEI red SiNPs, (PEI/PSS)3-PEI red SiNPs and (PEI/PSS)4 red SiNPs. Figure 4a shows that the prepared SiNPs are uniformly dispersed, and the surface is smooth, showing regular spherical. The SEM picture of PEI adsorption dye molecules deposited on the surface of particles to form red SiNPs coated with polycationic electrolyte film is shown in Fig. 4b. The surface of the (PEI/PSS)0-PEI red SiNPs is smooth without obvious bulging vesicles. A loose nano-film is wrapped on the surface of the particles, showing a slightly irregular sphere. Figure 4c shows the SEM of (PEI/PSS)3-PEI red SiNPs with polycation electrolyte adsorbed in the outermost layer after four staining. After seven times of alternation adsorption of polyelectrolyte, with the increase of the number of polyelectrolyte assembly layers, the polyelectrolyte films coated on the particles becomes compact under strong electrostatic adsorption, and the SiNPs returns to its original uniform spherical morphology. However, with the formation of multilayer polyelectrolyte films, the aggregation of PEI molecules leads to the roughness of the surface of the particles and the emergence of a small number of protruding vesicles. Figure 3S shows that the polyelectrolyte nanofilms on the surface of (PEI/PSS)0-PEI red SiNPs, (PEI/PSS)1-PEI red SiNPs, (PEI/PSS)2-PEI red SiNPs and (PEI/PSS)3-PEI red SiNPs gradually protrude vesicles with the increase of the number of PEI assembly layers. When polyanionic electrolyte PSS adsorbed on the outermost layer to form a film, the more dense nanofilms was formed under the action of static electricity due to the increase of support salt concentration. It can be clearly seen from Fig. 4d that there are many granular vesicles on the (PEI/PSS)4 red SiNPs, which are surrounded by polyanionic electrolyte membranes.

3.3.2 Analytical particle size

The size of the assembled red SiNPs was characterized by Malvern laser particle size analyzer.

Figure 4S shows the particles size distribution curve of unmodified SiNPs and red SiNPs after assembly of each layer of polyelectrolyte. The average diameter of the SiNPs from the curve is about 227 nm. After the first dyeing, the average particle size of (PEI/PSS)0-PEI red SiNPs was about 303 nm, which is significantly increased by 76 nm compared with the diameter of the SiNPs. After four times of dyeing, the average diameter of (PEI/PSS)4 red SiNPs is about and 234 nm. From this we can conclude that when the polycation electrolyte is assembled in the outermost layer, because the dye molecules are wrapped on the particles surface during film formation, the polyelectrolyte films formed is relatively loose, resulting in an increase in particle size. After electrostatically adsorbing a layer of polyanionic electrolyte, the strong electrostatic force makes the wrapped nanofilm compact and the particles diameter shrinks. It can be concluded that under the electrostatic interaction between polyelectrolytes, the particle size of nanofilms deposited on the surface of red SiNPs decreases with the increase of the number of assembly layers. The nanoparticles prepared by this method still have regular morphology and good dispersion.

3.3.3 Surface charge

Zeta measurement is one of the most widely used techniques to prove that polyelectrolytes are successfully adsorbed onto particles [29]. We measured the surface potentials of nanoparticles at each stage after assembling PEI and PSS sequentially, as shown in Fig. 5. The initial surface potential measured for native SiNPs is −36 mV, which makes it possible to absorb positively charged polyelectrolytes. After assembling PEI and C.I. Direct Red 224, the surface potential charges to −17.7 mV. After assembling PEI and PSS alternately, the surface potential charged from +21.3 mV to –20.9 mV. Then each time the polyelectrolyte with opposite charge is assembled, the potential is reversed to the same extent.

As a control we tried the case of not self-assembling another layer of PEI only one layer of PSS, the surface potential changes to −35 mV. Obviously, after assembling PSS, the negative charge becomes more. However, the surface of the nanoparticles obtained in the whole process has negative charge. Compared with Fig. 5S, the assembly of PEI is the key to change the potential from negative to positive. Not only that, we also found that if there is no layer of PEI, in the washing process, a large number of dyes will fall off, resulting in the color of red SiNPs will not be significantly deepened with the increase of dyeing times. Because of the particles is negative at each stage, there are still free dye molecules that are not completely wrapped on the particles. At this time, the assembly of polycationic electrolyte PEI, will adsorb all free dye molecules in the solution on the surface of the particles, making the particles with a positive charge, and then assembly PSS for negative modification and cyclic dyeing, which can significantly reduce the shedding of dyes.

3.3.4 FTIR spectrum

In order to better prove the successful assembly of polyelectrolytes on SiNPs, FTIR was used to confirm the existence of PEI and PSS. The infrared spectra of different samples at 400–4000 cm−1 are shown in Fig. 6. It can be seen from the spectrum of the SiNPs that the infrared absorption bands at 1108 cm−1 and 473 cm−1 correspond to the stretching vibration peak and bending vibration peak of the Si–O–Si bond, respectively. The symmetric stretching peak of Si–O–Si bond of SiNPs appears at 800 cm−1. The infrared absorption peaks near 3423 cm−1 and 1630 cm−1 reflect the stretching and bending vibrations of the OH group, which proves that the SiNPs containing OH on the surface are successfully synthesized. Compared with the spectra of SiNPs, the spectra of (PEI/PSS)4− PEI red SiNPs shows the C–H stretching band appears at 1355–1557 cm−1. The absorption peak near 3440 cm−1 indicates the existence of active group –NH and –OH. The FTIR spectrum of (PEI/PSS)4- PSS red SiNPs shows that the NO2 band appears in ~1384 cm−1 [30] due to the addition of dye molecules. An obvious carbonyl vibration peak appeared at ~1867 cm−1 [31]. The COOH band was observed near 1532 cm−1 and 1635 cm−1. FTIR spectrum proves that PEI and PSS are successfully assembled on the surface of the red silica nanoparticles.

3.3.5 Dye leakage test

The protective effect of electrostatic self-assembly of multilayer polyelectrolytes on dyes was proved through dye leakage experiments. 0.1 g (PEI/PSS)0 red SiNPs and 0.1 g (PEI/PSS)4 red SiNPs were dispersed in 3 mL pure water, respectively. Centrifuge every half an hour, and then test the absorbance of the supernatant. As shown in Fig. 7, the dye of (PEI/PSS)0 red SiNPs (at the top of the picture) fell off obviously under the condition of washing, resulting in the red of the supernatant. With the increase of washing times, the dye shedding did not decrease obviously. The (PEI/PSS)4 red SiNPs under the same centrifugation and washing conditions, the color of the supernatant is very light. With the increase of washing times, the supernatant is nearly colorless, which is consistent with the measured absorbance of the supernatant. We found that PEI was used as a bridge to adsorb C.I. direct red 224 on SiNPs to obtain (PEI/PSS)0 red SiNPs. Because the binding of dyes was not firm, and a large number of dyes fell off with the increase of washing times. Then, alternately assembled PEI and PSS, were dyed repeatedly for 4 times, (PEI/PSS)4 red SiNPs were obtained. The dyes shedding decreased significantly with the increase of the number of washings. It shows that the polyelectrolyte film formed by the assembled multilayer PEI and PSS under the action of strong electrostatic force firmly wraps the dye on the surface of the SiNPs and effectively prevents the dye from falling off.

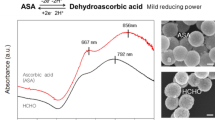

3.3.6 Preparation of high chroma blue SiNPs

Several dyes were selected from direct dyes, reactive dyes and disperse dyes for experiments. According to the coupling efficiency between the brightness of the color and the dye, C.I. Direct Blue 199 was selected to prepare high chroma blue nanoparticles by electrostatic layer-by-layer self-assembly. Due to the different amount of anions carried by different anionic dyes, the amount of negative charge in the aqueous solution of SiNPs and dyes is different, and the ability of electrostatic adsorption of polycation electrolyte is also different, so the brightness and coupling efficiency of dyes are different when the same concentration of polyelectrolyte is added. The UV–vis absorption spectrum in Fig. 8 proves that the absorbance of the high chromaticity blue SiNPs at the maximum absorption wavelength 214 nm increases sequentially and is significantly higher than that of the particles prepared by silane coupling agent grafted dye. At the same time, it also shows that the selection of suitable dyes is the key to the preparation of high chroma colored SiNPs by electrostatic self-assembly.

UV–vis absorption spectra of 3APTMS-blue SiNPs, (PEI/PSS)0-PEI blue SiNPs, (PEI/PSS)1-PEI blue SiNPs, (PEI/PSS)2-PEI blue SiNPs, (PEI/PSS)3-PEI blue SiNPs; Inset: photographs of 3APTMS-blue SiNPs, (PEI/PSS)0-PEI blue SiNPs, (PEI/PSS)1-PEI blue SiNPs, (PEI/PSS)2-PEI blue SiNPs, (PEI/PSS)3-PEI blue SiNPs

4 Conclusions

In this work, high chromaticity colored nanoparticles coated with dye on polyelectrolyte (PEI/PSS) composite membrane were prepared by LBL electrostatic self-assembly method on the surface of charged SiNPs for the first time. SEM, Zeta potential and FTIR studies have shown that when polyelectrolyte multilayers are assembled on red SiNPs, the changes in surface morphology and potentials make it possible to successfully adsorb dyes LbL on particles. The high chroma colored nanoparticles coated by the prepared multilayer films still show good dispersion, uniform particle size and regular surface morphology because of the strong electrostatic action of polyelectrolytes. The electrostatic LBL self-assembly method is simpler and more efficient than the silane coupling agent graft dye method. The whole process of self-assembly only needs to be carried out in aqueous solution without the introduction of organic reagents, which is more economical and environmentally friendly. This high chroma colored nanoparticles will be an excellent visualization marker in the application of immunochromatography.

References

Yu H, Zhao G, Dou W (2015) Simultaneous detection of pathogenic bacteria using agglutination test based on colored silica nanoparticles. Curr Pharm Biotechnol 16:716–723

Sun Q, Zhao G, Dou W (2015) A nonenzymatic optical immunoassay strategy for detection of Salmonella infection based on blue silica nanoparticles. Anal Chim Acta 898:109–115

Sun Q, Zhao G, Dou W (2016) An optical and rapid sandwich immunoassay method for detection of Salmonella pullorum and Salmonella gallinarum based on immune blue silica nanoparticles and magnetic nanoparticles. Sens Actuators B: Chem 226:69–75

Yu Q, Dou W, Liu J, Zhao G, Yang S, Zhu D, Zhao Y, Li L (2019) A sensitive and quantitative immunochromatographic assay for HBsAg based on novel red silica nanoparticles. Anal Methods 11:268–275

Zhu C, Zhao G, Dou W (2018) Core-shell red silica nanoparticles based immunochromatographic assay for detection of Escherichia coli O157:H7. Anal Chim Acta 1038:97–104

Winnik FM, Keoshkerian B, Fuller JR, Hofstra PG (1990) New water-dispersible silica-based pigments: synthesis and characterization. Dyes Pigments 14:101–112

Krysztafkiewicz A, Jesionowski T, Binkowski S (2000) Precipitated silicas modified with 3-aminopropyltriethoxysilane. Colloids Surf A: Physicochemical Eng Asp 173:73–84

Binkowski S, Jesionowski T, Krysztafkiewicz A (2000) Preparation of pigments on modified precipitated silicas. Dyes Pigments 47:247–257

Stöber W, Fink A, Bohn E (1968) Controlled growth of monodisperse silica spheres in the micron size range. J Colloid Interface Sci 26:62–69

Zhu C, Zhao G, Dou W (2017) A new synthesis method for bright monodispersed core-shell colored silica submicron particles. J Sol-Gel Sci Technol 85:76–83

Iler R (1966) Multilayers of colloidal particles. J colloid interface Sci 21:569–594

Jiang X, Chen Z, Lv D, Wu Q, Lin X (2008) Basic law controlling the growth regime of layer-by-layer assembled polyelectrolyte multilayers. Macromol Chem Phys 209:175–183

Zhang H, Nayak S, Wang W, Mallapragada S, Vaknin D (2017) Interfacial self-assembly of polyelectrolyte-capped gold nanoparticles. Langmuir 33:12227–12234

Richardson JJ, Björnmalm M, Caruso F (2015) Technology-driven layer-by-layer assembly of nanofilms. Science 348:aaa2491

Decher G (1997) Fuzzy nanoassemblies: toward layered polymeric multicomposites. science 277:1232–1237

Kaneko F, Kato T, Baba A, Shinbo K, Kato K, Advincula RC (2002) Photo-induced fabrication of surface relief gratings in alternate self-assembled films containing azo dye and alignments of LC molecules. Colloids Surf A: Physicochemical Eng Asp 198:805–810

Gao M, Yang Y, Yang B, Bian F, Shen J (1994) Synthesis of PbS nanoparticles in polymer matrices. J Chem Soc, Chem Commun 24:2779–2780

Gao S, Cao R, Yang C (2008) Dye-polyoxometalate composite films: self-assembly, thermal and photochemical properties. J Colloid Interface Sci 324:156–166

Campbell VE, Chiarelli PA, Kaur S, Johal MS (2005) Coadsorption of a polyanion and an azobenzene dye in self-assembled and spin-assembled polyelectrolyte multilayers. Chem Mater 17:186–19.

Kim S-H, Ahn C-H, Park S-Y, Shin C-J, Suh H-J (2006) Electrostatic layer-by-layer self-assembly of anionic squarylium and cationic polyelectrolyte. Dyes Pigments 69:108–110

Hiller JA, Mendelsohn JD, Rubner MF (2002) Reversibly erasable nanoporous anti-reflection coatings from polyelectrolyte multilayers. Nat Mater 1:59–63

Sun Q, Tong Z, Wang C, Ren B, Liu X, Zeng F (2005) Charge density threshold for LbL self-assembly and small molecule diffusion in polyelectrolyte multilayer films. Polymer 46:4958–4966

Caruso F, Caruso RA, Möhwald H (1998) Nanoengineering of inorganic and hybrid hollow spheres by colloidal templating. Science 282:1111–1114

Hammond PT (1999) Recent explorations in electrostatic multilayer thin film assembly. Curr Opin Colloid Interface Sci 4:430–442

Schönhoff M (2003) Self-assembled polyelectrolyte multilayers. Curr Opin Colloid Interface Sci 8:86–95

Haynie DT, Zhang L, Rudra JS, Zhao W, Zhong Y, Palath N (2005) Polypeptide multilayer films. Biomacromolecules 6:2895–2913

Wang C, Ye S, Sun Q, He C, Ye W, Liu X, Tong Z (2008) Microcapsules for controlled release fabricated via layer-by-layer self-assembly of polyelectrolytes. J Exp Nanosci 3:133–145

Chakraborty U, Singha T, Chianelli RR, Hansda C, Kumar Paul P (2017) Organic-inorganic hybrid layer-by-layer electrostatic self-assembled film of cationic dye Methylene Blue and a clay mineral: spectroscopic and atomic force microscopic investigations. J Lumin 187:322–332

Belbekhouche S, Bousserrhine N, Alphonse V, Carbonnier B (2019) From beta-cyclodextrin polyelectrolyte to layer-by-layer self-assembly microcapsules: from inhibition of bacterial growth to bactericidal effect. Food Hydrocoll 95:219–227

Akar A (1988) Reaction of some polymers containing carbonyl groups with phenol in the presence of mineral acids. Die Angew Makromol Chem: Appl Macromol Chem Phys 160:83–90

Hou Q, Wang X, Ragauskas AJ (2019) Dynamic self-assembly of polyelectrolyte composite nanomaterial film. Polymers Basel 11:1–11

Acknowledgements

This work was financially supported by a grant from National Natural Science Foundation of Zhejiang Province (LY17C200003).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Su, Z., Zhao, G. & Dou, W. Preparing high chroma colored silica nanoparticles based on layer-by-layer self-assembled technique. J Sol-Gel Sci Technol 101, 562–570 (2022). https://doi.org/10.1007/s10971-020-05317-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-020-05317-9