Abstract

Sub 2-μm monodisperse mesoporous silica spheres (MMSS) were synthesized using a mixed template system in a MeOH/H2O solution. 1-Dodecylamine (DDA) and polymeric type Jeffamine surfactants, including D2000, D4000, and T5000, were employed as templates. These mixed template syntheses realized to gain MMSS materials with good spherical shape and uniform particle size. When the MeOH/H2O (v/v) ratio was controlled between 2.5:1 and 3.0:1, mesoporous silica spheres of 2.10–2.35 μm with excellent dispersibility can be obtained. Depending on the surfactant chain length of Jeffamine, hydrothermal aging pH (4–9), time (12–24 h), and temperature (80–140 °C), MMSS with large-pore sizes (up to 14.3 nm), surface areas (153–791 m2/g), and pore volumes (0.47–1.28 cm3/g) can be synthesized.

Highlight

-

Monodisperse mesoporous silica spheres.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Mesoporous materials have received extensive attention in fields of catalysis, selective sorbents for separation processes, regulated transport systems, and the immobilization of biomolecules. A narrow particle distribution and a mean pore diameter larger than 8 nm are needed when used as high-performance liquid chromatography (HPLC) supports. Therefore, control of pore size, particle morphology, particle size, and particle-size distribution are of critical importance for successful HPLC applications.

In 1968, Stöber et al. synthesized nonporous silica spheres with a particle size of 0.05–2 μm by the hydrolysis of tetraethylorthosilicate (TEOS) in a solution of alcohol–water–ammonia. In recent decades, this method has been improved to synthesize monodisperse mesoporous silica spheres (MMSS) by adding a surfactant porogen in the reaction system. Alkyl quaternary ammonium salts or alkyl amines, such as cetyltrimethylammonium bromide [1, 2] and 1-dodecylamine (DDA) [3,4,5], are the most commonly used regents to synthesis MMSS. The particle sizes can be varied from several hundred nano meters to several micrometers, and the particle-size distribution can be well controlled within a narrow range. However, their pore diameters are largely depended on the size of porogen, and the pore sizes were usually less than 4 nm. Hence, pore size control is an important issue in the research area of mesoporous silica material.

Two strategies are mainly explored to enlarge the pore diameters. One is to introduce pore expansion reagents [6, 7], such as DDA, N,N-dimethyldecylamine in the posthydrothermal treatment, but with the restriction of a wider pore size distribution or particle cracks. The other is to use polymers with molecular weights larger than 2000 as structure-directing templates, such as P123 [8] and F127. Mesoporous silica materials with pore size can be varied in large range. The pore size of SBA-15 type mesoporous silicas with pore size varied from 2 to 30 nm were synthesized by using block copolymer P123 in acid media [9]. Gerardin [10] and his co-workers gained periodic mesoporous organosilicas with an inter-lamellae distance of around 15 nm by using polyion complex micelles formed from DHBC polymers. Jeffamine is a series of polyetheramine surfactants that have been gradually used in the synthesis of mesoporous silica materials due to its nontoxicity, low cost, and biodegradable characteristics. Pinnavaia’s group [11, 12] synthesized MSU-J with 14.3 nm pore size of wormhole framework structures using Jeffamine (D2000, D4000, M2005, T3000, T5000) and Surfonamine (ML300, MNPA1000) as the structure-directing porogen. Mesoporous silicas with onion-like morphology with 464 m2/g BET surface area, 1.16 m3/g volume, and 7.2 nm pore diameter, were also synthesized by the same family of amphiphilic Jeffamines D2000 by Sayari et al. [13]. Blin’s group [14,15,16] reported the preparation of ordered mesoporous materials myristoyl-end capped Jeffamine, synthesized from a polyoxyalkyleneamine (ED900) and myristoyl. By grafting stearic acid on Jeffamine ED2003, Liu with her co-workers [17] synthesized silica materials which were spherical nanoparticles of 20–30 nm, further agglomerating and forming a densely packed microspheres of 2–4 μm. However, achieving the control of particle size and large-pore mesoporous silica simultaneously has still been a concern for many researchers.

Our recent work [18] has shown that the pore size of MMSS can be varied in a wide range of 4.4–11.6 nm in a mixed template system of DDA and alkyl aminepolyoxyethylene ether surfactant. We herein investigated a group of large-pore MMSS synthesized based on sol–gel reaction by using the shorter chain aliphatic surfactant DDA and the larger molecular weight Jeffamine as dual template method. It was shown that pore sizes and pore volumes were range 4.2–14.3 nm and 0.47–1.28 cm3/g, respectively, by changing the molecular weight of the Jeffamine, hydrothermal aging pH, time, and temperature. The silicas with such properties can be applied in catalyst, selective sorbents, regulated transport systems, etc.

2 Experiment

2.1 Materials and synthesis

TEOS, ammonium hydroxide solution 28.0~30.0% (NH3·H2O), HCl and MeOH were purchased from Lingfeng Chemicals Co., Ltd (Shanghai, China). DDA and Jeffamine D2000 were purchased from Aladdin Reagent Co., Ltd (Shanghai, China). Jeffamine D4000 and T5000 were purchased from Huntsman Corporation. All the chemicals were used as obtained. Deionized water was used as solvent for the synthesis.

The typical synthetic route was shown in Fig. 1c. 6.50 g D2000 and 3.25 g DDA were dissolved in solutions consisted of 120 mL water and 300 mL MeOH with ultrasonic treatment for 2 min. Then 6.5 mL TEOS and 1 mL NH3·H2O were added in sequence. The solution pH was 9.5. The mixture was kept under static condition at ambient temperature for 24 h. The resulting powder was recovered by filtration, washed with deionized water and ethanol.

The obtained silica spheres were treated with ultrasound for 10 min in a hydrochloric acid solution (pH = 1). The slurry was kept under static condition at room temperature for 12 h. Then the silica spheres were filtered out and washed with deionized water to a neutral pH. The white solid was divided into different portions (~1.5 g) and put into 15 mL water for hydrothermal treatment in a temperature range of 80–140 °C from 6 to 24 h. Finally, the surfactants were removed from the washed, air-dried solids by calcination at 600 °C for 6 h in air. The surfactant-free sample was denoted as MMSS-1. MMSS-2 and MMSS-3 were synthesized under identical conditions with MMSS-1, but D2000 was replaced with D4000 and T5000, respectively.

2.2 Characterization

(1) Particle-size distribution

The Malvern Mastersizer 2000 was used to measure particle-size distribution. Prior to testing, samples were dispersed in deionized water and sonicated for 15 min to fully disperse. Deionized water was selected as the dispersion medium, and silica gel was selected as the dispersion sample with the refractive index of 1.330. The particle-size distribution of each sample was measured three times and finally averaged.

(2) Brunauer–Emmett–Teller (BET) surface area and pore size distribution

Nitrogen adsorption–desorption isotherms were obtained at 77 K with a volumetric adsorption analyzer TRISTAR II manufactured by micromeritics. The samples were dried in an oven at 200 °C for 4 h prior to testing. The surface area and pore size distribution were tested using the BET and Barrett–Joyner–Halenda (BJH) methods, respectively.

(3) Scanning electron micrographs (SEM) and Transmission electron micrographs (TEM)

SEM were observed on a Hitachi S-3400N instrument at an accelerating voltage of 15 kV. Prior to testing, the samples were dispersed on the conductive adhesive tapes, and the excess particles were blown off with the ear-washing ball, and the surface was sprayed with conductive paints.

TEM were observed on a JEM1400 (JEOL, Japan) at an acceleration voltage of 100 kV. Prior to testing, samples were dispersed in MeOH for 15 min, and a small amount of silica gel suspension was sucked up with a plastic pipette, dropped on a copper sheet, and dried in an oven.

(4) X-ray powder diffractometer (XRD)

XRD was obtained on an X-ray diffractometer model D/MAX 2550VB (Rigaku, Japan), equipped with a Cu–Kα radiation source and accelerator detector.

2.3 Chromatographic measurements

The MMSS-10 (0.2 g) were packed into the stainless-steel tube (50 mm × 2.1 mm i.d.) by slurry packing method with deionized water/acetonitrile as slurry solvent and acetonitrile as propulsion solvent under a pressure of 80 MPa.

HPLC was measured on a Waters Acquity UPLC system, equipped with a sample manager, a quaternary solvent delivery manager, and a tunable ultraviolet detector. Four samples, sulfadiazine, uracil, uridine, and adenine were separated on the column with the mobile phase of acetonitrile/water (90/10) at a flow rate of 0.2 mL/min. The injection volume was 1 μL with a concentration of 1.0 mg/mL of analysts (sulfadiazine, uracil, uridine, and adenine) dissolved in the mobile phase mixture. The detector wavelength was set at 254 nm and the column temperature was set at 30 °C.

3 Results and discussion

Firstly, the effect of the ratio of MeOH/H2O on the size of silica microspheres was investigated. Figure 2a, b shows that when MeOH/H2O ratio was lower than 2.5:1, no spherical silica gel was obtained, and the structure was loose and in an amorphous agglomerate state. When the volume ratio was 2.5:1, uniform and complete spherical particles with smooth surface could be obtained. However, with the proportion increased, the particle-size distribution of silica particles became less uniform. That is because the diffusion rate of the reactants increased, the hydrolysis rate slowed, and the nucleation rate increases. The precursor is slowly hydrolyzed, and once it is formed, micronuclei are formed immediately, thereby inhibiting the subsequent growth of existing micronuclei, and eventually forming smaller microspheres SiO2. As shown in Fig. 2g, MeOH/H2O volume ratio between 2.5: 1 and 3.0: 1 were suitable to grow MMSS with particle size of 2.10~2.35 μm in the synthesis of this work, which met the requirements of narrow particle-size distribution required for HPLC packing (Table 1).

The silica spheres synthesized at MeOH/H2O = 2.5:1 were treated by hydrothermal aging to expanse pore size. The N2 adsorption–desorption isotherms and BJH pore size distribution curves of obtained samples are shown in the Fig. 3. The sample MMSS-1 was hydrothermally aged for 12 h without hydrochloric acid treatment. A small bump could be seen around the relative pressure P/P0 = 0.8, and two double peaks at 10 and 20 nm could be clearly observed from the BJH curves, indicating silica spheres had a smaller pore in addition to the larger one. The speculated reason for forming two different pore sizes was the use of two surfactants in the synthesis of mesoporous silica. DDA and D2000 could not mix well in an alkaline solution of H2O to form a uniform composite micelle, but formed two different sizes of micelles instead. The smaller mesoporous were produced by the micelles formed by DDA, while the larger mesoporous were formed by D2000 or the composite micelles of two surfactants. The pH was assumed to have certain influences on the pore size and distribution when hydrothermal aging. Therefore, the impact of different pH of solution on the pore size was investigated and the experimental results validated our conjecture.

N2 absorption–desorption isotherms of three samples under different pH are shown in the Fig. 3. The acid-treated silica spheres formed a single peak, because the amine end of DDA and the amine end of D2000 formed –NH3+ under acidic media, attracting each other due to the hydrophilic effect. Then their alkyl chains also attracted each other due to hydrophobic interactions, so the rearrangements of the two micelles formed a uniform composite micelle, resulting in a single mesoporous structure. The mechanism is shown in Fig. 4. Meanwhile, the average pore size formed smaller with stronger acidity because the solubility of SiO2 under alkaline media was greater than that under acidic media. Therefore, under high temperature conditions, SiO2 in the alkaline media was dissolved in the solution, and due to the expansion of micelles, a larger pore size was formed.

We further discuss the hydrothermal temperature and aging time of MMSS. Figure 5 shows the samples obtained by changing the hydrothermal temperature at the same aging time, illustrating that as the temperature rose, the molecular thermal motion was more strenuous, the hydrogen bonding of the water molecule with the surfactant was destroyed, and the chain stretched to form a larger diameter the micelles. The volume of the micelles formed larger with higher temperature, which led to in the collapse of the pore wall between adjacent small pores and eventually forming a larger pore.

The N2 adsorption–desorption isotherms of mesoporous silica aged over different lengths of time are shown in Fig. 6. Different from the increase of aging temperature, the specific surface area decreased with the aging time extending, the pore size increased, but the pore volume did not change so much, indicating that the expansion of the DDA/D2000 composite micelles was limited. The experiment shows that the temperature had a great influence on the pore expanding ability of DDA/D2000 composite micelles and could be an important key for pore expansion. Besides, prolonging the aging time can improve the comprehensive effect. By reasonably changing the temperature and time, the specific surface (150–620 m2/g) and mesoporous (5.3~14.3 nm) satisfying the requirements can be obtained.

Finally, the effect of surfactants with different chain lengths on pore size at the same temperature and time was investigated. Figure 7 illustrates that under the same hydrothermal aging conditions, the pore size of silicas synthesized by T5000 was larger than D2000, but smaller than D4000. The Jeffamine’s structures are shown in Fig. 1a, b. We can know that the average chain length of T5000 (triamine) is longer than D2000 (diamine) but shorter than D4000 (diamine), which leads this result.

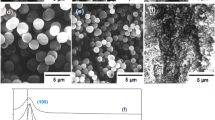

Figure 8 respectively illustrates the TEM images and XRD patterns of silica gel MMSS synthesized by different conditions. As seen in Fig. 8b, no diffraction peaks appeared within the range of 2θ = 0.5–5°, indicating that the pores of the three samples were disordered, which was consistent with the TEM results of the silica gel microspheres of Fig. 8a.

These large-pore mesoporous silica spheres MMSS-10 were applied as stationary phase in HPLC to separate the small molecules mixtures. The separation condition and chromatogram was shown in Fig. 9, which illustrates that the sulfadiazine, uracil, uridine, and adenine can be well separated on the MMSS-10 column. Thus, the mesoporous silica microspheres can be used as a stationary phase for HPLC to separate small molecules.

4 Conclusion

In this study, sub 2-μm monodispersed mesoporous silica spheres were successfully synthesized by using DDA as the structure-directing agent, D2000 as the pore expansion agent, TEOS as the inorganic silicon source and MeOH/H2O as the solvent. When the volume ratio of MeOH/H2O is equal to 2.5:1, the synthesized silica particle-size distribution is the best. The pH value influenced the self-assembly of the two nonionic surfactants. In basic solution, the silica spheres with a bimodal pore structure formed. Whereas acidification in a hydrochloric acid solution, the silica spheres showed a uniform pore size distribution from the N2 adsorption–desorption isotherm. Finally, MMSS with large-pore sizes (up to 14.3 nm), surface areas (153–791 m2/g) and pore volumes (0.47–1.28 cm3/g) can be synthesized by changing surfactants(D000, D4000, T5000), hydrothermal aging pH (4–9), time (12–24 h), and temperature (80–140 °C). The monodispersivity and smooth silica surface of the mesoporous silica spheres makes them ideal candidates for advanced chromatographic stationary phases.

References

Yoo WC, Stein A (2011) Solvent effects on morphologies of mesoporous silica spheres prepared by pseudomorphic transformations. Chem Mater 23:1761–1767

Zukal A, Thommes M, Čejka J (2007) Synthesis of highly ordered MCM-41 silica with spherical particles. Microporous Mesoporous Mater 104:52–58

Yu J, Zhao L, Cheng B (2006) Preparation of monodispersed microporous SiO2 microspheres with high specific surface area using dodecylamine as a hydrolysis catalyst. J Solid State Chem 179:226–232

Zhao D, Huo Q, Feng J, Chmelka BF, Stucky GD (1998) Nonionic triblock and star diblock copolymer and oligomeric surfactant syntheses of highly ordered, hydrothermally stable, mesoporous silica structures. J Am Chem Soc 120:6024–6036

Shimogaki T, Tokoro H, Tabuchi M, Koike N, Yamashina Y, Takahashi M (2016) Large-scale preparation of morphology-controlled microporous silica particles via gradual injection of reactants with different surfactants. J Sol–Gel Sci Technol 79:440–446

Sayari A, Hamoudi S, Yang Y (2005) Applications of pore-expanded mesoporous silica. 1. removal of heavy metal cations and organic pollutants from wastewater. Chem Mater 17:212–216

Sun J-H, Coppens M-O (2002) A hydrothermal post-synthesis route for the preparation of high quality MCM-48 silica with a tailored pore size. J Mater Chem 12:3016–3020

Kaneko T, Nagata F, Kugimiya S, Kato K (2018) Morphological control of mesoporous silica particles by dual template method. Ceram Int 44:20581–20585

Hsu Y-C, Hsu Y-T, Hsu H-Y, Yang C-M (2007) Facile synthesis of mesoporous silica SBA-15 with additional intra-particle porosities. Chem Mater 19:1120–1126

Birault A, Molina E, Carcel C, Bartlett J, Marcotte N, Toquer G, Lacroix-Desmazes P, Gerardin C, Chi Man MWong (2019) Synthesis of lamellar mesostructured phenylene-bridged periodic mesoporous organosilicas (PMO) templated by polyion complex (PIC) micelles. J Sol–Gel Sci Technol 89:189–195

Park I, Pinnavaia TJ (2009) Large-pore mesoporous silica with three-dimensional wormhole framework structures. Microporous Mesoporous Mater 118:239–244

Park I, Wang Z, Pinnavaia TJ (2005) Assembly of large-pore silica mesophases with wormhole framework structures from α,ω-diamine porogens. Chem Mater 17:383–386

Hossain K-Z, Sayari A (2008) Synthesis of onion-like mesoporous silica from sodium silicate in the presence of α,ω-diamine surfactant. Microporous Mesoporous Mater 114:387–394

May A, Pasc A, Stebe MJ, Gutierrez JM, Porras M, Blin JL (2012) Tailored jeffamine molecular tools for ordering mesoporous silica. Langmuir 28:9816–9824

May-Masnou A, Pasc A, Stébé MJ, Gutiérrez JM, Porras M, Blin JL (2013) Solubilization of decane into gemini surfactant with a modified Jeffamine backbone: design of hierarchical porous silica. Microporous Mesoporous Mater 169:235–241

Riachy P, Lopez G, Emo M, Stebe MJ, Blin JL, Ameduri B (2017) Investigation of a novel fluorinated surfactant-based system for the design of spherical wormhole-like mesoporous silica. J Colloid Interface Sci 487:310–319

Chunyan L, Caiyun G, Dongxue Z, Jing W, Jiashuo L, Zhaobin L (2015) Modified jeffamine molecular tools for ordered mesoporous and super-micorporous silica microsphere particles. Chin J Inorg Chem 31:954–960

Du Y, Cheng L, Chen L, He Y, Wu Y, He S, Ke Y (2017) Preparation of sub-2 μm large-pore monodispersed mesoporous silica spheres using mixed templates and application in HPLC. Microporous Mesoporous Mater 265:234–240

Funding

This work was supported by the National Natural Science Foundation of China (grant no. 21375038).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Q., Wang, H., Wu, Y. et al. Pore size control of monodisperse silica particles by dual template sol–gel method. J Sol-Gel Sci Technol 94, 186–194 (2020). https://doi.org/10.1007/s10971-019-05152-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-019-05152-7