Abstract

Alumina (Al2O3)-based diphasic aerogels have better physical properties than those of pure Al2O3 aerogel according to previous studies. In the present research, we focused on an alumina–titania (Al2O3-TiO2) diphasic aerogel. A series of Al2O3 aerogels were synthesized and studied with and without minor TiO2 dopants (up to 10 mol%). We found that the pure Al2O3 aerogel, which had the fiber-like particles, was stronger than those with TiO2 dopants that possessed the sphere-like particles. However, the sphere-like particles make the TiO2-doped Al2O3 aerogel (with 3 mol% TiO2) possessing the largest specific surface area (SSA) of 650 m2/g, much larger than that of the pure Al2O3 aerogel (326 m2/g). This work proved that fiber-like particles enhance strength but reduce SSA of Al2O3 aerogel. At last, ceramic fibers reinforced Al2O3 aerogel composites with the sizes of 20 cm width × 20 cm length × 1 cm thickness were fabricated. The aerogel composites possessed a thermal conductivity of 0.136 W/m K at 1000 °C, better than those of the ceramic fiber blankets itself (0.30 W/m K), indicating potential application as high-temperature thermal insulator.

Highlights

-

Particle morphology within Al2O3 aerogel changed due to the inhibited crystallization.

-

Fiber-like particles enhance strength but reduce specific surface area.

-

The optimized Al2O3 aerogel composites possessed a thermal conductivity of 0.136 W/m K at 1000 °C.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Aerogels, as a kind of nanoporous material with a high porosity of more than 90%, are synthesized by the sol–gel method and supercritical drying [1, 2]. Silica (SiO2) aerogel and the derivatives [3,4,5] have a long history and are the most widely explored aerogels. However, these aerogels decompose and/or sinter at a relative high temperature [6]. Alumina (Al2O3) aerogel exhibits the enhanced thermal stability which is better than those of the other oxide aerogels, e.g., zirconia [7], titania (TiO2) [8], and niobia [9]. In addition, Al2O3 aerogel exhibits ultralow thermal conductivity [10] and excellent catalytic activity [11]. Due to the fascinating properties, Al2O3 aerogel has great potential applications as high-temperature thermal insulator and catalyst [12]. Generally, the practical applications of aerogel have always been restricted due to their instinctive fragility and sintering behavior upon high temperature. Unfortunately, it is no exception to Al2O3 aerogel if it is used under loading and/or high temperature. Thermal conductivity of Al2O3 aerogel shows drastic increase after heat treatment above 800 °C (0.298 W/m K) [13]. Therefore, the mechanical strength and thermal stability of Al2O3 aerogel need to be further improved.

Kucheyev et al. [14] demonstrated that Al2O3 aerogel with excellent mechanical properties can be made by elaborately tuning the crystallographic phase, particle shape, and size of nanoligaments in the aerogel. Zu et al. [15, 16] casted SiO2 thin film on the skeleton of Al2O3 aerogel via a post-gelation method to form an Al2O3 core-SiO2 shell structure. The created core–shelled structure improves the mechanical properties of Al2O3 aerogel. The Young’s modulus of the core–shelled Al2O3 aerogel is as high as 6.7 MPa, which is nearly four times higher than that of the pristine one. However, those methods are sophisticated and time consuming. It is worth noting that earlier studies have shown that mechanical strength and thermal stability can be improved by the addition of dopants. Hurwitz et al. [17] proposed Al2O3–SiO2 diphasic aerogel. The obtained diphasic aerogel at an Al2O3:SiO2 ratio of 3:1 retains mesoporous structure up to a very high temperature of 1200 °C. Benad et al. [18] created a robust Al2O3-based diphasic aerogel via combining the toughness of Al2O3 and the hardness of ZrO2. With 20 mol% ZrO2 dopants, Young’s module of the diphasic aerogel reaches a maximum of 10.8 MPa.

TiO2 is an efficient opacifier due to its high reflection index and strong broad-band adsorption [19,20,21,22]. It also can be used as dopants for modifying Al2O3 aerogel. Some works on Al2O3–TiO2 diphasic system have reported. Hurwitz et al. [22] proposed the addition of TiO2 influences the viscosity and gelation time of boehmite sol as well as the specific surface area (SSA), pore size distribution (PSD), and crystalline phase of Al2O3 aerogel. However, boehmite powders were adopted as Al2O3 source in their synthesis routes during which the homogeneous distribution of TiO2 could not be realized. In order to obtain a more uniform doping, Wang et al. [23] prepared Al2O3–TiO2 diphasic aerogel by using potassium titanate and tetrabutyl titanate as precursors. According to the study [24], high-concentrated (≥40 mol%) TiO2 dopants within Al2O3 aerogel result in phase separation, during which TiO2 grows into crystalline anatase particles. On the contrary, when the concentration of TiO2 is low enough, TiO2 is homogeneous dispersed in Al2O3 aerogel matrix. Erkalfa et al. [25] proposed that, when the concentration of TiO2 in Al2O3 is less than 17.5 mol%, TiO2 is substantially dissolved in Al2O3 aerogel. Although the synthesis of Al2O3–TiO2 diphasic aerogels was well explored, their mechanical strengths and thermal properties upon high temperature were not fully studied. Since Al2O3–TiO2 diphasic aerogels are brittle and shrunken when being subjected to loading and high temperature, the knowledges of their mechanical and thermal properties are still of interest for technical applications as well as theoretical researches.

Herein, in this work, we first synthesized a series of Al2O3 aerogels with and without minor TiO2 dopants (up to 10 mol%) for realizing a homogeneous dispersion of TiO2 in Al2O3 aerogels. Then, the mechanical strengths and pore structures of the synthesized aerogels and the aerogels heat-treated at 1000 °C were comprehensively studied. The changes of physical properties of the Al2O3 aerogels due to TiO2 dopants were evaluated and the corresponding mechanism was proposed. At last, magnesium silicate ceramic fibers reinforced Al2O3 aerogel composites with the sizes of 20 cm width × 20 cm length × 1 cm thickness were fabricated for investigating thermal conductivity and possibility for the use as high-temperature thermal insulator.

2 Experimental section

2.1 Chemicals

All reagents were of analytical grade or higher and used as received without further purification. Aluminium chloride hexahydrate (AlCl3∙6H2O, Aladdin, AR, 97%), butyl titanate (TBOT, Kemiou, 98%), anhydrous ethanol (EtOH, Fuyu, 99.5%), Nitric acid (68%, Kangde), distilled water (DI water), propylene oxide (PO, aladdin, 99%), magnesium silicate ceramic fibers (Luyang Energy-Saving Materials Co., Ltd.).

2.2 Synthesis of Al2O3–TiO2 diphasic aerogels

In a typical synthesis, 4.83 g AlCl3∙6H2O was dissolved in 17.6 ml of a 50/50 v/v mixture of DI water and EtOH. In other bakers, 0.296, 0.430, and 0.882 ml TBOT was dissolved into a certain amount of EtOH at room temperature respectively. Nitric acid was added dropwise into the TiO2 sol to reduce the hydrolysis and polycondensation rate. The molar ratio of TBOT:EtOH:nitric acid was set as 1:19.1:0.42. Finally, Al2O3 and TiO2 sols were mixed to produce a bi-component sol in which the mole fractions of TiO2 were 3, 5, and 10 mol%, respectively. Subsequently, 5.7 ml of PO was added into the sol under vigorous stirring for 10 min. The gelation occurred within about 25 min under room temperature. After gelation, the wet gels were demolded, aged, and solvent exchanged with EtOH for a few days. Then the wet gels were put into an autoclave containing certain amount of EtOH. After it was sealed, ultrapure, dry nitrogen gas was flushed in the autoclave to produce an oxygen free atmosphere and as a safety precaution. The autoclave temperature was raised to 270 °C while the pressure rose and was controlled at ∼9 MPa for 2 h, and the autoclave was then decompressed slowly at a rate of 30 kPa/min. Finally, the system was cooled to room temperature naturally and the aerogels were removed. The pure Al2O3 aerogel and those with 3, 5, and 10 mol% TiO2 dopants were denoted as A, A-3T, A-5T, and A-10T, respectively.

2.3 Synthesis of fiber reinforced aerogel composites

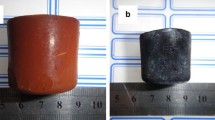

First, raw magnesium silicate ceramic fibers were cut into pieces with the sizes of 20 cm length × 20 cm width × 1 cm thickness. After being degassed in a self-made vacuum apparatus for 10 min, they were impregnated with A and A-10T sol, from which the samples were donated as A-fiber and A-10T-fiber, respectively. Ensuring no bubbles coming out from the composites any more, the composites within modules were proceeded to gelation under room temperature. The gelation times of the composites were a little longer than those of pure aerogels. After total gelation, the wet composited bodies were solvent exchanged, aged, and supercritical dried to obtain fiber reinforced aerogel composites.

2.4 Characterization

The XRD was performed on a Bruker D8 advance X-ray diffractometer at 40 kV and 100 mA with CuKα (λ = 1.540598 Å) radiation, employing a scanning rate 5° per min in the 2θ ranging from 10° to 80°. The IR spectra were recorded on a Nicolet 5DX-FT-IR spectrometer using the KBr pellet method in the range of 4000–375 cm−1. Super-critically dried aerogels were characterized by physical measurement to determine shrinkage and physical densities. Nitrogen gas adsorption–desorption at 77 K measured by JW-BK112 surface area and pore size analyzer after the samples were evacuated at 180 °C for 5 h under vacuum. The PSD and the pore volume (PV) were determined via the BJH (Barret–Joyner–Halenda) method from the adsorption curve. Transmission electron microscopy (TEM) images were recorded using a JEM-200CX electron microscope operating at 20 kV. Compressive strength of the aerogel was measured by using a WDW-5 Electronic Testing Machine under a quasi-static condition at a cross head speed of 1 mm/min. The thermal conductivities were measured by a high temperature thermal conductivity tester (DRS-III).

3 Results and discussion

The crystal phases of the as-dried aerogels were investigated first. Figure 1 provides the XRD patterns for pure Al2O3 aerogel and those with TiO2 dopants. The pure Al2O3 aerogel showed crystalline boehmite phase with broad diffraction peaks, indicating small crystallite sizes of the boehmite. The diffraction peaks at 14.3°, 28°, 38.2°, 49.3°, 64.9°, and 71.8° were matched well with boehmite (JCPDS.21-1307). With TiO2 dopants, no crystalline TiO2 was found in all doped aerogels but the crystalline boehmite. With the increase of TiO2 dopants, the diffraction peak at 14.8° and 71.8° disappeared. As the continuous increase of TiO2, the diffraction peak at 38.2° gradually vanished, indicating that the crystallization of boehmite was inhibited. According to the study [26], in aqueous, Al3+ ions exist as the unhydrolyzed species of [Al(OH)6]3+ below pH = 3; with increasing pH, [Al(OH2)6]3+ hydrolyzes into [Al(OH)h(OH2)6−h](3−h)+ (h = 0–4) which is the building block for crystalline boehmite. As shown in the following section, Fig. 3e exhibits the crystalline structure of boehmite; seen from the picture, crystalline boehmite consists of arranged [AlO6] octahedra which maybe derived from the hydrolysis and polycondensation of the [Al(OH)h(OH2)6−h](3−h)+. It is reasonable to presume that any factors affecting the hydrolysis and polycondensation of [Al(OH)h(OH2)6−h](3−h)+ are capable to influence the crystallization of boehmite. During our experiment, we tested the initial pH value after mixing Al2O3–TiO2 bi-component sol and they were 2.75, 2.49, 2.15, and 1.89 for A, A-3T, A-5T, and A-10T, respectively, mainly due to the acidities of TiO2 sol (i.e., both the nitric acid and TBOT are acidic in TiO2 sol). The added PO gel initiator increased the pH value of the bi-component sol, as a consequence, both [Al(OH)h(OH2)6−h](3−h)+ and TBOT were proceeded to hydrolysis and condensation. As we measured the decreased pH value upon the addition of TiO2 sol, it could be deduced that, the hydrolysis and polycondensation of [Al(OH)h(OH2)6−h](3−h)+ were retarded to some extent, resulting in the inhibited crystallization of boehmite. On the other hand, according to the sol–gel chemistry of transition metal oxides [27], the introduced nitrate ions within TiO2 sol would serve as complexed ligands toward [Al(OH)h(OH2)6−h](3−h)+, decreasing the reactivity of hydrolysis and condensation. Herein, it would expect that the introduced nitrite ion is another factor accounting for the inhibited crystallization of boehmite. After heat treatment at 1000 °C for 2 h, as shown in the diffraction patterns (Fig. 1b), phase transition occurred in the pure Al2O3 aerogel. The Al2O3 aerogel changed from boehmite to γ-Al2O3/θ-Al2O3. As consequences of TiO2 doping, γ-Al2O3 was observed as the main phase in the doped Al2O3 aerogels, indicating that TiO2 hinders the phase transition of the Al2O3 aerogel to a certain extent. Although the heat-treatment was implemented at a high temperature of 1000 °C and a long duration of 2 h, the crystalline TiO2 was not observed in the doped Al2O3 aerogels that supports the fact that there is no segregation or agglomeration of the secondary phase of TiO2 if the doped concentration is low. As a result, the homogeneous and advantageous structure developed during sol–gel process was preserved. γ-Al2O3 has a cation-deficient spinel structure and can easily react with metal oxides [28]. Therefore, we suggested that TiO2 dopants may stabilize the oxygen lattice and there with retard the phase transition of γ-Al2O3 to θ-Al2O3. A similar conclusion has also been reported by Smith et al. [29] and Sun et al. [30].

Figure 2 shows the FT-IR spectra of pure Al2O3 aerogel and those with TiO2 dopants before and after heat-treatment. As shown in Fig. 2a, the bands at 3423 and 1630 cm−1 are ascribed to –OH stretching and H–O–H bending vibration, respectively [31], indicating the presence of surface hydroxyls and absorbed water molecules. For the pure Al2O3 aerogel, the bands at 1068, 735, 616, and 473 cm−1 are the characteristic adsorption bands of boehmite due to [AlO6] octahedrons [15]. The small band near 870 cm−1 indicates the presence of some [AlO4] species [32]. Upon the doping of TiO2, the above-mentioned adsorption peaks, which are ascribed to [AlO6] octahedrons and [AlO4] tetrahedrons, were also detected and contributed by boehmite. However, the peak intensities weakened obviously, indicating the inhibited crystallization due to the TiO2 dopants. In addition, the decreased intensity of the peak at 3090 cm−1, which had been assigned to the –OH stretching of AlOOH [22], further proves the incorporation of TiO2 deteriorating the crystallinity of boehmite. As shown in Fig. 2b, after heat-treatment at 1000 °C, the characteristic peaks of boehmite disappeared. A broad band at 500–1000 cm−1 appeared and could be assigned to the characteristic [AlO4] tetrahedrons in γ-Al2O3 [32]. The absorption bands at 547 and 612 cm−1 are attributed to the O–Al–O bending and A–O stretching vibrations of [AlO6] octahedrons. The peaks demonstrate the phase transition from boehmite to γ-Al2O3 which is basically consistent with those results of XRD.

TEM was used to understand the microstructures of pure Al2O3 aerogels and TiO2-doped Al2O3 aerogels. As shown in Fig. 3a, the pure Al2O3 aerogel consisted of fiber-like particles with the diameters of 2–5 nm and the lengths of 30–80 nm. The fiber-like particles were interconnected into a complicated network. During the formation of boehmite fibers, some polymeric clusters (<1 nm), which contained [AlO6] octahedra, would form first via the hydrolysis and polycondensation of the mentioned [Al(OH)h(OH2)6−h](3−h)+. These clusters are likely to continue to grow via various growth mechanisms, e.g., Ostwald ripening and Oriented attachment. As shown in Fig. 3e, the crystal structure of boehmite consists of [AlO6] octahedra arranged in parallel layers linked by the hydrogen bonds of interstitial water molecules a long [010] direction. Due to the weak hydrogen bonds, thermodynamically, it is easy for the polymeric clusters to continue to grow along [010] direction via the formation of hydrogen bonds, resulting a preferential growth and one-dimensional boehmite with fiber-like morphology. Based on theoretical calculations, Mercuri et al. [33] also demonstrated that one dimensional boehmite along [010] direction is more preferential than the others of growth directions due to the high surface energy of (010) facets. Herein, the fiber-like particles are possibly because of the preferential and directional crystal growth of boehmite. However, significant variations on particle morphologies were observed upon the doping of TiO2. As shown in Fig. 3b, with the increase of TiO2 dopant, unlike the pure Al2O3 aerogel that is composed of fiber-like particles, the A-3T changed into very fine fibrous and spherical particles. With the further increase of TiO2 dopants, the fiber-like particles gradually decreased and replaced by some spherical particles. With 10 mol% TiO2 dopants, the fiber-like particles were rarely observed in the TEM image (Fig. 3d). The skeleton of A-10T was comprised of loose connected spherical particles as shown in Fig. 3d. Herein, it could be concluded that the incorporation of TiO2 significantly changes the morphologies of the particles within Al2O3 aerogel. The morphology evolutions shown in TEM are correlative with the XRD and IR results in which show that TiO2 dopants inhibit the crystallization of boehmite. Based on the correlation, it can ascribe the transition from fiber-like morphology to sphere-like morphology to the inhibited crystallization of boehmite. The morphologies transitions of Al2O3 aerogels due to metal cation dopants have been found in other works, e.g., shuttle-like particles in Fe3+-doped Al2O3 aerogel [34], honeycomb mesh structure in Ni2+-doped Al2O3 aerogel [35]. The morphologies of the pure Al2O3 aerogel and those with TiO2 dopants heat-treated at 1000 °C for 2 h were also studied via TEM. The pure Al2O3 aerogel retained the fiber-like particles with the thicknesses of 2–6 nm, larger than that of the non-heat-treatment. For the aerogel with TiO2 dopants, the sphere-like particles all turned into fiber-like particles, maybe due to the enhanced crystallization which had been proved by XRD measurements. As for A-3T and A-5T, the aerogels showed fiber-like particles with the thicknesses of 1–5 nm. They were 3–8 nm for the A-10T, larger than that of the pure Al2O3 aerogel.

The microstructural differences resulted in varying mechanical properties. The mechanical properties of Al2O3 aerogels were determined via uniaxial compress test. Before the test, the densities were calculated from the measured weight divided by the volume. Due to the inherent fragility, the failures of Al2O3 aerogels showed a certain randomness. For reliable compress test results, each compressive strength was determined by six samples. The stress–strain curves (Fig. S1) are typical brittle material characters that the stresses were suddenly dropped down when loads exceeded specific values. The values were identified as the compressive strengths. The results of mechanical strengths are shown in Fig. 4. As shown in Fig. 4a, the densities of pure Al2O3 aerogel, A-3T, A-5T, and A-10T aerogels were 0.109 ± 0.001 g/cm3, 0.127 ± 0.002 g/cm3, 0.138 ± 0.001 g/cm3, and 0.151 ± 0.002 g/cm3, respectively. Although, the densities increased with the increase of TiO2 dopants, pure Al2O3 aerogel was more robust (0.23 MPa) than those with TiO2 dopants (0.02–0.17 MPa). The Young’s moduli decreased with the increase of TiO2 dopants, showing the same trend as to the compressive strength. Yoldas et al. [36] pointed out that the mechanical behavior depends on the connectivity of secondary particle. Poco et al. [37] proposed that the high crystallinity and the highly connected fiber-like particles of boehmite maybe responsible for the enhanced mechanical properties. In terms of our compressive strength results, it also can be concluded that Al2O3 aerogel with the fiber-like particles (i.e., pure Al2O3 aerogel) is significantly stiffer and more robust than those with the sphere-like particles (i.e., those with TiO2 dopants). When being under loading, the Al2O3 aerogel with fiber-like particles was pressed tightly and the fibers interweaved with each other to strengthen mechanical properties. Therefore, the better mechanical strength of our pure Al2O3 aerogel compared to those with TiO2 dopants is maybe due to the interconnected fiber-like particles. Diphasic aerogels, e.g., Al2O3–C [38] and Al2O3–SiO2 [39], were claimed that have enhanced mechanical strengths compared to that of the individual Al2O3 aerogel. With Al2O3–C diphasic aerogel as example, it exhibited a fiber-like particles/sphere-like particles hybrid network. The interactions between boehmite nanofibers were enhanced via the incorporated sphere-like particles. Herein, these diphasic aerogels performed enhanced mechanical strengths. For our studies, with increasing TiO2 dopants, the boehmite fiber-like particles themselves turned into spherical particles rather than the fiber-like particles/sphere-like particles hybrid network. We think the decreased mechanical properties as the doping of TiO2 is reasonable.

For further exploring the origin of mechanical robustness of Al2O3 aerogel, these aerogels were heat-treated at 1000 °C for 2 h. The mechanical strengths were studied. Figure 4b collects the evolutions of densities, compressive stresses, and moduli of the aerogel after heat-treatment. The densities of pure Al2O3 aerogel, A-3T, A-5T, and A-10T aerogels were 0.135 ± 0.007, 0.153 ± 0.005, 0.164 ± 0.006, and 0.187 ± 0.005 g/cm3, respectively, larger than those without heat-treatment, indicating the densifying of aerogels during heat-treatment. Correspondingly, the mechanical strengths were overall enhanced. The compressive strength of pure Al2O3 aerogel was 0.27 ± 0.03 MPa, slightly larger than that without heat-treatment. The strengths of A-3T and A-5T aerogels showed a decrease compared to that of pure Al2O3 aerogel. However, the strength of A-10T aerogel was 0.26 ± 0.02 MPa, presenting a bounce as compared to those of A-3T and A-5T aerogel. Even, its Young’s modulus dramatically increased to 8.3 MPa, much larger than other Al2O3 aerogel, indicating the highest stiffness among the Al2O3 aerogels. Combining the TEM results, the increase of mechanical strength of A-10T compared to those of A-3T and A-5T comes from two following reasons: (1) the sphere-like particles turned into the fiber-like particles; (2) the connections between particles were enhanced as shown in the TEM results. The findings further prove the fiber-like particles enhance the strength of Al2O3 aerogel.

Figure 5a shows N2 adsorption/desorption isotherms and PSDs of Al2O3 aerogels before heat-treatment. The Al2O3 aerogels exhibited type IV isotherm curves with type H1 hysteresis loop. At a relative low pressure of 0–0.8, the gradual rises of adsorption volume result from multilayer adsorption on the external surface of pores. The abrupt increase stages and the hysteresis loops between 0.8 and 1.0 are attributed to the capillary condensation of N2 molecules in mesopores with the diameters of 2–50 nm. When relative pressure closed to 1, the adsorption was still unsaturated, indicating macropores with the diameters larger than 50 nm. Although the isotherms (Fig. 5a) demonstrated the characters of meso- and macro-pores within the pure Al2O3 and A-3T aerogels; however, as shown in Fig. 4c, the PSD curves showed nonobvious peak during the range of mesopores. With the further increase of TiO2 dopants, the Al2O3 aerogel performed typical mesoporous characters with some adsorption peaks located in the range of 20–60 nm. This is due to the fiber-like particles gradually turned into sphere-like particles. The fluffy accumulation between fiber-like particles is easy to form macropores; the compact packing of sphere-like particles is more likely to form micro- and meso-pores in terms of geometry. The SSA, PV, and pore diameter are listed in Table 1, the SSA of Al2O3 aerogels with TiO2 dopants improved significantly as compared to that of pure Al2O3 aerogel. The SSA of A-3T was 650 m2/g, nearly two times larger than that of the pure Al2O3 aerogel (326 m2/g). The PVs of Al2O3 aerogels with TiO2 dopants were larger than that of the pure Al2O3 aerogel. The sphere-like particles morphology may contribute to the high SSAs and high PVs of Al2O3 aerogels with TiO2 dopants. Even after heat-treatment at 1000 °C, the Al2O3 aerogels with TiO2 dopants performed higher PVs and higher SSAs than those of pure Al2O3 aerogel as shown in Table 1.

Al2O3 aerogel and its derivatives are considered as the potential candidates of high temperature thermal insulating materials. In purpose of determining thermal conductivities, we built composite structures which consist of Al2O3 aerogels and magnesium silicate ceramic fibers. After sol–gel and supercritical drying process, Al2O3 aerogel composites were achieved. Such composite configuration improved both the ease of handling and the overall thermal resistance of aerogels. As shown in Fig. 6, the densities of fiber blanket, Al2O3 aerogel composites and Al2O3 aerogel composites with TiO2 dopants were 0.139, 0.278, and 0.279 g/cm3, respectively; the thermal conductivity of the fiber reinforced Al2O3 aerogel composite at 1000 °C was 0.158 W/m K, which was much lower than that of the ceramic fiber blanket (0.30 W/m K). Although the density of the aerogel composite was larger than that of the ceramic fiber blanket, the thermal insulating performance of the aerogel composite seems to be much better than that of the ceramic fiber blanket. This is because the impregnation of Al2O3 aerogel greatly restricts the convection heat transfer of gas within the composite [16]. The influence of skeleton heat transfer of Al2O3 aerogel within the composite could be almost omitted. Moreover, we found that doping of TiO2 could further improve thermal insulating performance, endowing the composites a lowest thermal conductivity of 0.136 W/m K at 1000 °C. The low thermal conductivity of the fiber reinforced Al2O3 aerogel composite with TiO2 dopants at 1000 °C is lower than the pure Al2O3 aerogel (0.298 W/m K at 800 °C [13]) as well as other thermal insulation materials such as Al2O3 aerogel/mullite fiber composite (0.16 W/m K) [16], commercial polycrystalline mullite fiber (0.30 W/m K) [16], porous chamotte (0.28 W/m K) [40], indicating its potential application as high-temperature thermal insulator.

4 Conclusions

In summary, we synthesized and studied a series of Al2O3 aerogels with and without TiO2 dopants. The main conclusions are as follow:

- (1)

The pure Al2O3 aerogel, which had the fiber-like particles, was stronger than those with TiO2 dopants that presented the sphere-like particles. The sphere-like particles turned into fiber-like particles after heat-treatment accompanied with the enhanced mechanical strengths of the TiO2-doped Al2O3 aerogel.

- (2)

The sphere-like particles of TiO2-doped Al2O3 aerogel contributed the largest SSA (648 m2/g), much larger than that of the pure Al2O3 aerogel (326 m2/g). Herein, it can be concluded that the fiber-like particles enhance strength but reduce SSA.

- (3)

The thermal conductivity of ceramic fibers reinforced Al2O3 aerogel composite with 10 mol% TiO2 dopants possessed a thermal conductivity of 0.136 W/m K at 1000 °C, indicating the potential application as high-temperature thermal insulator.

References

Hüsing N, Schubert U (2010) Aerogels-airy materials: chemistry, structure, and properties. Angew Chem Int Ed 37:22–45

Dorcheh AS, Abbasi MH (2008) Silica aerogel; synthesis, properties and characterization. J Mater Process Tech. 199:10–26

Zu G, Shimizu T, Kanamori K, Zhu Y, Maeno A, Kaji H, Shen J, Nakanishi K (2018) Transparent, superflexible doubly cross-linked polyvinylpolymethylsiloxane aerogel superinsulators via ambient pressure drying. ACS Nano 12:521–532

Zu G, Kanamori K, Maeno A, Kaji H, Nakanishi K (2018) Superflexible multifunctional polyvinylpolydimethylsiloxane-based aerogels as efficient absorbents, thermal superinsulators, and strain sensors. Angew Chem Int Ed 57:9722–9727

Zu G, Kanamori K, Shimizu T, Zhu Y, Maeno A, Kaji H, Nakanishi K, Shen J (2018) Versatile double-cross-linking approach to transparent, machinable, supercompressible, highly bendable aerogel thermal superinsulators. Chem Mater 30:2759–2770

Emmerling A, Gross J, Gerlach R, Goswin R, Reichenauer G (1990) Isothermal sintering SiO2-aerogels. J Non-Cryst Solids 125:230–243

Dong JS, Park TJ (1996) Sol–gel strategies for pore size control of high-surface-area transition-metal oxide aerogels. Chem Mater 8:509–513

Suh DJ, Park TJ, Han HY, Lim JC (2002) Synthesis of high-surface-area zirconia aerogels with a well-developed mesoporous texture using CO2 supercritical drying. Chem Mater 141:452–1454

Campbell LK, Na BK, Ko EI (1992) Synthesis and characterization of titania aerogels. Chem Mater 4:1329–1333

Keysar S, Shter GE, Hazan YD, Cohen AY, Grader GS (1997) Heat treatment of alumina aerogels. Chem Mater 9:2464–2467

Hirashima H, Kojima C, Imai H (1997) Application of alumina aerogels as catalysts. J Sol–Gel Sci Technol 8:843–846

Pierre AC, Pajonk GM (2002) Chemistry of aerogels and their applications. Chem Rev 102:4243–4265

Xu L, Jiang Y, Feng J, Feng J, Yue C (2015) Infrared-opacified Al2O3-SiO2 aerogel composites reinforced by SiC-coated mullite fibers for thermal insulations. Ceram Int 41:437–442

Kucheyev SO, Baumann TF, Cox CA, Wang YM (2006) Nanoengineering mechanically robust aerogels via control of foam morphology. Appl Phys Lett 89:041911

Zu G, Shen J, Zou L, Wang W, Lian Y, Zhang Z, Du A (2013) Nanoengineering super heat-resistant, strong alumina aerogels. Chem Mater 25:4757–4764

Zu G, Shen J, Wang W, Zou L, Lian Y, Zhang Z, Liu B, Zhang F (2014) Robust, highly thermally stable, core-shell nanostructured metal oxide aerogels as high-temperature thermal superinsulators, adsorbents, and catalysts. Chem Mater 26:5761–5772

Hurwitz FI, Gallagher MT, Olin C, Shave MK, Ittes M, Olafson KN, Fields MG, Rogers RB (2014) Optimization of alumina and aluminosilicate aerogel structure for high-temperature performance. Int J Appl Glass Sci 5:276–286

Benad A, Jurries F, Vetter B, Klemmed B, Hubner R (2018) Mechanical properties of metal oxide aerogels. Chem Mater 30:145–152

Kwon YG, Choi SY, Kang ES, Baek SS (2000) Ambient-dried silica aerogel doped with TiO2 powder for thermal insulation. J Mater Sci 35:6075–6079

Kuhn J, Gleissner T, Schuster MCA, Korder S, Fricke J (1995) Integration of mineral powders into SiO2 aerogels. J Non-Cryst Solids 186:291–295

Wang J, Kuhn J, Lu X (1995) Monolithic silica aerogel insulation doped with TiO2 powder and ceramic fibers. J Non-Cryst Solids 186:296–300

Zhang H, Qiao Y, Zhang X, Fang S (2010) Structural and thermal study of highly porous nanocomposite SiO2-based aerogels. J Non-Cryst Solids 356:879–883

Yang J, Wang Q, Wang T (2017) Effects of Ti addition on alumina/titania composite aerogels synthesized by Sol–Gel process and supercritical ethanol drying. J Chin Chem Soc 64:978–985

Hurwitz FI, Rogers RB, Sheets EJ, Miller DR, Newlin KN (2012) Influence of Ti addition on boehmite-derived aluminum silicate aerogels: structure and properties. J Sol–Gel Sci Technol 64:367–374

Erkalfa H, Misirli Z, Baykara T (1998) The effect of TiO2 and MnO2 on the densification and microstructural development of alumina. Ceram Int 24:81–90

Baes CF, Mesmer RE (1976) The hydrolysis of cations. Wiley, New York

Livage J, Henry M, Sanchez C (1988) Sol–gel chemistry of transition metal oxides. Prog Solid State Chem 18:259–341

Bolt PH, Habraken FHPM, Geus JW (1998) Formation of nickel, cobalt, copper, and iron aluminates from α- and γ-alumina-supported oxides: a comparative study. J Solid State Chem 135:59–69

Smith JS (2012) The synthesis and structural characterization of metal oxide nanoparticles having catalytic applications. https://scholarsarchive.byu.edu/etd/3667. Accessed 3 July 2012

Sun X, Wu Y, Wang Y, Li M (2019) Investigation of the effect of lanthanum oxide on the thermal stability of alumina aerogel. J Porous Mater 26:327–333

Wu L, Huang Y, Wang Z, Liu L, Xu H (2010) Fabrication of hydrophobic alumina aerogel monoliths by surface modification and ambient pressure drying. Appl Surf Sci 256:5973–5977

Hurwitz FI, Rogers RB, Guo H, Yu K, Domanowski J, Schmid E, Fields MG (2017) The role of phase changes in maintaining pore structure on thermal exposure of aluminosilicate aerogels. MRS Commun 7:1–9

Mercuri F, Costa D, Marcus P (2009) Theoretical investigations of the relaxation and reconstruction of the γ-AlO(OH) boehmite (101) surface and boehmite nanorods. J Phys Chem C 113:5228–5237

Ren L, Li X, Cui S (2016) Synthesis of monolithic Fe2O3–Al2O3 composite aerogels via organic solvent sublimation drying. J Nanomater 2016:8135043

Li X, He H, Cui S, Ren L (2012) Synthesis and characterization of the monolithic NiO-Al2O3 aerogels. Am J Anal Chem 3:946–949

Yoldas BE (1992) In: Hench L, West JKChemical Processing of Advanced Materials. Wiley, New York

Poco JF, Satcher JH, Hrubesh LW (2001) Synthesis of high porosity, monolithic alumina aerogels. J Non-Cryst Solids 285:57–63

Zhong Y, Kong Y, Shen X, Cui S, Yi X, Zhang J (2013) Synthesis of a novel porous material comprising carbon/alumina composite aerogels monoliths with high compressive strength. Microporous Mesoporous Mater 172:182–189

Hayase G, Nonomura K, Kanamori K, Maeno A, Kaji H, Nakanishi K (2016) Boehmite nanofiber-polymethylsilsesquioxane core-shell porous monoliths for a thermal insulator under low vacuum conditions. Chem Mater 28:3237–3240

Saran G (2012) Investigation of refractory thermal insulation material. https://ieeexplore.ieee.org/abstract/document/6357515. Accessed 18–21 Sept 2012

Acknowledgements

This work was supported by the National Natural Science Foundations of China (No. 21603125), Shandong Provincial Natural Science Foundation of China (ZR2017BEM009), Youth Science Funds of Shandong Academy of Sciences (2018QN0031), Youth Science Funds of Qilu University of Technology (Shandong Academy of Sciences) (2018QNHZ02), and Science and Technology projects of Shandong Province (ZR2018LE003) are acknowledged for financial support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Gao, M., Liu, B., Zhao, P. et al. Mechanical strengths and thermal properties of titania-doped alumina aerogels and the application as high-temperature thermal insulator. J Sol-Gel Sci Technol 91, 514–522 (2019). https://doi.org/10.1007/s10971-019-05057-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-019-05057-5