Abstract

The aim of this study was the development of low-cost tannin-formaldehyde xerogel/TiO2 (XTi-w) and carbon xerogel/TiO2 (XTiC-w) photocatalysts. The materials used as precursors were recycled titanium scraps and black wattle tannin extract, highlighting the low-cost approach employed in the synthesis. The materials were characterized by diffuse reflectance spectroscopy, scanning electron microscopy, dispersive energy spectrophotometry, X-ray diffractometry, infrared and Raman spectroscopy. X-ray diffractometry showed that the XTiC-w have tetragonal crystalline structure (anatase), whereas the XTi-w has an amorphous structure. The Raman and infrared analysis also showed the presence of titanium dioxide in the composition of both XTi-w and XTiC-w. XTi-w and XTiC-w showed photocatalytic activity at the visible wavelength. Titanium dioxide displayed no photocatalytic activity at the visible wavelength. The XTi-60 composite displayed the highest efficiency in the removal of the methylene blue from the system, as well as good reusability properties. The radicals with higher influence in the photocatalytic reaction mechanism are the photo generated electron and the singlet oxygen molecule. The effect of the heat treatment is negative on the photocatalytic properties of the hybrids produced, due to the removal of acid sites, adsorbed water and OH surface groups.

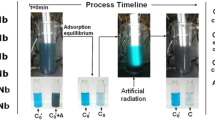

The graphical abstract displays an illustration of the materials obtained in this work and their respective efficiency in the adsorption and photocatalytic degradation of methylene blue under visible light.

Highlights

-

Hybrids were produced using low-cost materials, such as titanium scraps and tannin

-

Both hybrid materials showed photocatalytic activity at the visible wavelength

-

Heat treatment is negative on the photocatalytic properties of the hybrids

-

Reaction mechanism is controlled by trapped electrons and singlet oxygen molecules

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, environmental pollution is one of the most significant problems of contemporary civilization [1,2,3]. Based on this fact, a convergence of ideas toward what we can call the “ecologically correct” ideal can be perceived worldwide [4,5,6]. As a result, increasingly restrictive legislation has been adopted in order to minimize environmental impact [7, 8]. In this context, the study and development of new and efficient processes for effluent treatment is extremely important [9].

Advanced oxidation processes, or AOPs, are a promising alternative among effluent treatment processes due to their versatility [2, 10]. Among these AOPs, heterogeneous photocatalysis has been widely studied, mainly in the last decades [2, 11]. Photocatalytic processes can be used in the decontamination of effluents containing organic compounds, as this method allows the decomposition of these compounds into non-toxic molecules [12,13,14]. Titanium dioxide (TiO2), the photocatalyst generally used in this process, presents high photocatalytic activity when subjected to radiation in the ultraviolet region [15,16,17,18,19]. However, as only a small part of the solar radiation is composed of ultraviolet (UV) light, the use of artificial light sources is necessary for the photocatalytic process to occur, which is not economically feasible [20, 21].

The use of carbon xerogel as a support for TiO2 is a promising way to increase the efficiency of the photocatalytic process due its high surface area and high electrical conductivity, providing higher adsorption of molecules (fundamental step for photodegradation) and improving semiconductor light sensitivity [22].

The most common organic xerogels are produced by the evaporative drying of the product resulted from the polycondensation of resorcinol (high-priced synthetic molecule) with formaldehyde, in the presence of a catalyst [23, 24]. One way of avoiding the high production costs is the use of cheaper precursor materials. Natural condensed tannins may be a suitable alternative [23, 25]. Tannin is well known for being a low-cost and ubiquitous biomass that can be easily extracted from the bark of some trees [22, 26]. The black wattle tannin is a macromolecule that has a polyhydroxyphenolic structure, so its reactivity with formaldehyde is very similar to that of resorcinol [27, 28].

The synthesis proposed in this work aims at developing an environmental and economical effective material, evidenced by the use of low-cost precursors, such as tannin and recycled titanium scraps, obtained as waste material from the industrial machining of titanium. Therefore, it will be evaluated for the synthesis and photocatalytic efficiency of the hybrids tannin-formaldehyde xerogel/TiO2 and carbon xerogel/TiO2, specifically in the decomposition of the organic dye known as methylene blue.

2 Methodology

2.1 Preparation of tannin-formaldehyde xerogel/TiO2 and carbon xerogel/ TiO2 hybrids

The tannin-formaldehyde xerogel/TiO2 hybrid was prepared at room temperature. Initially, 14.1 g of black wattle tannin extract (PHENOTAN AP®, TANAC SA) and 120 g of deionized water were mixed. After complete dissolution of the PHENOTAN AP®, a solution of titanium ions, prepared by dissolving a pre-defined mass of recycled titanium scraps in HNO3 and HF, as described by Moraes et al. [29], and 15 mL of formaldehyde (37% w/w) were added to the reaction. Finally, a NH4OH solution (1:3 v/v) was added until pH = 10 was achieved. The formed material was washed to pH 7 and oven dried at 100 °C.

The proportion of Ti in the hybrid material was gradually increased by the addition of a higher amount of titanium ions and NH4OH during the preparation. Such materials are identified by the acronym XTi-w, where w is the mass percentage of TiO2 expected in the hybrid material. The amount of metallic titanium, acids and NH4OH used in the preparation of each material is listed below:

-

XTi-50: prepared by the dissolution of 5556 g of metallic titanium in 11 mL of HF (40% w/w), 5.5 mL of HNO3 (65% w/w) and 33 mL of H2O. Addition of 160 mL of NH4OH solution.

-

XTi-60: prepared by the dissolution of 8333 g of metallic titanium in 17 mL of HF (40% w/w), 8.5 mL of HNO3 (65% w/w) and 50 mL of H2O. Addition of 270 mL of NH4OH solution.

-

XTi-80: prepared by the dissolution of 22,222 g of metallic titanium in 45 mL of HF (40% w/w), 22.5 mL of HNO3 (65% w/w) and 135 mL of H2O. Addition of 700 mL of NH4OH solution.

The carbon xerogel/TiO2 hybrids were prepared by the calcination of the XTi-w materials. To this end, each XTi-w was treated thermically in a muffle furnace at 300 °C for 1 h. The calcined materials achieved will be identified by the acronym XTiC-w, where w represents the predicted mass percentage of TiO2 in the hybrid material. A material without metallic titanium was also prepared, using the same methodology proposed above. This material will be named XTF and its calcined counterpart XC.

2.2 Characterization

Crystalline structure was investigated by X-ray diffraction (XRD), using a PANalyticalX’Pert PRO MPD 3060 diffractometer, equipped with an X’celerator detector, operating at 40 kV and 30 mA with MoKα radiation. XRD patterns were collected in the 2θ range from 10 to 70° at step size of 0.026°.

Sample morphology was observed in a scanning electron microscope, HITACHI model TM-3000.

Energy dispersive spectroscopy (EDS) measurements were carried out in an Oxford INCA Energy Microanalysis System incorporated to SEM.

UV–vis diffused reflectance spectra were collected in a UV–vis spectrophotometer (Shimadzu UV-2600) with an integrating sphere attachment.

The infrared spectra were acquired by Fourier transform infrared spectroscopy using a universal attenuated total reflectance sensor (FTIR-UATR) (Perkin Elmer Spectrum, model Frontier). The resulting FTIR spectra are an average of 16 scans at a speed of 2 s per scan in the range of 450–4000 cm−1. The resolution of the spectrometer was set to 4 cm−1

Raman spectra of the materials were collected with a LabRAM HR Evolution model Raman Spectrophotometer (Horiba) equipped with a camera and using an Ar laser (532 nm). The spectra were recorded between 50 and 2000 cm−1 with acquisition time of 30 s, two cycles and slit size of 100 μm.

2.3 Evaluation of catalytic activity in the photodegradation of methylene blue

The tests were performed in a jacketed reactor, with dimensions of 30 cm in height and 10 cm in internal diameter. A PL-L lamp was placed inside a quartz tube (4 cm in diameter and 40 cm in length) with a closed end, which was immersed in the reactor. The reactor was filled with a pre-determined catalyst mass and 500 mL of methylene blue solution with known concentration, at 25 °C, under magnetic stirring. Aliquots of 2 mL were collected at regular intervals and filtered through 0.22 μm disposable filters. The concentration of the methylene blue in the filtrate was determined spectrophotometrically at a wavelength of 673 nm. Initially, tests were performed to determine the time required for the adsorption–desorption equilibrium to be reached. After the adsorption–desorption equilibrium was reached, the samples were exposed to radiation from an artificial light source. The visible light source was an OSRAM L 36 W/954 2G11 lamp. The photocatalytic reaction was monitored for 300 min, and the concentration of the dye in the solution was determined spectrophotometrically at determined intervals [30].

The trapping experiments used the following scavengers: silver nitrate (AgNO3, 1 mmol), methanol (1% v/v), benzoquinone (BenzQ, 1 mmol), EDTA (1 mmol) and sodium azide (1 mmol). The tests were conducted using the same methodology proposed above.

3 Results

3.1 Characterization

The diffractogram for the hybrids XTi-w, XTiC-w, XTF and XC are show in Fig. 1.

The XTi-w, XTF and XC have a low crystallinity index, as suggested by the formation of a curve with considerable width rather than well-defined peaks. This result indicates the amorphous structure of the materials. The XC, however, presents a halo at approximately 26°, characteristic of the graphitic structure (002) [31]. XTiC-w hybrids presented characteristic peaks of the tetragonal phase of TiO2 [32], confirming the presence of TiO2 in the prepared materials.

The results of scanning electron microscopy for the XTi-w and XTiC-w are shown in Fig. 2. Figure 3 presents the element mapping of the prepared materials.

Both hybrid materials were composed of a series of particles of considerably large size (approximately 100 µm), over which smaller particles can be observed. A large particle size may be detrimental to the photocatalytic process, as it decreases the available surface area for the adsorption of the species to be degraded, which may decrease the efficiency of the direct photocatalysis mechanism [33].

The results for the EDS analysis show that all hybrids showed elemental peaks of carbon, oxygen and titanium. It is observed that, in the analyzed regions, the chemical elements that compose the samples are homogeneously distributed on their surfaces. The homogeneity of elemental distribution will be beneficial for charge transfer efficiency, decreasing the surface recombination and, therefore, enhancing the availability of electrons for the photocatalytic mechanism [34]. Only one elemental mapping for each group of materials (XTi-w and XTiC-w) is shown due to similarity between results obtained.

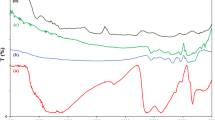

The absorption spectra in the infrared region for the XTi-w, XTiC-w, XTF and XC are shown in Fig. 4.

In the XTi-w, the band between 450 and 700 cm−1 corresponds to the Ti-O bridging stretch [35]. For the XTi-w and XTF, the band between 3000 and 3500 cm−1 is related to the water present in the material. The peak at 1440 cm−1 is attributed to Ti 4+ Lewis acid sites present on the material surface [36]. The band at 1630 cm−1 can be associated with the bending vibration of adsorbed water molecules (H2O-v2) on the surface of the material, whereas the band at 1700 cm−1 corresponds to the vibration of C=O groups. The band between 3000 and 3500 cm−1 is related to the hydrogen strongly bound to the OH group, characteristic of hydrogen bonds in carboxylic acids, phenolic groups and adsorbed water [37]. The bands at 1500 cm−1 (C=C) and 1000 cm−1 (C-O) are related to the presence of tri-substituted benzene rings. The band at 1200 cm−1 is related to the existence of C-O-C bonds, which can be found in the methyl ether bonds of tannin [38]. In the XTi-w, the peaks related to tri-substituted benzene and the C-O-C bond decrease with an increasing percentage of TiO2, indicating, accordingly, the reduction of the amount of xerogel in the matrix of the material.

The infrared IR spectrum of the XTiC-w and XC shows that the peaks at 1440 and 1630 cm−1 disappear with the heat treatment at 300 °C, indicating the elimination of some surface groups of the material. For all materials, there is a significant reduction in the band between 3500 and 3000 cm−1 due to the elimination of the adsorbed water in the material. In the XTiC-w, the band between 450 and 700 cm−1 corresponds to the Ti-O-Ti bridging, characteristic of well-organized TiO6 octahedra [35]. After the heat treatment, the amount of Lewis acid sites and adsorbed water decreases considerably, as seen by the decrease in the intensity of their relative peaks (1440, 1620 and 3000–3500 cm−1). As in the XTi-w, the 1200 cm−1 band is related to the existence of C-O-C bonds found in the methyl ether bonds of the tannin, whereas the band at 1500 cm−1 is relative to the presence of tri-substituted benzene rings. Also, the peaks related to tri-substituted benzene and the C-O-C bond decrease with a higher percentage of titanium oxide, indicating a reduction of the amount of xerogel in the material matrix.

The Raman spectra obtained for the XTiC-w and XC are shown in Fig. 5.

The XTiC-w and XC have two broad peaks centered at 1380 and 1580 cm−1. These positions are attributed to carbon D and G bands, respectively [38]. For the XTiC-w, the peaks at 150, 400, 516 and 640 cm−1 are characteristic of the tetragonal crystalline phase, or anatase, of the oxide [35]. The characteristic peaks of TiO2 decrease with a higher amount of carbon in the sample, being imperceptible in both the XTiC-50 and XTiC-60. One can also note that the ID/IG ratio in the XTiC-60 is lower than the ones found in the XTiC-50 and XTiC-80, which suggests the formation of material with a higher graphite particle size and superior crystallinity [39].

The spectra of the XTi-w and XTF did not present defined peaks; therefore, they will not be exposed in this work.

The absorption spectra obtained by diffuse reflectance for the XTi-w and XTiC-w are shown in Fig. 6.

The samples showed an intense transition in the UV region of the absorption spectra (below 400 nm), characteristic of the TiO2 [40]. Following the same synthesis methodology, Moraes et al. found that the pure TiO2 only absorbs radiation at wavelengths inferior to 400 nm [29]. Note that all hybrid materials can absorb radiation in a considerably wider range than the inorganic oxide; in this case, all materials present higher absorption in the entire range of wavelengths used. Among the hybrids, the XTiC-w absorbs more radiation in the visible range than the XTi-w. This is probably due to the higher conductivity of the calcined materials. In addition, the radiation absorption in the visible region increases with a higher amount of carbon in the material matrix, for both XTiC–w and XTi-w. It is also noticeable that the XTF absorbs considerably less radiation than the XTi-w in wavelengths superior to 400 nm. This behavior evidences the synergistic effect of xerogel and TiO2 on the optical properties of the materials, suggesting that the carbon enhances the charge transfer efficiency within and among the heterojunctions between the TiO2 and xerogel phases [37].

3.2 Photocatalytic activity

A high concentration of dye can influence the distribution of the radiation within the photocatalytic system, as the photons can be intercepted before they reach the surface of the catalyst. Considering this fact, the photocatalytic process was carried out at a low concentration of methylene blue (10 mg L−1) and catalyst (0.5 g L−1), so that these factors had a lesser influence in the scattering of light within the system.

Figure 7 shows the degradation curves obtained for this test. The shaded area in Fig. 7 represents the adsorption process. The time of t = 0 min represents the start of the photocatalytic experiment. It may be noted that, for all materials, the adsorption equilibrium was achieved before the artificial radiation source was initiated. Anhydrous TiO2, XTF and XC showed no photocatalytic capacity in the wavelengths tested.

It can be observed that, for all the hybrids, significant degradation of methylene blue was observed when the solution was submitted to visible light. This is caused by the increased radiation absorption in higher wavelengths, modified by the coupling between xerogel and semiconductor. This change can also be observed in the absorption spectrum of the hybrid, presented previously (Fig. 6). Also, the carbon matrix attached to the semiconductor may decrease the recombination process between electron and vacancy, probably due to its elevated electrical conductivity.

Concerning the methylene blue removal from the solution, the XTi-60 was the most efficient material, followed by its calcined counterpart. This is probably due to the lower content of carbon and TiO2 in the XTi-80 and XTi-50, respectively. Therefore, the XTi-60 presents the optimal synergy between the carbon matrix and TiO2, and will be used to evaluate the photocatalytic mechanism and recycling capability.

It can be also observed that, as the XTi-w, the XTiC-w has significant photocatalytic activity in the visible wavelength, however, a decrease in the removal efficiency of the methylene blue by materials subjected to calcination can be observed, when compared with their XTi-w counterparts. This result can be seen as an advantage, as the calcination process requires significant energy expenditure. Also, this fact can point that the amount of acid sites, adsorbed water and OH surface groups on the catalyst has an important role in the photocatalytic process, as the XTi-w has a higher quantity of these species than the XTiC-w. This influence can be attributed to the immobilization of the dye molecules by the acid sites, where they will react with the photo generated electrons and holes via direct photo-oxidation mechanism [33]. Also, the amount of adsorbed water molecules on the material may have a significant role in the formation of OH− radicals, which are necessary for the indirect mechanism of photodegradation [41].

When analyzing the photocatalysis process, it must also be taken into account the process of photolysis that occurs in parallel. This process consists in the degradation of the studied species caused only by the radiation applied in the system. If this event occurs significantly in the process, the obtained results can lead to erroneous conclusions about the photocatalytic efficiency obtained. For this reason, blank tests were performed, where no amount of the photocatalyst was added. It can be seen from the curve related to this test that the photolysis process did not manifest itself significantly when compared with the photocatalytic degradation present in the studied systems. The XTiC-50 was the exception, as the material presented no significant degradation capability after the calcination process. It is also worth noting that XTiC-50 displayed a significant reduction in its adsorption and degradation capacity, when compared with the XTi-50. This is probably due to the loss of oxygenated surface groups during the heat treatment of the material.

The model often applied to describe the kinetics of photocatalytic reactions is the simplified Langmuir–Hinshelwood, in the form of a pseudo first-order model, proposed in Eq. 1 [42].

Where: C0 is the concentration reached at the adsorption equilibrium (beginning of the photodegradation) and kapp the apparent specific velocity of the reaction.

The constant of Eq. 1 can be determined graphically using the graph ln(C0/C) versus t, where kapp can be calculated from the slope of the curve.

Considering that the materials adsorbed different amounts of methylene blue under the same operating conditions, the percentage of dye adsorbed at the end of the adsorption process will be calculated and shown in the tables related to the photodegradation kinetic parameters. Thus, a more detailed evaluation of the behavior of each material can be achieved.

The adsorbed percentage (%) can be determined by the following relation (Eq. 2) [43]:

Where: \(C{\prime}_0\) is the dye initial concentration (10 mg L−1).

Figure 8 shows the conversion obtained for each material, where the adsorption capacity was discounted. Table 1 presents the results obtained for the correlation of the experimental data to the proposed kinetic model.

Based on the degradation curves and the kinetic parameters obtained, it can be seen that the degradation process follows the kinetic model proposed. Also, the XTi-60 confirms its position as the best photocatalyst at the visible wavelength, due to its higher specific velocity.

Note that the calcination of the materials tends to reduce their kapp, proving that the heat treatment is not necessary to obtain or optimize the photocatalytic effect of the hybrid materials.

To determine the photocatalytic reaction mechanism, the influence of each active radical must be evaluated. Therefore, trapping experiments with the following scavengers were conducted: silver nitrate (AgNO3, e− scavenger), methanol (OH• scavenger), benzoquinone (BenzQ, \(O_2^{ \cdot - }\) scavenger), EDTA (h+ scavenger) and sodium azide (singlet oxygen scavenger) [44,45,46,47]. The tests were conducted for the XTi-60 and XTiC-60 photocatalysts. The results are shown in Figs. 9a, b.

In literature, it has been reported that the main active radical in TiO2 based photocatalysis is the hydroxyl radical (OH•) [48]. However, the results obtained here demonstrate that, for both the XTi-60 and XTiC-60, the main active radical is the free electron (e-) generated during the composite photoexcitation. This result corroborates the fact that, due to its elevated electrical conductivity, the carbon matrix attached to the TiO2 has the ability to capture the photo generated electrons and, therefore, diminish the recombination process and increase the photocatalytical efficiency of the process.

One can also notice that, for the XTi-60, the singlet oxygen has a significant influence in the photocatalytic process. This molecule is reported to be a strong oxidant agent for organic compounds [49]. The formation of this specie is reported to be caused by either hydroxyl (OH•) and/or superoxide radicals (\(O_2^{ \cdot - }\)) [50], as described by Eqs. 3–5.

As stated by Eqs. 3 and 5, the existence of OH• and acid sites are highly influential in the generation of the singlet oxygen molecule. Therefore, due to the XTiC-60 lower amount of acid sites, adsorbed water and OH surface groups, caused by the calcination process, the formation of the singlet oxygen may be inhibited, decreasing the XTiC-60 photocatalytic efficiency.

The tests where EDTA was used as a hole (\(h^ +\)) scavenger showed a significant increase in the photocatalytical efficiency, probably due to the increase of the recombination time generated by the hole trapping effect [51]. This result highlights the importance of the photo generated electron (e-) in the photocatalytic mechanism.

Therefore, the following mechanism can be used to describe the main photocatalytic mechanism involved in the methylene blue (MB) degradation by the XTi-60 [52].

In summary, due to the irradiation, the TiO2 present in the samples became photo-excited, which led to the transference of an electron (e−) from the valence band to the conduction band. This separation generates a hole (h+), positively charged [53]. Due to its high conductivity, the xerogel (both carbon and tannin-formaldehyde) will accept the generated electrons, diminishing the recombination process. This photo generated xerogel(e-) complex will react with the adsorbed methylene blue, causing its degradation. The electron may also react with oxygen on the material’s surface to generate the superoxide radical \(\left( {O_2^{ \cdot - }} \right)\). Also, the hole generated in the charge separation can react with water molecules, creating hydroxyl radicals (OH•). Both radicals will combine to generate the singlet oxygen molecule, which will also mineralize the methylene blue present in the system.

Recycle tests for the XTi-60 were performed by evaluating the methylene blue dye degradation efficiency under visible light source. The same XTi-60 sample was used in three process cycles (5 h each), being washed with deionized water after each cycle. The degradation efficiency of the catalyst obtained for all the three cycles is shown in Fig. 10.

The results show that the XTi-60 maintained its efficiency during the three cycles, therefore presenting a high stability and reusability, which is necessary for industrial applications.

4 Conclusion

It is concluded that the tetragonal crystalline structure (anatase) of TiO2 is present in the XTiC-w. XTi-w manifest themselves with low crystallinity index, indicating an amorphous material. It is also concluded that all hybrid materials exhibit photocatalytic activity in the visible wavelengths, which can be advantageous in industrial effluent treatment processes. XTi-w showed, generally, higher efficiency than the XTiC-w. The XTi-60 presented the highest photocatalytical efficiency and high stability in recycling tests. The main active radical in the photocatalytic mechanism is the photo generated electron, probably due to the carbon matrix high electrical conductivity. Acid sites, adsorbed water and OH− groups on the materials surfaces are important variables for the photocatalytical efficiency, due to their influence in the generation of the singlet oxygen molecule. The process of calcination of the hybrid materials at 300 oC did not lead to significant improvements in the photocatalytical properties of the composites, thus this thermal treatment can be considered dispensable.

References

Kasiri MB, Aleboyeh H, Aleboyeh a (2008) Degradation of Acid Blue 74 using Fe-ZSM5 zeolite as a heterogeneous photo-Fenton catalyst. Appl Catal B Environ 84:9–15. https://doi.org/10.1016/j.apcatb.2008.02.024

Etaiw SEH, El-bendary MM (2012) Degradation of methylene blue by catalytic and photo-catalytic processes catalyzed by the organotin-polymer 3∞[(Me3Sn)4Fe(CN)6]. Appl Catal B Environ 126:326–333. https://doi.org/10.1016/j.apcatb.2012.07.032

Thakur M, Sharma G, Ahamad T, Ghfar AA, Pathania D, Naushad M (2017) Efficient photocatalytic degradation of toxic dyes from aqueous environment using gelatin-Zr(IV) phosphate nanocomposite and its antimicrobial activity. Colloids Surf B Biointerfaces 157:456–463. https://doi.org/10.1016/j.colsurfb.2017.06.018

Bilal M, Asgher M, Parra-Saldivar R, Hu H, Wang W, Zhang X, Iqbal HMN (2017) Immobilized ligninolytic enzymes: an innovative and environmental responsive technology to tackle dye-based industrial pollutants – a review. Sci Total Environ 576:646–659. https://doi.org/10.1016/j.scitotenv.2016.10.137

Zhang S, Zhu D, Shi Q, Cheng M (2018) Which countries are more ecologically efficient in improving human well-being? An application of the index of ecological well-being performance. Resour Conserv Recycl 129:112–119. https://doi.org/10.1016/j.resconrec.2017.10.015

Baker L (2017) Of embodied emissions and inequality: rethinking energy consumption,. Energy Res Soc Sci 36:52–60. https://doi.org/10.1016/j.erss.2017.09.027

Rawat D, Sharma RS, Karmakar S, Arora LS, Mishra V (2018) Ecotoxic potential of a presumably non-toxic azo dye. Ecotoxicol Environ Saf 148:528–537. https://doi.org/10.1016/j.ecoenv.2017.10.049

Boyes SJ, Elliott M, Murillas-Maza A, Papadopoulou N, Uyarra MC (2016) Is existing legislation fit-for-purpose to achieve Good Environmental Status in European seas? Mar Pollut Bull 111:18–32. https://doi.org/10.1016/j.marpolbul.2016.06.079

Zeng Z, Chen S, Tan TTY, Xiao FX (2018) Graphene quantum dots (GQDs) and its derivatives for multifarious photocatalysis and photoelectrocatalysis. Catal. Today. 0–1. https://doi.org/10.1016/j.cattod.2018.01.005.

Flores N, Sharif F, Yasri N, Brillas E, Sirés I, Roberts EPL (2018) Removal of tyrosol from water by adsorption on carbonaceous materials and electrochemical advanced oxidation processes. Chemosphere. https://doi.org/10.1016/j.chemosphere.2018.03.028.

Ge M, Liu L, Chen W, Zhou Z (2012) Sunlight-driven degradation of Rhodamine B by peanut-shaped porous BiVO4 nanostructures in the H2O2-containing system. CrystEngComm 14:1038. https://doi.org/10.1039/c1ce06264f

Bandara J, Kuruppu SS, Pradeep UW (2006) The promoting effect of MgO layer in sensitized photodegradation of colorants on TiO2/MgO composite oxide, colloids. Surf A Physicochem Eng Asp 276:197–202. https://doi.org/10.1016/j.colsurfa.2005.10.059

Basturk E, Karatas M (2015) Decolorization of antraquinone dye Reactive Blue 181 solution by UV/H2O2 process. J Photochem Photobiol A Chem 299:67–72. https://doi.org/10.1016/j.jphotochem.2014.11.003

Peng Z, Liu X, Lin G (2016) The synergistic degreasing treatment of background irradiated photocatalysis and microreactor. Catal Commun 90:79–82. https://doi.org/10.1016/j.catcom.2016.11.008

Macedo L, Pauli E (2006) Remediação de águas residuais por Fotocatálise Heterogênea: Estudo dosparâmetros experimentais aplicados a fotocatálise eletroquímica Semin Ciências Exatas 27:11–21

Kudo A, Miseki Y (2009) Heterogeneous photocatalyst materials for water splitting. Chem Soc Rev 38:253–78. https://doi.org/10.1039/b800489g

de Souza ML, Corio P (2013) Effect of silver nanoparticles on TiO2-mediated photodegradation of Alizarin Red S. Appl Catal B Environ 136–137:325–333. https://doi.org/10.1016/j.apcatb.2013.02.012

Han F, Kambala VSR, Srinivasan M, Rajarathnam D, Naidu R (2009) Tailored titanium dioxide photocatalysts for the degradation of organic dyes in wastewater treatment: a review. Appl Catal A Gen 359:25–40. https://doi.org/10.1016/j.apcata.2009.02.043

Li J, Xu X, Liu X, Qin W, Wang M, Pan L (2017) Metal-organic frameworks derived cake-like anatase/rutile mixed phase TiO2 for highly efficient photocatalysis. J Alloy Compd 690:640–646. https://doi.org/10.1016/j.jallcom.2016.08.176

Tan P, Chen X, Wu L, Shang YY, Liu W, Pan J, Xiong X (2017) Hierarchical flower-like SnSe2 supported Ag3PO4 nanoparticles: towards visible light driven photocatalyst with enhanced performance. Appl Catal B Environ 202:326–334. https://doi.org/10.1016/j.apcatb.2016.09.033

Yao J, Chen H, Jiang F, Jiao Z, Jin M (2017) Titanium dioxide and cadmium sulfide co-sensitized graphitic carbon nitride nanosheets composite photocatalysts with superior performance in phenol degradation under visible-light irradiation. J Colloid Interface Sci 490:154–162. https://doi.org/10.1016/j.jcis.2016.11.051

Rodrigues LA, Parmentier J, Parra JB, patrocínio Thim G (2013) Preparation of nodular carbon cryogel from simple and inexpensive polycondensation reaction of commercial modified black wattle tannin. J Sol-Gel Sci Technol 67:519–526. https://doi.org/10.1007/s10971-013-3109-3

Pekala RW, Alviso CT, Kong FM, Hulsey SS (1992) Aerogels derived from multifunctional organic monomers Journal of Non-Crystalline Solids 145:90–98

Al-Muhtaseb SA, Ritter JA (2003) Preparation and properties of resorcinol-formaldehyde organic and carbon gels. Adv Mater 15:101–114. https://doi.org/10.1002/adma.200390020

Sánchez-Martín J, Beltrán-Heredia J, Carmona-Murillo C (2011) Adsorbents from Schinopsis balansae: optimisation of significant variables. Ind Crops Prod 33:409–417. https://doi.org/10.1016/j.indcrop.2010.10.038

Queiroz EA, Morais CRAAQ, Nascimento SAL (2002) Caracterizaçao dos taninos da aroeira-preta. Árvore 26:485–492

Amaral-Labat G, Szczurek A, Fierro V, Stein N, Boulanger C, Pizzi A, Celzard A (2012) Pore structure and electrochemical performances of tannin-based carbon cryogels. Biomass Bioenergy 39:274–282. https://doi.org/10.1016/j.biombioe.2012.01.019

Szczurek A, Amaral-Labat G, Fierro V, Pizzi A, Masson E, Celzard A (2011) The use of tannin to prepare carbon gels. Part I: carbon aerogels. Carbon N Y 49:2773–2784. https://doi.org/10.1016/j.carbon.2011.03.007

de Moraes NP, Carvalho T, da Silva MLCP, Rodrigues LA, Thim GP, Campos TMB (2017) A novel synthesis route of titanium dioxide with (NH4)0.3TiO1.1F2.1 as byproduct. Ceram Int 43:13677–13682. https://doi.org/10.1016/j.ceramint.2017.07.078

de Moraes NP, Bacani R, da Silva MLCP, Campos TMB, Thim GP, Rodrigues LA (2018) Effect of Nb/C ratio in the morphological, structural, optical and photocatalytic properties of novel and inexpensive Nb2O5/carbon xerogel composites. Ceram Int 0–1. https://doi.org/10.1016/j.ceramint.2018.01.073.

Mishra AK, Ramaprabhu S (2011) Carbon dioxide adsorption in graphene sheets. AIP Adv 1:0–6. https://doi.org/10.1063/1.3638178

El-Sheikh SM, Khedr TM, Hakki A, Ismail AA, Badawy WA, Bahnemann DW (2017) Visible light activated carbon and nitrogen co-doped mesoporous TiO2 as efficient photocatalyst for degradation of ibuprofen. Sep Purif Technol 173:258–268. https://doi.org/10.1016/j.seppur.2016.09.034

do Prado NT, Oliveira LCA (2017) Nanostructured niobium oxide synthetized by a new route using hydrothermal treatment: high efficiency in oxidation reactions. Appl Catal B Environ 205:481–488. https://doi.org/10.1016/j.apcatb.2016.12.067

Bailón-García E, Elmouwahidi A, Álvarez MA, Carrasco-Marín F, Pérez-Cadenas AF, Maldonado-Hódar FJ (2017) New carbon xerogel-TiO2 composites with high performance as visible-light photocatalysts for dye mineralization. Appl Catal B Environ 201:29–40. https://doi.org/10.1016/j.apcatb.2016.08.015

Rashidzadeh M (2008) Synthesis of high-thermal stable titanium dioxide nanoparticles, Int J Photoenergy. https://doi.org/10.1155/2008/245981.

Busca G, Marchetti L, Centi G, Trifirò F (1985) Surface characterization of a grafted vanadium-titanium dioxide catalyst, J Chem Soc Faraday Trans 1 Phys Chem Condens Phases 1003–1014. https://doi.org/10.1039/F19858101003.

Ma X, Chen Y, Li H, Cui X, Lin Y (2015) Annealing-free synthesis of carbonaceous Nb2O5 microspheres by flame thermal method and enhanced photocatalytic activity for hydrogen evolution. Mater Res Bull 66:51–58. https://doi.org/10.1016/j.materresbull.2015.02.005

Rodrigues LA, Campos TMB, Alvarez-Mendes MO, Coutinho ADR, Sakane KK, Thim GP (2012) Phenol removal from aqueous solution by carbon xerogel. J Sol-Gel Sci Technol 63:202–210. https://doi.org/10.1007/s10971-012-2745-3

Schwan J, Ulrich S, Batori V, Ehrhardt H, Silva SRP (1996) Raman spectroscopy on amorphous carbon films. J Appl Phys 80:440–447. https://doi.org/10.1063/1.362745

Altomare M, Selli E (2013) Effects of metal nanoparticles deposition on the photocatalytic oxidation of ammonia in TiO2 aqueous suspensions. Catal Today 209:127–133. https://doi.org/10.1016/j.cattod.2012.12.001

Lopes OF, Paris EC, Ribeiro C (2014) Synthesis of Nb2O5 nanoparticles through the oxidant peroxide method applied to organic pollutant photodegradation: a mechanistic study. Appl Catal B Environ 144:800–808. https://doi.org/10.1016/j.apcatb.2013.08.031

Shaban YA, El Sayed MA, El Maradny AA, Al Farawati RK, Al Zobidi MI, Khan SUM (2016) Photocatalytic removal of polychlorinated biphenyls (PCBs) using carbon-modified titanium oxide nanoparticles. Appl Surf Sci 365:108–113. https://doi.org/10.1016/j.apsusc.2016.01.001

Zhang H, Tang Y, Cai D, Liu X, Wang X, Huang Q, Yu Z (2010) Hexavalent chromium removal from aqueous solution by algal bloom residue derived activated carbon: equilibrium and kinetic studies. J Hazard Mater 181:801–8. https://doi.org/10.1016/j.jhazmat.2010.05.084

Liang Z, Cao Y, Qin H, Jia D (2016) Low-heating solid-state chemical synthesis of monoclinic scheelite BiVO4 with different morphologies and their enhanced photocatalytic property under visible light. Mater Res Bull 84:397–402. https://doi.org/10.1016/j.materresbull.2016.08.038

Jones W, Martin DJ, Caravaca A, Beale AM, Bowker M, Maschmeyer T, Hartley G, Masters A (2016) A comparison of photocatalytic reforming reactions of methanol and triethanolamine with Pd supported on titania and graphitic carbon nitride. Appl Catal B Environ 1–7. https://doi.org/10.1016/j.apcatb.2017.01.042.

Zhao X, Hongda C, Wang T (2017) Novel synthesis of plasmonic Bi2Sn2O7/Ag-AgCl nanocomposite with enhanced visible light photocatalytic property. Mater Lett 95:392–401. https://doi.org/10.1016/j.matlet.2015.01.097

Bancirova M (2011) Sodium azide as a specific quencher of singlet oxygen during chemiluminescent detection by luminol and Cypridina luciferin analogues. Luminescence 26:685–688. https://doi.org/10.1002/bio.1296

Li M, Yin J-J, Wamer WG, Lo YM (2014) Mechanistic characterization of titanium dioxide nanoparticle-induced toxicity using electron spin resonance. J Food Drug Anal 22:76–85. https://doi.org/10.1016/j.jfda.2014.01.006

Nosaka Y, Daimon T, Nosaka AY, Murakami Y (2004) Singlet oxygen formation in photocatalytic TiO2 aqueous suspension Phys Chem Chem Phys 6:2917–2918

Nakajima N, Ito Y, Yokoyama K, Uno A, Kato K, Iwasaki A, Arakawa Y, Kinukawa N, Nemoto N, Lacy ER (2005) The expresssion of Mdm2 on Helicobacter pylori infected intestinal metaplasia and gastric cancer. J Clin Biochem Nutr 128:A401–A402. https://doi.org/10.3164/jcbn.16

Xu T, Zhang L, Cheng H, Zhu Y (2011) Significantly enhanced photocatalytic performance of ZnO via graphene hybridization and the mechanism study. Appl Catal B Environ 101:382–387. https://doi.org/10.1016/j.apcatb.2010.10.007

Zhang L, Ni C, Jiu H, Xie C, Yan J, Qi G (2017) One-pot synthesis of Ag-TiO2/reduced graphene oxide nanocomposite for high performance of adsorption and photocatalysis. Ceram Int 43:5450–5456. https://doi.org/10.1016/j.ceramint.2017.01.041

Li B, Yuan H, Yang P, Yi B, Zhang Y (2016) Fabrication of the composite nanofibers of NiO/Al2O3 for potential application in photocatalysis. Ceram Int 42:17405–17409. https://doi.org/10.1016/j.ceramint.2016.08.040

Acknowledgements

The authors gratefully acknowledge the financial support provided by the São Paulo Research Foundation (FAPESP) for this research (grant no. 2015/08995-7) and for the fellowship provided to NPM. (grant no. 2016/04244-0). The authors are also grateful to TANAC SA company that supplied the mimosa tannin.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

de Moraes, N.P., da Silva, M.L.C.P., Campos, T.M.B. et al. Novel synthetic route for low-cost carbon-modified TiO2 with enhanced visible light photocatalytic activity: carbon content and calcination effects. J Sol-Gel Sci Technol 87, 380–390 (2018). https://doi.org/10.1007/s10971-018-4700-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4700-4