Abstract

In this work, a novel bridged organosilane precursor, adamantane-bridged organosilane (ADBO), was synthesized successfully which was employed to prepare adamantane-based (ADH-based) periodic mesoporous organosilica (PMO) thin film in the presence of porogen and acid catalyst via evaporation-induced self-assembly (EISA) after spin-coating procedure. The resultant ADH-based PMO thin films were characterized by FTIR, NMR, TEM, and small-angle XRD. The ADH-based PMO thin film with weight ratio of porogen to ADBO (0.75:1) possesses low dielectric constant (1.55 ± 0.04@1 MHz), excellent Young’s modulus (6.69 ± 0.54 GPa), and ideal hydrophobic property (90.2° of water contact angle) simultaneously. These outstanding properties of ADH-based PMO film can be ascribed to lower polarity, lower density, and rigid cavity structure of adamantane, which suggests its potential application as high-performance low-κ material in next-generation microelectronics.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With the increasingly high integration and compact structure, integrated circuits (ICs) contain more and more layers of metal lines to accommodate a large number of transistors [1]. The increasing resistance–capacitance (RC) delay of the interconnected materials needs to be reduced urgently with the shrinkage of the dimensions of the devices [2]. To address this problem, Al metal wire was replaced by Cu in the 1990s for its lower resistivity [3]. In the context of interconnected dielectrics, developing a novel interlayer dielectric (ILD) with lower dielectric constant (low-κ) instead of traditional silicon-based ILD has become vital for IC industry [4]. It is well known that there are two feasible ways to reduce κ-value, decreasing polarity and density [3]. First, lower polarity which means reducing dipole strength and less dipoles can be achieved through introducing weak polar bonds, such as C–C and C–F. Second, the lower density which means higher porosity, is much more beneficial to decrease the dielectric constant in accordance with reducing polarity. Higher porosity means more air, which almost has the lowest κ-value of 1.0 in nature [5]. However, excessive pores would deteriorate the mechanical properties, which are of great significance in the subsequent process in semiconductor industry, such as chemical mechanical polish (CMP) and so on [4]. Therefore, developing a promising low-κ material with excellent mechanical strength is desirable [1, 2, 4].

Periodic mesoporous organosilica (PMO), a particular class of material possesses ordered porous structure, in which pore walls array in periodic sequence arrangement with a uniform pore size of 2–30 nm [6, 7]. For this organic–inorganic hybrid material, each individual organic group is covalently bonded to two or more silicon atoms and evenly distributed in pore wall. Owing to the unique organic components and periodic mesostructure, PMO possesses a more hydrophobic environment inside the pores, which benefits in various applications, such as catalysis [8], drug delivery [9], protein refolding [10], separation [11], and optical [12]. Given the low polarity and density, PMO exhibits immeasurable potential in terms of dielectric constant and mechanical properties [13,14,15]. In recent years, many researchers have devoted to low-κ PMO materials [16,17,18,19,20], which were developed by alternating different organic bridging groups [3, 21,22,23,24]. For example, A. Ozin’s group reported a novel precursor using polyhedral oligomeric silsesquioxane (POSS) as a bridging group and further prepared POSS–PMO thin film via evaporation-induced self-assembly (EISA) method [25]. Introducing POSS with nanosized (0.3 nm) cage structure was helpful to reduce the κ-value to 1.73@1 MHz due to its in-house cavity. But Young’s modulus of POSS–PMO was only 3.30 GPa, which was slightly smaller than the stiffness limit of 4 GPa required for CMP [25, 26]. To meet the demands of practical application for IC manufacturing, PMO material should be promoted for low dielectric constant and excellent mechanical properties [6, 27,28,29]. In our previous work, a novel bridged organosilane precursor with star-shaped construction and tetrafunctional organosilane branches was developed to prepare PMO film, which exhibited excellent dielectric property (1.58@1 MHz of dielectric constant) and high mechanical property (5.54 ± 0.11 GPa of Young’s modulus) simultaneously [30]. On the basis of these progresses, we tried to introduce adamantane structure as the bridging group into the pore wall to develop a promising PMO material as a potential candidate for next-generation ILD. As it is well known, adamantane possesses a unique rigid structure but strain-free ring system, composed of three fused chair cyclohexane rings, which can contribute to the expected mechanical strength [31]. Meanwhile, plenty of carbon–carbon bonds and face-centered cubic structure of adamantane lead to lower polarity and lower density simultaneously. All characteristics of adamantane as mentioned above are beneficial to develop a promising low-κ material for ILD applications.

In this work, a novel adamantane-bridged organosilane (ADBO) precursor was prepared successfully through facile organic synthesis. The resultant ADBO precursor was employed to prepare adamantane-based (ADH-based) PMO thin films after mixing with porogen and other additional agents via spin-coating and EISA method. At last, the microstructure, crystallization, dielectric, mechanical, thermal, and hydrophobic properties of as-prepared ADH-based PMO thin films were investigated comprehensively.

2 Experimental

2.1 Materials

1,3-Adamantanedicarboxylic acid (ADDA, 95%) was obtained from TCI Shanghai Development Co Ltd., China. 3-(Triethoxysilyl)-propylamin (TPA, 97%) and triethylamine (Et3N, 99%) were supplied by Aladdin Industrial Co Ltd., China. Poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol) (P123, Mw ~ 5800) was purchased from Sigma-Aldrich Co. LLC., China. Thionyl chloride (SOCl2), trichloromethane (CHCl3), and ethanol were obtained from Sinopharm Co Ltd. and the latter two should be purified with a molecular sieve before use. N-type (111) silicon wafer (0.001 ~ 0.004 Ω) was obtained from Suzhou resemi Co Ltd. All other reagents and materials were used as received.

2.2 Synthesis of the ADBO precursor

To improve the product yield, the ADDA needs to be chlorinated. First, 0.2243 g (1.0 mmol) of ADDA powder and excessive amounts of SOCl2 were added into a 100-mL round-bottomed flask, keeping the temperature at 80 °C for 12 h with exhaust treatment. The first-step product, 1,3-adamantanedicarbonyl dichloride, should be purified by rotary evaporation and stored in sealed condition because of higher activity. Then, under argon atmosphere, 0.4870 g (2.2 mmol) of TPA and 0.2226 g (2.2 mmol) of Et3N were added into a 100-mL three-neck flask. Following that, the acylchlorides were dissolved by CHCl3, and the solution was poured into a flask. Owing to the excellent activity, the second-step reaction can run completely with stirring at room temperature for another 12 h. The precursor can be purified by column chromatography on silica gel, developing agents that contain mixed solvent petroleum ether:CHCl3 = 2:1 and mixed solvent CHCl3:CH3COOC2H5 = 4:1. Finally, the ADBO precursor was obtained with 74.9% of product yield.

2.3 Preparation of ADH-based PMO thin films

ADBO precursor can be dissolved in CHCl3 solution as a proper ratio. First, in each coating solution, ADBO precursor (0.1260 g, 0.2 mmol) in 2 mL of CHCl3 was mixed with P123 ethanol solution (0.1260 g mL−1). Then, all the ADBO precursor solutions can be prepared according to the different weight ratio of porogen to precursor, 25, 50, 75, and 100%, respectively, as shown in Table 1. Meanwhile, moderate volume of ethanol should be added into the precursor solution for the same concentration of ADBO in every sample, and then 0.1 mL of HCl (0.5 M) was added into each one followed by 30 min of stirring. Before sample preparation, silicon substrates should be rinsed with propylene glycol monomethyl ether and blow-dried by pure nitrogen. The as-prepared precursor solutions were dropwise added onto a preclean substrate and spin-coated at rotary speed of 900 r.p.m. for 30 s. Preparing process of PMO by EISA needs sufficient solvent evaporation. The resultant fresh films should be treated at room temperature overnight and 60 °C for another 48 h. Next, porogen P123 was extracted by ethanol solution at 60 °C for 1 h, and the mild condition is beneficial to improve the order of mesoporous structure of PMO. In order to increase the condensation degree of the thin film and remove residual porogen, all samples were calcined at 300 °C for 6 h under flowing argon. For convenience, the as-prepared ADH-based PMO thin films with different weight ratios of porogen to precursor from 25, 50, and 75 to 100%, can be denoted as A25, A50, A75, and A100, respectively.

2.4 Characterization

Preparing process of ADBO was confirmed through nuclear magnetic resonance (NMR) spectrum by AVANCE III 400 NMR spectrometer and gas chromatography–mass spectrometry (GC–MS) was operated with Agilent 7890B (GC)-5977A (MS). Fourier transform-infrared (FT-IR) spectrum (KBr) was measured using a Bruker Optics VERTEX 70 Fourier transform-infrared spectrometer. The calculation on the ABDO precursor in this work had been performed using the Gaussian 09 program package. Calculation on the electronic ground state was carried out using density functional theory DFT//B3LYP/6-31G*. The structure of PMO thin films was confirmed through transmission electron microscope (TEM) by FEI Tecnai G2 F20 S-Twin TEM. For TEM, samples should be scraped from substrates and dispersed in ethanol; then, solutions were drop-casted on lacey copper grid and ethanol was required to evaporate thoroughly before imaging. The scanning electron microscope (SEM) images were taken on FEI Nova NanoSEM 450 field emission SEM, and before loading into the SEM chamber, samples were sputtered with a 10-Å-thick gold coating. Small-angle X-ray diffraction (XRD) patterns were recorded on Rigaku D/MAX-2500/PC X-ray powder diffractometer with Cu Kα radiation (λ = 0.15406 nm). Meanwhile, the leakage current density was measured by Keithley 4200-SCS semiconductor parameter analyzer and the dielectric constant was determined from the capacitance, which was measured by Agilent 4294A RF impedance analyzer. The mechanical properties characterization was performed on Hysitron TI Premier nanoindentation with applied force from 100 to 200 μN, and we tested a random of eight points from each sample to promise the accuracy. The thermal properties were performed on Mettler-Toledo thermogravimetric analyzer–differential scanning calorimeter (TGA–DSC), which ran from 30 to 900 °C at a heating rate of 10 °C min−1. Besides, the contact angle was pictured using DataphysicsOCA20 optical contact angle measuring device.

3 Results and discussion

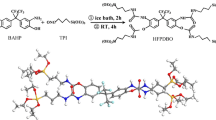

ADBO was synthesized through simple two-step reactions including chloroformylation and amidation as shown in Fig. 1a. After chloroformylation, the two carboxyls in ADDA can be easily grafted by TPA to yield amide due to high activity of –COCl and –NH2. Based on the special molecular design, adamantane was chosen as a bridging group of a novel organosilane precursor for its special structure. Figure 1b shows the optimized structure of ADBO calculated by DFT//B3LYP/6-31G*. It can be noted that a certain angle between two branch strains of ADBO was present owing to the strong steric hindrance which improves the order of mesoporous structure of PMO. Furthermore, adamantane possesses an extremely rigid but strain-free ring system, composed of three fused chair cyclohexane rings [32]. Therefore, introducing adamantane into the organosilane precursor improves the proportion of organic component and reduces polarity, whose own face-centered cubic structure as well as cavity is beneficial to decrease material density. Second, because of its rigid structure and big maximum force constant [31], adamantane promotes the mechanical properties of the resultant PMO film. Therefore, the novel ADBO precursor can be considered as a promising candidate for preparing PMO film with excellent integrated properties.

For verifying the molecule structure of ADBO precursor, the as-prepared product was dissolved in deuterated chloroform (CDCl3) and confirmed by NMR spectrum as shown in Fig. 2. In the 1H-NMR spectrum, except the peak (δ = 0.00 ppm) of internal standard substances (tetramethylsilane) and the peak (δ = 7.26 ppm) of CDCl3, the strongest resonance peak appears at δ = 1.44 ppm corresponding to the methyl hydrogen atoms of alkoxysilane. And another strong peak appears at δ = 3.55 ppm which corresponds to the ethylene hydrogen atoms of alkoxysilane. Besides, 1H-NMR spectrum has several characteristic peaks at δ = 3.24, 1.64, and 0.66 ppm, respectively, corresponding to the ethylene hydrogen atoms between N and Si. In addition, peaks around δ = 1.80 and 5.88 correspond to hydrogen atoms from adamantine skeleton and imide hydrogen, respectively. The ADBO precursor molecule was also characterized by mass spectrogram (Fig. S1). All these above-mentioned results suggested that the ADBO precursor was successfully prepared.

After successful synthesis of organosilane precursor, a schematic preparation procedure of ADH-based PMO thin film was depicted in Scheme 1. To prepare precursor solution, the ADBO was mixed with porogen P123, hydrochloric acid, and ethanol at a predetermined and optimized ratio, stirring for 10 min at room temperature. P123, a nonionic surfactant, has been widely used as a soft template to fabricate ordered mesoporous materials. It can be assembled to a micelle facilely in a precursor solution and is easy to be removed, which are significant to form a periodic mesoporous structure [33]. With the removal of porogen in the process of forming a periodic mesoporous structure, the condensation reaction between –Si–(OEt)3 groups was underway until forming the pore wall with –Si–O–Si– and bridged organic groups.

Meanwhile, FT-IR was employed to further confirm the molecule structure transition from raw materials including ADDA and TPA to ADH-based PMO film as shown in Fig. 3. Compared with ADDA, it can be seen that a characteristic peak at 1719 cm−1, ascribed to –COOH groups from ADDA, migrated to a wave number of 1639 cm−1 in the spectrum of ADBO because of the introduction of amino groups. But the spectrum of ADBO retains characteristic peaks at 958 and 690 cm−1 originating from skeletal vibrations of adamantane. Similarly, there are some characteristic peaks that originated from TPA. The peak at 3406 cm−1 is ascribed to the vibration of –N–H and absorption peaks at 1192 and 1082 cm−1 correspond to –Si–O– group [5, 16]. Furthermore, characteristic peaks at 2941 and 2841 cm−1 corresponding to –C–H bond can be considered that they are derived from both ADDA and TPA. All of these features confirmed the successful synthesis of ADBO precursor. Compared with ADBO, the characteristic peaks at 1194 and 1084 cm−1 corresponding to –Si–O– bond obviously enhance in the FT-IR spectrum of ADH-based PMO film. It proved that the condensation reaction between –Si–(OEt)3 groups as well as the formation of Si–O–Si was completed. Meanwhile, some similar characteristic peaks retain as a precursor. The characteristic peak at 3406 cm−1 ascribed to –N–H and the peak around 2900 cm−1 ascribed to –Si–O can testify the organic structure of the precursor that still maintains in the pore wall of PMO thin film.

After the successful preparation of ADH-based PMO film, the morphology was measured by SEM as shown in Fig. 4. It shows that the surface of A25 is compact and smooth (Fig. 4a), but more and more obvious pores emerge in films with the increase of porogen content. Pores become more and more denser in A50 and A75, though films are still complete and adhesive to the substrate well (Fig. 4b,c). Numbers of defects and PMO particles appear in the cross section of A100 sample and the continuing and orderly film is deteriorated (Fig. 4d). It can be ascribed that the content of porogen is beyond the critical micelle concentration (CMC) of precursor solution, leading to aggregation of PMO particle with certain crystalline properties [18]. SEM images also indicate that the thickness of PMO films is mostly maintained between 180 and 320 nm, which is not gravely affected by the porogen content.

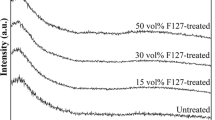

According to IUPAC [7], visible pores in SEM images belong to a macropore for the diameter exceeding 50 nm. To confirm the periodic mesoporous structure of organosilica, small-angle XRD and TEM were adopted to characterize the microstructure of thin films. Figure 5a shows the typical small-angle XRD patterns of as-prepared A25, A50, A75, and A100. The diffraction peaks of PMO films can reflect their mesoporous structure and 2θ value of peak position can indicate the d-spacing between channels [34]. For A25, A50, and A75, it is interesting that all (100) peaks of films appear at 2θ = 1.32o, which indicates that the d-spacing of films is similar, and the presence of diffraction peaks is characteristic of an ordered hexagonal material. Compared with others, the (100) reflection peak of A100 displays a lower 2θ value of about 1.24o, due to too much porogen that enlarges pore size probably. Meanwhile, the (100) peak of A100 also has a weaker diffraction intensity and broader peak width, reflecting its mesostructure- ordering impairment [25]. However, there are not any particular differences between XRD peaks of samples from A25 to A75. In the pattern of A75, the strongest diffraction peak appears at 1.32° of 2θ, which associates with spacing (d) of 6.69 nm between the lattice planes. For more evidence, the fragments scratched from the A75 sample were confirmed visually by TEM as shown in Fig. 6. The well-formed mesoporous channels can be visually observed, arranging orderly and neatly with uniform spacing and consistent size. TEM images and selected-area electron diffraction (SAED) reveal that A75 film presents the long-range two-dimensional hexagonal order and channels with average spacing of around 5.66 nm. Hence, adamantane as a bridged organic group did not seriously imperil the long-range two-dimensional hexagonal order of PMO.

Through small-angle XRD, the periodic mesoporous structure of ADH-based PMO films has been proven. Then, the dielectric properties of films were further investigated by RF impedance analyzer and semiconductor parameter analyzer. And heavily doping silicon wafer with low resistance value (0.001–0.004 Ω) was used as a substrate, and Cu was sputtered on the surface of as-prepared PMO thin films at around 500-nm thick dots as the electrode. Figure 5b shows the relative dielectric constant of films, and it is obvious that the κ-value reduces progressively with the increase of porogen content at current frequency (1 MHz). When porogen content rises to 75%, the κ-value of A75 reaches the lowest point of 1.55 ± 0.04@1 MHz, and the leakage current density of A75 film is 1.72 × 10−6 A cm−2 at applied voltage of 1 V (Figure S2). However, the dielectric constant increases with further increasing porogen content, and the κ-value of A100 rebounds to 2.07 ± 0.03@1 MHz. When the porogen content is far beyond the CMC value, the feature size of a micelle composed of P123 and ADBO increases, which leads to the aggregation of PMO particles in the as-prepared films, resulting in shrinkage and collapse in following the annealing process at 300 °C [18]. Therefore, the rebound of A100 dielectric constant can be ascribed to the deterioration of a periodic mesoporous structure and it is also consistent with the morphology displayed in SEM image (Fig. 4d).

With the increase of porogen content, the κ-value of films decreases, but high porogen content can also impair the mechanical properties. Superior elastic modulus and hardness are essential for low-κ materials to withstand stress occurring during processing, and the mechanical properties of ADH-based PMO have been measured by a nanoindenter. As shown in Fig. 7a, Young’s modulus of films reduces drastically with the increase of porogen content from 25 to 75%. Particularly, the A75 with the lowest κ-value among all ADH-based PMO films, possesses Young’s modulus of 6.69 ± 0.54 GPa. Although its Young’s modulus is much lower than that of A25, this value is high enough to meet the requirement of CMP [25]. High Young’s modulus of films can be ascribed to the introduction of rigid adamantane. For that, not only the periodic mesostructure was damaged, but the excellent mechanical properties were maintained (Fig. S3). Furthermore, the A100 thin film cannot acquire its Young’s modulus value, because it cannot withstand the minimum stress required by the test, which maybe due to too much porogen content.

Besides the dielectric and mechanical properties, the TGA–DSC curve of A75 was recorded under flowing nitrogen as shown in Fig. 7b. The TGA profiles show 3.14% weight loss below 150 oC, which is due to the removal of physically adsorbed water. From 150 to 538 oC, the mass decreases by 64.02%, and it can be assigned to the decomposition of loosely bound Si-(OR)1–3 groups and loss of ethanol and water by the condensation of residual silanol and ethoxy groups [34]. The TGA curve tends to keep steady after 538 oC and the heat release peak appears at 369.5 oC in DSC curve, which proves that the decomposition begins from 369.5 oC and finishes at 538 oC. Therefore, A75 has excellent thermal stability and would be compatible with the following procedure of IC fabrication (Fig. S4).

As is known to all, water has extremely polar O–H bonds and possesses a much higher dielectric constant; in this case, the hydrophobicity of PMO film is significant to low-κ applications [3, 7]. All the ADH-based PMO films have been characterized by contact angle meter as shown in Fig. 8. It is obvious that the water contact angle of films decreased from 92.7o down to 79.4o with the increase of porogen content. The water contact angle of A75 film is 90.2o, verifying that it possesses a hydrophobic property and can prevent interference from water.

4 Conclusion

A novel bridged organosilane, ADBO precursor was successfully synthesized and employed to prepare ADH-based PMO thin films via EISA spin-coating procedure. The resultant ADH-based PMO film (A75) displayed a periodic mesoporous structure, low dielectric constant (1.55 ± 0.04@1 MHz), excellent mechanical properties (6.69 ± 0.54 GPa of Young’s modulus), good thermal stability (370 oC of thermal degradation), and ideal hydrophobic property (90.2o of water contact angle). All the outstanding properties for low-κ materials have been presented in the ADH-based PMO thin films, which can be ascribed to the excellent properties of adamantane used as a bridge group. Therefore, the as-prepared ADH-based PMO film can be considered as a promising candidate for next- generation low-κ materials.

References

Kohl PA (2011) Low-dielectric constant insulators for future integrated circuits and packages. Annu Rev Chem Biomol 2:379–401

Baklanov MR, Maex K (2006) Porous low dielectric constant materials for microelectronics. Philos Trans R Soc A 364:201–215

Shamiryan D, Abell T, Iacopi F, Maex K (2004) Low-k dielectric materials. Mater Today 7:34–39

Hatton BD, Landskron K, Hunks WJ, Bennett MR, Shukaris D, Perovic DD, Ozin GA (2006) Materials chemistry for low-k materials. Mater Today 9:22–31

Maex K, Baklanov MR, Shamiryan D, lacopi F, Brongersma SH, Yanovitskaya ZS (2003) Low dielectric constant materials for microelectronics. J Appl Phys 93:8793–8841

Wang WD, Lofgreen JE, Ozin GA (2010) Why PMO? Towards functionality and utility of periodic mesoporous organosilicas. Small 6:2634–2642

Wang WD, Grozea D, Kohli S, Perovic DD, Ozin GA (2011) Water repellent periodic mesoporous organosilicas. ACS Nano 5:1267–1275

Yang QH, Liu J, Zhang L, Li C (2009) Functionalized periodic mesoporous organosilicas for catalysis. J Mater Chem A 19:1945–1955

Lin CX, Qiao SZ, Yu CZ, Ismadji S, Lu GQ (2009) Periodic mesoporous silica and organosilica with controlled morphologies as carriers for drug release. Micro Mesopor Mat 117:213–219

Wang XQ, Lu DN, Austin R, Agarwal A, Mueller LJ, Liu Z, Wu JZ, Feng PY (2007) Protein refolding assisted by periodic mesoporous organosilicas. Langmuir 23:5735–5739

Rebbin V, Schmidt R, Fröba M (2006) Spherical particles of phenylene-bridged periodic mesoporous organosilica for high-performance liquid chromatography. Angew Chem Int Ed 45:5210–5214

Tani T, Mizoshita N, Inagaki S (2009) Luminescent periodic mesoporous organosilicas. J Mater Chem 19:4451–4456

Hunks WJ, Ozin GA (2005) Challenges and advances in the chemistry of periodic mesoporous organosilicas (PMOs). J Mater Chem 15:3716–3724

Wills AW, Michalak DJ, Ercius P, Rosenberg ER, Perciano T, Ushizima D, Runser R, Helms BA (2015) Block copolymer packing limits and interfacial reconfigurability in the assembly of periodic mesoporous organosilicas. Adv Funct Mater 25:4120–4128

Hoffmann F, Cornelius M, Morell J, Fröba M (2006) Silica-based mesoporous organic–inorganic hybrid materials. Angew Chem Int Ed 45:3216–3251

Liu HC, Su WC, Liu YL (2011) Self-assembled benzoxazine-bridged polysilsesquioxanes exhibiting ultralow-dielectric constants and yellow-light photoluminescent emission. J Mater Chem 21:7182–7187

Hatton BD, Landskron K, Whitnall W, Perovic DD, Ozin GA (2005) Spin-coated periodic mesoporous organosilica thin film-towards a new generation of low-dielectric-constant materials. Adv Funct Mater 15:823–829

Jiang T, Zhu B, Ding SJ, Fan ZY, Zhang DW (2014) High-performance ultralow dielectric constant carbon-bridged mesoporous organosilica films for advanced interconnects. J Mater Chem C 2:6502–6510

Huang YQ, Economy J (2006) New high strength low-k spin-on thin films for IC application. Macromolecules 39:1850–1853

Edelstein D (2008) Extendibility of Cu/low-k/airgap BEOL. Electrochem Soc 28:2073

Guo Y, Mylonakis A, Zhang ZT, Yang GL, Lelkes PI, Che SN, Lu QH, Wei Y (2008) Templated synthesis of electroactive periodic mesoporous organosilica bridged with oligoaniline. Chem-Eur J 14:2909–2917

Landskron K, Ozin GA (2005) Periodic mesoporous organosilicas: self-assembly from bridged cyclic silsesquioxane precursors. Angew Chem Int Ed 44:2107–2109

Gao L, Wei F, Zhou Y, Fan XX, Wang Y, Zhu JH (2009) Periodic mesoporous organosilica materials: self-assembly of carbamothioic acid-bridged organosilane precursors. Chem-Eur J 15:8310–8318

Schachtschneider A, Wessig M, Spitzbarth M, Donner A, Fischer C, Drescher M, Polarz S (2015) Directional materials-nanoporous organosilica monoliths with multiple gradients prepared using click chemistry. Angew Chem Int Ed 127:10611–10615

Seino M, Wang WD, Lofgreen JE, Puzzo DP, Manabe T, Ozin GA (2011) Low-k periodic mesoporous organosilica with air walls: POSS-PMO. J Am Chem Soc 133:18082–18085

Lu HY, Teng CL, Kung CH, Wan BZ (2011) Preparing mesoporous low-k films with high mechanical strength from noncrystalline silica particles. Ind Eng Chem Res 50:3265–3273

Goethals F, Levrau E, Pollefeyt G, Baklanov MR, Ciofi I, Vanstreels K, Detavernier C, Driessche IV, PVD Voort (2013) Sealed ultra low-k organosilica films with improved electrical, mechanical and chemical properties. J Mater Chem C1:3961–3966

Yuan H, Xu JQ, Xie LL (2011) Ultra low-dielectric-constant methylated mesoporous silica films with high hydrophobicity and stability. Mater Chem Phys 129:1195–1200

Rathore JS, Interrante LV, Dubois G (2008) Ultra low-k films derived from hyperbranched polycarbosilanes (HBPCS). Adv Funct Mater 18:4022–4028

Zhang JW, Zhang GP, Gao YJ, Sun R, Wong CP (2016) Ultra-low-κ HFPDB-based periodic mesoporous organosilica film with high mechanical strength for interlayer dielectric. J Mater Sci 51:7966–7976

Zhang GP, George TF, Assoufid L, Mansoori GA (2007) First-principles simulation of the interaction between adamantane and an atomic-force-microscope tip. Phys Rev B 75:035413

Fort RC, Schleyer PV (1964) Adamantane: consequences of the diamondoid structure. Chem Rev 64:277–300

Tong J, Zhang H, Gu J, Li L, Ma C, Zhao J, Wang C (2016) Poly (ethylene glycol)-block-poly (propylene glycol)-block-poly (ethylene glycol)-assisted synthesis of graphene/polyaniline composites as high-performance supercapacitor electrodes. J Mater Sci 51:1966–1977

Landskron K, Hatton BD, Perovic DD, Ozin GA (2003) Periodic mesoporous organosilicas containing interconnected [Si(CH2)]3 rings. Science 302:266–269

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (Grant No. 21201175, 61505123, and 21601065), NSFC––Guangdong Jointed Funding (U1601202), NSFC––Shenzhen Robot Jointed Funding (U1613215), Guangdong and Shenzhen Innovative Research Team Program (No. 2011D052, KYPT20121228160843692), Key Laboratory of Guangdong Province (2014B030301014), and R&D Funds for basic Research Program of Shenzhen (Grant No. JCYJ20120615140007998, 20150401145529012, and 20150525092940976) and Shenzhen Fundamental Research Program (Grant No. JCYJ20160331191741738 and JSGG20160229194437896).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Highlights

-

Design a novel bridged organosilane precursor, introdcuing adamantane (ADH) with rigid cavity structure

-

Prepare adamantane-based (ADH-based) periodic mesoporous organosilica (PMO) through evaporation-induced self-assembly (EISA)

-

The best ADH-based PMO possesses low dielectric constant (1.55 ± 0.04@1 MHz), excellent Young’s modulus (6.69 ± 0.54 GPa), and ideal hydrophobic property (90.2° of water contact angle) simultaneously

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Zhang, G., Zhang, J., Niu, F. et al. Novel adamantane-based periodic mesoporous organosilica film with ultralow dielectric constant and high mechanical strength. J Sol-Gel Sci Technol 85, 703–711 (2018). https://doi.org/10.1007/s10971-018-4582-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4582-5