Abstract

Analytical methods for separating individual lanthanide elements from each other are needed to support various scientific fields. This work reports a systematic evaluation of analytical separations using Eichrom Industries Ln resin and simple peristaltic pump fed low-pressure chromatography columns. Systematic studies of isocratic elutions over a range of acid concentrations (0.10 to 0.25 M HNO3) and column lengths (15 to 45 cm) show that with careful selection of the separation conditions baseline separation of the majority of the lanthanide elements can be achieved, with the exception Nd, Pr, Pm and Ce which co-elute at low acid concentrations. The employment of a novel Ce3+/Ce4+ oxidation–reduction approach using NaBrO3 and ascorbic acid enables isolation of Ce, however baseline separation of Nd, Pr and Pm could not be accomplished using Ln resin, simple acids, and low-pressure chromatography. A method for rapid separation and preconcentration of fission product lanthanides is also reported based upon the optimized conditions identified in this work; the separation approach enables isolation of lanthanide isotopes in high purity and chemical yield, with final elution fraction volumes of 4 mLs

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Methods for chemically separating the lanthanide elements from each other and from matrix constituents are needed to support numerous fields including geochemistry, astrophysics, medical isotope production, nuclear fuel cycle analyses and so forth [1,2,3,4,5,6,7,8,9,10,11,12]. The necessity for chemical separations results from diverse application-specific requirements; examples of these include the need to remove isobarically interfering species prior to mass spectrometry analyses (e.g., 150Nd versus 150Sm, 152Sm versus 152Gd, etc.), the required reduction in the Compton background associated with detection of short lived lanthanide isotopes by gamma spectrometry, the removal of β− emitting impurities to enable radiometric analysis of non-gamma emitting lanthanide isotopes (e.g. 151Sm and 147Pm, etc.) and the necessity for obtaining extremely high yield/high purity isotope solutions for in vitro and in vivo research and therapeutic trials [13,14,15,16,17,18,19,20,21,22,23].

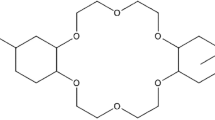

Ln resin (Eichrom Industries) is an extraction chromatographic resin that was designed specifically to enable analytical scale lanthanide separations. The resin consists of the cationic extractant di(2-ethylhexl)orthophosphoric acid (HDEHP) ligand bound to a stationary hydrophobic resin bead surface via weak hydrophobic interactions [24, 25]. Separation of the lanthanides using Ln resin is achieved through exploiting two phenomena: 1) the increasing charge/size ratio across the lanthanide series resulting from decreased nuclear shielding with increasing atomic number (known as the lanthanide contraction phenomena) and 2) competition of the Ln3+ and H+ ions for the active sites on the resin [24, 26]. Distribution coefficient values for this resin have been published by Horwitz et al. and show a very sharp acid dependency for this resin, with the light lanthanides eluting in dilute nitric or hydrochloric acid and the heavy lanthanides eluting at high (e.g. > 6 M) acid concentrations [27].

While numerous studies of lanthanide separations using Ln resin have been reported, separations to date have been unable to achieve the high yields and separation resolution requirements needed for many applications. For example, Gioia et al. utilized a 6.5 cm × 5 mm gravimetric column and HCl matrix to isolate La and Sm, however they were unable to resolve Ce from Pr and Nd, Eu, Gd, and Yb from each other [3]. Using a 2 mL prepacked gravimetric column and HNO3, Payne et al. achieved partial separation of La–Nd and Sm–Eu [28]. Hirahara et al. accomplished Nd/Sm separations using a 0.5 mL Ln resin column followed by a second 0.3 mL Ln resin column, however they too were unable to achieve baseline separation of the light lanthanides [29]. Arrigo et al. [30] utilized 2 different column sizes (2 mL of 0.7 cm ID and 1.0 cm ID) and were able to achieve near complete separation of Eu, Sm, and Gd, however they also were unable to accomplish baseline separation of La, Ce, and Nd; furthermore, the separation process took between 5 and 14 h to accomplish as they were using gravimetric columns. Ireland et al. [31] employed a novel approach using Ln resin within a custom fabricated high performance liquid chromatography system (HPLC); while this technique provides baseline separation of all the lanthanides except Nd/Pr (and possibly Pm) and Y/Er, it requires an expensive, custom fabricated system that may not be possible to construct and utilize in all laboratories. On the other hand, low pressure chromatography may be advantageous when compared to other methods as it is inexpensive and widely accessible. However, no effective lanthanide separation method using Ln resin and low pressure chromatography has been developed. Thus, a method is desired that enables 1) baseline separation of individual lanthanides while 2) only utilizing inexpensive, easily obtained chromatographic columns and techniques.

This paper explores effective separation methods for the light lanthanides (La-Dy) using Ln resin and simple low-pressure chromatography columns. Systematic evaluations of the effects of chromatographic parameters including the column length, acid concentration, and the presence of oxidation/reducing reagents are reported. Based upon optimized conditions for Ln resin, a separation system (termed the Lanthanide-Chromatography Separation System, Ln-CSS) was designed and constructed. The system utilizes an initial Ln resin column for lanthanide separations, followed by eluting directly onto a lanthanide preconcentration column (RE Resin, Eichrom Industries) for reducing the total volume of the final purified lanthanide fractions. Ln-CSS was then applied to a fresh uranium-fission product sample for evaluation of the system/methodology on a complex fission product mixture.

Experimental

All reagents and chemicals were trace metal grade or better. Lanthanide resin (50–100, and 100–150 µm bead size) was purchased from Eichrom (Lisle, IL). Multi-elemental inductively coupled plasma-mass spectroscopy (ICP-MS) standards were purchased from High-Purity Standards (North Charleston, SC) and a natural uranium metal foil (99.7% pure) was purchased from Goodfellow (Coraopolis, PA).

Numerous literature studies using Ln resin with gravity fed columns show long elution timescales (e.g. 2–14 + hours with only partial separation of the majority of the lanthanides from neighboring elements [3, 30]. To improve separation timelines and resolution (including minimizing band broadening due to diffusion), separations were performed using a peristaltic pump (ESI) and low-pressure chromatography columns (Omnifit). Most columns were packed using the 50–100 µm Ln resin bead size in order to maximize the separation resolution. Ln resin was added to the columns as a dilute nitric acid-resin slurry to achieve consistent column packing between different columns.

Initial evaluations and optimizations of lanthanide separations were performed using multi-elemental ICP-MS standard solution samples. Aliquots of the ICP-MS standards were evaporated to dryness and reconstituted in 0.01 M HNO3 to produce load solution concentrations of 200 or 500 ppb of the lanthanides. Appropriate quantities of the load solution were then added to the column via peristaltic pump, following which reagents of varying volumes and concentrations were pumped through each column at a flow rate of 2 ml/min (unless otherwise specified) to elute the lanthanides. Columns were eluted to dryness between different acid concentrations to ensure consistent elution volumes and concentrations between each separation.

Acid concentration evaluations

Initial evaluations demonstrated that baseline or near baseline separation of the heavy lanthanides (e.g. Tb through Lu) could be achieved at acid concentrations greater than 1.5 M HNO3. On the other hand, the light lanthanides Ce, Nd, and Pr (as well as likely Pm, which was not investigated during initial non-radioactive scoping studies) were found to be more challenging to separate. To determine the effects of slight differences in HNO3 concentration on Ce/Nd/Pr separation factors, systematic evaluation of different HNO3 concentrations was performed, with the acid concentration varying stepwise between 0.10 M, 0.11 M, 0.12 M, 0.13 M, 0.15 M, and 0.25 M. A 10 mm (ID) × 21.5 cm column was utilized for these tests.

Systematic evaluation of column dimensions

To evaluate the practical effect of increasing the column length on the separation resolution and timeline achievable, separation experiments utilizing 3.3 mm internal diameter columns with either 15 cm, 30 cm and 45 cm column lengths were performed. To balance separation resolution with simultaneous minimization of elution volumes and time, a solution matrix of 0.15 M HNO3 acid concentration was utilized for these tests. Each column was filled with 100–150 µm bead size due to column backpressure issues arising from the small internal diameter and long column length of the 30 and 45 cm columns.

Based upon results from the column length study a final optimized separation that balanced the resolution with elution volumes was also performed using a 21.5 cm × 10 mm column. Separations, carried out using this column, were performed using a 15 mL 0.01 M HNO−3 load solution containing 200 ppb of the lanthanides followed by the addition of 0.15 M HNO3 to elute the light lanthanides.

Effect of oxidation/reduction reagents

To further improve the separation of the light lanthanides, the potential oxidation of Ce3+ to Ce+4, with subsequent reduction back to Ce3+ following the elution of the other lanthanides, was evaluated. NaBrO3 was selected as the oxidizing reagent for this reaction because of its known ability to oxidize Ce3+ to Ce4+. The optimal NaBrO3 concentration for this reaction was determined via a set of batch contact studies to determine the distribution coefficient values for Ce as a function of the NaBrO3 concentration (where the distribution coefficient, Kd, is defined as the quantity of analyte bound to the stationary phase divided by the amount of analyte retained in the mobile phase). For this study a series of lanthanide solutions at a fixed 500 ppb concentration in 0.15 M HNO3 were utilized. NaBrO3 was added to each individual sample to achieve NaBrO3 concentrations ranging from 0.001 to 0.1 M NaBrO3. Solutions were then contacted with ~ 50 mg of Ln resin for 30 min, following which the solution was filtered, diluted gravimetrically, and analyzed via ICP-MS. The ability to reduce Ce4+ back to Ce3+ was later explored via additions of ascorbic acid while eluting Ce in 1 M HNO3.

Preconcentration

While several separation methods developed in this work show promise for application to individual lanthanide separations, elution volumes for each separated fraction were in many cases very large (50–200 mL). Furthermore, the presence of NaBrO3 in many of the fractions could cause undesired interferences for certain measurement methods (such as ionization dampening during mass spectrometric analysis). To mitigate these factors, a method for reducing the volume of individual purified lanthanides and removing NaBrO3 was investigated. In consideration of published Kd values, a second RE resin column immediately following the Ln resin column was employed due to RE resin’s high retention of the lanthanides at 3 M HNO−3 and low retention at 0.01 M HNO3 [32]. Scoping studies using a small 2.4 mL RE resin column were performed to determine the breakthrough volume and chemical yield obtainable using this approach. To perform these evaluations, Re resin columns were loaded with 100 mLs of 3 M HNO3 + 0.05 M NaBrO3 + 50 ppb of the lanthanides. Elutions were collected in 5 mL fractions. The column was then rinsed with 25 mLs of 3 M HNO3-, which was also collected in 5 mL fractions. The lanthanides were then eluted using 6 mL of 0.01 M HNO3 collected in 2 mL fractions.

Optimized lanthanide separation and pre-concentration step with stable surrogates (Ln-CSS)

Based upon the results from previous studies, a system for rapid elution of individual lanthanide isotopes was designed and termed as the “Lanthanide-Chromatography Separation System” (Ln-CSS). A flowsheet illustrating this process is shown in Fig. 1. The system utilizes an initial 31.5 cm × 10 mm (ID) Ln resin column optimized based upon results from previous experiments outlined in this paper. Due to the sensitivity of Ln resin to the acid concentration, several cautionary steps were taken. First, the Ln resin was never replaced in this column but was preconditioned between every use using 50 mL of 8 M HNO3 followed by 50 mL of 0.01 M HNO3 to rinse out any remaining lanthanides and to matrix match the loading solution, respectively. Second, the elution acids were prepared in large volumes to ensure that the concentrations of each acid were identical to the calibration separation, ensuring that each lanthanide eluted at the same volume every time. Third, NaBrO3 was added to all the eluents in order to maintain Ce3+ to Ce4+ to minimize the potential for Ce bleeding in the light lanthinides fractions. Finally, to decrease separation timelines the flow rate for Ln-CSS was increased to 4 mL/min, with negligible difference in elution profiles observed at this higher flow rate.

Flow chart of procedural steps of Ln-CSS, consisting of a 31.5 cm × 1 cm column dimension of 50–100 mm Ln resin bead size with 2.4 mLs Re resin column in tandem. Detailed procedure of this flow chart is in contained within “Optimized Lanthanide separation and preconcentrationstep with stable surrogates (Ln-CSS).”

Ln-CSS separations were optimized using non-radioactive lanthanide ICP-MS standard solutions and resuts shown in Table SI-1. A 15 mL load solution containing 500 ppb lanthanides in 0.01 M HNO3 was loaded onto the column. One hundred milliliters of 0.15 M HNO3 + 0.05 M NaBrO3 was then added to rinse the column and quantitatively oxidize the Ce3+ to Ce4+. The lanthanides were then eluted as follows: La was eluted using 190 mLs of 0.15 M HNO3 + 0.05 M NaBrO3, Nd and Pr were eluted using 40 mLs of 0.35 M HNO3 + 0.05 M NaBrO3, Sm was eluted using 60 mLs of 0.5 M HNO3 + 0.05 M NaBrO3, Eu was eluted using 100 mLs of 0.5 M HNO3 + 0.05 M NaBrO3, Gd was eluted using 200 mLs of 0.5 M HNO3 + 0.05 M NaBrO3, Tb was eluted using 60 mLs of 1.25 M HNO3 + 0.05 M NaBrO3, Dy was eluted using 60 mLs of 1.5 M HNO3 + 0.05 M NaBrO3 and Y/Ho/Er/Tm/Yb/Lu were eluted using 30 mLs of 8 M HNO3 + 0.05 M NaBrO3. The column was rinsed with 30 mL of 0.01 M HNO3 (to rinse out the NaBrO3 without eluting Ce) following which Ce was eluted using 40 mLs of 1 M HNO3 + 0.05 M ascorbic acid.

Application of the separation method to irradiated U foil

Final evaluation of the Ln-CSS system was performed using a radioactive fission product sample. The sample was generated by irradiating a natural uranium foil using the 38 MeV electron linear accelerator at the Idaho Accelerator Center (IAC). The foil was irradiated for 10 h at a 38 MeV bremsstrahlung end-point energy, producing a total of ~ 2x1014 total fissions. After cooling for 2 days the target was shipped to Idaho National Laboratory (INL) for subsequent separations chemistry. An initial foil dissolution and bulk fission product separation was performed using the Streamlined-Rapid Chromatography Isotope Separation System (S-RCISS) developed by Snow et al. [32]. The purified bulk lanthanide fraction (15 mL of 0.01 M HNO3) was diluted with an additional 15 mL of 0.01 M HNO3, following which the solution was loaded onto the Ln-CSS system and processed according to the procedure described previously. Following separations, the purified lanthanide fractions were analyzed via gamma spectroscopy.

Instrumentation and analysis

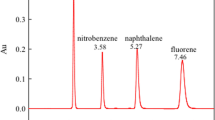

Analysis of all non-radioactive samples was performed using a Thermo iCAP-Q Quadrupole ICP-MS. Aliquots of each sample were diluted in dilute HNO3 prior to analysis. Lanthanide concentrations were determined via external calibration using NIST traceable ICP-MS standards (High Purity Standards, Inorganic Ventures).

Analysis of radioactive fractions were performed using a 12% relative efficiency liquid nitrogen-cooled coaxial High Purity Germanium (HPGe) γ-ray detector shielded with lead bricks to suppress background radiation. An Ortec DSPEC jr 2.0 digital signal processing unit was used to acquire γ-ray spectra for the various chemical fractions. Energy and efficiency calibrations were performed using a NIST traceable mixed radionuclide calibration standard (Eckert and Ziegler Isotope Products). Samples were generally counted for several minutes at a distance of 1 m from the detector endcap. The 1 m distance was chosen to limit the count rate in the detector but still ensuring reasonable statistics could be achieved within the minutes timescale allotted for counting each of the many samples produced directly following the Ln-CSS procedure. The chemical purity of each fraction was assessed by careful identification of individual gamma energy lines through comparison to spectral libraries and nuclear decay databases.

Quantitative comparisons of separations were performed by calculating the resolution obtained for different sets of chromatographic conditions. The resolution (Rs) was calculated using Eq. 1 below [33].

where V1 and V2 are the peak volumes of adjacent analytes used to determine the peak distance, W1 and W2 are the base peak width measured in volume. Baseline separations is defined herein as having a resolution of 1.5 or greater [33].

Results and discussion

Acid dependence and column length studies

Isocratic separations performed at various HNO3 concentrations are shown in Fig. 2, with the calculated resolution for each analyte given in Table 1. Higher resolution between the light lanthanides is observed at lower HNO3 concentrations, at the cost of significantly larger volumes of acid required and thus much broader elution peak profiles. At 0.13 M HNO3 and above, significant cross-over between Ce, Pr and Nd peaks is observed. Although the peak-to-peak separations appear to improve at a slightly faster rate than peak broadening (as seen in available Rs values in Table 1) and thus a slight improvement in peak separations is observed with decreasing HNO3 concentration below 0.15 M HNO3, significant improvements in light lanthanide separations at concentrations below ~ 0.15 M does not appear to be practical for most analytical separations due to the large volumes that would be required to achieve baseline resolution. Thus, for additional improvements in light lanthanide separations using this resin, alternate approaches may be required.

Figure 3 shows the impact of column length upon light lanthanide elution profiles, with the Rs values reported in Table 1. Doubling and tripling the length of the column results in increases in the resolution for La/Ce from 0.2 to 0.3 and 0.7 (respectively), while the resolution for Pr/Nd is not observed to measurably improve. As observed in the isocratic separation studies in Fig. 2/Table 1, the small increase in resolution gained by the increase in column length may be outweighed by the volume of acid required. Furthermore, at 45 cm the flow rates were significantly reduced relative to those at shorter lengths due to the small interior diameter and long length of this column. This pressure may be overcome by using higher pressure systems but cannot be easily overcome with gravimetric or simple low-pressure systems and thus represents a limitation in the total columns length.

A reasonable compromise between resolution, total elution volume, and pressure can be obtained using a 21.5 cm × 10 mm column as shown in Fig. 4 and Table SI-2. Separations using this column are very close to achieving the resolution reported for T-HPLC without the requirement for an expensive, custom instrument [31]. Using this approach, 5 pairs (La/Ce, Sm/Eu, Gd/Tb, Tb/Dy, and Tm/Y) of the lanthanide elements have resolutions greater than 1, representing a 97.7% separation of each of the adjacent analytes from each other. Three (Gd/Tb, Tb/Dy, and Tm/Y) of these 5 analytes have baseline separation or greater (having a resolution of at least 1.5) [33]. The remaining lanthanides (La/Ce, Ce/Pr, Pr/Nd, Nd/Sm, Eu/Gd, and Dy/Ho) have resolution values ranging between 0.5 and 0.8, indicating incomplete separation under these conditions (though as shown in the section Cerium Oxidation Evaluations, Ce can be isolated via the NaBrO3 oxidation approach, resulting in further improved resolution between Ce and the light lanthanides).

Cerium oxidation evaluations

Figure 5 shows the Kd values for Ce as a function of the concentration of NaBrO3. Kd values of Ce are observed to increase as the concentration of NaBrO3 increases until the concentration reaches 0.05 M NaBrO3, beyond which the Kd value is observed to decrease slightly. Increasing retention of Ce at increasing NaBrO3 concentrations up to 0.05 M is likely due to the oxidation of Ce3+ to Ce4+ [34, 35]. As HDEHP is a cationic extractant, the decreasing retention of Ce on the resin at concentrations above 0.05 M NaBrO3 is likely a result of Na+ ion competition with Ce4+ for the active cationic extractant sites [36]. Later column studies using NaBrO3 showed that oxidation of Ce3+ to Ce4+ could be performed directly on the column and that reduction of Ce4+ back to Ce3+ could be accomplished on-column using 0.05 M ascorbic acid. The large increase in Kd values as a result of NaBrO3 addition indicates significant potential for improving Ce/La, Nd, Pr, Pm separation factors using this approach (as demonstrated in the section Optimized Lanthanide separation and pre-concentration step with stable surrogates (Ln-CSS) and Radioactive sample).

Optimized lanthanide separation and pre-concentration with stable surrogates (Ln-CSS)

Optimized Ln-CSS separations are shown in Fig. 6, with the chemical yields of each lanthanide when fraction collections are balanced between obtaining high yields and high resolution given in Table 2. Baseline separation of Ce from all of the other lanthanides is achieved using the NaBrO3/ascorbic acid procedure described previously. The chemical yields for Ce, Pr, Nd, and Y are > 95%, while those of La, Sm, Eu, Gd, Tb, and Dy are greater than 75% (due to greater overlap between neighboring lanthanide fractions).

Gradient elution plot for optimized lanthanide separation utilized for Ln-CISS (31.5 cm)10 mm column with 50–100 μm Ln resin bead size). (I) 0.15 M HNO3 + 0.05 M NaBrO3, (II) 0.35 M HNO3 + 0.05 M NaBrO3, (III) 0.5 M HNO3 + 0.05 M NaBrO3, (IV) 1.25 M HNO3 + 0.05 M NaBrO3, (V) 1.5 M HNO3 + 0.05 M NaBrO3 (VI) 8 M HNO3 + 0.05 M NaBrO3, (VII) 0.01 M HNO3, (VIII)1 M HNO3 + 0.05 M ascorbic acid

The optimization of purity over fraction volume created fractions of up to 200 mLs, thus necessitating a volume reduction or preconcentration step. The retention of the lanthanides on RE resin with a large load volume and a small elution volume is shown in Figure SI-2. Lu, Yb, Tm, Er, and Ho begin to bleed within 30 mL of loading solution onto the column. Lower retention of these elements is due to the gradual decrease of Kd values across the lanthanide series on RE resin, with Kd values for La and Lu at 3 M HNO–3 on the order of 100 ± 10 and 10 ± 2, respectively [32]. As isotopes of these heavy lanthanides are not produced to an appreciable extent during nuclear fission, this bleeding does not impact performance of Ln-CSS on radioactive samples; should preconcentration of these elements be required for other applications, however, the RE resin column length can simply be extended to improve their retention at high load solution volumes. On the other hand, the light lanthanides (e.g., La, Ce, Pr, Nd, Sm, Eu, Dy, and Tb) remain on the column with up to 100 mL of 3 M HNO3 load solution and are not eluted until the addition of 0.01 M HNO3. The RE resin approach thus presents an excellent option for rapid preconcentration of the individual lanthanides without requiring evaporation or matrix transpositions.

Analysis of lanthanides from the U foil

The gamma spectra of each lanthanide fraction extracted from the photo-irradiated U foil are shown in Figures SI-3 and 4. Each of the fractions contain 99mTc and 131I contaminants which were present in the initial bulk lanthanide fraction produced by the S-RCISS system (see separation of radioactive sample). In the fractions of Y, La, Ce, Pm, Sm, Eu, and Gd no adjacent lanthanides were observed, while only a small amount of Pm was observed in the Nd fraction. The Tb and Dy fractions are shown separately in Fig. 8. Since these are produced to a much lesser extent in fission compared to the lighter lanthanides, they had to be positioned up against the front of the HPGe endcap in order to observe their decay lines within the minutes timescale allotted for counting each sample. Moreover, the activities were so low that even minor impurities dominated the spectra. For example in the Dy fraction, Ce was the primary lanthanide contaminant; while this Ce represented 0.04% of the total Ce from the sample it appears as a major contaminant in the gamma spectrum due to the trace concentrations at which 166Dy is produced during the nuclear fission process compared to those of Ce isotopes (0.0006% fission yields of Dy versus 4% for Ce from standard 14 MeV neutron fission of 238U). In the case of Tb several lanthanide impurities were present including Ce (0.002% of total Ce) and Nd (0.003% of total Nd). Further refinements in the Tb and Dy separation from Ce could be achieved by simply changing the separation conditions to elute Ce prior to Tb and Dy.

Conclusions

An evaluation of an effective separation of the light lanthanides (La-Dy) and the practical limits for individual lanthanide separations using Ln resin is reported in this work. Through careful selection of the column dimensions, acid concentrations and volumes, baseline separation of the majority of the lanthanides can be achieved using Ln resin. The use of simple peristaltic pumps (rather than gravimetric columns) results in improvements to both the separation timeline and resolution versus gravimetric approaches previously reported in the literature and is thus highly recommended for applications where sample analyses are time sensitive or higher resolution than simple light-heavy lanthanide separation is required. On the other hand, light lanthanide separations are found to be challenging using this resin; while La can be isolated by careful selection of the separation conditions and Ce isolation from Nd and Pr (and likely Pm) can be achieved using the NaBrO3/ascorbic acid Ce3+/Ce4+ oxidation–reduction approach outlined herein, baseline separation of Nd from Pr or Pm was not accomplished under the conditions utilized in this work. Further refinements in Nd/Pr/Pm separations using this resin might be possible using novel approaches such as the usage of high pressure chromatography systems, selective chelating agents, and so forth. For standard lanthanide separations from nuclear fission samples, the Ln-CSS approach outlined in this work represents an attractive option for rapid isolation and preconcentration of light lanthanide isotopes, with high purity achieved for all but Dy and Tb (with additional improvements to Dy and Tb purities possible via simple elution of Ce prior to Dy/Tb elutions).

References

Rajendran J, Balasubramanian G, Thampi PK (2008) Determination of rare earth elements in Indian costal monazite by ICP-AES and ICP-MS analysis and their geochemical significance. Curr Sci 94(10):1296–1302

Cassidy RM (1988) Determination of rare-earth elements in rocks by liquid chromatography. Chem Geol 67:185–195

Gioia SMCL, Pimentel MM (2000) The Sm-Nd isotopic method in the geochronology laboratory of the University of Brasília. An Acad Bras Ciênc. https://doi.org/10.1590/s0001-37652000000200009

Fivet V, Quinet P, Biémont É, Jorissen A, Yushchenko AV, Van Eck S (2007) Transition probabilities in singly ionized promethium and the identification of Pm II lines in Przybylski’s star and HR 465. R Astron Soc 5:69. https://doi.org/10.1111/j.1365-2966.2007.12118.x

Goyal A, Khatri I, Aggarwal S, Singh AK, Mohan M (2016) Calculation of energy levels, lifetimes and radiative data for La XXIX to Sm XXXIV. At Data Nucl Data Tables. https://doi.org/10.1016/j.adt.2015.07.001

Monroy-Guzman F, Salinas EJ (2015) Separation of micro-macrocomponent systems: 149Pm-Nd, 161 Tb-Gd, 166Ho-Dy, and 177Lu-Yb, by extraction chromatography. J Mex Chem Soc 59(2):143–150

Ekanger LA, Badal LA, Allen MJ (2016) The role of coordination environment and pH in tuning the oxidation rate of europium(II). Chemistry. https://doi.org/10.1002/chem.201604842

de Vries LH, Lodewijk L, Braat AJAT, Krijger GC, Valk GD, Lam MGEH, Borel Rinkes IHM, Vriens MR, de Keizer B (2020) 68Ga-PSMA PET/CT in radioactive iodine-refractory differentiated thyroid cancer and first treatment results with 177Lu-PSMA-617 EJNMMI. Resarch. https://doi.org/10.1186/s13550-020-0610-x

Derlin T, Sommerlath Sohns JM, Schmuck S, Henkenberens C, von Klot CAJ, Ross TL, Bengel FM (2020) Influence of short-term dexamethasone on the efficacy of 177Lu-PSMA-617 in patients with metastatic castration-resistant prostate cancer. Prostate. https://doi.org/10.1002/pros.23974

Lumetta GJ, Gelis AV, Carter JC, Niver CM, Smoot MR (2014) The actinide-lanthanide separation concept solvent. Extr Ion Exc. https://doi.org/10.1080/07366299.2014.895638

Karslyan Y, Sloop FV Jr, Delmau LH, Moyer BA, Popovs I, Paulenova A, Jansone-Popova S (2019) Sequestration of trivalent americium and lanthanide nitrates with bis-lactam-1,10-phenanthroline ligand in a hydrocarbon solvent. RSC Adv. https://doi.org/10.1039/C9RA06115K

Fernández RG, García Alonso JI (2007) Separation of rare earth elements by anion-exchange chromatography using ethylenediaminetetraacetic acid as mobile phase. J Chromatogr A. https://doi.org/10.1016/j.chroma.2007.12.008

Raut N, Huang LS, Aggarwal SK, Lin KC (2005) Mathematical correction for polyatomic isobaric spectral interferences in determination of lanthanides by inductively coupled plasma mass spectrometry. J Chin Chem Soc Taip 52(4):589–597

Raut N, Huang LS, Aggarwal SK, Lin KC (2003) Determination of lanthanides in rock samples by inductively coupled plasma mass spectrometry using thorium as oxide and hydroxide correction standard. Spectrochim Acta B 58(5):809–822

Leoncini A, Huskens J, Verboom W (2017) Ligands for f-element extraction used in the nuclear fuel cycle. Chem Soc Rev. https://doi.org/10.1039/c7cs00574a

Sajimol R, Bera S, Sivaraman N, Joseph M (2017) Direct burn-up determination of fast reactor mixed oxide (MOX) fuel by preferential evaporation of interfering elements. J Radioanal Nucl Chem. https://doi.org/10.1007/s10967-015-4631-22016

Maity UK, Manoravi P, Sivaraman N, Joseph M, Mudali UK (2018) Fast burn-up measurement in simulated nuclear fuel using ICP-MS. Radiochim Acta. https://doi.org/10.1515/ract-2018-2961

Sivaraman N, Subramaniam S, Srinivasan TG, Vasudeva Rao PR (2002) Burn-up measurements on nuclear reactor fuels using high performance liquid chromatography. J Radioanal Nucl Chem 253(1):35–40

Ostapenko V, Vasiliev A, Lapshina E, Ermolaev S, Aliev R, Totskiy Y, Zhuikov B, Kalmykov S (2015) Extraction chromatographic behavior of actinium and REE on DGA, Ln and TRU resins in nitric acid solutions. J Radioanal Nucl Chem 306:707–711

Miranda MG, Russell B, Ivanov P (2018) Measurement of 151Sm in nuclear decomissioning samples by ICP-MS/MS. J Radio Anal Nucl Chem 316:831–838

Dry DE, Oldham WJ, Sm Bowen (2009) Determination of 151Sm and 147Pm using liquid scintillation tracer methods. J Radioanal Nucl Chem 282:635

Cawthray JF, Weekes DM, Sivak O, Creagh AL, Ibrahim F, Iafrate M, Haynes CA, Wasan KM, Orvig C (2015) In vivo study and thermodynamic investigation of two lanthanum complexes, La(dpp)3 and La(XT), for the treatment of bone resorption disorders. Chem Sci 6(11):6439–6447

Castelli DD, Terreno E, Cabella C, Chaabane L, Lanzardo S, Tei L, Visigalli M, Aime S (2009) Evidence for in vivo macrophage mediated tumor uptake of paramagnetic/fluorescent liposomes. NMR Biomed. https://doi.org/10.1002/nbm.1416

Bertelsen ER, Jackson JA, Shafer JC (2020) A survey of extraction chromatographic f-element separations developed by E. P. Horwitz Solvent. Extr Ion Exc. https://doi.org/10.1080/07366299.2020.1720958

McAlister DR, Horwitz EP (2007) Characterization of extraction of chromatographic materials containing bis(2-ethyl-1-hexyl)phosphoric acid, 2-ethyl-1-hexyl (2-ethyl-1-hexyl) phosphonic acid, and bis(2,4,4-trimethyl-1-pentyl)phosphinic acid solvent. Extr Ion Exc. https://doi.org/10.1080/07366290701634594

Choppin GR (2002) Covalency in f-element bonds. J Alloys Compd 344(1–2):55–59

Horwitz EP, Bloomquist CAA (1975) Chemical separations for super-heavy element searches in irradiated uranium targets. J Inorg Nucl Chem 37(2):425–434

Payne RF, Schulte SM, Douglas M, Friese JI, Farmer OT III, Finn EC (2010) Investigation of gravity lanthanide separation chemistry. J Radioanal Nucl Chem. https://doi.org/10.1007/s10967-010-0838-4

Hirahara Y, Chang Q, Miyazaki T, Takahashi T, Kimura JI (2012) Improved Nd chemical separation technique for 143Nd/144Nd analysis in geological samples using packed Ln resin columns. JAMSTEC Rep Res Dev 15:27–33

Arrigo LM, Beck CL, Finn EC, Finch ZS, Gregory SJ, Seiner BN, Snow LA, Metz LA (2014) Optimization of lanthanide separations using Eichrom’s LN resin. American Chemical Society National Meeting. Dallas, TX

Ireland TJ, Tissot FLH, Yokochi R, Dauphas N (2013) Teflon-HPLC: a novel chromatographic system for application to isotope geochemistry and other industries. Chem Geol 357:203–314

Snow M, Ward J (2019) Fundamental distribution coefficient data and separations using eichrom extraction chromatographic resins. J Chromatogr A 2:6. https://doi.org/10.1016/j.chroma.2019.460833

Miller JM (2005) Chromatography: concepts and contrasts, 2nd edn. Wiley, Hoboken

Field RJ, Koros E, Noyes RM (1972) Oscillations in chemical systems II Thorough analysis of temporal oscillation in the bromate-cerium-malonic acid system. J Am Chem Soc. https://doi.org/10.1021/ja00780a001

Schnabel C, Münkerab C, Strub E (2017) La–Ce isotope measurements by multicollector-ICPMS. J Anal At Spectrom. https://doi.org/10.1039/c7ja00256d

Zawierucha I, Nowik-Zajac A (2019) Evaluation of permeable sorption barriers for removal of Cd(II) and Zn(II) ions from contaminated groundwater. Water Sci Technol 80(3):448–457

Acknowledgements

This material is based upon work supported through the INL Laboratory Directed Research & Development Program under DOE Idaho Operations Office Contract DE-AC07-05ID14517. Neither the U.S. Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe on privately owned rights. References herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise, does not necessarily constitute or imply its endorsement, recommendation, or favoring by the U.S. Government or any agency thereof. Views and opinions of the authors expressed herein do not necessarily reflect those of the U.S. Government or any agency thereof.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ward, J., Bucher, B., Carney, K. et al. Exploring lanthanide separations using Eichrom’s Ln Resin and low-pressure liquid chromatography. J Radioanal Nucl Chem 327, 307–316 (2021). https://doi.org/10.1007/s10967-020-07491-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-020-07491-0