Abstract

We present the validation of a radiochemical procedure for the determination of 55Fe and 63Ni in water and steel samples from nuclear decommissioning activities. The in-house validation was an essential requirement of the accreditation to ISO/IEC 17025. A combination of co-precipitation, anion chromatography and extraction chromatography steps was used for separating and purifying both radionuclides. The activities were measured by liquid scintillation counting. Due to the lack of reference materials, the method was validated by analysing simulated samples and by the standard addition technique. The parameters precision/accuracy, repeatability/linearity, selectivity/specificity, decision threshold, detection limit and uncertainty of the method were evaluated.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

After 47 years of continuous operation, the Mühleberg Nuclear Power Plant (NPP) in Switzerland was permanently shut down in December 2019. Nuclear decommissioning has therefore become an important issue in Switzerland. The decommissioning of this NPP started in January 2020 and will continue for approximately a period of 15 years. One of the most important decommissioning activities will be the dismantling of the nuclear reactor. Materials and equipment near the reactor case may be activated by the long-term irradiation with neutrons from the reactor core and can therefore be radioactive [1, 2]. Before dismantling and stocking these materials/equipment, they must be checked for radiation [2]. The radiological characterisation is essential for a cost-effective dismantling planning and for minimizing the radiation exposure of the staff involved in dismantling activities.

A large number of neutron activated radionuclides are gamma emitters and their contents in the construction materials of the reactor can be rather easily determined by non-destructive methods like gamma-ray spectrometry [2, 3]. Some important radionuclides are, nonetheless, alpha or beta emitters and destructive methods need to be used for their analyses. Iron-55 (55Fe) and nickel-63 (63Ni) are among the so-called difficult-to-measure radionuclides. Both radionuclides can be produced by neutron activation reactions in the structural materials of a nuclear reactor [1, 2].

55Fe (half-life: 2.747 years) is the most abundant neutron activated radionuclide in a nuclear power plant shortly after shutdown [4]. 55Fe is produced by the reactions 54Fe(n,γ)55Fe and 56Fe(n,2n)55Fe (Table 1). This radionuclide can be found in high levels in steel, and at important levels in concrete. 55Fe is one of the main contributors to the total activity of the radioactive wastes in the first decades after the NPP shut down.

55Fe decays via electron capture to stable 55Mn emitting Auger electrons and low energy X-rays (5.9 and 6.5 keV). Due to the strong self-absorption of the low energy radiation, the quantitative determination is rather challenging and expensive. Liquid scintillation counting (LSC) has shown to be the most sensitive technique for determining this radionuclide [5, 6]. This counting technique avoids absorption and assure a high detection efficiency. The amount of stable Fe in the sample needs to be limited due to the potential increase of the quenching effect in LSC from the typically colored iron species. Before any counting by LSC, 55Fe needs nonetheless to be isolated from potential interferences. Several studies have shown that a combination of hydroxide precipitation with anion exchange chromatography is a successful way to isolate and purify this radionuclide [7,8,9]. 60Co (half-life: 5.27 years) with two β transitions (Table 1) is one of the most important interfering radionuclide. 59Fe, another potential interference, has a relatively short half-life of 0.12 years (Table 1). Hence, high activities of this radionuclide would normally not be expected in decommissioning samples after the cooling period of five years that follows the switch off of a nuclear power plant [10]. Both 60Co and 59Fe, if present in the materials, can be rather easily determined by gamma-ray spectrometry.

63Ni (half-life: 98.70 years) is mainly produced by the activation reactions 62Ni(n,γ)63Ni and 63Cu(n,p)63Ni (Table 1). Hence, this radionuclide can be found in steel, but also in other materials used in the reactor such as graphite, concrete, lead, and aluminium alloys [11]. 63Ni is a pure β emitter, with a maximum beta energy of 66.98 keV, and is therefore important for the effective long-term management of the radioactive wastes. LSC is the most widely used method for measuring 63Ni [5,6,7, 11]. However, 63Ni has to be fully isolated from other interfering radionuclides before its measurement. Most published procedures rely on the complexation of Ni with butanedioxime (2,3) [old name: dimethylglyoxime, DMG]) [12].

In recent years, the use of extraction chromatography materials based on the fixation of the DMG extractant in a solid phase (e.g. Ni-Resin from Triskem) has become the leading technique for separating and purifying Ni [7, 9, 11]. DMG is nonetheless not selective for Ni ions, and other interfering elements such as Cr, Co and Cu are as well complexed by DMG. Consequently, additional purification steps are necessary to separate Ni from potentially interfering radionuclides such as 60Co. Several studies have demonstrated that Ni can be separated from these radionuclides by anion exchange chromatography. Hence, most methods are based on the combination of anion exchange separation with extraction chromatography in a Ni-Resin [7].

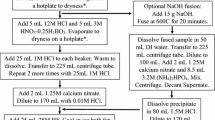

The present study deals with the validation of the radiochemical procedure used at Spiez Laboratory (Switzerland) for determining 55Fe and 63Ni in steel and water samples from decommissioning activities. The in-house validation of the method was an essential requirement of the accreditation to ISO 17025, in order to demonstrate the validity of the method. The radiochemical method is based on previously published methods [6,7,8, 11, 13] and included the following main steps: (1) co-precipitation; (2) anion exchange chromatography; (3) extraction chromatography; and (4) activity counting by LSC (Fig. 1).

The analysis of reference materials with certified activities for the radionuclides of interest is usually the easiest way for testing and validating a radiochemical method. However, there were not readily available reference materials for 55Fe and/or 63Ni radionuclides at the laboratory. This problem was partly avoided by analysing simulated samples, spiked with known amounts of tracer solutions, assuming that the spiked sample behave the same way as the real sample. In this study, we have only spiked liquid samples with known chemical composition and that are easy to homogenize. One important advantage of spiking the samples is that the isotope/element of interest is added in a precisely known amount. This is one of the major reasons for employing spiked samples to determine the accuracy and precision of an analytical procedure. The results were further validated by applying the standard addition technique. The repeatability of the method was demonstrated by repeated analysis of an activated steel sample that was several years under neutron irradiation in a Swiss nuclear reactor.

Experimental

Reagents

All reagents were of analytical grade. Deionised water from an arium® pro UF Ultrapure Water system (Sartorius), 65% nitric acid p.a. (prepared on a quartz sub-boiling apparatus) and 37% hydrochloric acid p.a. were used for the analyses. Ultima Gold A/B (PerkinElmer Inc.) was used as scintillation cocktail. 63Ni standard solution (No. 1912/27562) was purchased from the Laboratoire de Métrologie des Rayonnements Ionisants National (nowadays Laboratoire National Henri Becquerel) of the Commissariat à L'Énergie Atomique (CEA, Gif-sur-Yvette, France). 55Fe standard solution (No. 1895-49) was obtained from Eckert&Ziegler (California, USA). 60Co standard solution (No. S7/44/51) was purchased from Isotrak, AEA Technology (Amersham Laboratories, Buckinghamshire, UK). Fe, Ni and Co single element standard solutions were obtained from Merck (in Switzerland). The high and low-alloy steel reference samples (NIST125b and NIST345b) were purchased from NIST (USA). The anion exchange resin (A4-B500-M-Cl, 1 × 4, Cl− form, 100–200 mesh) and the pre-packed 2 mL Ni-resin columns were purchased from Triskem International (France).

Equipments

All 63Ni and 55Fe measurements were performed in an ultra-low level Liquid Scintillation Counter Quantulus 1220 (PerkinElmer Inc., Wallac Oy, Finland). A high-resolution gamma spectrometry system, with a high purity germanium detector (HPGe, resolution of 1.8 keV at 1332 keV), equipped with APEX-GAMMA analysis software (Canberra Industries, USA) was used to acquire and analyse all the gamma spectra. LABSOCS software (Canberra) was used for obtaining the efficiency calibration curve of the gamma detector. Inductively coupled plasma optical emission spectrometry (ICP–OES, Varian Vista Pro, Varian Inc.) was used for measuring stable Ni, Fe and other chemical elements. Inducted coupled plasma mass spectrometry (NexION 300 D, PerkinElmer) was used to measure stable Fe, Ni and other elements during testing digestion methods for steel samples. A microwave digester Multiwave PRO (Anton Paar GmbH) was utilized to digest the steel samples.

Sample preparation

A set of non-radioactive simulated samples was freshly prepared by adding known amounts of Co, Cu, Cr, Sr, Eu, Fe and Ni element standard solutions to deionized water. The standard solutions were added in such a way to obtain element specific masses varying between 0.1 and 4 mg per volume of sample. After adding the standard solutions, the spiked samples were homogenized by stirring for 1 h at room temperature. Another set of non-radioactive simulated samples was prepared by diluting the steel solutions obtained from the digestion of the two NIST steel reference materials. The chemical composition of the simulated samples was controlled by ICP-OES. All these samples were prepared to test the radiochemical separation method (e.g. selectivity / specificity, precision / accuracy), investigate decontamination factors and to study the background of the liquid scintillation counters. It was assumed that a simulated sample behave the same way as a real sample.

As no reference material was available for 55Fe and 63Ni, a set of radioactive simulated samples (containing 55Fe and 63Ni) was prepared for further validating the radiochemical method and for characterizing selected method parameters. Some of the previously prepared non-radioactive simulated samples (deionized water and steel solutions from the NIST reference materials) were spiked with known amounts of 55Fe and 63Ni standard solutions in order to obtain radionuclide activity concentrations in the range of 10 to 340 Bq per volume of spiked sample. These samples were additionally spiked with 60Co, in the same range of activities, for further verifying the decontamination from this potential interference. After adding the radionuclide standard solutions, samples were further homogenized by stirring for 1 h at room temperature.

For steel samples, the matrix needs first to be dissolved. However, there was no accredited method in our laboratory for steel dissolution. Hence, several digestion techniques were tested on two non-radioactive steel NIST reference materials (NIST125b and NIST345b). Aliquots of circa 300 mg of the reference materials were dissolved by the following digestion techniques:

-

Method 1: first step with a mixture of HNO3 65%/ HCl 30%/ HF 40% (2:3:5); and second step with HF 40%/ H3BO4 (1:8).

-

Method 2: one step with HNO3 65% / HCl 30% (2:6)

-

Method 3: first step with a mixture of HNO3 65%/ HCl 30%/ HF 40% (5:1:1); and second step with HF 40%/ H3BO4 (1:3).

For the three methods, the same program (Maximum temperature and pressure of 240 °C and 40 bars, respectively) was used in the microwave digester. After dissolution, the samples were filtered to remove non-dissolved particles, and then aliquots were analyzed by ICP-MS.

Radiochemical separation method

The procedure used at Spiez Laboratory (Switzerland) for determining 55Fe and 63Ni is based on methods published elsewhere [7]. Therefore, we do not describe here all the separation steps in detail, but the most important ones. Before any destructive method can be applied, decommissioning samples must be analysed by gamma-ray spectrometry. This information is essential for taking the proper radiation protection measures at the laboratory during their analysis, and for estimating the presence of potential interfering radionuclides.

An aliquot of the sample solution is analyzed by ICP-OES to get information about its chemical composition, especially the Fe and Ni contents. In water samples, the Fe and Ni contents are usually very low or negligible, and the addition of carriers is required. In the case of steel, however, the addition of carrier would depend on the Fe and Ni contents in the sample and the amount of sample.

In a first step, both radionuclides are concentrated by co-precipitating their hydroxides at pH 8–9 with NaOH. The use of ammonia is not recommended as Ni ions can be further complexed at pH above 8 and then remain soluble in the liquid phase [7]. An anion exchange resin (1 × 4, Cl− form) is then used for separating Fe from Ni and Co. Fe is fixed in the organic phase of the resin in strong HCl solutions as a tetrahedral-coordinated complex ([FeCl4]−). Ni and most elements with redox states (+ 1) or (+ 2) are not retained in the resin and flow through. Potential interferences such as Co and Cu are eluted by washing the resin with 4 M HCl. Fe is finally eluted from the resin with 0.5 M HCl. In order to further purify the Fe fraction, the eluted volume is evaporated to dryness, re-dissolved in 9 M HCl and passed a second time through an anion exchange resin (1 × 4, Cl− form) following the same separation scheme. The Fe-fraction is evaporated to dryness and the residues dissolved in a few mL of 1 M H3PO4. This solution is quantitatively transferred to a 20 mL plastic scintillation vial and filled up to 10 mL with water.

An aliquot of 0.1 mL is taken for the determination of the chemical separation yield by ICP-OES. The vial is then measured by gamma spectrometry to determine if 59Fe and/or 60Co are present in the Fe fraction, and in this case quantify them. The contribution of 59Fe and/or 60Co to the region of interest (ROI) in the liquid scintillation spectra can then be corrected.

For the separation of Ni from the remaining matrix elements, the extraction chromatography Ni-Resin is used. Nickel ions (Ni2+) form a chelate complex with the DMG ligand (Ni(C4H7O2N2)2 [7, 12] in ammonia solutions, and are held back in the column. Nickel is not complexed with DMG in 3 M HNO3, and Ni2+ is washed off the column. The Ni fraction is evaporated to near dryness, and then re-dissolved in a few mL of water. The solution is quantitatively transferred to a 20 mL plastic scintillation vial and filled up to 10 mL with water. An aliquot of 0.1 mL is taken for the chemical yield determination by ICP-OES. The vial is then measured by gamma spectrometry for determining if any 60Co is present in the Ni fraction, and if present quantify it. The contribution of 60Co to the region of interest in the liquid scintillation spectra can then be corrected.

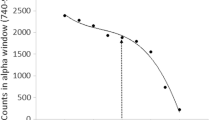

Counting 55Fe and 63Ni by liquid scintillation

The scintillation cocktail (10 mL Ultima Gold AB) is added to the sample vials containing the Fe or Ni fractions, mixed and then counted by LSC in a Quantulus 1220. The activity of 55Fe is determined by measuring the low energy X-rays (Kα: 5.9 keV and Kβ: 6.5 keV) in a measuring range from 0 to 6 keV (ROI: 50–220). Hence, the low energy beta window is used for this measurement. The activity of the 63Ni is determined by measuring the β radiation (Eβmax: 63 keV) in the energy range from 0 to 30 keV (ROI: 50–320). The samples are counted in three to five intervals of 1800 s.

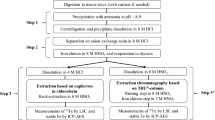

The counting efficiency in the ROI of the spectra was determined using certified 63Ni and 55Fe standard solutions. For each radionuclide, a set of samples spiked with known amounts of the standard solution and different quench parameters was prepared. These samples have approximately the same composition and geometry as the 63Ni and 55Fe fractions prepared by our method. The quench parameter was simulated by adding different quantities of CCl4 (up to 200 μL) to the set of samples. The counting efficiency ε (Bq−1 s−1) was determined for each sample of the quench set, and the equation relating it with the quench parameter (SQP(ε) for the Quantulus) was calculated (Fig. 2a).

For 59Fe, no standard solution was available at the laboratory. Therefore, for calibrating the LSC, the CIEMAT/NIST method was used [14]. This method is a relative method, which is suitable for the activity determination of pure beta, beta-gamma, pure EC and EC-gamma decaying radionuclides using commercial liquid scintillation counters. Tritium (3H) was used as tracer radionuclide for obtaining the universal curve for which the probability of detection for each radionuclide can be determined. A model for the counting efficiency depending on a free parameter was developed for 59Fe. A similar approach was used for 60Co. We then calculated the detection efficiency ε for 59Fe or 60Co according to the equations given in Fig. 2b.

Activity, decision threshold and detection limit

The activity concentration (a, in Bq L−1 or Bq kg−1) of 55Fe or 63Ni in the original sample is calculated according to the Eq. (1):

where Nb and No are sample and blank counts respectively; tm is the counting time (s−1); ε the liquid scintillation counting efficiency (Bq−1 s−1); η the chemical separation yield; ms the mass or volume of the sample (L or kg); λ is decay constant of the radionuclide (55Fe: 8.051⋅10−9 s−1; 63Ni: 2.198⋅10−10 s−1); and t is time elapsed between the sampling and measurement dates (s). The chemical yield η is calculated according to the Eq. (2):

where Ce is the Fe or Ni concentration in the final fraction (mg mL−1); Cp is the Fe or Ni concentration in the sample (mg L−1); Ve is the elution volume (ml); and Vp is the sample volume used for the chemical separation process (L). If a carrier is used then (3):

in which mo is the Fe or Ni content in the original sample (volume used only for the separation process, in mg); and mt is the Fe or Ni mass added with the carrier solution (in mg).

The uncertainty of the activity concentration of 55Fe or 63Ni was calculated as a combined uncertainty, taking into account the contribution of each parameter uncertainty. The relative standard deviation of the calibration factor results from the statistical parameters of the regressions represented in Fig. 2. Experience has shown that standard deviations of up to 3% are expected (k = 2). The relative standard deviation of the chemical yield when using the ICP-OES is of maximum 5% (k = 2). The uncertainties of pipetting and dilution processes have already been taken into account. With these relative uncertainties, the combined uncertainties of the activity concentrations of 55Fe and 63Ni are of maximum 12%.

Taking into account that samples and background are counted over the same time (tm, in s), the decision threshold y* (in Bq) is calculated according to the following Eq. (4) [15, 16]:

where w is a conversion factor (here w = 1/(ε∙η)); u(0) denotes the uncertainty of the background measurement; k1−α is the quantile for the specified error of the first kind (k1−α = 1.645 for α = 5%); η is the chemical yield and ε is the calibration factor in Bq−1 s−1.

The detection limit y# (or minimum detectable activity, in Bq) is calculated from explicit equations according to [15, 16]:

where k1−β is the quantile for the pre-set risk of not detecting anything in the sample (k1−β = 1.645 for β = 5%); urel(w) is the relative uncertainty of the conversion factor; and k = k1−α = k1−β (k1−α = k1−β = 1.645 for α = β = 5%).

Results and discussion

Digestion methods for steel samples

A summary of the recoveries obtained by the three methods tested for dissolving steel samples is presented in Table 2. All three methods showed excellent recoveries for Fe and Ni, and for most of the elements present in the steel reference materials. The Method-2 has the advantage of not using HF and therefore a second step to complex fluoride ions was not necessary. However, unlike Method-1 and Method-3, the solution obtained by Method-2 was not completely clear. This was probably due to the presence of silicates in solution, which were present in both NIST reference materials. According to the results given in Table 2, this had no significant impact on the recovery of most of the elements, including Fe and Ni. Hence, the Method-2 was chosen as a standard technique for dissolving steel samples from decommissioning activities in our laboratory.

Selectivity and specificity of the method

For testing the selectivity/specificity of the chemical separation method, the non-radioactive simulated samples were used. The simulated samples were prepared in such a way that the total contents of Co, Cu, Cr, Sr, Eu, Fe and Ni in the sample varied between 0.1 and 4 mg. The chemical separation was carried out following the procedure depicted in Fig. 1. Aliquots from all loading, breakthrough and washing solutions and from the Fe and Ni final fractions were analysed by ICP-OES. The distribution of the elements in each fraction and their corresponding separation factors were determined.

A summary of the results in the final fractions is presented in Table 3. Ni was separated quantitatively from Co and Fe; and Fe was as well separated from Co. Our method does not assure high decontamination factors of Ni from Cr or of Fe from Cu. However, Cu and Cr radionuclides are rarely present in significant levels, or not present at all, in steel and water samples from decommissioning activities.

The experiments showed that high decontamination factors for Fe and Ni from most of the relevant elements are achieved with the proposed chemical separation method (Fig. 1). A quantitative separation from potentially interfering radionuclides such as 60Co, 152Eu and 90Sr is therefore assured (Table 3). With the radiochemical separation method, 55Fe or 63Ni can then be analysed accurately after separation from potential interferences that may be expected to be present in the sample matrix.

Precision and accuracy

The precision and accuracy of the method were verified by analysing a serial of simulated samples, spiked with known amounts of 63Ni and 55Fe standard solutions. As 60Co is one of the most important interfering radionuclides, known amounts of a 60Co standard solution were also added to the simulated samples. Final activities of the radionuclides in the simulated samples varied between 10 and 340 Bq. All the results of the analyses (20 for 55Fe and 17 for 63Ni), expressed as the ratio of the measured to the reference activity in each simulated sample, are summarized in Fig. 3.

For both radionuclides, the measured activities were in good agreement with the target activities, with maximum deviations of circa 20%. The radiochemical method showed a better accuracy for 55Fe (average ratio of 0.99) than for 63Ni (average ratio of 0.94), but a slightly better precision for 63Ni (± 0.09) compared to 55Fe (± 0.13) (Fig. 3). These results highlight the rather good precision and accuracy of the method for these radionuclides.

The chemical yields are high and reproducible, with mean values for Fe and Ni of 80% and 96%, respectively. 60Co was not detected in any of the 55Fe or 63Ni fractions, which further demonstrate the robustness and high selectivity of the radiochemical method.

Repeatability and linearity

The repeatability of the method was demonstrated by repeated analysis of an activated steel sample. The activated steel was taken from the bottom structure of the nuclear fuel element. As the steel was several years under neutron irradiation in a Swiss nuclear reactor, high activity levels of 55Fe and 63Ni were expected. The analysis of the activated steel sample by gamma-ray spectrometry indicated that 60Co was present at a high activity concentration of 3.0 × 108 Bq g−1. 54Mn was also detected, but at an activity two orders of magnitude lower (1.5 × 106 Bq g−1). 59Fe was not detected in the activated steel, probably because it had completely decayed at the time of the measurement.

The activated steel sample (about 1 mg) was dissolved by using the digestion Method-2. As a dose rate of 0.3 mSv h−1 was measured at the surface of the non-shielded activated steel sample, the steel solution was diluted to 100 mL with deionized water. The objective of the dilution was to avoid high radiation protection requirements during further analysis of aliquots.

The measurement by ICP-OES showed that the major components of the steel were Fe (54%), Cr (15%), Ni (6.8%), Mn (0.62%), Co (0.15%), Cu (0.12%) and Pb (0.3%). Trace concentrations of V (0.075%) and Mo (0.096%) were also measured.

For testing the repeatability, four parallel analyses of 55Fe and 63Ni in the activated steel solution were conducted (Table 4, Fig. 4). Aliquots of 1 mL (runs 1 and 2, Table 4) and 5 mL (runs 3 and 4, Table 4) of the steel solution were taken. These aliquots were further diluted to 100 mL with deionized water before the radiochemical separation. Due to the low levels of Fe, Ni and Co in these aliquots, carriers (1 mg of each element) were added for the analysis.

As observed in Table 4, the radiochemical method exhibits an excellent repeatability for both radionuclides in the activated steel sample. 60Co was not detected (< 0.03 Bq) in any of the 55Fe or 63Ni fractions, which further confirm the high decontamination factors of Fe and Ni from Co. The efficient sample preparation and purification steps successfully removed this interference.

The 55Fe and 63Ni activities in the activated steel sample were also determined by the standard addition method (Fig. 4), which is a useful technique for validating analytical methods. Known amounts of 55Fe and 63Ni standard solutions were added in an incremental way to four aliquots of the same amount of the activated steel solution. These four aliquots were then analyzed for 55Fe and 63Ni following the same radiochemical method. The activities of 55Fe and 63Ni in the activated steel sample were determined by fitting the data to a linear regression and then finding the intercept of the linear correlation (Fig. 4).

The activities of 55Fe and 63Ni, determined with the standard addition method, were in good agreement with the ones obtained by the direct application of the radiochemical method (Fig. 4). The standard addition approach demonstrated as well the good linear response of the method for both radionuclides in the range of activities analysed (Fig. 4).

Decision threshold and detection limit

The decision threshold and detection limit were determined based on the analysis of blank samples (deionised water or inactive steel), free of radioactive 55Fe or 63Ni. The blanks were analyzed as normal samples, and the Fe and Ni fractions were measured four times by LSC. As for the samples, the counting time was fixed to 1800s. For 55Fe, typical decision threshold and detection limit were of 0.05 and 0.10 Bq, respectively. For 63Ni, typical decision threshold and detection limit were of 0.02 and 0.03 Bq, respectively. The low detection limits are appropriate for the identification and quantification of 55Fe and 63Ni in samples from nuclear decommissioning activities.

Conclusions

In this study, we validated a radiochemical method for the determination of 55Fe and 63Ni in two important types of decommissioning samples, steel and water. The validation of this method addressed the needs of the nuclear power plant decommissioning activities in Switzerland. As no reference materials for 55Fe and 63Ni were readily available, repeated analysis of simulated samples was used for the validation. A good agreement between the results in the simulated samples and the target values revealed a good accuracy of the method. The selectivity/specificity of the method was ensured by the refined chemical separation and purification of 55Fe and 63Ni from potential interferences, and by the targeted decay counting of the radioactive beta radiation by liquid scintillation. The standard addition technique was used for further validating the application of the method. This technique showed to be useful as an alternative validation approach, especially if reference materials with certified activities are not readily available.

The application of the method to an activated steel from a Swiss nuclear reactor produced repeatable results. The analysis of this specific sample evidenced the high levels of activity from these two radionuclides that are to be expected in decommissioning activities.

References

Pretzsch G, Gmal B, Hesse U, Hummelsheim K (2012) Neutron activation of reactor components during operation lifetime of a NPP. Trans. Proceedings of an international symposium: nuclear power plant life management. Vienna, Austria

IAEA (1998) Technical report series no. 389: radiological characterization of shut down nuclear reactors for decommissioning purposes. Trans, vol., vol, edn. International Atomic Energy Agency, Vienna.

Leskinen A, Salminen-Paatero S, Räty A, Tanhua-Tyrkkö M, Iso-Markku T, Puukko E (2020) Determination of 14C, 55Fe, 63Ni and gamma emitters in activated RPV steel samples: a comparison between calculations and experimental analysis. J Radioanal Nucl Chem Art 323(1):399–413. https://doi.org/10.1007/s10967-019-06937-4

König W, Schupfner R, Schüttelkopf H (1995) A fast and very sensitive LSC procedure to determine Fe-55 in steel and concrete. J Radioanal Nucl Chem 193(1):119–125. https://doi.org/10.1007/bf02041925

Hou X (2018) Liquid scintillation counting for determination of radionuclides in environmental and nuclear application. J Radioanal Nucl Chem. https://doi.org/10.1007/s10967-018-6258-6

Bowers D, Greenwood LR (1988) Analysis of long-lived isotopes by liquid scintillation spectrometry. J Radioanal Nucl Chem 123:461–469. https://doi.org/10.1007/BF02034910

Hou X, Østergaard LF, Nielsen SP (2005) Determination of 63Ni and 55Fe in nuclear waste samples using radiochemical separation and liquid scintillation counting. Anal Chim Acta 535(1–2):297–307. https://doi.org/10.1016/j.aca.2004.12.022

Raymond A, Revy D (1989) Determination of iron 55 in nuclear wastes and effluents. Trans., vol, edn., France.

Song L, Ma L, Ma Y, Yang Y, Dai X (2019) Method for sequential determination of 55Fe and 63Ni in leaching solution from cement solidification. J Radioanal Nucl Chem 319(3):1227–1234. https://doi.org/10.1007/s10967-018-6391-2

Röllin S, Sahli H, Holzer R, Astner M, Burger M (2009) Pu and Np analysis of soil and sediment samples with ICP-MS. Appl Radiat Isot 67(5):821–827. https://doi.org/10.1016/j.apradiso.2009.01.041

Gautier C, Colin C, Garcia C (2015) A comparative study using liquid scintillation counting to determine 63Ni in low and intermediate level radioactive waste. J Radioanal Nucl Chem 308(1):261–270. https://doi.org/10.1007/s10967-015-4301-4

Taddei MHT, Macacini JF, Vicente R, Marumo JT, Sakata SK, Terremoto LAA (2013) Determination of 63Ni and 59Ni in spent ion-exchange resin and activated charcoal from the IEA-R1 nuclear research reactor. Appl Radiat Isot 77:50–55. https://doi.org/10.1016/j.apradiso.2013.02.014

Lehto J, Hou X (2011) Radiochemistry of the 3d-transition metals. In: Chemistry and analysis of radionuclides. Wiley-VCH, Weinheim, pp 123–137. https://doi.org/10.1002/9783527632770.ch8

Carles PG, Malonda AG (2001) Free parameter, figure of merit and ionization quench in liquid scintillation counting. Appl Radiat Isot 54(3):447–454. https://doi.org/10.1016/S0969-8043(00)00272-4

De Felice P, Jerome S, Petrucci A (2017) Practical implementation of ISO 11929: 2010. Appl Radiat Isot 126:256–262. https://doi.org/10.1016/j.apradiso.2017.02.004

ISO (2010) ISO 11929 Standard. Determination of the characteristic limits (decision threshold, detection limit and limits of the confidence interval) for measurements of ionizing radiation—fundamentals and application. Trans., vol, edn., Geneva, Switzerland

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Corcho-Alvarado, J.A., Sahli, H., Röllin, S. et al. Validation of a radiochemical method for the determination of 55Fe and 63Ni in water and steel samples from decommissioning activities. J Radioanal Nucl Chem 326, 455–463 (2020). https://doi.org/10.1007/s10967-020-07297-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-020-07297-0