Abstract

Plutonium certified reference materials (CRMs) 136, 137, and 138 were produced, characterized, and certified in the period 1966 through 1971 by the National Bureau of Standards. The thermal ionization mass spectrometry (TIMS) instruments and the analytical methodologies evolved significantly since the characterization of these Pu isotopic standards. Given the excellent precision of modern TIMS and inductively coupled plasma instruments, systematic biases at the major and minor isotope ratios of these plutonium (Pu) isotopic standards (compared to the certified values) are to be expected. Studies on the major and minor isotope ratios of uranium (U) CRMs indicated systematic bias in the certified ratios of several of these standards. We present a systematic investigation of the 240Pu/239Pu major isotope ratio of Pu isotopic CRM138. The 240Pu/239Pu isotope ratio is shown to be biased by ~ 0.07–0.08%, larger than the bias seen in the major isotope ratio of any of the U CRM from New Brunswick Laboratory (NBL).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Standards traceable to the international system of units (S.I.) are used for calibration of the TIMS instruments used for isotope ratio measurements in support of nuclear safeguards. For plutonium isotope ratio measurements by TIMS CRMs 136, 137, and 138 characterized during the period 1966–1971 are commonly used for instrument calibration. During the characterization measurements of these Pu isotopic CRMs at National Bureau of Standards (NBS, predecessor organization to National Institute of Standards & Technology—NIST) gravimetric mixtures of uranium, prepared by quantitatively mixing highly enriched uranium isotopes, were used for calibration of the custom-built NBS mass spectrometer instruments. As sufficiently pure isotopic end-members were not available for preparation of gravimetric mixtures of plutonium, mass fractionation effects at Pu were corrected using U isotopic mixtures using the assumption that in isotope ratio measurements of plutonium and uranium the mass fractionation effects are similar. The responsibility for distributing, maintaining, and certifying nuclear standards, including plutonium and uranium, was transferred to NBL in 1987.

CRMs with characterized values for the amount contents and isotopic ratios are used to assure that the measurement systems are free of systematic biases in the whole measurement process at all stages including sample preparation and qualification/validation of measurement techniques used by nuclear analytical facilities. The standards used for evaluation of the performance of the measurement systems undergo the same preparation steps as the samples being analyzed. In order to assure that biases due to matrix effects are absent or insignificant, both the standards (working reference materials prepared from CRMs or cross-calibrated against CRMs can also be used as standards) and the samples are analyzed in matrices as similar as possible. For isotope-amount ratio measurements, systematic biases due to matrix effects are well documented in literature [1]. TIMS measurements are less prone to such biases and therefore had been more widely applied to certification measurements of isotopic CRMs [2, 3]. Most commonly used TIMS analytical methods are total evaporation (TE) following ASTM Test Method C1672, modified total evaporation (MTE) following ASTM Test method C1832, and conventional analyses following ASTM Test Method C1625. These methods have been used extensively for the characterization measurements of new isotopic CRMs from NBL and Institute for Reference Materials and Measurements (IRMM—now called, Joint Research Center—Geel).

TE is an established technique for U and Pu major isotope ratio measurements using TIMS instruments. Additional details about the application of the TE method to U and Pu isotopic measurements using TRITON instrument are available in literature [4, 5]. Due to the better precision obtained for the major isotope ratios (235U/238U ratio for U materials and 240Pu/239Pu ratio for Pu materials) the TE technique has emerged as the preferred technique for major ratio measurements. For minor isotope ratio measurements, the TE method yields biased data due to the inability to make peak-tailing corrections. The magnetic field stays constant during the course of the TE analyses and measurement of the peak-tail intensities is not possible as part of the measurement routine. For accurate minor isotope-amount ratio measurements, the ability to perform the peak-tailing corrections is necessary.

The accuracy and precision of TIMS isotopic measurements, vary significantly from one analytical technique to another. This was demonstrated for uranium isotope ratio measurements using the TE, MTE, and Conventional analytical techniques using the TRITON multi-collector TIMS instrument and NBL CRMs [2, 3, 6, 7]. The MTE analytical method using Triton has been extensively used for characterization/certification measurements [2, 3].

For U CRMs, Richter and Goldberg [6] performed a cross-comparison of isotopic standards w.r.t. CRM U500 using the state-of-the-art analytical technique MTE. These measurements, performed at NBL, found systematic biases in the range of − 0.04 to + 0.05% for the 235U/238U major isotope ratio of some U standards. Systematic biases in the range of − 0.32 to 0.20% were identified in the certified 234U/238U ratios and of − 0.65 to 0.71% were observed in the 236U/238U ratio. These biases in the major and minor isotope ratios of U standards have since been confirmed during the recent characterization work at NBL [2, 7]. Recent studies also identified systematic biases in other U isotopic CRMs from NBL.

For Pu isotopic standards, no such cross-comparison study has been performed. Given that the characterizations of the Pu isotopic CRMs were performed in the 1966–1971 period, using the NBS fabricated (custom-made) TIMS instruments, the magnitude of the systematic biases are expected to be larger for the Pu CRMs. Note also that, as previously mentioned, gravimetric U mixtures were used for instrument calibration. Even for the major ratios, biases larger than those observed at U CRMs is expected.

Experimental

Experimental details about the analytical methods TE [4, 5], MTE [8], and Conventional [9] are available in literature and will not be repeated here for brevity. All data presented here were analyzed by the TRITON multi-collector (MC) TIMS instrument using the double filament geometry. Zone refined rhenium filaments as described in ASTM Test method C1672-17 [5] were used for the Pu isotopic analyses described here. Sample loads of 30 ng of plutonium were used for the TE experiments using the cup configuration shown in Table 1. TE analyses were performed at a summed signal intensity of 6 V (sum of the 239Pu and 240Pu signal intensities).

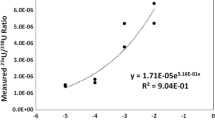

In the TE analytical technique, measurements (data acquisition) start as soon as a (summed) signal intensity of about 50 mV (sum of the 239Pu and 240Pu signal intensities) is obtained. Often, this requires heating of the evaporation filament (filament onto which analytes are loaded) to ~ 600–1000 mA whereas the ionization filament (filament onto which no sample is loaded—is used to generate the temperature conditions suitable for thermal ionization) is at a current of ~ 5000–5200 mA (sufficient to obtain 200–300 mV ion signal intensity at 187Re).

Multiple aliquots of CRM 137, Plutonium Isotopic Standard—10 mg Pu, in the form dry plutonium sulfate was analyzed as QC standard for the analyses reported here. Several aliquots of CRM 138, Plutonium Isotopic Standard (0.25 g of plutonium, in the form of plutonium sulfate tetrahydrate) were analyzed by the same analytical methodology (same ionization filament currents, same starting and ending signal intensities for isotope ratio measurements, same focus and peak centering actions before the start of the analyses, same sum intensities for data collection, and same integration time). All analyses were completed in an automatic sequence following daily calibrations that included updating of the magnetic field values for Re and Pu isotopes, gain and baseline calibrations, and source lens focusing parameters. All standards, for which data are presented here, were drop deposited onto the Re filaments as nitrate solutions. The concentrations of the Pu standard solutions were such that each 1 μL contained ~ 30 ng Pu.

Results and discussion

CRM 136, Plutonium Isotopic Standard—10 mg Pu, in the form of dry plutonium sulfate, was used as the comparator standard (standard used in TIMS analysis for estimation of the mass fractionation correction factor or K-factor is known as comparator standard). The mass fractionation correction was performed on a turret-per-turret basis using three to four aliquots of CRM 136 analyzed on the same sample wheel (turret). The acceptance criteria for TE analyses using TIMS are shown in Table 2. Table 2 shows that the mass fractionation correction factors are small and that the samples ran acceptable number of cycles. Small mass fractionation correction factor (close to unity) implies that the measured major isotope ratios are close to the true values for these ratios. The precision of the isotopic analyses (as represented by the standard deviation of the replicate analyses on the turret formatted as a percent, %RSD) are smaller than the 3-σ alarm limits for isotopic analyses of Pu materials in the respective category (For Pu analyses the standards/samples are categorized into low-burn-up and high-burn-up materials, corresponding to fuel grade and weapons grade material).

Table 2 also shows that the mass fractionation correction factor (for the 240Pu/239Pu ratio) varies between the different TE turrets. The fractionation correction factor between the different turrets varies by ~ 0.01–0.03% for the 240Pu/239Pu ratio. The sum integrated ratio from TE analyses is always slightly below the certified value decay corrected to the date of Pu/Am separation. Thus, if the assumption is made that the TE analysis yield true ratios for the major isotopes, an uncertainty of ~ 0.02% (average of the observed variability of 0.01–0.03%) will have to be attributed to that assumption. The TE analysis is, in principle, expected to yield true values. In practice, for Pu materials, the TE analysis yield 240Pu/239Pu ratios that are about 0.01–0.03% below the certified values.

Table 3 summarizes the analytical data on CRMs 137 and 138. Precisions (percent relative standard deviations for three to four aliquots measured on the same turret) in the range of 0.0022–0.0122% were observed for both 137 and 138. The observed precisions for 137 and 138 are also comparable to those in 136 (listed in Table 2).

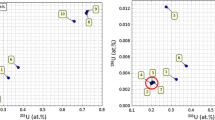

Figure 1 shows a comparison of the 240Pu/239Pu major isotope ratios in CRM 137 analyzed at actinide analytical chemistry of LANL. The ratios shown are corrected for mass bias effects using multiple aliquots of CRM 136 (see Table 2 for magnitude of the mass bias corrections and the other acceptance criteria for turret data). The relative deviations of the measured ratios in CRM 137 compared to the certified ratios decay corrected to the date of Pu/Am separation prior to analysis are shown.

Deviations of the mass fractionation corrected major ratio values in CRM 137 from the certified values (filled symbols). An average bias of 0.016% is observed in CRM 137 (relative to CRM 136). Within the observed precision of the measurements 0.0093% (percent relative standard deviation), CRM 137 data are biased. The measured values (not corrected for mass fractionation) in CRM 137 are shown as open symbols, for comparison purposes. For CRM 137, the 240Pu/239Pu ratio decay corrected to 8 June 2017 is 0.240753

The relative deviations (%RDs) shown in the control charts are calculated using Eq. (1) below:

The 2-σ warning and 3-σ alarm limits indicated in the control charts (Figs. 1, 2, 3) are calculated using Eqs. (2) and (3), shown below:

where %RSD is the relative standard deviation of the data set expressed as a percent (representing the contribution of the precision component to the overall uncertainty) and %RD is the average deviation of the measured values from the certified values expressed as a percent (representing the contribution of accuracy component to the overall uncertainty).

Deviations of the fractionation corrected major ratio values in CRM 138 from the certified values. An average bias of 0.073% is observed in CRM 138 (240Pu/239Pu in CRM 136 ≅ 0). Fractionation corrected values are shown as the filled symbols and the values corrected for the systematic bias are shown as open diamonds. For comparison the measured values (uncorrected for mass fractionation) are shown as open triangles. The mass fractionation corrected (as well as majority of the as measured 240Pu/239Pu) data for CRM 138 fall outside the alarm (3-σ) limits for the TE analytical method. For CRM 138, the 240Pu/239Pu ratio decay corrected to 8 June 2017 is 0.086122

Deviations of the mass fractionation corrected major ratio data for CRMs in the high-burnup category. Whereas only CRM 136 is used as the comparator standard in Fig. 1, four turrets here are corrected for mass fractionation effects using CRM 136 as comparator and two turrets are corrected using CRM 137 as comparator. Turrets for which CRM 137 are used as comparators are indicated by the ellipsoids (data shown in these cases is for CRM 136). The larger 2-σ and 3-σ limits (compared to Fig. 1) show that the systematic bias gets propagated into the uncertainty limits obtained as control limits. The as measured (uncorrected for mass fractionation) data are shown by the open triangles

The coverage factors of 2 and 3, respectively, for the warning and alarm limits are used to obtain 95 and 99% confidence limits for the analytical data set. These warning (2-σ) and alarm (3-σ) limits can be considered conservative estimates of the uncertainties realized in a single measurement using the analytical method.

Figure 1 shows that, for CRM 137, within the precision of the measurements, slight positive bias in the major ratio data is present. Figure 2 shows the relative deviations of the 240Pu/239Pu major isotope ratio in CRM 138. In both Figs. 1 and 2, CRM 136 is used as comparator standard (%RSD data for CRM 136 and the magnitude of the fractionation correction factor are stated in Table 2). The fractionation corrected major isotope ratio of CRM 138 is systematically biased by ~ 0.073%.

For isotope ratio measurements using TE, two different approaches are typically used by analytical laboratories to incorporate mass fractionation correction. Some facilities assume that the TE method, due to its very nature, yield isotope ratios close to the true value for the major isotope ratio [3, 4]. No correction for mass fractionation is made for total evaporation measurements. In this case, the absence of mass fractionation is established through bias-free measurement of traceable standards as QC materials. Other facilities measure the magnitude of the mass fractionation correction, often on a per turret basis, and apply this correction on another traceable standard (QC standard) and if the percent deviations in the QC standard falls within the performance limits for that QC standard, the mass fractionation correction is applied to the unknown samples. This latter approach also has the advantage that whereas traceability is achieved through the use of one certified standard for instrument calibration, all other functions the standard is expected to provide (measurement QC, evaluation of the performance limits of the analytical method, ensuring that instrument performance is acceptable, etc.) are performed by the second certified standard.

Another common practice with regard to mass fractionation correction is to use multiple traceable standard for mass fractionation correction. If multiple traceable standards are used as comparator standard, provided that the isotopic ratios of the standards used are not systematically biased, the uncertainty limits obtained from the control charts are more conservative. Figure 3 illustrates this. Whereas when CRM 136 alone is used as the comparator standard, 2-σ warning limit of 0.03 is obtained for the high-burnup enrichment category, 2-σ limit of 0.042% is obtained when both CRMs 136 and 137 are used as comparator standards. The systematic bias between CRM standards 136 and 137, as evident in the control chart shown in Fig. 1, is manifested in Fig. 3 as the larger variability of the data set (%RSD of 0.0186) compared to that of Fig. 1 (%RSD of 0.0093).

Conclusions

Systematic bias in the 240Pu/239Pu major isotope ratio of certified reference material standard 138 is identified. The magnitude of the bias is outside the performance limit of the Triton instrument for the total evaporation method. A systematic comparison of the different Pu isotopic CRMs is needed to evaluate the relative biases in these standards in relation one another. As CRMs 136, 137, and 138 were certified using similar instrumentation at NBS, a comparison of these standards against the newer isotopic standards (e.g. 126-A) will provide a better understanding of the systematic biases in Pu CRMs.

For the 240Pu/239Pu major ratio, the TE method performs at similar levels for both high-burnup materials and low burnup materials, as indicated by the similar control limits for these materials. This is consistent with the performance observed at U CRMs, where for both low-enriched-uranium (LEU) and high-enriched-uranium (HEU) materials similar control limits are observed. This also attests to the robustness of the total evaporation methodology in that it performs at similar performance levels for materials with vastly different enrichments. The performance limits of the total evaporation method are lower than the certified uncertainties of NBL Pu CRMs by factors in the range of four to five. There is a critical need for standards with lower uncertainty limits [8] that are also consistent with the excellent precision achievable with modern multi-collector TIMS and ICPMS instruments.

References

Habfast K (1998) Int J Mass Spectrom 176(1):133–148

Mathew KJ, Mason P, Voeks A, Narayanan U (2012) Int J Mass Spectrom 315:8–14

Mialle S, Quémet A, Ponvienne A, Gourgiotis A, Aubert M, Isnard H, Chartier F (2012) Int J Mass Spectrom 309:141–147

Mathew KJ, O’Connor G, Hasozbek A, Kraiem M (2013) J Anal At Spectrom 28:866–876

Standard test method for determination of uranium or plutonium isotopic composition or concentration by the total evaporation method using a thermal ionization mass spectrometer, C1672-17

Richter S, Goldberg S (2003) Int J Mass Spectrom 229:181–197

Mathew KJ, Stanley FE, Thomas MR, Spencer KJ, Colletti LP, Tandon L (2016) Anal Methods 8:7289–7305

Richter S, Kühn H, Aregbe Y, Hedberg M, Horta-Domenech J, Mayer K, Zuleger E, Bürger S, Boulyga S, Köpf A, Poths J, Mathew KJ (2011) J Anal At Spectrom 26:550–564

Test method for uranium and plutonium concentrations and isotopic abundances by thermal ionization mass spectrometry, C1625

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mathew, K.J., Ottenfeld, C., Keller, R. et al. Systematic bias in the 240Pu/239Pu isotopic ratio of plutonium isotopic standard CRM138. J Radioanal Nucl Chem 318, 395–400 (2018). https://doi.org/10.1007/s10967-018-5974-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-018-5974-2