Abstract

This contribution characterizes the stability of scintillating resins for ionizing radiation detection that were synthesized with 2-(1-naphthyl)-5-phenyloxazole (α-NPO) or 2-(1-naphthyl)-4-vinyl-5-phenyloxazole (v-NPO) fluor in polystyrene (PS) or poly(4-methyl styrene) (PVT) matrices. Leaching studies of the PS and PVT resins with methyl acetate show a 60 % reduction in luminosity and 80 % reduction in detection efficiency for α-NPO samples; while v-NPO resins retained detection properties. Degradation studies indicate the nitration of PS resins and the fluors after nitric acid exposure, resulting in a 100 % reduction in optical properties; whereas PVT resins with v-NPO fluor maintained 20 % detection efficiency. Heuristics are reported for designing stable scintillating resins.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The worldwide expansion of nuclear power, increase in nuclear and radiological threats and requirements for environmental monitoring after disasters such as the tragedy at Fukushima Daiichi make the need for capabilities in ultra-trace level sensing of radionuclides in the environment of paramount importance. The ability to rapidly detect and quantify post-detonation radionuclides or monitor the spread of radionuclides in environmental waters would be a powerful nuclear forensic tool. Flow-cell detectors packed with extractive scintillating resins have emerged as an analytical technique to meet these environmental monitoring needs. These resins utilize an organic extractant (ligand) that is selective to an analyte of interest. They are a modern extension of the scintillating ion-exchange resins that were developed in the mid-1960s by Heimbuch et al. [1]. Beginning in 2000, extractive scintillating resins were developed for high-sensitivity aqueous monitoring of α- and β-emitting radionuclides [2]. These resins serve the dual purpose of selectively concentrating the radionuclide(s) of interest and serving as a radiation transducer. The advantages of these materials are that (1) the radionuclide is retained on the radiation transducer for increased sensitivity, and (2) when coupled with modern radiation detection and measurement instrumentation, a real-time signal can be collected for analysis. Application of extractive scintillating resins has been demonstrated for the quantification of strontium-89,90 [3], technetium-99 [4, 5], iodine-129 [6], uranium [7] and actinides [8]. For technetium-99, quantification below the maximum contaminant level, as established by the U.S. Safe Drinking Water Act, has been reported [9].

A limitation of these resins has been that excellent initial sensor performance is followed by declining performance during sequential loading and elution [3]. The challenge is to develop a material that is both physically and chemically stable enough to elicit reliable and sustained performance under extended field conditions. For the resins to be reusable, they must be durable and able to withstand a harsh acidic environment, needed for loading and eluting the column, while retaining scintillation properties and luminosity. Additionally, in many cases the process of attaching the selective extractant to the surface of the scintillating resin requires contact with organic solvents; hence, the fluor must not leach from the scintillating resin during the functionalization reactions.

Next-generation solid-phase extractive scintillating media are being produced to increase physical and chemical stability so that resins can be reused over many cycles. One approach to produce stable resins is called the core–shell arrangement in which a stable scintillating core is coated with a covalently bound outer ‘shell’ of selective ligands to create high-selectivity sensor materials with permanent surface chemistries and rapid response rates. The fluors of these resins are entrapped physically within the polymer matrix and further sealed with the addition of the extractive shell [5]. Another approach is to synthesize a stable scintillating core through the copolymerization of a vinyl fluor with, for example, styrene, 4-chloromethyl styrene, and divinylbenzene [10].

The goal of this work was to understand how scintillator properties such as fluor incorporation method (physically entrapped versus covalently bound) and polymer type influence the stability of porous scintillating resins. Batch leaching experiments were performed with polystyrene (PS) based resins containing either physically entrapped 2-(1-naphthyl)-5-phenyloxazole (α-NPO), or covalently bound 2-(1-naphthyl)-4-vinyl-5-phenyloxazole (v-NPO), to test the effect of solvent exposure on resin luminosity. PS and PVT resins were characterized by Fourier-transform infrared spectroscopy (FTIR) before and after exposure to nitric acid to determine the effects of the acid on the polymer structure. Finally, the optical properties of α-NPO were characterized by spectrofluorometry, before and after nitric acid exposure, to test the stability of the fluor in oxidizing, acidic conditions. The results of this research will contribute to the rational design of stable extractive scintillating resins for applications in environmental water monitoring.

Experimental

Reagents

2-(1-Naphthyl)-4-vinyl-5-phenyloxazole (v-NPO) was synthesized according to a previously reported procedure [10]. Additional reagents and sources were 2-(1-naphthyl)-5-phenyloxazole (α-NPO, laser grade +99 %, Alfa Aesar), 4-methyl styrene (96 %, Sigma-Aldrich), chloroform-d (99.8 atom % D, Sigma Aldrich), divinylbenzene (technical grade 80 % mixture of isomers, Sigma-Aldrich), ethyl acetate (Sigma-Aldrich), methyl acetate (Acros Organics), nitric acid (Merck), styrene (+99 %, Sigma-Aldrich), toluene (HPLC grade, Fisher Scientific).

Resin synthesis

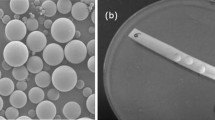

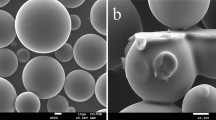

PVT and PS scintillating resins with 25 wt% crosslinking were synthesized by suspension polymerization according to a previously reported procedure using toluene as the porogen [11]. Fluors were included in the organic phase during suspension polymerization. The non-polymerizable fluor, α-NPO, was incorporated physically in the poly[styrene-co-divinylbenzene] or poly[4-methyl styrene-co-divinylbenzene] copolymer. The polymerizable v-NPO was bound covalently within the polymer matrix resulting in the terpolymer, poly[4-methyl styrene-co-divinylbenzene-co-(2-(1-naphthyl)-4-vinyl-5-phenyloxazole)]. After synthesis, the dry resin was sieved into multiple size fractions. The resin size fraction with a diameter of 106–212 μm was used for all experiments.

Resin characterization

Fluor leaching

Experiments were designed to test the stability of the fluor within the resin with respect to leaching. To accelerate the leaching process, PS resins with either v-NPO or α-NPO were contacted with methyl acetate for 24 h in an end-over-end mixer. In the true application, the resins may not be exposed to methyl acetate; however, using a good solvent for both the polymer and the fluor can provide insight to the long-term stability of the fluor in the resin matrix. Luminosity of the resin was measured before and after solvent exposure using an electroplated, alpha-emitting, americium-241 point source with an activity of 37 kBq. The source was positioned at a fixed height of 1 cm above the bottom of a polyethylene scintillation vial. Twenty five milligrams of resin was placed inside the scintillation vial for each measurement and the photopeak was recorded with a Hidex Triathler. Non-linear peak fitting was performed using a Gaussian model to determine the photopeak channel. The Gaussian curves were integrated in the region of interest to calculate the detection efficiency. The region of interest for the peak fitting was determined to be channels 200 and greater to avoid the background region that exists below channel 200. The relative luminosity was calculated by dividing the post-treatment luminosity by the pre-treatment luminosity. The relative detection efficiency was calculated in the same manner. Measurements were performed in triplicate to estimate the error associated with the detection geometry. Slight variations in the distance between the source and the resin or variations in the distribution of resin across the bottom of the vial could result in differences in peak channel as well as variations in the calculated detection efficiency.

Polymer degradation

Column experiments were conducted to mimic the application of the resin in a flow-cell scintillation detector. Nitric acid is often used to extract strontium from solution in the form of a nitrate complex. The effect of acid concentration was not studied in this experiment, because the objective was to determine whether or not nitration would occur. Varying acid concentration would provide insight to the kinetics of the nitration reactions, which is outside the scope of this paper. A total of 300 mL of 4 M nitric acid was pumped through a resin-packed column at a flow rate of 1.5 mL min−1. The polytetrafluoroethylene column (0.48 cm inner diameter) was packed with 400 mg of PS or PVT resin containing v-NPO. Twenty-five milligrams of resin were removed from the column after 100 mL, 200 mL and 300 mL of acid was eluted from the column. The resins were washed with ethanol and dried on a Buchner funnel prior to luminosity measurements. Resin luminosity was characterized in the same manner as the fluor leaching experiments. Measurements were performed in triplicate to estimate the error associated with the detection geometry.

To decouple the effect of nitric acid on the fluor from the effect of nitric acid on the polymer alone, the polymer stability to nitric acid was studied by contacting 25 mg of either PS or PVT resins that did not contain fluor with 15 mL of 4 M nitric acid for a period of 5 days. The acid concentration and exposure time were chosen to observe whether or not the polymer would be nitrated. Kinetic studies investigating length of exposure or acid concentration were considered outside the scope of this study. The resin was characterized by FTIR before and after acid exposure to monitor changes in the polymer structure. Resin samples were analyzed in KBr pellets using a nitrogen purged Nicolet Nexus 870 FTIR Spectrometer (ThermoScientific, USA) in transmission mode for 64 scans. Resulting spectra were analyzed with Omnic software.

Fluor degradation

To study the effect of nitric acid on the optical and structural properties of the fluor, 50 mg of α-NPO was exposed to 15 mL of 4 M nitric acid for 24 h in a round-bottom flask and stirred with a magnetic stir bar. The α-NPO was dried by rotary evaporation at 60 °C and then dried to constant weight under vacuum at a pressure of 17 kPa at 25 °C. The dried fluor was dissolved in ethyl acetate to create a solution with concentration of 0.03 mM that was used for absorbance and emission measurements. Absorption spectra were measured using a Varian Cary 50 Bio UV–Visible spectrophotometer in a quartz cell. Emission spectra of α-NPO in ethyl acetate were measured using a HORIBA fluoroMax-4 spectrofluorometer (Edison, NJ, USA) in a glass fluorometer cell (Starna Cells, Inc., CA) using 1 nm slits, a scanning interval of 5 nm and excitation wavelength of 335 nm. Structural changes to the fluor were characterized by nuclear magnetic resonance spectroscopy (NMR) using a 300 Hz Jeol ECX-300 NMR in proton mode for 32 scans. NMR samples were prepared by dissolving 10 mg of fluor in 2 mL of chloroform-d. The fluors α-NPO and v-NPO have similar chemical structures and possible sites for nitration (SM-1), differing only at position 4 on the 1,3 oxazole; therefore, α-NPO was used as the representative compound for the nitration study.

Results and discussion

Fluor leaching

Table 1 compares the relative luminosity and detection efficiency of PS resin containing physically incorporated α-NPO and PS resin containing covalently bound v-NPO before and after contact with methyl acetate for 24 h in a batch experiment. After methyl acetate exposure, the photopeak of PS resin with α-NPO exhibited a 60 % reduction in relative luminosity and 80 % reduction in relative detection efficiency, which can be attributed to the fluor leaching from the polymer. The photopeak for the covalently incorporated v-NPO increases in channel number from 401 to 474, corresponding to a 15 % increase in relative luminosity after methyl acetate exposure. Polymerization inhibitors present in the divinylbenzene and styrene monomers, can absorb light emitted by the fluor before it reaches the detector thereby quenching the photo-signal. A potential cause for the increased luminosity is the removal of these quenching compounds by leaching with methyl acetate.

Polymer degradation

The stability of the polymer to nitric acid was tested by performing column experiments in which 300 mL of 4 M nitric acid were pumped through a column packed with PS or PVT resin containing v-NPO. Figure 1a shows the relative change in luminosity for PS and PVT resins, which both exhibit a decrease in luminosity as a function of the volume of eluted acid. After 300 mL of eluted acid, the photopeak of the PS resin was below the defined region of interest and therefore was considered to have a 100 % loss of relative luminosity. Noticeable yellowing of the PS resin was observed after pumping 300 mL of nitric acid through the column. The PVT resin experienced a 25 % reduction in relative luminosity after 300 mL of nitric acid exposure. Figure 1b shows the change in relative detection efficiency for both PS and PVT resins. Larger relative errors in the detection efficiency can be attributed to systematic error in the detection geometry. The height of the photopeak influences the integrated area (detection efficiency) under the Gaussian curve. Potential sources of peak height variation can be attributed to a non-homogeneous distribution of resin on the bottom of the scintillation vial, inconsistencies in the distance between the americium-241 point source and the resin or differences in the mass of resin measured for each datum point. The PS resin shows a 100 % reduction in detection efficiency after eluting 300 mL of acid from the column while the PVT resin shows an 80 % reduction in detection efficiency.

It is clear from the luminosity data that nitric acid reduced the detection efficiency of the scintillating resin; however, the luminosity measurements cannot identify the source of the quench, i.e. chemical quench, color quench, or polymer degradation. To decouple the effect of nitric acid on v-NPO from the effect of nitric acid on the polymer, PS and PVT resins were synthesized without the incorporation of a fluor and were exposed to 4 M nitric acid for 5 days. The resin was analyzed by FTIR before and after contact with the acid. After 5 days, the PS resin showed considerable yellowing. Figure 2b shows the FTIR spectrum for the PS resin with a characteristic absorbance band for the monosubstituted benzene of styrene at 1601 cm−1. Figure 2a shows the FTIR spectrum with strong absorbance bands at 1697, 1631 and 1562 cm−1 that are characteristic of NO2 substituents, supporting nitration of the aromatic ring as shown in Scheme 1. The discoloration of the PS can lead to the absorption of light emitted by the fluorophore, called color quenching, which decreases the luminosity of the resin. Another mechanism of quenching caused by the nitrated aromatic ring of styrene is charge transfer between the excited fluor and the 4-nitrostyrene, which then undergoes nonradiative de-excitation [12].

Since styrene is a monosubstituted benzene ring with a vinyl group that is ortho-para directing in nitration reactions [13], it was hypothesized that by blocking the para position with a methyl substituent, like in PVT, it would be possible to slow the rate of nitration of the polymer. After exposing PVT to nitric acid for 5 days, the resin was significantly less discolored than the PS resin under the same conditions. The FTIR spectrum of the PVT resin in Fig. 3 does not show characteristic NO2 peaks. The absence of nitro-groups and translucent color of the PVT resin further support that the yellowing of the PS resin can be attributed to the nitration of the styrene monomer units.

Fluor degradation

To characterize the stability of the α-NPO in nitric acid, the absorption and emission spectra of the fluor were analyzed before and after nitric acid exposure. Figure 4 shows that the maximum absorption for α-NPO in ethyl acetate before and after nitric acid exposure occurs at 335 nm. Upon nitric acid exposure, the absorbance peak for α-NPO decreases in intensity and broadens such that it overlaps with the α-NPO emission band.

The optical properties of the fluor were essentially destroyed by the nitric acid as seen by the negligible emission spectrum after acid exposure. The overlapping absorption and emission spectra will cause self-quenching, in which the fluor reabsorbs the emitted light before it can reach the detector [14]. Another possible cause for the quench could be the color change. Similar to the PS resin, the fluor visibly yellowed after nitric acid exposure, suggesting that the nitric acid was chemically modifying the fluor. To test this hypothesis, α-NPO was exposed to nitric acid and analyzed by H NMR. Figure 5 shows the H NMR spectra for α-NPO before and after nitric acid exposure. The persistence of the oxazole singlet at 7.26 ppm in both spectra indicates that the oxazole ring was not nitrated. While the proton NMR spectra cannot provide quantitative information regarding the degree of nitration of the fluor, the downfield shift of the proton peaks support the modification of the aromatic rings with an electron withdrawing group, like NO2. The nitration of monosubstituted phenyl and naphthyl rings at room temperature with nitric acid has been observed in the literature [13, 15, 16].

Conclusions and future work

The stability of scintillating resins was characterized with respect to fluor leaching, polymer degradation and fluor degradation. Fluor leaching can be mitigated by the incorporation of a covalently bound fluor (like v-NPO) in the polymer matrix. The chemical stability of the resin can be improved by utilizing PVT instead of PS due to its resistance to aromatic ring nitration, which disrupts the scintillation energy transfer pathway. Nitric acid also can nitrate the aromatic rings of the fluor, destroying its fluorescence by self-absorption and resulting in a loss of detection efficiency. Since nitration of the resin can be mitigated by using PVT, the primary mechanism for detection efficiency reduction is through fluor degradation in nitric acid. Future efforts to synthesize stable, extractive scintillating resins should focus on the use of a PVT matrix with covalently bound v-NPO as the fluor. Further, alternative acids to nitric acid, such as hydrochloric acid, should be pursued to mitigate the degradation of the fluor. The experiments presented in this work will be combined with parallel studies of resin morphology (surface area and pore distribution) to steer further research into development of the porous scintillating resins for ultra-trace level radionuclide sensing in environmental media.

References

Heimbuch AM, Gee HY, DeHaan A, Leventhal L (1965) In the assay of alpha- and beta-emitters by means of scintillating ion-exchange resins. the symposium on radioisotope sample measurement techniques in medicine and biology. International Atomic Energy Agency, Vienna, pp 505–519

DeVol TA, Roane JE, Williamson JM, Duffey JM, Harvey JT (2000) Development of scintillating extraction resins for separation and measurement of charge-particle emitting radionuclides in aqueous media. Radioact Radiochem 11(1):34–36

DeVol TA, Duffey JM, Paulenova A (2001) Combined extraction chromatography and scintillation detection for off-line and on-line monitoring of strontium in aqueous solutions. J Radioanal Nucl Chem 249(2):295–301

Grate JW, Egorov OB, O’Hara MJ, DeVol TA (2008) Radionuclide sensors for environmental monitoring: From flow injection solid-phase absorptiometry to equilibration-based preconcentrating minicolumn sensors with radiometric detection. Chem Rev 108(2):543–562

Seliman AF, Samadi A, Husson SM, Borai EH, DeVol TA (2011) Preparation of polymer-coated, scintillating ion-exchange resins for monitoring of tc-99 in groundwater. Anal Chem 83(12):4759–4766

Grogan KP, DeVol TA (2011) Online detection of radioactive iodine in aqueous systems through the use of scintillating anion exchange resin. Anal Chem 83(7):2582–2588

Hughes L, DeVol TA (2003) On-line gross alpha radiation monitoring of natural waters with extractive scintillating resins. Nucl Instrum Methods Phys Res A 505:435–438

Roane JE, DeVol TA (2002) Simultaneous separation and detection of actinides in acidic solutions using an extractive scintillating resin. Anal Chem 74(21):5629–5634

Agency, U. S. E. P. Table of Regulated Drinking Water Contaminants. (April 5),

Seliman AF, Bliznyuk VN, Husson SM, DeVol TA (2015) Development of polymerizable 2-(1-naphthyl)-5-phenyloxazole scintillators for ionizing radiation detection. J Mater Chem C 3(27):7053–7061

Bliznyuk VN, Duval CE, Apul OG, Seliman AF, Husson SM, DeVol TA (2015) High porosity scintillating polymer resins for ionizing radiation sensor applications. Polymer 56:271–279

Kwak J, Choi O, Sim ES, Lee S-Y (2015) Evaluation of photoluminescence quenching for assessing the binding of nitroaromatic compounds to a tyrosyl bolaamphiphile self-assembly. Analyst 140:5354–5360

Lewis RJ, Moodie RB (1997) The nitration of styrenes by nitric acid in dichloromethane. J Chem Soc, Perkin Trans 2(2):563–568

Lakowicz JR (ed) (2013) Principles of fluorescence spectroscopy, 3rd edn. Springer, Berlin, pp 188–218

Thompson HW (1932) Orientation in the substitution reactions of alkylnaphthalenes—Part II: Nitration of 1-methylnaphthalene. J Chem Soc 329:2310–2315

Larina L, Lapyrev V (2009) Nitroazoles: synthesis, structure and applications. Springer, New York

Acknowledgments

This work was supported by the Defense Threat Reduction Agency, Basic Research Award #HDTRA1-12-1-0012, to Clemson University.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Duval, C.E., DeVol, T.A., Wade, E.C. et al. Stability of polymeric scintillating resins developed for ultra-trace level detection of alpha- and beta-emitting radionuclides. J Radioanal Nucl Chem 310, 583–588 (2016). https://doi.org/10.1007/s10967-016-4913-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-016-4913-3