Abstract

The response surface methodology is used to obtain optimal rate and extent of extraction of low concentration U(VI) (≤100 mg/L) by liquid emulsion membrane technique. Three different ligands viz. Tri-n-octyl phosphine oxide (TOPO), Tri-n-octyl amine (TOA) and Di-(2-ethylhexyl)phosphoric acid (D2EHPA), are used. 23 factorial design is applied to generate second order regression equation for studying the effect of concentration of ligand, surfactant and feed acidity. The regression model is in good agreement with the experimental data for all ligands. The rate of extraction of U(VI) by LEM is found to be in the order TOA > TOPO > D2EHPA.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Presently, nuclear industry uses solvent extraction method to recover U(VI) from various sources. Since the conventional extraction is equilibrium limited process, extraction of U(VI) from low concentrated source (<100 mg/L), using solvent extraction is not efficient. Since in liquid emulsion membrane (LEM) extraction process, the extraction and stripping steps occur simultaneously, it is not constrained by phase equilibria and hence is considerably more efficient than the conventional extraction. However, LEM extraction of heavy metals is practised only to some extent in Zinc industry [1]. Considering the fact that LEM is not extensively used in nuclear industry for recovery of U(VI), there is a need for further investigations on this method. This includes stabilisation studies of LEM, improvement of demulsification step and process intensification of various factors influencing the extraction efficiency. This study focuses to quantify and optimise process parameters of LEM for U(VI) extraction. Stas et al. [2] studied U(VI) and Fe(III) co-extraction using conventional solvent extraction parameters and generated two mathematical models based on general linear regression equation. They found out that the concentration of ligand (D2EHPA) primarily controls the selectivity and yield. Kadous et al. [3] made a comparative study on effectiveness of extraction of U(VI) by D2EHPA/TOPO using 23 full factorial design between supported liquid membrane (SLMs) with one single membrane and two membranes in series [3]. Natchanun et al. [4] used 32 factorial design to predict the uranium concentration in the feed tank at different times using hollow fibre SLM extraction and optimised the process. They observed with the increasing of initial U(VI) concentration in feed, the recovery of U(VI) is more effective using SLM with two membranes in series as compared to single SLM. We have not come across any study on LEM with mutual interaction and correlation between the variables which affects extraction of U(VI). Literature is available on impact of various parameters like ligand concentration, acid concentration in feed phase, viscosity of membrane, etc. on LEM extraction of U(VI) by TOPO [5–16]. Also literature is available on extraction of U(VI) by the ligands ( D2EHPA, TOPO and TOA ) using bulk liquid membrane (BLM), SLM and liquid-liquid extraction [19–21]. However, no correlation studies on the impact of these vital factors on LEM extraction was carried out. The previous study by the author [17] established the following factors to be most influential for extraction of U(VI) using LEM.

-

(i)

Concentration of ligand in organic phase

-

(ii)

initial concentration of acid in external feed phase and

-

(iii)

concentration of surfactant which affects yield (percent of extraction) and rate of extraction.

The effects of these individual parameters affecting the LEM extraction are not additive. Individual variation cannot be used to obtain the overall effect, when all the parameters are varied together. Therefore response surface method is useful in such cases to study the interaction parameters as well as to optimise the process.

This study aims at the optimisation of U(VI) extraction from low concentrated solutions (initial concentration of U(VI) 100 mg/L in feed) using various ligands. The focus of present investigation is to study the contribution of each of the above factors on the LEM extraction in order to arrive at the best operating conditions for efficient recovery of U(VI) from dilute streams of nuclear industries. The response surface methodology (RSM) was used to achieve the following goals

-

(i)

to study mutual interaction among these factors,

-

(ii)

to arrive at the optimal conditions for extraction of U(VI) and

-

(iii)

to obtain a regression model which can estimate rate constant and percent extraction of U(VI) using LEM.

Experimental

Chemicals

The ligands TOPO, TOA, D2EHPA were obtained from M/s Sigma Aldrich Co Ltd. Light paraffin oil, supplied by M/s Merck, had kinematic viscosity 30 cs and density 800 kg m−3. All other chemicals were of analytical grade and obtained from the companies of repute.

Experimental procedure

Primary emulsion (W/O) was prepared by 20 ml of organic solution containing polymeric surfactant AbilEM90, any one of these complexing ligands (TOPO, TOA and D2EHPA) and diluents paraffin. Then 20 ml of the stripping aqueous phase was added dropwise in the organic phase. The solution was then emulsified using Ultra-Turrax mixer (IKA T25) at the mixer speed of 14,000 rpm. Emulsification time was fixed at 10 min for all experiments. Polymeric surfactant Abil EM90 was varied in the range from 1 to 4 % (w/v). The primary emulsion (W/O) was poured into a specially designed 500 ml batch stirred reactor (pertractor) containing 200 ml aqueous feed solution containing U(VI). The glass vessel was equipped with a four bladed turbine agitator. Samples were drawn from the sample tap (as shown in Fig. 1) at different time interval into a separating funnel in which external aqueous phase (raffinate) was separated from the emulsion phase. Filtration through Whatman 41 filter paper was resorted to in cases where fine emulsion globules were not easily separated by separating funnel. After withdrawing 2–3 ml of sample from the raffinate for the determination of the concentration of U(VI), the rest of the content of the separating funnel was poured back into the pertractor in order to minimize the error associated with the loss of material.

Schematic diagram of LEM extraction procedures M DC motor, C controller and tachometer, E emulsifier, P primary emulsion, I internal strip phase, G emulsion globules, F external feed phase (aqueous), R raffinate (aqueous), S secondary emulsion containing extract/strip phase, J rotating Jack/sliding assembly

The extraction experiment was carried out with different complexing ligands (TOPO, D2EHPA, TOA) dissolved in paraffin. Abil EM90 was used as the polymeric surfactant. The agitator speed for LEM extraction was maintained at 400 rpm in all the experiments. The schematic of experimental procedure is described in Fig. 1.

In order to optimise the LEM process experimental design was performed. In our previous study we have studied rate of extraction of U(VI) using LEM with varying one at a time each of the individual parameter viz. (i) concentration of ligand, (ii) initial concentration of acid in the feed phase, initial concentration of U(VI) in feed, (iii) speed of emulsifier, (iv) speed of petraction, (v) strip phase and remaining parameters were kept as constant [17]. The rate constant of extraction of U(VI), k were calculated for all such cases. The effect of the individual parameters on rate constant of U(VI) extraction by TBP were plotted and linear relationship was found. The most influential parameters were chosen based on the slope of this linear fit. Higher slope indicates most influential parameters on LEM extraction of U(VI) by TBP.

The parameters used in this work for optimization were the concentration of ligand in the membrane phase, concentration of acid in the external feed phase and concentration of AbilEM90 in the membrane phase. The choice of these parameters was based on the results of our pervious studies [17]. Also, the following parameters were fixed a priori as optimal (again based on the previous studies [14, 17]) and were not subjected to optimization. The composition of the internal strip phase which was 0.5MNa2CO3 for the LEM extraction involving TOPO or TOA, or 2 M H2SO4 for the LEM extraction involving D2EHPA and speed of pertraction. The initial concentration of U(VI) in the feed was fixed at 100 mg/l.

The raffinate phase was sampled at regular time intervals and samples were analysed for concentration of U(VI) using inductively coupled plasma emission spectrometer (ICP-AES, Horiba Jobin–Yvon model JY 238, Ultrace make). Uranium emission intensity was monitored at wavelength of 386 nm. The standard samples of U(VI) having concentrations between 0 and 20 μg/ml in 4 % (v/v) nitric acid were used for calibration of ICP. The strip phase was analysed for U(VI) only at the end of the experiment. Concentration of U (VI) in the membrane phase at the end of the experiment was estimated by mass balance, knowing its concentrations in the feed and the strip phase.

Extraction kinetics of U(VI) by LEM extraction

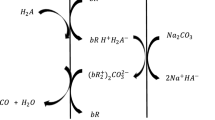

It is hypothesised that extraction of U(VI) in membrane phase of LEM by ligand RH (TOPO, TOA) occurs according to the following reactions

For the ligand D2EHPA [which exists in dimer form represented as (RH)2], the complexation reaction with U(VI) occurs as follows

where, ‘a’ stands for the aqueous phase and ‘o’ for the organic phase. To describe the overall reaction kinetics of U(VI) we assume Eq. 1–2 follows the first order rate equation. A combining mole balance of U(VI) on a constant volume batch reactor and the rate law gives

Here, “e”, denotes the external feed phase, t, the time, and k is the apparent rate constant of U(VI) permeation using ligand, RH (TOPO, TOA, D2EHPA)

Using the initial conditions \( \left[ {{\text{U}}({\text{VI}})(e)} \right]_{t = 0} = \left[ {{\text{U}}({\text{VI}})(e)} \right]^{0} \) at t = 0 gives the following solution

The extent of extraction (%) of U(VI) by LEM can be defined as

Here, “t”, denote extraction time in minutes

Experimental design and optimisation

The objective of an experimental design is to quantify the impact of the experimental factors on the efficiency of the treatment by establishing a regression model to predict rate of extraction of U(VI) and percent of extraction efficiency with a function of three factors (ligand concentration (X 1), feed acid concentration (X 2), surfactant concentration (X 3) Here, a second order regression model design was applied, and the relation obtained was for 3 variables (i = 1, 2, 3).

where predicted response of the system is \( \hat{y} \) [percent of extraction of U(VI)] or \( \hat{k} \) (extraction rate constant of U(VI) complexation reaction with ligand), X i is the coded variable of associated with actual process variable i, β j and b ij are coefficients of the model. The experimental error is denoted by ε. The maximal value associated to the coded variable was +1 and the minimal value was −1

The experimental design used for this study is presented in Table 1.

Table 1 represent coded level for the natural variables used to develop the mathematical model.

The fitted second order multiple regression model in matrix notation is written below:

where \( \bar{\beta } \) is the column vector of β j and \( \bar{\bar{B}} \) is the matrix of coefficients, b ij .

At the optimal condition, the derivative of \( \hat{y} \) with respect to elements of the vector x should be zero, i.e.

Therefore the optimal value \( \bar{X}_{o} \) of set \( \bar{X} \) is

where \( \bar{\beta } \) is a vector of the first order regression coefficients and \( \bar{\bar{B}} \) is a symmetric matrix whose main diagonal elements are the quadratic coefficients \( \left( {\hat{\beta }_{ii} } \right) \) and whose off diagonal elements are one half of the mixed quadratic coefficients \( \left( {\hat{\beta }_{ij} ,i \ne j} \right) \)

In result, the estimated response value at the optimal point can be calculated as

The non- linear, second order regression analysis and the response surface plot of the best fitted model for coded factor level is carried out by using Matlab programming. Three coded variables used for this model are (i) the concentration of ligand \( \left( {X_{{1{\text{Ligand}}}} } \right) \), (ii) the acid concentration of feed \( \left( {X_{{2{\text{Acid}}}} } \right) \), and the (iii) concentration of polymeric surfactant, Abil EM90 \( \left( {X_{{3{\text{Abil}}}} } \right) \). The predicted response variable \( \hat{y} \) and \( \hat{k} \) of the system are the percent extraction and corresponding extraction rate constant of U(VI) using regression model Eq. 6. The empirical model was fitted to the response through regression analysis and best fit was obtained which includes linear, interaction and square terms.

Results and discussion

A wide range of values between low level (−1) and high level (+1) (see Table 1), of variables was chosen in order to make sure that the optimum lies within the chosen range.

In order to simplify the calculation, coded variables are assumed as independent variables. The independent variables are rescaled, such that 0 is in the centre of the design represents mean value, (M) of each of the variable and ±1 are the distance from the centre with direction. Therefore three natural independent variables \( \left( {V_{j} } \right) \) viz. ligand concentration, acid concentration in feed and polymeric surfactant concentration are related to coded variable \( X_{j} \) by the following relation

Here, “R”, denotes the range and “H” and “L” respectively represent high and low value of natural variables “V”.

Extraction of U(VI) by TOPO using LEM

The design matrix of a 23 factorial design for extraction of U(VI) by TOPO and the response are shown in Table 2.

Figure 2a and b respectively represent experimental concentration of U(VI) in raffinate at different stirring times and corresponding plots of logarithmic of the ratio of initial concentration of U(VI) to that at time t, for measuring the rate constant, k of U(VI) extraction from various combination of experimental factors (as shown in Table 2) by TOPO in paraffin using LEM.

Efficiency of U(VI) extraction for LEM formulation with TOPO [conditions: 1 Feed 0.1 M HNO3, org. 0.1 M TOPO, 4 %(w/v) AbilEM90 (slope = 0.787) 2 Feed 0.1 M HNO3, org. 0.1 M TOPO, 4 % (w/v) AbilEM90 (slope = 0.377) 3 Feed 0.01 M HNO3, org. 0.1 M TOPO, 4 % (w/v) AbilEM90 (slope = 0.300) 4 Feed 0.01 M HNO3, org. 0.1 M TOPO, 1 % (w/v) AbilEM90, (slope = 0.207) 5 Feed 0.1 M HNO3, org. 0.01 M TOPO, 4 % (w/v) AbilEM90, (slope = 0.118) 6 Feed 0.1 M HNO3, org. 0.01 M TOPO, 1 % (w/v) AbilEM90, (slope = 0.111) 7 Feed 0.01 M HNO3, org. 0.01 M TOPO, 4 %(w/v) AbilEM90, (slope = 0.059) 8 Feed 0.01 M HNO3, org. 0.01 M TOPO, 1 %(w/v) AbilEM90, (slope = 0.039) 9 Feed 0.01 M HNO3, org. 0.01 M TOPO, 1 %(w/v) AbilEM90, (slope = 0.493)] Strip 0.5MNa2CO3. a Effect of factors on extraction of U(VI) [Ref. Eqs. 12–14] b Effect of factors on rate constant, k

The experimental rate constants are obtained by measuring the slope of Fig. 2b.

From the experimentally obtained percent extraction of U(VI), y(t) after elapsed time t, and corresponding coded variables as shown in Table 2, the following second order regression Eqs. 12, 13 and 14 are obtained.

Equations 12 and 13 represents second order regression equation for percent extraction of U(VI), \( \hat{y}(5) \) and \( \hat{y}(10) \) by TOPO using LEM after elapse of time 5 and 10 min respectively

Equation 14 represents second order regression equation for rate constant, \( \hat{k} \) for the extraction of U(VI) by TOPO using LEM

The above regression equation shows acid concentration in feed \( (X_{{2{\text{Acid}}}} ) \) and surfactant concentration \( \left( {X_{{3{\text{Abil}}}} } \right) \) have a linear positive effect on response functions \( \left( {\hat{y}} \right) \) and \( \left( {\hat{k}} \right) \). The concentration of ligand, TOPO \( \left( {X_{{1{\text{TOPO}}}} } \right) \) shows both positive and negative effect (quadratic term). The quadratic term in ligand shows curvature in the response surface. Hence optimal value of the response function lie between high and low levels. The constant coefficient term of the regression model (Eqs. 12, 13, 14) represents value of response functions \( \left( {\hat{y}} \right) \) and \( \left( {\hat{k}} \right) \) at the mean values of concentrations of ligands \( \left( {X_{{1{\text{TOPO}}}} = 0} \right) \), acid in feed \( (X_{{2{\text{Acid}}}} = 0) \) and surfactant \( \left( {X_{{3{\text{Abil}}}} = 0} \right) \) respectively. The value of constant coefficient term in Eq. 13 is higher than Eq. 12 indicates higher percent of extraction of U(VI) which is possible due to elapse of more time of extraction.

The test for the significance of the regression can be applied to determine if the relationship between the dependent variable, \( \left( {\hat{y}} \right) \) and \( \left( {\hat{k}} \right) \) and independent variables \( X_{{1{\text{Ligand}}}} \), \( X_{{2{\text{Acid}}}} \), \( X_{{3{\text{Abil}}}} \) exists. The proper hypotheses are

Analysis of variance (ANOVA) table deducted from the results of LEM extraction of U(VI) by TOPO, is reported in Table 3.

At the significant level α = 0.05, the critical value F 0.05,3,7 = 4.35 which is far less than the observed value of F = 1,104.35. There is a significant statistical evidence to reject null hypothesis. It implies that at least one of the independent variable among the three chosen variables viz. ligand concentration \( \left( {X_{{1{\text{Ligand}}}} } \right) \), acid concentration \( \left( {X_{{2{\text{Acid}}}} } \right) \), surfactant concentration \( \left( {X_{{3{\text{Abil}}}} } \right) \) contributes significantly to the extent of extraction and rate constant. The small p values for linear and square terms also point out that their contribution is significant to the model. But, small p values for the squared term of TOPO concentration suggest there is curvature in the response surface.

Since the response surface is explained by the second-order model, it is necessary to analyse optimum setting. The graphical visualization is very helpful in understanding the second-order response surface.

Figure 3 shows the response surface plots of the pairwise interaction between the concentration of TOPO \( \left( {X_{{1{\text{TOPO}}}} } \right) \) in the organic phase, concentration of HNO3 in the feed \( \left( {X_{{2{\text{Acid}}}} } \right) \) and concentration of Abil EM90 \( \left( {X_{{3{\text{Abil}}}} } \right) \) in the organic phase.

Figure 3a shows the response surface plot from the model (Eq. 12), where the concentration of Abil EM90 is kept at its mean value \( \left( {X_{{3{\text{Abil}}}} = 0} \right) \) and the interaction between TOPO concentration and acid concentration in external aqueous feed phase is examined. It is seen from Fig. 3a, that the interaction between the TOPO concentration in organic phase \( \left( {X_{{1{\text{TOPO}}}} } \right) \) and concentration of HNO3 in aqueous feed phase \( \left( {X_{{2{\text{Acid}}}} } \right) \) is significant, however the coefficient term is negative (−15.31) which implies negative impact on extraction of U(VI). This can be explained in terms of higher acid extraction capability of high level of TOPO concentration at higher acid level (within the experimental range) concentration, is high in LEM extraction. We find that the percent extraction of U(VI) increases with increase in TOPO concentration initially (up to the coded level near to +0.6) and beyond which there is a fall which can be explained based on our previous study that with increasing TOPO concentration acid extraction increases in strip phase causing reduction in U(IV) extraction [17]. Figure 3b, shows the interaction between the TOPO concentration \( \left( {X_{{1{\text{TOPO}}}} } \right) \) and concentration of surfactant in organic phase \( \left( {X_{{3{\text{Abil}}}} } \right) \) which shows maxima of extraction at around mean level of the coded variable revealed that influence of TOPO is quadratic (nonlinear). The coefficient term of \( \left( {X_{{1{\text{TOPO}}}} X_{{3{\text{Abil}}}} } \right) \) is −1.53 in Eq. 12, implies negative impact on U(VI) extraction, because viscosity of the membrane increases with increase in TOPO concentration. The increase in membrane (organic) viscosity reduces diffusivity of TOPO. U(VI) complex into internal strip phase of LEM. This causes reduction in mass transfer which in turn affects the extraction rate constant \( \left( {\hat{k}} \right) \) and the yield of extraction [y(5), y(10)]. This is in congruence with Eq. 12, 13 & 14. Figure 3c shows that interaction between concentration of Abil EM90 \( \left( {X_{{3{\text{Abil}}}} } \right) \) and HNO3 \( \left( {X_{{2{\text{Acid}}}} } \right) \) on extraction of U(VI) is positive. It can be seen that with increase in the concentration of Abil EM90 \( \left( {X_{{3{\text{Abil}}}} } \right) \) and HNO3 \( \left( {X_{{2{\text{Acid}}}} } \right) \) the extent of extraction of U(VI) increases and the behaviour is linear. The increase in surfactant (Abil EM90) reduces interfacial tension between organic and aqueous phase causing more interfacial area, thus increasing rate of extraction \( \left( {\hat{k}} \right) \) as well as yield. This is in agreement with the regression model Eq. 12–14.

The optimum conditions (X 1, X 2 and X 3) for LEM extraction of U(VI) by TOPO, were obtained by using Eq. 9 and the values are (i) TOPO concentration of 0.082 M \( (X_{{1{\text{TOPO}}}} = 0.596) \), (ii) Feed acid concentration of 0.1 M HNO3 \( (X_{{2{\text{Acid}}}} = 1) \) and (iii) polymeric surfactant concentration of 4 % (w/v) in paraffin \( (X_{{3{\text{Abil}}}} = 1) \). The optimal response \( \left( {\hat{y}} \right) \) obtained by substituting the above values in the regression equation (Eq. 12) is extraction of 99.72 % U(VI) by TOPO after elapse of 5 min.

Extraction of U(VI) by D2EHPA using LEM

Similar to TOPO experiments we have conducted 3 factors (X1, X2 & X3) study to compare and find out best suitable ligand and optimum conditions for U(VI) extraction using LEM.

The matrix of a 23 factorial design for extraction of U(VI) by D2EHPA and the corresponding responses are shown in Table 4. Figure 4a represents the concentration of U(VI) in the raffinate as a function of time. Each curve corresponds to a different set of parameters (which are listed below the figure). Figure 4b shows plots against time of the logarithm of ratio of initial concentration of U(VI) to its concentration at time t in the feed for the data corresponding to Fig. 4a.

Efficiency of U(VI) extraction for LEM formulation with D2EHPA [conditions: 1 Feed 0.1 M HNO3, org.0.1(M) D2EHPA, 4 % (w/v) AbilEM90 (slope = 0.571) 2 Feed HNO3, org. 0.1(M) D2EHPA, 1 % (w/v) AbilEM90 (slope = 0.266) 3 Feed 0.01 M HNO3, org. 0.1(M) D2EHPA, 4 %(w/v) AbilEM90 (slope = 0.595) 4 Feed 0.01 M HNO3, org 0.1(M) D2EHPA, 1 % (w/v) AbilEM90, (slope = 0.373) 5 Feed 0.1 M HNO3, org. 0.01(M) D2EHPA, 4 % (w/v) AbilEM90, (slope = 0.448) 6 Feed 0.1 M HNO3, org. 0.01(M) D2EHPA, 1 %(w/v) AbilEM90, (slope = 0.280) 7 Feed 0.01 M HNO3, org. 0.01(M) D2EHPA, 4 %(w/v) AbilEM90, (slope = 615) 8 Feed 0.01 M HNO3, org. 0.01(M) D2EHPA, 1 %(w/v) AbilEM90, (slope = 0.319) 9 Feed 0.055 M HNO3, org. 0.055 M D2EHPA, 2.5 %(w/v) AbilEM90, (slope = 0.395)] Strip:2MH2SO4. a Effect of factors on extraction of U(VI) [Ref. Eqs. 16–18] b Effect of factors on rate constant, \( k \)

The values of the rate constant, k of U(VI) extraction, obtained from the slope of these plots are listed in Table 4

Percent extraction of U(VI) after elapse of 5 min, \( \hat{y}(5)_{\text{DEHPA}} \), and after elapse of 10 min \( \hat{y}(10)_{\text{DEHPA}} \) (obtained from Fig. 4a) are correlated to the parameters using a quadratic form as shown in Eq. 16 and 17 respectively.

Equation 18 represents predicted rate constant, \( \hat{k} \) for the extraction of U(VI) by TOPO using LEM

Table 5 represents the ANOVA deducted from these data

At the significant level α = 0.05, the critical value F 0.05,3,7 = 4.35 < the observed F = 5.80. Therefore it can be concluded that the true response surface is explained by the quadratic model

Figure 5 shows the response surface plot of the interaction between the concentration of D2EHPA, HNO3 concentration in the feed and concentration of polymeric surfactant (Abil EM90) in the organic phase.

It is observed from Fig. 5a that the interaction between the D2EHPA concentration in the membrane phase and HNO3 in the feed phase is quadratic (non-linear) similar to TOPO. Whereas Fig. 5b shows that with increase in Abil EM90, percent extraction of U(VI) increases linearly with slope lager than TOPO. This indicates that positive influence of AbilEM90 in presence of D2EHPA is more in extraction of U(VI) as compared to TOPO. Since D2EHPA is more surface active, its combination with Abil causes higher reduction in interfacial tension (which causes increase in interfacial area) and increases extraction of U(VI). Figure 5c response surface describes that with increase of acid concentration in the feed phase % extraction of U(VI) decreases linearly, because D2EHPA is cation exchange ligand, and hence increase in [H+] reduces extraction.

The optimum conditions (X1, X2 and X3) for LEM extraction of U(VI) by D2EHPA, were obtained by using Eq. 9 and the values are (i) D2EHPA concentration of 0.097 M \( (X_{{1{\text{DEHPA}}}} = 0.938) \), (ii) Feed acid concentration 0.011 M HNO3 \( (X_{{2{\text{Acid}}}} = - 0.979) \) and (iii) polymeric surfactant concentration 4 %(w/v) in paraffin \( (X_{{3{\text{Abil}}}} = 1) \). The optimal response \( \left( {\hat{y}} \right) \) obtained by substituting the above values in the regression equation (Eq. 16) is extraction of 96.02 % U(VI) by D2EHPA after elapse of 5 min.

Extraction of U(VI) by TOA using LEM

The design matrix of a 23 factorial design for extraction of U(VI) by TOA and the corresponding responses after elapse of 5 and 10 min of LEM extraction are shown in Table 6.

Figure 6a respectively represents concentration of U(VI) in raffinate as a function of time for different operating conditions, whereas Fig. 6b plots logarithm of the ratio of initial concentration of U(VI) to that at time t. The values of the rate constants for extraction (k), obtained from the slopes of these plots, are listed in Table 4

Efficiency of U(VI) extraction for LEM formulation with TOA [conditions: 1 Feed 0.1 M H2SO4, org. 0.1 M TOA, 4 % (w/v) AbilEM90 (slope = 0.927) 2 Feed 0.1 M H2SO4, org. 0.1 M TOA, 1 % (w/v) AbilEM90 (slope = 0.575) 3 Feed 0.01 M H2SO4, org. 0.1 M TOA, 4 %(w/v) AbilEM90 (slope = 0.798) 4 Feed 0.01 M H2SO4, org. 0.1 M TOA, 1 %(w/v) AbilEM90, (slope = 0.467) 5 Feed 0.1 M H2SO4, org. 0.01 M TOA, 4 % (w/v) AbilEM90, (slope = 0.680) 6 Feed 0.1 M H2SO4, org. 0.01 M TOA, 1 % (w/v) AbilEM90, (slope = 0.208) 7 Feed 0.01 M H2SO4, org. 0.01 M TOA, 4 % (w/v) AbilEM90, (slope = 0.067) 8 Feed 0.01 M H2SO4, org. 0.01 M TOA, 1 % (w/v) AbilEM90, (slope = 0.016) 9 Feed 0.055 M H2SO4, org. 0.055 M TOA, 2.5 %(w/v) AbilEM90, (slope = 0.772)] Strip 0.5MNa2CO3. a Effect of factors on extraction of U(VI) [Ref. Eqs. 19–21] b Effect of factors on rate constant, k

Equation 19 represents the quadratic relation between \( \hat{y}(5) \), the extent of extraction of U(VI) after elapse of 5 min and the values of the parameters.

The corresponding relation for \( \hat{y}(10) \) is given by Eq. 20

Equation 21 correlates \( \hat{k} \), the rate constant for the extraction of U(VI) by TOA using LEM, with the values of the parameters.

Analysis of variance table deducted from the results of U(VI) extraction using LEM by TOA is reported in Table 7

At the significant level α = 0.05, the critical value F 0.05,3,7 = 4.35 < the observed F = 279.74. Therefore it can be concluded that the true response surface is explained by the quadratic model.

Figure 7 shows the response surface plot of the interaction between the concentration of TOA, concentration of H2SO4 in feed and concentration of polymeric surfactant of Abil EM90 in organic phase.

It is observed from Fig. 7a, that the interaction between TOA concentration in the organic phase with HNO3 in the feed is quadratic (non-linear) similar to TOPO and D2EHPA.

Whereas Fig. 7b shows the interaction between TOA and Abil, the response surface plot shows that with increase in Abil EM90, % extraction of U(VI) increases linearly (slow rise) similar to TOPO. Figure 7c indicates the interaction between acid and AbilEM90, the response surface plot shows that the extraction of U(VI) increases linearly (high rise) with increase in the acid concentration in the feed phase. The high rise implies, in presence of more acid the influence of AbilEM90 is more.

The optimum conditions (X 1, X 2 and X 3) for LEM extraction of U(VI) by TOA, were obtained by using Eq. 9 and the values are (i) TOA concentration of 0.054 M \( (X_{{1{\text{TOA}}}} = - 0.03) \), (ii) Feed acid concentration of H2SO4 in the feed 0.1 M \( (X_{{2{\text{Acid}}}} = 1) \) and (iii) polymeric surfactant concentration 4 %(w/v) in paraffin \( (X_{{3{\text{Abil}}}} = 1) \). The optimal response \( \left( {\hat{y}} \right) \) obtained by substituting the above values in the regression equation (Eq. 19) is extraction of 99.24 % U(VI) by TOA after elapse of 5 min.

Validation of model

To validate the model, one experiment was conducted for each of the ligand with a different set of treatment factors than those used in arriving at the rate constant and percent extraction of U(VI) using Eqs. 4 and 5. Table 8 compares the observed responses with those predicted using Eqs. 12–14 and 16–21. The regression model seems to slightly under predict the extent of extraction. This could be due to the fact that our response surface is quadratic and ignores higher order nonlinearities.

Table 9 describes best operating conditions for the U(VI) extraction by LEM based on our experimental design and optimisation studies.

We found that with increase in polymeric surfactant (AbilEM90) % extraction of U(VI) increases for all the ligands (TOPO, D2EHPA, TOA). We have independently verified (in previous study), that AbilEM90 alone can extract U(VI) even in absence of any ligand [17] and AbilEM90 also increase the interfacial area of mass transfer. Therefore in addition to increase in stability of membrane, Abil EM90 also facilitate in extraction of U(VI). From the above regression models (Eqs. 12–14 and 16–21) we find that the coefficient of X 3Abil is always positive for all ligands discussed here. This indicates positive interaction of AbilEM90 on the rate and extent of extraction of U(VI). Polymeric surfactant, AbilEM90 (R1-O-R2-O-R3-O-R4) has etherial oxygen as shown in the structure in Fig. 8. In general ether has tendency to form complex with U(VI) [18].

Possible structure of U(VI).AbilEM90 complex is shown in Fig. 9.

However because of long chain and branching of the polymeric surfactant, Abil EM90 the accessibility of etherial oxygen to U(VI) is hindered and hence positive interaction effect is not so strong as compared to the ligand.

Conclusion

Polymeric surfactant, Abil EM90 can extract U(VI) thus positive interaction was observed on rate and extent of extraction of U(VI). It is observed that percent extraction of U(VI) increases linearly with increase acid concentration in the feed phase for TOPO and TOA and concentration of AbilEM90 in the membrane phase. Whereas D2EHPA shows an opposite trend as it extracts U(VI) by cation exchange mechanism, hence with increase in acid, percent of extraction of U(VI) reduces. However the extent of extraction of U(VI) shows the initial increase followed by a decrease with the increase in concentration of all ligands (TOPO, D2EHPA, TOA) in the membrane phase. Thus maximum in percent extraction of U(VI) was observed at an intermediate value between high and low levels of these three ligand concentration. Although, the extraction equilibrium of U(VI) is favoured by increase in the concentration of TOPO, D2EHPA, TOA, but simultaneously acid extraction in strip phase increases, which causes reduction in U(VI) extraction. The achieved optimal yield of extraction of U(VI) are 99.72, 96 and 99.9 % for 0.08 M TOPO, 0.097 M D2EHPA and 0.05 M TOA in LEM respectively.

References

Ahmad AL, Kusumastuti A, Derek CJC, Ooi BS (2011) Emulsion liquid membrane for heavy metal removal: an overview on emulsion stabilization and destabilization. Chem Eng J 171:870–882

Stas J, Dahdough A, Shlewit H, Khorfan S (2002) Statistical study of factors affecting the co-extraction of uranium and iron in the second cycle of extraction with DEHPA/TOPO in kerosene. Hydrometallurgy 65:23–30

Kadous A, Didi MA, Villemin D (2009) Extraction of Uranium (VI) using D2EHPA/TOPO based supported liquid Membrane. J Radioanal Nucl Chem 280(1):157–165

Leepipatpaiboon Natchanun, Pancharoen U, Sunsandee N, Ramakul P (2014) Factorial design in optimization of the separation of uranium from yellowcake across a hollow fiber supported liquid membrane, with mass transport modeling. Korean J Chem Eng 31(5):868–874

El-Reefy SA, Selim YT, Aly HF (1997) Equilibrium and kinetic studies on the separation of uranium and thorium from nitric acid medium by liquid emulsion membrane based on trioctylphosphine oxide extractant. Anal Sci 13(3):333–337

Kulkarni PS (2003) Recovery of uranium(VI) from acidic wastes using tri-n-octylphosphine oxide and sodium carbonate based liquid membranes. Chem Eng J 92(1–3):209–214

Macasek F, Rajec P, Rehacek V, Anh VN, Popovnakova T (1997) Emulsion membrane systems for preconcentration of uranium. J Radioanal Nucl Chem Lett 13(3):333–337

El-Hazek NT, El Sayed MS (2003) Direct uranium extraction from dihydrate and hemi-dihydrate wet process phosphoric acids by liquid emulsion membrane. J Radioanal Nucl Chem 257(2):347–352

El Sayed MS (2003) Uranium extraction from gatar sulfate leach liquor using aliquat-336 in a liquid emulsion membrane process. Hydrometallurgy 68(1–3):51–56

El-Reefy SA, Selim YT, Aly HF (1998) Recovery of uranium from thorium in hydrochloric acid medium by liquid emulsion membranes containing trioctylphosphine oxidem. J Radioanal Nucl Chem 228(1–2):21–25

Kulkarni PS, Mukhopadhyay S, Bellary MP, Ghosh SK (2002) Studies on membrane stability and recovery of uranium (VI) from aqueous solutions using a liquid emulsion membrane process. Hydrometallurgy 64(1):49–58

Hirato T, Kishigami I, Awakura Y, Majima H (1991) Concentration of uranyl sulfate solution by an emulsion-type liquid membrane process. Hydrometallurgy 26(1):19–33

Guo J-X, Sun X, Du D-L, Wu X, Li M-X, Pang H, Sun S-X, Wang A-H (1991) Uranium (VI) extraction from chloride solution with benzyloctadecyldimethyl ammonium chloride (BODMAC) in a liquid membrane process. Hydrometallurgy 26(1):19–33

Das D, Juvekar VA, Roy SB, Bhattacharya R (2014) Comparative studies on Co-extraction of Uranium (VI) and different mineral acid from aqueous feed solutions using TBP, TOPO and TOA. J Radioanal Nucl Chem 300:333–343

Abdelziz Y, Mohamed N, Abdelmonem A, Karameldin T (2012) Studies on membrane stability for recovery of uranium from waste solution by liquid emulsion membrane (LEM). J Am Sci 8(12):1292–1297

Elsayed HM, Foaud EA, El-Hazek NMT, Khoniem AK (2013) Uranium extraction enhancement from phosphoric acid by emulsion liquid membrane. J Radioanal Nucl Chem 298:1763–1775

Das D, Juvekar VA, Bhattacharya R (2015) ‘Problem associated with the use of TBP for LEM extraction of U(VI) and attempt to overcome this problem using other ligands (Article in press)

Misra NL (2006) Uranium determination in seawater by total reflection X-ray fluorescence spectrometry. Spectrochimica Acta Part B 61:1166–1169

Candela AM, Benatti V, Pallet C (2013) Pre-concentration of Uranium (VI) using bulk liquid and supported liquid membrane systems optimized containing bis(2-ethylhexyl) phosphoric acid as carrier in low concentrations. Sep Purif Technol 120:172–179

Kedari CS, Pandit SS, Gandhi PM (2013) Separation by competitive transport of uranium(VI) and thorium(IV) nitrates across supported renewable liquid membrane containing trioctylphosphine oxide as metal carrier. J Membr Sci 430:188–195

Popov L (2013) Novel method for determination of uranium isotopes in environmental samples by liquid-liquid extraction with triisooctylamine in sulfuric and hydrochloric acid media. J Radioanal Nucl Chem 298:555–562

Acknowledgement

The author wishes to thank Quality Control Division of Uranium Extraction Division (QCS-UED), Bhabha Atomic Research Centre, India for allowing us to carry out the experimental work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Das, D., Juvekar, V.A. & Bhattacharya, R. Efficacy of extraction of U(VI) by liquid emulsion membrane (LEM) using TOPO, D2EHPA and TOA. J Radioanal Nucl Chem 304, 1261–1274 (2015). https://doi.org/10.1007/s10967-015-3946-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-015-3946-3