Abstract

Herein, this investigation aims to provide insight into the copolymerization of 5-ethylidene-2-norbornene (ENB) and norbornene (NB) by mononuclear and dinuclear α-diimine nickel catalysts. Modified methylaluminoxane (MMAO) was utilized as a cocatalyst. To that end, various copolymers containing different fractions of ENB (3- 42%) were produced by two catalysts. Interestingly, it was realized that increasing the ENB molar ratio would result in a corresponding rise in the activities; the dinuclear precursor exhibited higher activity (113.8–250 kg polym/molcat.h) than the mononuclear precursor (63.8–225 kg polym/molcat.h). Of note, the highest activity was observed for the dinuclear catalyst that was 250 kg polym/molcat.h. Subsequently, the synthesized copolymers were characterized by 1HNMR, DSC, TGA, and DMTA. DSC analysis indicated that catalyst structure and variation in the proportion of ENB exerted a profound effect on the glass transition of the resulting cyclic polyolefin. Copolymers produced via a dinuclear precursor, showed a lower Tg rang (99–190 °C) than those produced by a mononuclear one (86–233 °C). These findings were further supported by DMTA analysis. Apart from addition polymerization, a detailed inspection of the polymer structures (1HNMR) unexpectedly revealed that both cationic and ring-opening polymerizations can also occur during copolymerization, albeit with distinct levels of involvement.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Polyolefins are widely used polymers that have found extensive commercial applications due to their accepted physical and mechanical properties. These groups of synthetic polymers are classified into linear and cyclic polyolefins [1]. Cyclic olefin copolymers, which contain both cyclic olefins and ethylene units, have attracted considerable attention owing to their outstanding properties, such as high chemical resistance, low water absorption, and good optical transparency [2]. Due to their unique structure, cyclic olefin monomers, including cyclobutene, and cyclopentene, can be polymerized via different polymerization routes. This impressive feature enables the production of novel copolymers with outstanding properties [3]. Among the cyclic olefin monomers, norbornene, a bridged cyclic hydrocarbon, is a polymer with properties to polyethylene [4, 5]. This cyclic monomer has many ester and diene derivatives. For example, 5-vinyl-2-norbornene, 5-ethylidene-2-norbornene (ENB), 5-methylidene-2-norbornene, norbornadiene and dicyclopentadiene are among its diene derivatives [6, 7]. As one of the most important categories of engineering polymers, cyclic olefin copolymers are conventionally produced via copolymerization of cyclic olefins together with ethylene or α-olefins. The norbornene-ethylene copolymer produced by metallocene catalysts is one of the most extensively utilized cyclic copolymers, commercially available under the name TOPAS [8, 9]. Norbornene and its derivatives can also be polymerized through ring-opening, cationic or anionic, and addition polymerization techniques [10]. The ring-opening mechanism is extensively used in norbornene polymerization. In this technique, the presence of double bonds within the polymer backbone coupled with the cyclopentane ring is a unique characteristic of the PNB [4, 11]. For radical polymerization, azobisisobutyronitrile (AIBN) and tert-butyl peracetate are used as the initiator. Such a process delivers low molecular weight oligomeric molecules [12].Whereas in addition polymerization, C = C double is exclusively involved in the polymerization reaction, and the bicyclic structure of norbornene remains unaffected thereby producing polymers with saturated structure [7, 13].

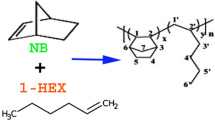

Transition metal catalysts based on nickel, palladium, chromium, vanadium, titanium, zirconium, cobalt, iron, and copper are common catalysts in olefin polymerization and copolymerization [14, 15]. Wang and his coworkers investigated norbornene copolymerization with styrene by 1,2-bis(imidazolidin-2-imine)benzene nickel complexes [16]. Zeng et al. studied the homopolymerization of norbornene and its copolymerization with ethylene by a palladium-based catalyst [17]. He et al. also explored the copolymerization of norbornene and 1-hexene by bis-(salicylaldehyde-benzhydrylimino) nickel-based complexes in the presence of B(C6F5)3; through this procedure, amorphous copolymers with extraordinary thermal stability, great solubility and optical transparency were achieved [18]. Alan et al. conducted the vinyl-addition polymerizations of cycloalkanes by the catalyst, [(π-allyl)NiOCOCF3]2; this polymerization system strikingly revealed features associated with living character [19]. High molecular weight and comonomer insertion were observed for the copolymerization of ethylene and 5-ethylidene-2-norbornene by a vanadium-based catalyst [20]. Bermesheva's group also reported the production of soluble high molecular weight poly 5-ethylidene-2-norbornene (PENB) using the Pd–N-heterocyclic carbene complexes [21].

Hong et al. described the synthesis of cyclic olefin copolymer, comprising ethylene and bulky cyclic olefin, with high glass transition temperature and good mechanical performance [22]. Since the ethylidene double bond of 5-ethylidene-2-norbornene stays unchanged during addition polymerization, it provides opportunities for further modification and improved properties [21]. Given the promising results from emerging research, the possibility of ENB/NB copolymerization and post-functionalization requires a deeper investigation. In this way, the main goal of the present study is to investigate the copolymerization of this monomer and norbornene by mononuclear, and binuclear catalysts. This polymerization system can be used to produce copolymers with distinctive properties, not only enabling further modification but also opening a promising way for designing products with enhanced performance such as membranes for gas separations applications, and adhesives in the foreseeable future. In our previous studies, higher activity was demonstrated by the dinuclear catalyst compared to the mononuclear one for the polymerization of long-chain monomers such as 1-hexene and 1-decene and the polymerization of 5-ethylidene-2-norbornene (PENB) [23,24,25]. To the best of our knowledge, little attention has been drawn to the copolymerization of 5-ethylidene-2-norbornene and cyclic monomers like norbornene by dinuclear catalysts.

Experimental

Material

Norbornene, 5-ethylidene-2-norbornene (ENB), and modified methylaluminoxane solution (MMAO) 7% were purchased from Aldrich Chemical Company. Solvents were purified using standard procedures. Toluene was dried over sodium/benzophenone and distilled before use. All manipulations of air-sensitive and water-sensitive compounds were performed under N2 gas atmosphere. N2 gas with a purity of 99.999% was purchased from Roham Company and passed through silica gel and 4A molecular sieve before use.

Characterization

Nuclear magnetic resonance (NMR) spectra of copolymer samples were recorded on a Bruker 400 MHz NMR spectrometer at ambient temperature with CDCl3 and CCl4 as solvents. Thermal gravimetric analysis measurements were performed on a Mettler-Toledo TGA instrument from ambient temperature to 600 °C at a heating rate of 10 °C / min under nitrogen atmosphere. Differential scanning calorimetry (DSC) measurements were done on a Perkin Elmer Q100 DSC apparatus from room temperature to 350 °C at a heating rate of 10 °C / min under nitrogen atmosphere. Dynamic mechanical thermal analysis (DMTA) measurements were performed on a Tritec 2000 DMA from room temperature to 350 °C at a rate of 5 °C / min and a frequency of 1 Hz with an amplitude of 0.025 mm. Rectangular samples with dimensions of 8 mm × 5 mm × 0.67 mm were clamped in the measuring head of DMTA.

Catalyst synthesis

Nickel α-diimine catalysts were synthesized and fully characterized in accordance with previous publications [23,24,25,26,27], and their structures are shown in Scheme 1.

Copolymerization

In a typical procedure, a two-necked round-bottom Schleck flask was deoxygenated by several vacuum-nitrogen purging cycles. Under the nitrogen atmosphere, a proper amount of freshly distilled 5-ethylidene-2-norbornene, norbornene and toluene was introduced into the flask, which already contained the required amount of MMAO activator. The reaction was started by injecting the catalyst solution mixture into the flask, which was stirred with a magnetic stirrer. After the desired time, the polymerization was terminated by adding 500 mL of acidified methanol to the reaction mixture. The precipitated polymer was filtered and washed with a large volume of methanol and then dried in a vacuum oven for 24 h.

Results and discussion

Copolymerization of 5-ethylidene-2-norbornene and norbornene

Following the interesting findings of our previous study, the polymerization of 5-ethylidene-2-norbornene by mononuclear and dinuclear α-diimine nickel catalysts [25], the copolymerization of ENB and norbornene were studied to complement our developing knowledge of binuclear catalyst behavior. Regarding the catalyst activity, as the data in Tables 1 and 2 suggest, the copolymerization of ENB and norbornene also exhibited trends comparable to those observed for the polymerization of 5-ethylidene-2-norbornene [25]. The highest activity was shown by dinuclear precursors. It is tempting to suggest that the proximity of two active centers acts as a contributing factor, thereby elevating the catalyst tendency to interact more with the unsaturated monomers [14, 15]. Comparatively speaking, a close examination of the statistics demonstrated for the NB-ENB copolymerization proposes that the use of dinuclear catalysts brings about considerable changes in the registered numbers for the glass transition temperature. For polynorbornene (PNB II) produced via a dinuclear precursor, Tg = 270 °C was observed [15]. It is obvious that this content greatly surpasses the corresponding numbers for (PNB I) made by the mononuclear precursor (Tg = 210 °C). To explain this dissimilarity in the content, one can refer to the ultimate confluence of addition, ring-opening polymerizations coupled with cationic polymerization, which provides polymers with strikingly different structures and elevated glass transition temperatures [25]. Furthermore, evaluation of data further shows that the addition and change in mole percent of ENB as comonomer significantly changes the glass transition temperature of the final copolymer. It is also evident that both categories approximately follow almost the same trend, although there are several deviations, both minor and major. Remarkably, the collected data propose that the introduction of ENB (5% mole) as acomonomer led to a dramatic decline in the observed Tg for NB-ENB II copolymer (the first row in Table 2), but the NB-ENB I copolymer indicate an ascending trend (the first row in Table 1). For higher proportions of ENB (15 and 40%), the glass transition temperatures steadily declined, before we see an increase to a higher temperature for samples with 70% ENB. As shown in Tables 1 and 2, copolymers with the lowest percentage of ENB exhibited higher Tg values than that of other PENBs, nevertheless, as the ENB ratio rises, the observed glass transition temperature moves in the opposite direction, bringing about an incremental reduction in Tg value.

Characterization of ENB/NB copolymer

NMR analysis

To determine the chemical microstructure of synthesized copolymers, the 1HNMR spectra of the synthesized NB-ENB copolymers were studied. Figures 1 and 2 demonstrate the 1HNMR spectra for the obtained samples. In accord with the previous investigation, the microstructural analysis of PNB by 1HNMR, 1HNMR peak assignment for PNB samples exhibits several peaks, covering an area of chemical shifts, ranging from 0.8–3 ppm to 5.8–6 which can be assigned to aliphatic bond and olefinic bond respectively. Interestingly, what stands out from the presented spectra is the presence of the resonance signal in the vicinity of 2.4 ppm which seems to be an inseparable part of all 1HNMR spectra, even at low ENB feeding (5% mol). As you may remember from the assumption stated in our previous paper [25], the basis for the appearance of this signal can supposedly be attributed to the fact that in tandem with other mechanisms, namely addition and probably cationic polymerization [25], the simultaneous occurrence of ring-opening polymerization can be regarded as another governing mechanism partly dominating the monomer insertion into the growing chains [6, 25]. One further hypothesis is closely correlated to the probability of 1,3 cationic polymerization. Having considered the probable participation of three suggested mechanisms, one can point to the appearance of weak signals sweeping the region of 5–6 ppm, although hardly distinguishable for the NB-ENB copolymer sample synthesized with the lowest elected ENB feeding (5% mol). Supposedly, these peak assignments can be attributed to the existence of double bonds with different natures resulting from the interaction of the mentioned mechanisms. As shown, the sample possesses an ethylidene proton between 4.8–5.3 ppm, usually seen as a double bond peak due to two stereoisomers of this monomer [22, 28, 29]. More significantly, the represented spectra indicate that the intensity of the observed peak, which is associated with the presence of the double bonds, is closely linked to the amount of ENB in the feed, the higher the percentage of ENB, the higher the intensity of the peak. Collectively, taking into account the recorded 1HNMR spectra for NB-ENB copolymers, it can be assumed that the transition from mononuclear catalyst to the bimetallic catalyst favors conditions that are more appropriate for higher participation of ring-open polymerization.

H NMR spectra of the copolymers synthesized with a mononuclear catalyst; (Table 1) a) Co-I 1, b) Co-I 2, c) Co-I 3, and d) Co-I 4

H NMR spectra of the copolymers synthesized with a dinuclear catalyst; (Table 2) a) Co-II 1, b) Co-II 2, c) Co-II 3, and d) Co-II 4

Comonomer incorporation

Comonomer incorporation into NB and ENB copolymers (Tables 1 and 2) is determined using the related 1HNMR spectra. As could be seen in these spectra, the peaks of the ENB ring completely overlap with the NB ring at 1–3 ppm, therefore, to determine the comonomer incorporation, the characteristic peak of the ethylidene bond, located at 5.2–5.8 ppm, was used. Since ENB is a combination of two stereoisomers that have the same reactivity [20], peaks of C5 and C8 were considered ENB characteristic peaks (Scheme 2) and named B in Eq. 1. If A is taken as the intensity of all protons of the copolymer, the comonomer incorporation could be calculated from the following equation. The results are summarized in Tables 1 and 2.

As the summarized data show, at low concentrations of ENB, its incorporation into the copolymer backbone is nearly the same as the feeding ratio. Nonetheless, at high concentrations, the difference between the feed ratio and ENB incorporation in the copolymer gradually becomes more obvious.

Thermal properties and stability of copolymers

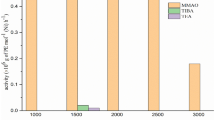

Having viewed the experimental data (1HNMR) regarding the likely presence of double bonds of diverse natures, and their effects on the thermal stability of macromolecules, this section is particularly allocated to evaluate the thermal stability of the synthesized NB-ENB copolymers. The presented graph (Fig. 3) comparatively indicates the relative thermal stability of selected samples prepared by both mono and dinuclear catalysts. In support of the above mentioned hypothesis (the function of the double bond), the NB-ENB copolymer produced in the presence of 5% ENB revealed the highest figures in terms of stability and approximately outperformed the remaining samples, (CO-I 1 and CO-II 1). As evidenced by the 1HNMR analysis, the reduced double bond intensity for NB-ENB copolymer (5% ENB) appears to lessen the possibility of thermal degradation compared to other candidates containing a higher content of ENB incorporation. Besides, the weakest performance in terms of delaying the unwanted degradation of the polymer was observed for the copolymer with 40% ENB. This means that by inserting ENB comonomer into the polymer backbone and creating the resulting stereoregularity, this type of unfamiliar thermal stability is observed in the resulting polymer. It is worth mentioning that the resulting stereoregularity can be introduced into the polymer chains through the participation of three previously described polymerization mechanisms, alongside the heterogeneous distribution of double bonds and the possible involvement of crosslinking points [30, 31].

In comparison with the mononuclear catalyst, it is noticeable that copolymer obtained by using the dinuclear catalyst depicts a lower decomposition temperature, illustrating weaker thermal stability. Samples mostly undergo thermal degradation at temperature above 300 °C. The primary degradation temperatures are as follows: for copolymers obtained by a binuclear catalyst (CO-II 1 (405 °C), CO-II 2 (340 °C), CO-II 3 (330 °C), CO-II 4 (350 °C), and for copolymers produced using a mononuclear catalyst (CO-I 1(410 °C), CO-I 2 (370 °C), CO-I 3 (360 °C), CO-I 4 (390 °C).

As you may recall, it was suggested that ROMP possibly occurs using this catalytic system (the appearance of an olefinic bond in the polymer backbone), producing polymer chains that are more vulnerable to chain scission and degradation at a lower temperature [30, 31]. Of note, both macromolecules followed an approximately identical pattern during the given thermal examination. Lastly, a careful examination of ash contents regarding both obtained polymers suggests that the figures are lower than 10%, indicative of low mineral content and the indubitable appearance of the absence of network structure polymers [30].

DMTA of copolymers

Figure 4 provides a comparative analysis of selected candidates containing different ENB contents, namely CO (I) and CO (II), the former is indicative of a copolymer obtained via a mononuclear catalyst, and the latter is representative of a sample produced via the utilization of dinuclear catalyst. It is immediately apparent that the change in the content of ENB feed caused a noticeable shift from a broader curve to a narrower one. In addition, Fig. 4 also reveals that CO-I 1 and CO-II 1 samples display a broad tanδ peak in the glass transition region. The tanδ of CO-I 1 and CO-I 4 copolymers (Fig. 4 (a)), as well as CO-II 1 and CO-II 4 copolymers (Fig. 4 (b)), confirms the glass transition temperatures reported in Tables 1 and 2 obtained via DSC analysis. In the copolymers containing the highest insertion of ENB, CO-I 4, and CO-II 4, the appearance of a narrow peak instead of a broad one in the glass transition region is obvious, undoubtedly, indicating drastic changes in the copolymer microstructures, which can also be confirmed by DSC analysis. The results clearly show that changing the structure of the catalyst and the molar ratio of the comonomer will certainly produce copolymers whose behavior is different from what DMTA analysis shows. A literature survey of previous studies on the concerning coordinative polymerization of the linear monomer of high olefin ranging from 1-hexene to 1-decene, reveals that the behavior shown is most likely due to the participation of various polymerization mechanisms [23, 24]. In other words, it can be supposed that a set of microstructural variations is the basis for different degrees of polymer chain mobility. Due to the possible polymerization mechanisms, it can be concluded that a significant change in the structure of the polymer chains has probably occurred. This hypothesis can be related to the presence of side branching, the length of side chains, crosslinking, diverse distributions of double bonds, and the resulting change in polydispersity, which give different rigidity to copolymers chains. This means that the transformation of 5-ethylidene-2-norbornene into nortricyclene repeating skeleton as well as the presumed presence of cyclopentane units resulting from ring-opening polymerization and cyclopentene as a consequence of cationic polymerization [25], certainly further confirms the explanation of the behavior provided by the DMTA analysis.

Conclusion

In the present study, copolymerization of 5-ethylidene-2-norbornene and norbornene by mono and dinuclear nickel α-diimine catalysts was investigated in detail. Irrespective of the addition polymerization, the results provided compelling evidence in favor of both cationic and ring-opening polymerizations. As far as the catalyst activity is concerned, the dinuclear catalyst revealed a superior catalytic performance as compared to the mononuclear one. For both catalysts, the highest activity was realized at 25 °C. The glass transition temperatures of homopolymers namely, PENB and PNB obtained by dinuclear catalyst were noticeably higher than those of mononuclear catalyst. Meanwhile, the Tg value for copolymers (ENB-NB) produced using a mononuclear catalyst (with ENB incorporation less than 5%), was relatively higher than that produced using a binuclear one. While the Tg of polynorbornene is higher than that of poly 5-ethylidene-2-norbornene, it was conclusively confirmed that the incorporation of more 5-ethylidene-2-norbornene would certainly cause significant changes in the observed Tg, ultimately lowering the glass transition of the copolymers. Higher thermal stability was observed for the copolymers obtained by the mononuclear catalyst than the copolymer produced by the dinuclear catalyst. DMTA analysis sheds light on the fact that increasing the ENB ratio, as a determining factor, significantly affects the final structure of the copolymers. Taken together, as the findings suggest, the incorporation of ENB into PNB chains during polymerization via utilization of both catalysts, especially the dinuclear one, delivered copolymers with appreciably dissimilar microstructures, this phenomenon can be exploited to introduce further manipulations in the polymer microstructure through the post functionalizations procedure, thereby enabling the preparation of polymers with enhanced properties and expanded scope of applications.

References

Tan C, Zou C, Chen C (2022) An ionic cluster strategy for performance improvements and product morphology control in metal-catalyzed olefin–polar monomer copolymerization. J Am Chem Soc 144(5):2245–2254. https://doi.org/10.1021/jacs.1c11817

Chen C (2018) Designing catalysts for olefin polymerization and copolymerization: beyond electronic and steric tuning. Nat Rev Chem 2:6–14. https://doi.org/10.1038/s41570-018-0003-0

Peng D, Chen C (2021) Photoresponsive Palladium and Nickel catalysts for ethylene polymerization and copolymerization. Angew Chemie Int Ed 60:22195–22200. https://doi.org/10.1002/anie.202107883

Wang W, Chen M, Pang W, Li Y, Zou C, Chen C (2021) Palladium-catalyzed synthesis of norbornene-based polar-functionalized polyolefin elastomers. Macromolecules 54:31973203. https://doi.org/10.1021/acs.macromol.1c00201

Xu M, Chen C (2021) A disubstituted-norbornene-based comonomer strategy to address polar monomer problem. Sci Bull 66:1429–1436. https://doi.org/10.1016/j.scib.2021.03.012

Bermeshev MV, Bulgakov BA, Genaev AM, Kostina JV, Bondarenko GN, Finkelshtein ES (2014) Cationic polymerization of norbornene derivatives in the presence of boranes. Macromolecules 47:5470–5483. https://doi.org/10.1021/ma5010919

Blank F, Janiak C (2009) Metal catalysts for the vinyl/addition polymerization of norbornene. Coord Chem Rev 253:827–861. https://doi.org/10.1016/j.ccr.2008.05.010

Chen Z, Changle C (2020) Polar-functionalized, crosslinkable, self-healing, and photoresponsive polyolefins. Angew Chem Int Ed 59:395–402. https://doi.org/10.1002/anie.201910002

Zhang H, Zou C, Zhao H, Cai Z, Chen C (2021) Hydrogen-bonding-induced heterogenization of Nickel and Palladium catalysts for copolymerization of ethylene with polar monomers. Angew Chem Int Ed 60:17446–17451. https://doi.org/10.1002/anie.202106682

Bermeshev MV, Bulgakov BA, Finkel’shtein ES (2013) Cationic polymerization of 5-ethylidene-2-norbornene in the presence of boron compounds. Dokl Chem 449:83–86. https://doi.org/10.1134/S001250081303004X

Pereira QL, Marques MFV (2018) Influence of diethyl zinc on ethylene-norbornenecopolymerization. Polyolefine J 5:71–84. https://doi.org/10.22063/poj.2017.1512

Wu Q, Lu Y (2002) Synthesis of a soluble vinyl-type polynorbornene with a half-titanocene/methylaluminoxane catalyst. J Polym Sci A Polym Chem 40:1421–1425. https://doi.org/10.1002/pola.10227

Wang X, Jeong YL, Love C, Stretz HA, Stein GE, Long BK (2021) Design, synthesis, and characterization of vinyl-addition polynorbornenes with tunable thermal properties. Polym Chem 40:5831–5841. https://doi.org/10.1039/D1PY01050F

Khoshsefat M, Dechal A, Ahmadjo S, Mortazavi MM, Zohuri GH, Soares JPB (2019) Amorphous to high crystalline PE made by mono and dinuclear Fe-based catalysts. Eur Polym J 119:229–238. https://doi.org/10.1016/j.eurpolymj.2019.07.042

Shakeri SE, Mortazavi SMM, Ahmadjo S, Zohuri GH (2020) Comparison of mono and dinuclear α–diimine Ni-based catalysts for synthesis of polynorbornene and its microstructure study. J Macromol Sci Part A Pure Appl Chem 57:837–843. https://doi.org/10.1080/10601325.2020.1796494

Wang Z, Shu X, Zhang H, Gao L, Li Y, Cai Z (2021) Synthesis of 1,2-bis(imidazolidin-2-imine)benzene nickel complexes and their application for norbornene (co)polymerization with styrene. Eur Polym J 150:110426. https://doi.org/10.1016/j.eurpolymj.2021.110426

Zeng Y, Mahmood Q, Zhang Q, Liang T, Sun WH (2018) Highly thermo-stable and electronically controlled palladium precatalysts for vinyl homo/co-polymerization of norbornene-ethylene. Eur Polym J 103:342–350. https://doi.org/10.1016/j.eurpolymj.2018.04.028

He X, Tu G, Zhang F, Huang S, Cheng C, Zhu C, Duan Y, Wang S, Chen D (2018) Bis-(salicylaldehyde-benzhydrylimino) nickel complexes with different electron groups: crystal structure and their catalytic properties toward (co)polymerization of norbornene and 1-hexene RSC Adv 8:36298–36312. https://doi.org/10.1039/C8RA06561F

Galan NJ, Burroughs JM, Maroon CR, Long BK, Brantley JN (2020) Vinyl-addition polymerizations of cycloallenes: synthetic access to congeners of cyclic-olefin polymers. Polym Chem 11:5578. https://doi.org/10.1039/D0PY01018A

Wang K, Wang J, Li Y, Pan L, Li Y (2017) Efficient copolymerization of ethylene with norbornene-containing dienes promoted by single site non-metallocene oxo vanadium (V) catalytic system. Polymers 9:353. https://doi.org/10.3390/polym9080353

Bermesheva EV, Wozniak AI, Andreyanov FA, Karpov GO, Nechaev MS, Asachenko AF, Topchiy MA, Melnikova EK, Nelyubina YV, Gribanov PS, Bermeshev MV (2020) Polymerization of 5-alkylidene-2-norbornenes with highly active Pd–N-heterocyclic carbene complex catalysts: catalyst structure–activity relationships. ACS Cat 10:1663–1678. https://doi.org/10.1021/acscatal.9b04686

Hong M, Cui L, Liu S, Li Y (2012) Synthesis of novel cyclic olefin copolymer (COC) with high performance via effective copolymerization of ethylene with bulky cyclic olefin Macromolecules 45:5397–5402. https://doi.org/10.1021/ma300730y

Khoshsefat M, Ahmadjo S, Mortazavi SMM, Zohuri GH, Soares JBP (2018) Synthesis of low to high molecular weight poly(1-hexene); rigid/flexible structures in a di- and mononuclear Ni-based catalyst series. New J Chem 42:8334–8337. https://doi.org/10.1039/C8NJ01678J

Dechal A, Khoshsefat M, Ahmadjo S, Mortazavi SMM, Zohuri GH, Abedini H (2018) Mono- and binuclear nickel catalysts for 1-hexene polymerization. Appl Organomet Chem 32:1. https://doi.org/10.1002/aoc.4355

Mansouri S, Omidvar M, Mortazavi SMM, Ahmadjo S (2022) 5-Ethylidene-2-norbornene plymerization by α -diimine nickel catalyst: A revealing insight into the pivotal function of binuclear and mononuclear catalyst structure in tailoring polymer architecture. Macromol Reac Eng 16:2100052. https://doi.org/10.1002/mren.202100052

Kateb M, Karimi M, NejabatG MSMM, Ahmadjo S (2020) Synthesis of 1-hexene/1,7-octadiene copolymers using coordination polymerization and postfunctionalization with triethoxysilane. J Appl Polym Sci 137:48934. https://doi.org/10.1002/app.48934

Soleimannezhad A, Mortazavi SMM, Ahmadjo S, Mansori S, Rashedi, R (2022) Iran Polym J 31:237–245. https://doi.org/10.1007/s13726-021-00986-x

He X, Chen Y, Liu Y, Yu S, Hong S, Wu Q (2007) Addition polymerization of norbornene using bis(ß-ketoamino) nickel(ll)/tris(pentafluorophenyl) borane catalytic systems. J Polym Sci Part A Polym Chem 45:4733–4743. https://doi.org/10.1002/pola.22221

Liu JY, Liu SR, Pan L, Li YS (2009) Facile, efficient copolymerization of ethylene with bicyclic, nn-Conjugated dienes by titanium complexes bearing bis(β-enaminoketonato) ligands. Adv Syn Cat 351:1505–1511. https://doi.org/10.1002/adsc.200900126

Liu C, Yu J, Sun X, Zhang J, He J (2003) Thermal degradation studies of cyclic olefin copolymers. Polym Deg Stab 81:197–205. https://doi.org/10.1016/S0141-3910(03)00089-2

Tan C, Chen C (2019) Emerging Palladium and Nickel catalysts for copolymerization of olefins with polar monomers. Angew Chem Int Ed 58(22):7192–7200. https://doi.org/10.1002/anie.201814634

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mansouri, S., Omidvar, M., Soleimannezhad, A. et al. Copolymerization of cyclic monomers by nickel α-diimine catalysts: catalyst structure, polymer characterization. J Polym Res 29, 409 (2022). https://doi.org/10.1007/s10965-022-03264-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03264-3