Abstract

Magnetic properties of nanoparticles are size dependent and surface grafting of nanoparticles not only prevents their agglomeration but can also lead to effective domains separation. Present study deals with the synthesis of manganese oxide nanoparticles (< 5 nm) by microwave assisted solvothermal process and its grafting with poly L-lactic acid by a self-catalyzed ring opening polymerization of L-lactide. The Mn3O4 nanoparticles and Mn3O4/PLLA nanocomposite were characterized by many analytical techniques such as FT-IR, TEM, 1H NMR, 13C NMR, XRD, XPS, TGA and DSC etc. The magnetic properties of nanoparticles and nanocomposites were studied using VSM and SQUID showed marked shift in magnetic behavior of Mn3O4 nanoparticles which were super paramagnetic, on coating with PLLA.

Effect of PLLA grafting on magnetic behaviour of Mn3O4 nanoparticles

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the past few years efforts have been made to develop and characterize nanomaterials having unique properties (optical, electrical or magnetic). Due to such properties these nanomaterials have found applications in the field of electronics, optics, aerospace, medicine, fuel cells etc. [1, 2]. Especially noteworthy is their contribution in the field of biomedicine and biotechnology as nanoparticles can interact with biological systems at the molecular level [3, 4]. Among the variety of nanomaterials investigated for biomedical applications, magnetic nanoparticles play a prominent role in the area of magnetic separation [5], biosensors [6], contrast agents for magnetic resonance imaging, [7,8,9], drug delivery [10,11,12] tissue repair [13], hyperthermia [14, 15] storage of information [16] color imaging [17], and magnetic refrigeration [18] etc. Therefore synthesizing nanoparticles with magnetic properties is very important [19, 20]. The main features affecting the magnetic properties of materials are particle size, surface aspects and domain separation [21, 22].

Till date, iron oxide nanoparticles are the most frequently employed materials for magnetic and electrical properties [23]. Magnetic properties of oxides of manganese are comparatively less explored in spite of their low cost and low toxicity. In comparison to other electrically conductive metal oxides, manganese oxide stores electrical charge by double insertion of electrons and cations into the solid state [20]. Manganese shows many oxidation states (II –IV) and hence a large number of manganese oxides such as MnO, Mn2O3 and Mn3O4 are possible [24]. Magnetic properties of materials shows drastic change when particle size become similar to the distinctive length of magnetic interaction or length of spin diffusion implying that nanoscale material can have magnetic properties different from bulk form [21, 22]. The magnetic properties of manganese oxides vary from anti ferromagnetic to ferromagnetic. These properties depend on three factors oxidation state, crystal structure and the finite size [24]. The most stable among the oxides of manganese, Mn3O4 is a soft magnetic material and its magnetic properties at nanoscale are of great interest for researchers [25]. As the nanoparticles are prone to agglomeration due to high surface energy, their stability and hence, the magnetic properties can be enhanced by coating them with suitable agents. Polymer coating, especially by grafting onto surface of nanoparticles, can enhance their magnetic properties immensely by efficient domain separation.

In the present work we report synthesis of Mn3O4 nanoparticles by microwave enhanced solvothermal process and grafted them with PLLA a renewable and biodegradable polymer [26]. The effect of polylactide coating on the magnetic properties of nanocomparticles was studied. PLLA was grafted onto manganese oxide by self-catalyzed ring opening polymerization of L-lactide. Polymerization was carried out by taking various concentrations of nanoparticles and resulting composites were characterized using various analytical techniques Such as TEM, SEM, IR, NMR, TGA and DSC. At 5% Mn3O4/PLLA beautiful core shell structures were observed and this material was studied for its magnetic properties using VSM and SQUID.

Experimental

Material

All chemicals used were of analytical grade or of highest purity available. L-lactide was purchased from Aldrich. Manganese acetate was purchased from Qualigens fine chemicals. All the chemicals were used as received.

Synthesis of Mn3O4 nanoparticles

Mn3O4 nanoparticles were synthesized by microwave enhanced solvo thermal hydrolysis using manganese acetate and benzyl alcohol. CEM microwave operating with a power output that can be varied between 0 and 300 W was used. The solution was swiftly stirred by a magnetic stir bar to ensure homogeneity. The exposure time and temperature were programmed. In a 5 mL vessel, 1 mmol of manganese acetate and 5 mL of benzyl alcohol were placed with a magnetic bar [27]. This mixture was microwave heated at 60 °C for 3 min. Then the reaction temperature was elevated to 160 °C and kept at this temperature for 20 min. The product was collected, washed with methanol, diethyl ether and dried in oven overnight at 50 °C. Further, the nanoparticles formed were calcined in muffle furnace at 500 °C for 4 h.

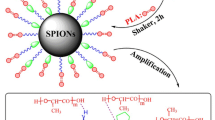

PLLA grafted Mn3O4 nanoparticles

Different amounts of Mn3O4 nanoparticles were dispersed in 20 ml 1, 4-dioxane in a 50 mL round bottom flask. Reaction mixture was stirred at 60 °C using a magnetic stirrer to uniformly disperse the nanoparticles. The temperature was raised to 80 °C after the addition of 1 g of L-Lactide. The solvent was distilled off using vacuum and the temperature increased to 160 °C. After 4 h the reaction was quenched by cooling. The gelatinous mass was dispersed in chloroform, filtered and the residue washed with methanol. The product (Scheme 1) thus obtained was dried in a desiccators.

Instrumentation

Shimadzu FTIR spectrophotometer was used to analyze the synthesized compounds. Anhydrous KBr and sample were crushed using mortar pestle. Using this mixture thin pellets were made and further analysis was done.

The Transmission electron microscope (TEM) images were recorded on Hitachi (H-7500). The sample was finely powdered and dispersed in ethanol. One drop from this dispersion was kept on a 200 mesh carbon coated copper grid. After evaporating solvent, recording of images at different magnifications was done.

To study the surface morphology of synthesized nanocomposites Scanning Electron Microscope (SEM) Model JSM6100 (Jeol) with acceleration voltage range of 0.3 to 30 kV, working distance of 6–48 nm, was used.

The powder XRD of the nanoparticles was recorded on Panalytical X Pert Pro using Cu Kα radiation (= 1.54060 Å) and a filter of nickel at 40 kV and 40 mA with step size 0.03 and count time 0.7 s.

13C NMR and1H NMR spectra were recorded with Bruker Avance II 400 MHz NMR spectrophotometer with CDCl3 as solvent and TMS as an internal standard at room temperature.

To study thermal properties of the nanocomposites, Differential scanning calorimeter DSC-60 of Shimadzu was used.5 mg of the sample was placed on an aluminium pan, sealed and heated up to 100 °C. After cooling it to room temperature it was again scanned from ambient to 300 °C at a rate of 10 °C / min. Thermal stability of samples were determined using Thermogravimetric Analysis (TGA, Shimadzu DTG-60H). The samples were heated at the rate of 10 °C / min under nitrogen atmosphere.

XPS measurements were conducted at an ultrahigh vacuum (UHV) multipurpose surface analysis system (SpecsTM model, Germany) at the SCAI in Universidad de Cordoba (Spain), operating at pressures <10–14 MPa using a conventional X-Ray source (XR-50, Specs, Mg–K, 1253.6 eV) in a “stop-and-go” mode to reduce potential damage due to sample irradiation. The survey and detailed high resolution spectra (pass energy 25 and 10 eV, step size 1 and 0.1 eV, respectively) were recorded at room temperature using a Phoibos150-MCD energy analyzer. Powdered samples were deposited on a sample holder using double sided adhesive tape and subsequently evacuated under vacuum (<10–6 Torr) overnight. Eventually, the sample holder containing the degassed sample was transferred to the analysis chamber for XPS studies.

Magnetic properties of nanoparticles were measured by means of PAR 155 vibrating sample magnetometer (VSM) at room temperature from −10 to +10 kOe. The sample is rotated up to 360° w.r.t magnetic field and recorded in X-Y/(t) recorder.

The magnetic measurements were also performed on superconducting quantum interference device (SQUID) magnetometer (Quantum design MPMS XL-Evercool). The temperature ranged from 5 to 300 K in a zero-field cooling/field cooling (ZFC/FC) procedure at 100 Oe.

Results and discussion

The Mn3O4 nanoparticles were synthesized by microwave assisted solvo thermal process which involved trans-esterification of benzyl alcohol and manganese acetate. The synthesized nanoparticles were calcined at 500 °C. Bilecka et al. [27] have reported nanoparticles of various oxides from different precursors. However, prepared with slight modified procedure, our results showed that nanoparticles obtained from manganese acetate as precursor are that of Mn3O4. This was confirmed by XRD and the magnetic properties observed by VSM and SQUID.

Transmission electron microscopy is a useful tool to determine the size and shape of nanoparticles. TEM images of synthesized Mn3O4 nanoparticles are shown in the Fig. 1. The nanoparticles are almost spherical in shape and most of nanoparticles have size ranging from 1 to 3 nm. The blurriness of TEM images is due to magnetic nature of the Mn3O4 nanoparticles.

XRD of the calcined nanoparticle and non-calcined nanoparticle is shown in the Fig. 2. It can be seen that phase boundaries are not well defined in as prepared sample. However, after calcination these became clear and the diffraction pattern obtained was compared with the standard. Obtained values confirm the formation of tetragonal phase of Mn3O4 in accordance with JCPDS 24–0735. The diffraction peaks were recorded and unit cell parameters were calculated (a = b = 5.761 Å, c = 9.46). These were comparable to the standard JCPDS values (a = b = 5.762 Å, c = 9.46 Å). The unit cell volume calculation (Table 1) of the particles is in agreement with the standard values [28].

Surface grafting of metal oxide nanoparticles is a useful tool to stabilize them and prevent their aggregation. It was carried out by ring opening polymerization of L-lactide. Many metal oxides have been reported as catalyst for the ring opening polymerization of L-lactide [29, 30]. To the best of our knowledge manganese oxide has not been tried as catalyst. With an aim to graft polymer onto the surface of nanoparticle we checked whether Mn3 O4 can catalyze ring opening of L-lactide and got wonderful results. A series of polymerization reactions were carried out with concentration of metal oxide varying from 0.5 to 20% and polymerization confirmed by FTIR. Infrared spectrum of manganese oxide nanoparticles showed a few bands only due to stretching of metal oxide bonds, whereas those of nanocomposite showed a number of bands pertaining to the different groups present in the polymer chain. The results are depicted in Fig. 3. Only two main absorption bands observed at 520 and 633 cm−1 in the IR spectrum of Mn3O4 were attributed to the stretching modes of Mn-O. Presence of small broad absorption peaks between 3560 and 3500 cm−1 indicated the presence of surface hydroxyl groups. In the FTIR spectrum of Mn3O4/PLLA the most intense band at 1758 cm−1 was attributed to the ester group of PLLA main chain. The peaks at 1270, 1189 and 1132 cm −1 were attributed to -C-O stretching vibrations of ester in the main chain. The asymmetrical and symmetrical -CH3 stretching of the methyl group in the side chains were observed at 2999 and 2881 cm−1. The bending vibration of -CH3 group was noticed at 1458 cm−1. The stretching of -CH group present in the main chain of PLLA was observed at 2944 cm−1 and the corresponding bending vibration appeared between 1386 and 1362 cm−1. A small peak observed at 1621–1604 cm−1 in the FT-IR spectrum of 5% nanocomposite was assigned to the O-C-O stretching of the chain ending carboxylate group through which the chain is attached to metal oxide surface. This peak increased in size with increase in metal oxide content in the Mn3O4/PLLA. Some workers observed that splitting of this band does not occur and in some cases proximity to the Mn3O4 nanoparticles may cause shift in the peak values.

NMR is another useful tool to confirm the formation of polymer chains. 1 H NMR spectra of different Mn3O4 /PLLA nanocomposites were taken but due to decreased solubility of the nanocomposite with increase in metal oxide content, no estimation of chain length was possible [See ESI]. 1H NMR spectra of Mn3O4/PLLA are shown in the Fig. 4. The methine and methyl proton of the PLLA main chain were indentified due to peaks at 5.16 and 1.56 ppm respectively. The small peak at 3.75 ppm corresponds to hydroxyl end group. Another small peak at 4.36 ppm was assigned to the methine proton attached to terminal hydroxyl group. The optical purity of L-lactide was indicated by a quartet at 5.16 ppm. The peak at 7.82 ppm was due to CDCl3. In the 13C NMR (Fig. 5) of 2% Mn3O4/PLLA nanocomposite three major peaks were observed. The peak at 16.65 ppm was assigned to methyl group, 69.01 ppm to methine group and 169.62 ppm to carbonyl carbon. The triplet at 77.36 ppm is due to CDCl3.

Thermal properties of synthesized nanocomposites were studied by TGA and DSC. Thermogravimetric analysis of nanocomposites was carried out to calculate the amount of polymer material incorporated into composite. TGA thermograms of Mn3O4/PLLA nanocomposites with different concentrations of Mn3O4 were carried out under nitrogen atmosphere and results are shown in Fig. 5. The weight loss (%) because of volatile products formed after decomposition was observed as a function of temperature. The degradation of polylactic acid chain occurs via unzipping mechanism. Initially degradation of nanocomposites was slow which was attributed to moisture present in it and unreacted monomers. In the end the degradation was fast because unzipping of polymer chain occured. The degradation patterns were found to be similar in (1%, 2% and 5%). Results summarized in Table 2 show decomposition temperatures for the composites are above 230 °C and the amount of residue left increases with the increase in the quantity of nanoparticles.

Differential scanning calorimetry is widely used to study thermal transitions. Glass transition temperature was not observed in any of the DSC thermograms (Fig. 6) and this was similar to our earlier observations with ZnO/PLLA nanocomposites [30]. Further the first small dip in the graph corresponds to the melting point of polymer and the data is given in Table 2. Melting point of various nanocomposites varied from 137 to 140 °C. This is considerably lower than that reported for pure PLLA. Also it was observed that at 0.5% of Mn3O4 probably two phases are present which melt at two different temperatures. These phase separation disappeared at higher loading of catalyst. At 5% loading a broad peak was observed and this point corresponded to the core/shell morphology observed by TEM. From both the TGA and DSC thermograms it was concluded that the decomposition of nanocomposite starts at around 220–260 °C.

The morphology of nanocomposites and size of nanoparticles was found from TEM images. At 2% loading it was observed that nanoparticles are uniformly dispersed in polymer matrix (Fig. SI). However, in the case of 5% Mn3O4/PLLA core shell type morphology of nanocomposite was observed [31]. The size of spherical core shell particles varied between 70 to 180 nm. However, most of the particles were of less than 100 nm dimension. SEM image of 5% Mn3O4/PLLA (Fig. 7) taken from powdered sample showed small globules but they were tightly adhering to each other. EDAX analysis of 5% Mn3O4/PLLA showed 54.14% of carbon, 42.92% of oxygen and 2.94% of manganese (Fig. S3). As these values are area specific they may vary slightly from actual values.

XPS analysis gives the elemental composition of the surface atoms of nanocomposite. Figure 8 shows XPS analysis of 5% Mn3O4/PLLA nanocomposite. XPS analysis of Mn3O4/PLLA showed peaks corresponding to Mn 2p, C 1 s and O 1 s. The Mn 2p XPS spectra of composite exhibited two peaks at 642.9 and 641.0 eV corresponding to Mn 2p1/2 and Mn 2p3/2 spin orbital states of Mn3O4 respectively [32]. It was observed that there is energy separation of 11.9 eV between Mn2p 3/2 and Mn2p1/2 peaks which is in accordance with the reported data of Mn 2p1/2 and Mn 2p3/2 in the spectrum of Mn3O4 [33]. There are four peaks of C1s for Mn3O4/PLLA in which are 284.94, 286.47, 289.76 eV were assigned to C-C, C- O and C = O respectively and the one at 288.80 eV to carboxylic group coordinating with Mn. Peaks observed in deconvoluted spectrum of O1s were 532.08, 532.36, 533.43 and 534.61 eV which were assigned to Mn-O, C-O, C = O and H-O-H respectively [34].

Magnetization of nanoparticles and that of polymer coated nanoparticles was studied to check the effect of polymer coating on magnetic properties of the synthesized nanoparticles. Vibrating spin magnetometer (VSM) and Superconducting Quantum Interference Device (SQUID) were used to measure magnetic properties of both coated and uncoated nanoparticles. The magnetization curve of Mn3O4 nanoparticles at room temperature is shown in the Fig. 9a. The M-H curve is found to be linear with the fields and has zero coercivity at room temperature [35]. It has been reported that the hysteresis in the single-domain ferrimagnetic particles disappears, as particle size becomes small. This state of ferrimagnetism is called “superparamagnetism”. In this case no hysteresis was found in M–H curve. Even when high magnetic field was applied the magnetization never became saturated. As the maximum anisotropy energy becomes close to the thermal energy at the room temperature, the process of flipping of the single-domain spin of nanoparticles becomes uninhibited [36] and magnetization curve shows no hysteresis which indicates the superparamagnetic character of the Mn3O4 nanoparticles [37, 38]. However, at a certain low temperature the situation may change and this was studied by SQUID analysis.

SQUID magnetometer was used to study the magnetic properties of nanoparticles at different temperature (Fig. 9b). The temperature dependence of magnetization of the sample was measured with the use of zero field cooling (ZFC) and field cooling (FC) procedures in the applied magnetic field of 100 Oe at temperature between 5 to 300 K. There was pronounced difference between the two curves and phenomenon of superparamagnetic blocking of magnetic nanoparticles was clearly observed. The uncoated particles are ferromagnetic and show some ferromagnetic interaction between each other. The temperature where the two curves split is known as the blocking temperature and it was observed at 40 K. Above this temperature the particles are still ferromagnetically ordered, but the magnetization of each particle is pointing in a random direction. Essentially the system behaves like a paramagnet and such a paramagnet is called a superparamagnet as the individual moments are not those of the individual atoms but those of the individual particles. Below this blocking temperature, the magnetization of a particle is no longer free to rotate on the time scale of the experiment but is frozen in a certain orientation. This freezing of the orientation is dictated by the applied field and the interaction between particles. Hence, the pronounced difference between ZFC and FC. Literature available on the magnetic behaviour of Mn3O4 nanoparticles also supports this observation [39,40,41].

To study magnetization of the nanocomposite, two different concentrations were prepared i. e. 5% Mn3O4 / PLLA and 20% Mn3O4 / PLLA. The temperature dependence of magnetization on 5% and 20% Mn3O4 /PLLA is shown in Fig. 10. The FC magnetization curve was an exact duplicate of the ZFC pattern in both the cases, which demonstrates that only one magnetic phase exists [42, 43]. There is no pronounced blocking temperature anymore. The loss of splitting between ZFC and FC can be due to many reasons. It may be due to stress caused by different expansion rates of nanoparticles and polymer or it may be due to large paramagnetic contribution of individual nanoparticles [44] In addition it may also be that the interaction between the particles is completely suppressed after polymer coating. Further, studies to understand this behavior is in progress.

Conclusion

We have successfully synthesized Mn3O4 nanoparticles of size 1–3 nm by microwave enhanced process. We were also able to coat synthesized Mn3O4 nanoparticles by PLLA resulting in core shell structures in a facile single step. It was concluded that Mn3O4 nanoparticles can catalyse ring opening polymerization of L-lactide and result in surface grafting. VSM and SQUID studies of nanoparticles showed that individual Mn3O4 nanoparticles were ferromagnetic but behaved as superparamagnetic above blocking temperature of 40 K. However, after surface grafting no noticeable blocking temperature was observed either due to stress caused by surface grafting or complete loss of interactions between individual particles. Further work is in progress to understand the magnetic behavior of Mn3O4/PLLA nanocomposites.

References

Hussein AK (2015) Applications of nanotechnology in renewable energies—a comprehensive overview and understanding. Renew Sust Energ Rev 42:460–476

Fan Z, Huang X, Tan C, Zhang H (2015) Thin metal nanostructures: synthesis, properties and applications. Chem Sci 6:95–111

Bogunia-Kubik K, Sugisaka M (2002) From molecular biology to nanotechnology and nanomedicine. Biosystems 65:123–138

Patsula V, Moskvin M, Dutz S, Horák D (2016) Size-dependent magnetic properties of iron oxide nanoparticles. J Phys Chem Solids 88:24–30

Pankhurst QA, Connolly J, Jones SK, Dobson J (2003) Applications of magnetic nanoparticles in biomedicine. J Phys D Appl Phys 36:167–181

Perez JM, Josephson L, O’Loughlin T, Hogemann D, Weissleder R (2002) Magnetic relaxation switches capable of sensing molecular interactions. Nat Biotechnol 20:816–820

Sun C, Lee JSH, Zhang MQ (2008) Magnetic nanoparticles in MR imaging and drug delivery. Adv Drug Deliv Rev 60:1252–1256

Fattahi H, Laurent S, Liu F, Arsalani N, Elst LV, Muller RN (2011) Magnetoliposomes as multimodal contrast agents for molecular imaging and cancer nanotheragnostics. Nanomedicine 6:529–544

Shin TH, Choi Y, Kim S, Cheon J (2015) Recent advances in magnetic nanoparticle-based multi-modal imaging. Chem Soc Rev 44:4501–4516

Mody VV, Cox A, Shah S, Singh A, Bevins W, Parihar H (2014) Magnetic nanoparticle drug delivery systems for targeting tumor. Appl Nanosci 4:385–392

Unsoy G, Khodadust G, Yalcin S, Mutlu P, Gunduz U (2014) Synthesis of Doxorubicin loaded magnetic chitosan nanoparticles for pH responsive targeted drug delivery. Eur J Pharm Sci 62:243–250

Bhatnagar SP, Rosensweig RE (1995) Introduction to the magnetic fluids bibliography. J Magn Magn Mater 149:198

Solanki A, Kim JD, Lee KB (2008) Nanotechnology for regenerative medicine: nanomaterials for stem cell imaging. Nanomedicine 3:567–578

Serantes D, Simeonidis K, Angelakeris M, Chubykalo-Fesenko O, Marciello M, Morales MP, Baldomir D, Martinez-Boubeta C (2014) Multiplying Magnetic Hyperthermia Response by Nanoparticle Assembling. J Phys Chem C 118:5927–5934

Dutz S, Hergt R (2014) Magnetic particle hyperthermia—a promising tumour therapy? Nanotechnology 25:452001

Audran RGL, Huguenard AP (1981) Magnetic recording elements containing transparent recording layer. US Patent 4,302,523

Ziole RF, Webster NY (1984) Developer composition containing superparamagnetic polymers. US Patent 4,474,866

McMichael RD, Shull RD, Swartzendruber LJ, Bennett LH, Watson RE (1992) Magnetocaloric effect in super paramagnets. J Magn Magn Mater 111:29–33

Shafi KVPM, Ulman A, Dyal A, Yan X, Yang N, Estournès C, Fournès L, Wattiaux A, White H, Rafailovich M (2002) Magnetic Enhancement of γ-Fe2O3 Nanoparticles by Sonochemical Coating. Chem Mater 14:1778–1787

Lai J, Shafi KVPM, Ulman A, Yang N, Cui M, Vogt T, Estournès C (2003) Mixed iron-manganese oxide nanoparticles. Prepr Pap-am Chem Soc Div Fuel Chem 48:729–730

Seo WS, Jo HH, Lee K, Kim B, Oh SJ, Park JT (2004) Size- dependent magnetic properties of colloidal Mn3O4 and MnO nanoparticles. Angew Chem Int Ed 43:1115–1117

Djerdj I, Arcˇon D, Jaglicˇic Z, Niederberger M (2007) Nonaqueous Synthesis of Manganese Oxide Nanoparticles, Structural Characterization, and Magnetic Properties. J Phys Chem C 111:3614–3623

Laurent S, Forge D, Port M, Roch A, Robic C, Vander Elst L, Muller RN (2008) Magnetic iron oxide nanoparticles: Synthesis, Stabilization, Vectorization, Physicochemical characterization and biological applications. Chem Rev 108:2064–2110

Pugazhvadivu KS, Ramachandran K, Tamilarasan K (2013) Synthesis and Characterization of Cobalt doped Manganese Oxide Nanoparticles by Chemical Route. Physics Procedia 49:205–216

Bose VC, Biju V (2015) Optical, electrical and magnetic properties of nanostructured Mn3O4 synthesized through a facile chemical route. Physica E 66:24–31

Raquez J-M, Habibi Y, Mararu M, Dubois P (2013) Polylactide (PLA)-based nanocomposites. Prog Polym Sci 38:1504–1542

Bilecka I, Elser P, Niederberger M (2009) Kinetic and Thermodynamic Aspects in the Microwave-Assisted Synthesis of ZnO Nanoparticles in Benzyl Alcohol. ACS Nano 3:467–477

Raj AME, Victoria SG, Jothy VB, Ravidhas C, Wollschlager J, Suendorf M, Neumann M, Jayachandran M, Sanjeeviraja C (2010) XRD and XPS characterization of mixed valence Mn3O4 hausmannite thin films prepared by chemical spray pyrolysis technique. App Surf Sci 256:2920–2926

Kricheldor HR, Serra A (1985) Polylactones 6: Influence of various metal salts on optical purity of poly (L-Lactide). Polym Bull 14:497–502

Kaur H, Rathore A, Raju S (2014) A study on ZnO nanoparticles catalyzed ring opening polymerization of L-lactide. J Polym Res 21:537–547

Si PZ, Li D, Choi CJ, Li YB, Geng DY, Zhang ZD (2007) Large coercivity and small exchange bias in Mn3O4/MnO nanoparticles. Solid State Commun 142:723–726

Wang D, Li Y, Wang Q, Wang T (2012) Facile Synthesis of Porous Mn3O4 Nanocrystal–Graphene Nanocomposites for Electrochemical Supercapacitors. Eur J Inorg Chem 2012:628–635

An GM, Yu P, Xiao MJ, Liu ZM, Miao ZJ, Ding KL, Mao LQ (2008) Low-temperature synthesis of Mn3O4 nanoparticles loaded on multi-walled carbon nanotubes and their application in electrochemical capacitors. Nanotechnology 19:275709

Luo Y, Wang X, Xu D, Wang Y (2009) Preparation and characterization of poly (lactic acid)-grafted TiO2 nanoparticles with improved dispersions. App Surf Sci 255:6795–6801

Rohani Bastami T, Entezari MH (2012) A novel approach for synthesis of superpramagnetic Mn3O4 nanocrystals by ultrasonicbath. Ultrason Sonochem 19:560–569

Ozkaya T, Baykal A, Kavas H, Koseoglu Y, Toprak MS (2008) A novel synthetic route to Mn3O4 nanoparticles and their magnetic evaluation. Phys B 403:3760–3764

Du J, Gao Y, Chai L, Zou G, Li Y, Qian Y (2006) Hausmnnite Mn3O4 nanorods: synthesis, characterization and magnetic properties. Nanotechnology 17:4923–4928

Sicard L, Le Meins J-M, Methivier C, Herbst F, Ammar S (2010) Polyol synthesis and magnetic study of Mn3O4 nanocrystals of tunable size. J Magn Magn Mater 322:2634–2640

Borovik-Romanov AS, Orlova MP (1957) Magnetic properties of manganese oxides at temperatures from 20 to 300 K. J Exp Theor Phys 32:1255

Dwight K, Menyuk N (1960) Magnetic properties of Mn3O4 and canted spin problem. N Phys Rev 119:1470–1479

Lei S, Tang K, Fang Z, Zheng H (2006) Ultrasonic-Assisted Synthesis of Colloidal Mn3O4 Nanoparticles at Normal Temperature and Pressure. Cryst Growth Des 6:1757–1760

Kang C, Cai H, Zhang X, Tang J, Xu P, Li M, Zong H (2015) The study of high Curie temperature ferromagnetism properties in Mn-doped SiC thin film. Results Phys 5:178–181

Martinez B, Obradors X, Balcells L, Rouanet A, Monty C (1998) Low Temperature Surface Spin-Glass Transition in γ- Fe2O3 Nanoparticles. Phys Rev Lett 80:181–184

Inamdar DY, Lad AD, Pathak AK, Dubenko I, Ali N, Mahamuni S (2010) Ferromagnetism in ZnO Nanocrystals: Doping and Surface Chemistry. J Phys Chem C 114:1451–1459

Acknowledgments

One of the authors Anuradha Rathore is grateful to University Grant Commosion for BSR fellowship. We greatly acknowledge Saurashtra University for TGA, DSC and 1H NMR, and SAIF, Chandigarh for13C NMR, SEM EDAX and TEM, IIT Roorkee for VSM and SQUID. We are grateful to Prof. Christian Binek of University of Nebraska–Lincoln for discussion on magnetic behavior of nanoparticles.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

ESM 1

(DOCX 686 kb)

Rights and permissions

About this article

Cite this article

Rathore, A., Kaur, H. & Luque, R. Self-catalyzed surface grafting of Mn3O4 nanoparticles with polylactide and its magnetic properties. J Polym Res 25, 2 (2018). https://doi.org/10.1007/s10965-017-1395-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-017-1395-0