Abstract

The functional blends of green materials are of great interest. In this study, we discovered a rare case of inherent miscibility in blends comprising a biodegradable polymer, poly(butylene adipate-co-butylene terephthalate) [P(BA-co-BT)], and a biocompatible natural polyphenol, catechin. According to the homogeneous phase morphology and single composition-dependent Tg (obtained from the microscopy and thermal analysis measurements), this work demonstrated that a natural polyphenol could be intimately mixed with a biodegradable copolyester showing a special aliphatic-aromatic backbone. The results of IR spectra and equilibrium melting point depression further indicated that it existed intermolecular interactions in the blends. We suggest that the molecular mixing between catechin and P(BA-co-BT) should be attributed to the preferable interactions of hydrogen bonding. Physical properties were also discussed in detail with studying the crystallization property of the blends. The nonisothermal crystallization of P(BA-co-BT) was also found to be influenced by the catechin in the blends. By the analysis results of the Mo model, it demonstrated that the rate dependent parameter, F(T), was increased as the catechin content was increased in the blends. In indicated that the rate of nonisothermal crystallization of P(BA-co-BT) was decreased with the addition of catechin in the blends.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Although general plastics can benefit our life, one drawback of them is that they are not able to be decomposed or biodegraded naturally after being used. Many scientists are studying new polymeric materials with novel ability of biodegradation in order to apply them for various end-uses [1–7]. Such biodegradable polymers can be converted into carbon dioxide, water or even biomass while the microorganisms are present so that they can minimize the extent of environmental pollution and also reduce the amount of waste. Although biodegradable polymers have been able to be produced, some of their behaviors and properties are still unknown. Inherent behaviors of them or their related systems are still the issues which are not explored well currently.

Backbone structures of biodegradable polymers can generally be divided into two forms. One of them is shown as the feature of aliphatic ester, and the other one is presented as an aliphatic-aromatic ester. Biodegradable polymers with aliphatic ester backbone have been widely studied [8–10]. Their physical properties have been characterized; furthermore, some investigations have also explored their ability of biodegradation. A number of these aliphatic polyesters have been commercialized such as poly(3-hydroxybutyric acid) (PHB) with the trademark BiopolTM [11], poly(L-lactide) with the trademark NatureWorksTM [12] and poly(butylene succinate adipate-co-butylene adipate) copolyester with the trademark BionolleTM [13]. Apart from those biodegradable aliphatic polyesters, biodegradable aliphatic-aromatic copolyesters have also been synthesized. It provides a choice of the biodegradable polymers with sufficient biodegradability and superior physical and mechanical properties. One typical aliphatic-aromatic copolyester is poly(butylene adipate-co-butylene terephthalate) [P(BA-co-BT)]. BASF AG (Germany) has commercialized the biodegradable copolymer of poly(butylene adipate-co-44 mol% butylene terephthalate) [P(BA-co-BT)] under the trademark as Ecoflex. The aliphatic butylene adipate (BA) unit on polymeric backbone enables P(BA-co-BT) to be biodegraded. The other moiety, butylene terephthalate (BT), is incorporated into the polymeric main chain to improve the physical properties of the polymer owing to its essential functionality of aromatic structure. Studies on P(BA-co-BT) were mainly performed for the purposes to identify its structures and physical properties [14–16]. Although chemically copolymerization is one possibility to tune the properties of P(BA-co-BT). On purpose to broaden the application of P(BA-co-BT) in various fields, different ways other than the chemical copolymerization for optimizing the properties of P(BA-co-BT) should be further conducted. Preparation of the multi-component systems comprising P(BA-co-BT) is one suggested way to broaden the application of P(BA-co-BT). For example, blending P(BA-co-BT) with other moieties could be a promising way in developing novel products of P(BA-co-BT) with specific functionality. However, related systems have not been sufficiently explored and understood yet. Behaviors and properties of these blends and multi-component systems are still pending issues which are necessary to be further investigated.

Recently, owing to the considerable attention to green chemistry and green science, blending systems of biodegradable polymers have attracted a lot of interests [17–19]. Concerning the investigations of biodegradable polymer blends, studies of miscibility and phase behavior are important and can not be easily ignored. Relative discussions offer very useful information for scientific research and practical application. Most of the biodegradable polymer blends have been reported as immiscible systems with phase separation. Miscible state is generally favorable in multi-component systems such as the blends. Although a well-mixing situation among blended components could efficiently enhance the functions of their final blends, to obtain a miscible state in the blends is always a critical issue. Introducing specific interactions in the blends could be a useful way to promote the miscibility in the blends. Blends comprising of poly(p-vinyl phenol) (PVPh) are typically miscible systems with introducing hydrogen bonding (H-bonding) interactions in the blends [20–22]. PVPh shows proton-donating character and can interact with proton-accepting species via H-bonding interactions by its phenolic side groups attached on the backbone. Although PVPh is quiet useful in enhancing miscibility with H-bonding, a problem of PVPh is that it presents poor biodegradability and inferior biocompatibility. The application of PVPh in fabricating bio-related materials is restricted. Exploring an appropriate substituent of PVPh which showing biological function and sufficient ability in forming H-bonding would be the following research subject. Catechin could be suggested as a good candidate for substituting PVPh. Firstly, catechin is a natural polyphenol with preferable biodegradability and biocompatibility [23]. The superior biological nature of catechin would benefit its further development toward bio-related materials. Secondary, catechin can be a useful proton donating material to form H-bonds owing to its phenolic feature in structure. As it has been demonstrated by the literature, H-bonding could be formed between the proton-donating catechin and the proton-accepting polyesters [24]. In the future, it can expect more versatile usages of catechin in green polymer blends. Relative explorations are also necessary to be performed.

As mentioned above, P(BA-co-BT) and catechin are attractive green materials with the capability of practical application and their superior functions. It is worthy of thoroughly studying them and their blends. Based on carrying out detail discussions, unclear concepts relating to P(BA-co-BT), catechin and the blending system of catechin and P(BA-co-BT) could be understood. This work was performed to clarify the following issues by the investigations of catechin/P(BA-co-BT) blends: (I) Can an intimately mixing state be shown between the polyphenolic catechin and the biodegradable copolyester with aliphatic-aromatic structure? If so, can we address any factor to the occurrence of miscibility? (II) Comparing the neat P(BA-co-BT) to its blends with catechin, will the addition of catechin obviously change the physical properties of P(BA-co-BT)?

Experimental

Materials and preparation

Biodegradable P(BA-co-BT) with the commercial name as Ecoflex and molecular weight as 135,000 g/mol was obtained from BASF AG (Germany). It is an aliphatic-aromatic copolyester. The copolymer’s relative molar fractions as characterized by 13C solid-state cross-polarization/magic angle spinning NMR is 56 mol% BA and 44 mol% BT [15]. Analytical grade catechin with a molecular weight as 290 g/mol was obtained Sigma-Aldrich Co. Catechin/P(BA-co-BT) blends containing 100 to 0 wt% catechin were prepared by solution casting from THF. The concentration of THF solution is 4 wt% for preparing each blend. Initial evaporation was performed on a hot-plate at 45 °C. Afterward, the obtained blends were dried under vacuum at 60 °C for 1 day to remove residual solvent before further measurements.

Apparatus and procedures

Optical microscopy (OM)

An Olympus CX41 optical microscope (OM) was used to observe the phase behavior and morphology of the blends. It equips with a CCD camera and a Linkam THMS-600 microscopic heating stage with the TP-95 system controller. OM samples were cast on the glass substrate, covered with top glass, and pressed into films of the thickness about 10 ~ 15 μm. All samples for the observations were preliminarily heated to the temperature above the Tm of P(BA-co-BT) (130 °C) to melt the crystallites induced by sample preparation. Subsequently, samples were gradually heated at a heating rate of 2 °C/min. The phase behavior and the possible phase transition caused by the elevation of temperature were carefully observed in this study.

Differential scanning calorimetry (DSC)

Perkin-Elmer DSC-8500 equipped with a mechanical intracooler was adopted to perform the thermal analysis for the blends. Measurements to measure Tg values of the blends were made by a scanning rate of 20 °C/min. The onset value of thermal transition was taken as the Tg value for each blend of catechin/P(BA-co-BT). All samples were pressed to flat films to have good temperature distribution and thermal conductivity. The treatment of pre-melting/quenching for the blends was adopted to obtain amorphous specimens for characterizing their Tg’s. To determine the equilibrium melting temperature (Tm 0) of neat P(BA-co-BT) and those of catechin/P(BA-co-BT) blends, the samples were first annealed at 150 °C for 5 min to erase thermal history and then quenched to the crystallization temperature (Tc) for crystallization. After the samples had been complete crystallized, they were heated again at a rate of 10 °C/min to obtain their melting temperatures. For the measurements of nonisothermal crystallization, all samples were pre-annealed at 150 °C for 5 min and then cooled at different rates to crystallize the blends nonisothermally. The information of nonisothermal crystallization was obtained from the cooling traces. Physical aging was performed for 8 h at aging temperature (Ta) that is 10–20 °C below the Tg of the respective blend composition.

Fourier-transform infrared spectroscopy (FT-IR)

Fourier-transform infrared spectroscopy (FT-IR; Perkin-Elmer Frontier™) was adopted to investigate the interactions in catechin/P(BA-co-BT) blends. All spectra were recorded at a resolution of 4 cm−1 with an accumulation of 64 scans in the range of 400 ∼ 4,000 cm−1. To prepare the specimens for IR studies, the solutions of catechin/(P(BA-co-BT) (ca. 2 ∼ 4 wt%) were solution-cast directly onto KBr pellets at 45 °C to form thin and uniform films. Afterward, vacuum-dried specimens were then used for IR measurements at ambient temperature.

Scanning electron microscopy (SEM)

The catechin/P(BA-co-BT) blends were also subjected to morphological observations with greater magnification by using a scanning electron microscope (SEM, model: Hitachi S3000). Blend films were solution-cast to be thick enough so that fracture surfaces (cross-sections) of the blends could be conveniently examined. Before the observation, the fracture surfaces of the blends were coated with gold by vapor deposition using vacuum sputtering.

Results and discussion

Morphological characterizations of catechin/P(BA-co-BT) blends

To realize the inherent miscibility of the catechin/P(BA-co-BT) blends, morphology characterizations, and thermal analyses were performed. Optical microscopy (OM) was firstly applied for the morphological characterizations. Results with logical arrangement are revealed in Fig. 1. Figure 1 presents the OM results for catechin/P(BA-co-BT) blends recorded at different temperatures. In the figure, results of catechin/P(BA-co-BT) blends with different compositions of 30/70, 50/50 and 70/30 are displayed. Generally, “optically clear” OM images can be revealed for homogeneous phase morphology of miscible blends. The OM images of Fig. 1 demonstrate two results. Firstly, all blends show similar morphology by Fig. 1, as they generate optically clear images at 800× magnifications of OM. No obviously domains of phase separation can be resolved from OM images. Secondly, no phase-separated morphology can be found by increasing the temperature (at a controlled heating rate of 2 °C/min). It infers that the blends exhibit no LCST phase behavior, which is normally presented by the formation of phase-separated domains in the blends with the increase of observing temperature. Preliminary OM observations indicate that catechin/P(BA-co-BT) blends are all miscible without significant phase separation under the resolution of OM; also, OM images also elaborate that catechin/P(BA-co-BT) blends are without LCST phase behavior by raising the temperature. It should be noted that OM observations were also performed on entire composition range of catechin/P(BA-co-BT) blends. Similar results as optically clear images with homogeneous phase morphology were obtained.

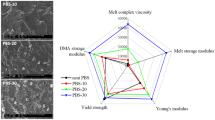

To elucidate the miscibility and phase morphology, scanning electron microscopy (SEM) was utilized to get high-resolution phase images. SEM images with high magnification were obtained and the phase morphology of the catechin/P(BA-co-BT) blends was resolved. The fracture surfaces of blending samples were observed using SEM. Typical results from the blends of catechin/P(BA-co-BT) = 50/50 and 70/30 are presented here. Figure 2 shows SEM images for catechin/P(BA-co-BT) blends with the compositions: (a) 50/50 and (b) 70/30. As presented in Fig. 2, all SEM images reveal homogeneous morphology without discernible phase domains for the blends, indicating that the blends are miscible and without phase separation. By the results of OM and SEM, it suggests that the catechin/P(BA-co-BT) blends with various compositions are all miscible without distinct phase-separated domains. Furthermore, the blends also do not present the LCST behavior which can generally be found by elevating the observation temperature for morphological study.

DSC to determine thermal properties and miscibility of catechin/P(BA-co-BT) blends

To further investigate the miscibility of catechin/P(BA-co-BT) blends, the measurements of DSC were carried out. The DSC single Tg criterion was adopted to identify the miscibility of the blends. Figure 3 presents DSC thermograms of catechin/P(BA-co-BT) blends with varying compositions. As the initial crystallinity was totally suppressed in the quenched samples prior to the Tg measurements, the measured Tg presented the state of the blend samples in entirely amorphous chains. The figure shows one single and composition-dependent Tg (onset positions indicated with arrow marks) for each of the compositions examined in this study, indicating that the catechin/P(BA-co-BT) blends with any compositions are miscible. Catechin and P(BA-co-BT) are suggested to be mixed at the molecular level. Notably, although catechin is not the high-MW polymer that undergoes successive covalent bonds on the backbone, the intra-molecular hydrogen bonds among the hydroxyl groups of catechin can afford the stable interactions to form supra-molecular catechin with a detectable Tg for the DSC thermogram transition (with an onset at 109 °C). Some small molecules with bisphenol structure have also been reported to show a similar phenomenon [25]. The Tg-v.s.-composition relationship of the blends can also be investigated. Normally, the composition-dependent Tg can be described by various equations. One of them is the Gorden-Taylar equation [26]. Taking into account the free volume and the thermal expansion of the blends, the Gordon-Taylor equation can be presented below as Eq. (1),

where w1 and w2 are the weight fractions of the components in the blends, Tg1 and Tg2 represent the corresponding glass transition temperatures, and k is the fitting parameter. Moreover, to discuss the influence of specific interactions such as the hydrogen bonding interactions on the Tg-v.s.-composition relationship, the conventional Gorden-Taylor equation was modified by Kwei et al. to diversify its application. A term to reflect the influence of specific interactions on the Tg-v.s.-composition relationship was included:

The Kwei equation [27] as Eq. (2) is obtained by adding a term of qw1w2 to the Gorden-Taylor equation. The parameter q can be related to the strength of specific interactions in the blends. The kwei equation can provide a suitable way to study the Tg-v.s.-composition relationship for the blends with specific interactions. The Tg’s values of catechin/P(BA-co-BT) blends are plotted again as a function of the catechin content. Figure 4 presents the Tg-v.s.-composition relationship for catechin/P(BA-co-BT) blends. Both the Gorden-Taylor equation and the Kwei equation are applied and fitted to the experimental data. As displayed in Fig. 4, the Kwei equation (k = 0.4, q = 180) provides the better fit, rather than the Gorden Taylor equation. By analyzing the results of Fig. 4, it can suggest that the specific interactions are present between catechin and P(BA-co-BT) in the blends. Coleman et al. [28] have demonstrated that the parameter “q” may be associated the balance between the original intramolecular hydrogen bonding interactions (in neat catechin) and the newly formed intermolecular hydrogen bonding interactions (catechin-P(BA-co-BT)). For the blends comprised of catechin and P(BA-co-BT), the positive q value of 180 can be ascribed to the specific interactions between catechin and P(BA-co-BT). The specific interactions between catechin and P(BA-co-BT) would cause intimate mixing of the two constituents, behaving as the miscible blends that are indicated by DSC and microscopy. The specific interactions in the blends will be further clarified by the discussions of FTIR results. Figure 5 demonstrates a plot for the dependence of the heat of fusion (∆Hf) on blend composition. In this study of catechin/P(BA-co-BT) blends, P(BA-co-BT) is the only crystallizable component in the blends and catechin is inherently amorphous. The values of ∆Hf of the blends were estimated by the area of melting transition from DSC traces as demonstrated in Fig. 4. The values of heat of fusion were normalized by the content of P(BA-co-BT) in the blends. As presented by Fig. 5, the blends exhibit decreasing ∆Hf with increasing the catechin content. A significant negative deviation from linearity with respect to the catechin content in the blends is also demonstrated for the observed ∆Hf. In general in the blends composed of crystalline polymer and non-crystalline (amorphous) components, a blend’s heat of fusion showing linear dependence on blend composition can imply the weak interactions or no intermolecular interactions in the blends; however, an obvious negative deviation from linearity can infer that the crystallizing polymer chains are distorted by interacting with the non-crystalline components. It shows additional evidence by Fig. 5 that the interactions between catechin and P(BA-co-BT) are present. Also, the interactions may also cause the miscibility between catechin and P(BA-co-BT) blends as proved by OM, SEM, and relevant DSC studies.

In miscible blends, the melting point of the crystalline component is generally lower than that of the neat polymer because of thermodynamically favorable interactions; therefore, the miscibility and favorable interactions in the blends can also be confirmed by the depression of the melting point of the crystalline component. The equilibrium melting temperatures of P(BA-co-BT) in the catechin/P(BA-co-BT) blends were obtained by the classical Hoffman-Weeks method [29]. By this method, the measured Tm of the samples that were crystallized at Tc was plotted against Tc and a linear extrapolation to the line Tm = Tc was performed, where the intercept yielded Tm 0

where Tm 0 is the equilibrium melting temperature, and γ = l/l* is the ratio of lamellar thickness l at the time of melting to the thickness l* of the critical nucleus at Tc. Figure 6 displays the Hoffman-Weeks plots for catechin/P(BA-co-BT) blends. The Tm 0 values of neat P(BA-co-BT) and catechin/P(BA-co-BT) blends (10/90 and 20/80) were calculated by the Hoffman-Weeks method with the plots of Fig. 6. Notably, the typical isothermal crystallization results of catechin/P(BA-co-BT) = 20/80 blend for determining its Tm 0 is inserted as the small right-hand-side block diagram in Fig. 6. Table 1 lists the Tm 0 values of neat P(BA-co-BT) and catechin/P(BA-co-BT) blends (10/90 and 20/80). It is clear that the Tm 0 of P(BA-co-BT) is depressed from 139.5 to 134.8 °C by blending with catechin. The miscibility and the presence of favorable interactions in the blends of catechin and P(BA-co-BT) were also approved by the relative results of equilibrium melting point depression.

In general, the resolution of Tg in DSC curve can be enhanced by the physical aging process. A polymeric sample can be physically aged at a temperature that is 10–20 °C below its Tg. For the aged sample, subsequent heating would lead to a thermal response caused by the enthalpy relaxation, which is generally shown as an endothermic peak in the resultant DSC curve. Several studies have reported that the physical aging process could be adopted to examine the miscibility of polymer blends [30, 31]. The physical aging process is useful to confirm further the miscibility that is pre-characterized by the single Tg criterion. Figure 7 shows the DSC traces for the physically aged blends of catechin/P(BA-co-BT). Typical compositions of catechin/P(BA-co-BT) = 70/30, 50/50 and 30/70 were investigated. Physical aging was performed for 8 h at an aging temperature that is 10–20 °C below the Tg of the respective blend. Apparently, there is only a single enthalpy relaxation peak, indicating that there is indeed only a single Tg. The result of physical aging can further confirm the miscibility in the blends, suggesting that the blends of catechin/P(BA-co-BT) are miscible.

IR spectroscopic determination of specific interactions in catechin/P(BA-co-BT) blends

Catechin and P(BA-co-BT) have excellent potential for hydrogen bonding (H-binding) interactions as the proton donator and the proton acceptor, respectively. The specific phenolic hydroxyl (OH) groups and the carbonyl (C = O) groups of catechin and P(BA-co-BT) may enable them to form hydrogen bonds (H-bonds) with each other. Even though the interactions that are caused by H-bonds can be expected to occur between catechin and P(BA-co-BT), direct evidence for proving the existence of H-bonds is required. In this study, we attempted to clarify H-bonding interactions between catechin and P(BA-co-BT) by the studies of FT-IR. Figure 8 shows the FT-IR spectra in the OH stretching region of catechin and various catechin/P(BA-co-BT) blends. The OH stretching region displays a broad absorbance band centering at 3335 cm−1 for the neat catechin, and this absorbance band can be attributed to the self-associated (intramolecular H-bonding) OH group of catechin. Note that there is almost no absorbance of P(BA-co-BT) in the OH stretching region of IR as shown in Fig. 8. In Fig. 8, upon mixing with P(BA-co-BT), it can find that the self-associated OH group band of catechin shifts from 3335 to 3419 cm−1 with a higher frequency. This spectral result can further demonstrate that the interaction state in the blends gradually changes upon blending catechin with P(BA-co-BT) since the original intramolecular H-bonds in neat catechin are broke and the newly formed intermolecular H-bonds are generated between catechin and P(BA-co-BT) in the blends. Similar phenomena are also observed in the blends of catechin and polyesters with the formation of H-bonding interactions [24]. The high-frequency shift of self-associated OH band can also suggest that the strength of intermolecular H-bonds are relatively weaker than that of intramolecular H-bonds in the blends.

IR C = O stretching region of P(BA-co-BT) was also resolved to investigate the specific interactions in the blends. Figure 9 displays the FT-IR spectra in the C = O stretching region of various catechin/P(BA-co-BT) blends. Notably, the C = O absorbance of neat catechin is not presented in the figure because there is no absorbance of neat catechin in IR C = O stretching region. As revealed by Fig. 9, one new absorbance at 1702 cm−1 is gradually developed as the increase of catechin content in the blends, indicating the formation of specific interactions between the C = O groups of P(BA-co-BT) and catechin. The absorbance of 1702 cm−1 can be assigned as the absorbance of H-bonded C = O group of P(BA-co-BT) in the blends. Regarding IR spectra in the OH stretching region of catechin and the C = O stretching region of P(BA-co-BT), it suggests that specific interactions can be generated upon blending catechin with P(BA-co-BT). Specific interactions such as the H-bonding interactions can be formed between the OH groups of catechin and the C = O groups of P(BA-co-BT) in the blends. Figure 10 presents the illustration for the hydrogen bonding interactions between the OH groups of catechin and the C = O groups of P(BA-co-BT) in the catechin/P(BA-co-BT) blends. OM, SEM and DSC results have demonstrated that the blends of catechin/P(BA-co-BT) are inherently miscible with interactions. IR characterizations further proved that the interactions between catechin and P(BA-co-BT) are specific H-bonding interactions. Results of OM, SEM, DSC and IR indicate that the polyphenolic catechin can intimately mix with the biodegradable P(BA-co-BT) showing particular aliphatic-aromatic backbone structure. It can also suggest that the factor to cause the miscibility in the catechin/P(BA-co-BT) blends is the H-bonding interactions between OH groups of catechin and C = O groups of P(BA-co-BT). The first issue addressed to this work has been clarified. It has found the inherent miscibility in the catechin/P(BA-co-BT) blends and proposed the factor in causing the miscibility in the blends as the specific H-bonding interactions by thorough discussions.

Influence of catechin on physical property as nonisothermal crystallization in catechin/P(BA-co-BT) blends

Physical property as the behavior of nonisothermal crystallization was also concerned for the blends of catechin and P(BA-co-BT). The study related to the crystallization kinetics is an important subject to correlate between processing and properties of polymers. Therefore, an understanding of nonisothermal crystallization behavior is of practical importance. In this work, nonisothermal crystallization was also discussed to understand the influence of catechin during the nonisothermal crystallization process. Blending samples were subjected to melting/cooling processes with different cooling rates for nonisothermal crystallization. Figure 11 displays the DSC thermograms of nonisothermal crystallization with different cooling rates for (a) neat P(BA-co-BT), (b) catechin/P(BA-co-BT) = 10/90, and (c) catechin/P(BA-co-BT) = 20/80. It should note that for the blends with catechin = 30 wt% or greater, the blends are not crystallizable under nonisothermal crystallization. Only the results for the blends with catechin = 20 wt% or less are shown. The values of peak temperature (Tp) in Fig. 11 are summarized in Fig. 12 for further discussions. Figure 12 illustrates a plot for the correlation between Tp and catechin content in the blends with different cooling rates of nonisothermal crystallization. As shown in Fig. 12, it can display that at the same cooling rate for different specimens, the Tp is shifted to lower temperature values as the catechin content increases in the blends. It reveals that the addition of catechin in the blends would obviously influence the nonisothermal crystallization of P(BA-co-BT) in the blends. Nonisothermal crystallization of P(BA-co-BT) in the blends could be affected by the hydrogen bonding interactions between catechin and P(BA-co-BT). The increase in catechin content is suggested to inhibit/retard the nonisothermal crystallization of P(BA-co-BT) in the blends. To further discuss the nonisothermal crystallization behaviors, kinetic analyses were also performed. The model proposed by Mo and coworkers [32, 33] were adopted for relative investigations. As shown in the literature, the Mo model [32, 33] has been demonstrated as an adequate model to describe the nonisothermal crystallization kinetics of polymeric systems. Equations of the Mo model are showing as followings,

where Φ is the cooling rate, and a is the quotient of Avrami exponent divided by Ozawa exponent. F(T) is a parameter of the kinetics of crystallization. The physical meaning of F(T) is the value of cooling rate, chosen at a unit crystallization time when the system arrives at a certain degree of crystallinity [32, 33]. Figure 13 presents the plot of Model for (a) neat P(BA-co-BT), (b) catechin/P(BA-co-BT) = 10/90, and (c) catechin/P(BA-co-BT) = 20/80. From the plot, a good linearity is shown, indicating that the Mo model could describe nonisothermal crystallization process for the blends of catechin/P(BA-co-BT) adequately. Table 2 summarizes the Mo model parameters data for nonisothermal crystallization of the blends of catechin/P(BA-co-BT). It is shown that the value of F(T) is increased with increasing catechin content at a certain degree of crystallinity. Woo et al. [33] have found a similar phenomenon in their system as a blend comprising polymers and an organically modified clay. In their system, with further loading an organically modified clay in polymers from 1 wt%, it would retard the nonisothermal crystallization process. They mentioned that the higher F(T) infers that the higher cooling rate or higher crystallization rate is required [33]. If the higher crystallinity rate is required to arrive at a certain degree of crystallinity, it means that the greater effort must be made to reach the same degree of crystallinity. That is, the barrier or higher retardation effect. The second issue addressed in this work has also been clarified. The addition of catechin in the blends would influence the physical properties of P(BA-co-BT). By the miscible state with specific interactions in the blends, catechin would retard the nonisothermal crystallization of P(BA-co-BT).

Conclusions

The miscible blends composed a biodegradable polymer, P(BA-co-BT), and a biocompatible natural polyphenol, catechin, was discovered in this study. We found that a natural polyphenol could be well-mixed with a biodegradable copolyester showing a particular aliphatic-aromatic backbone. OM, SEM and DSC results revealed that the catechin/P(BA-co-BT) blends are miscible. The phenomenon of equilibrium melting point depression could further suggest that the blends are inherent miscible with the intermolecular interactions. FTIR was carried out to elucidate the intermolecular interactions in the blends. According to the IR spectra, as the amount of P(BA-co-BT) in the blends increased, a high-frequency shift resolved from the hydroxyl stretching band of catechin was presented. Analysis of the carbonyl stretching region reveals one new absorbance at 1702 cm−1 is gradually developed as the increase of catechin content in the blends, indicating the formation of specific interactions between the C = O groups of P(BA-co-BT) and catechin. The evidence that is provided by the IR spectral and related analyses suggests that intermolecular hydrogen bonding can occur in the binary blends of catechin and P(BA-co-BT). The physical properties as the crystallization properties of the blends were further discussed. The nonisothermal crystallization of P(BA-co-BT) was also found to be inhibited by the addition of catechin in the blends. By the results analyzed by the Mo model, the rate dependent parameter, F(T), was found to be increased as the catechin content was increased in the blends. It indicated that the rate of nonisothermal crystallization of P(BA-co-BT) would be decreased with the addition of catechin in the blends. Nonisothermal crystallization of P(BA-co-BT) in the blends could be affected by the hydrogen bonding interactions between catechin and P(BA-co-BT).

References

Hikima Y, Morikawa J, Hashimoto T (2013) Macromolecules 46:1582–1590

Barrett JSF, Abdala AA, Srienc F (2014) Macromolecules 47:3926–3941

Bagheri M, Motirasoul F (2012) e-Polymers. Article Number 087

Wang X, Zhuang Y, Dong L (2012) J Appl Polym Sci 126:1876–1884

Ojijo V, Ray SS, Sadiku R (2012) ACS Appl Mater Interfaces 4:6689–6700

Nimah H, Woo EM, Nurkhamidah S (2014) J Polym Res 21. doi:10.1007/s10965-013-0339-6

Su CC, Woo EM, Hsieh YT (2013) Phys Chem Chem Phys 15:2495–2506

Shieh YT, Twu YK, Su CC, Lin RH, Liu GL (2010) J Polym Sci B Polym Phys 48:983–989

Anderson S, Zhang J, Wolcott MP (2013) J Polym Environ 21:631–639

Kong XH, Qi H, Curtis JM (2014) J Appl Polym Sci 131. doi:10.1002/app.40579

Ishioka R, Kitakuni E, Ichikawa Y (2002) In: Doi Y, Steinbüchel A (eds) Polyesters III: applications and commercial products, vol 4. Biopolymer, Weinheim, Germany, pp 275–298

Gruber P, O’Brien M (2002) In: Doi Y, Steinbüchel A (eds) Polyesters III: applications and commercial products, vol 4. Biopolymer, Weinheim, Germany, pp 235–249

Aarar J, Gruys KJ (2002) In: Doi Y, Steinbüchel A (eds) Polyesters III: applications and commercial products, vol 4. Biopolymer, Weinheim, Germany, pp 53–90

Gan Z, Kuwabara K, Yamamoto M, Abe H, Doi Y (2004) Polym Degrad Stab 83:289–300

Cranston E, Kawada J, Raymond S, Morin FG, Marchessault RH (2003) Biomacromolecules 4:995–999

Kuwabara K, Gan Z, Nakamura T, Abe H, Doi Y (2002) Biomacromolecules 3:390–396

Zhao Y, Qiu Z (2015) RSC Adv 5:49216–49223

Lugito G, Woo EM (2015) Soft Matter 11:908–917

Zhang J, Fujizawa S, Isogai A, Hikima T, Takata M, Iwata T (2014) Polym Degrad Stab 110:529–536

Kuo SW, Chen CJ (2012) Macromolecules 45:2442–2452

Lee LT, Woo EM, Hou SS, Förster S (2006) Polymer 47:8350–8359

Papageorgiou GZ, Grigoriadou I, Andriotis E, Bikiaris DN, Panayiotou C (2013) Ind Eng Chem Res 52:11948–11955

Madhan B, Subramanian V, Rao JR, Nair BU, Ramasami T (2005) Int J Biol Macromol 37:47–53

Zhu B, Li J, He Y, Yoshie N, Inoue Y (2003) Macromol Biosci 3:684–693

Kuo SW, Chan SC, Chang FC (2002) Polymer 43:3653–3660

Gordon M, Taylor JS (1952) J Appl Chem 2:493–500

Kwei TK (1984) J Polym Sci Polym Lett Ed 22:307–313

Coleman MM, Graf JF, Painter PC (1991) Specific interactions and the miscibility of polymer blends. Technomic, Lancaster University

Hoffman JD, Weeks JJ (1962) J Res Natl Bur Standards A 66:13–28

Zhang H, Bhagwagar DE, Graf JF, Painter PC, Coleman MM (1994) Polymer 35:5379–5397

Lee LT, Woo EM (2006) J Polym Sci B Polym Phys 44:1339–1350

Liu X, Wu Q (2002) Eur Poly J 38:1383–1389

Auliawan A, Woo EM (2012) J Appl Polym Sci 125:E444–E458

Acknowledgments

This work has been financially supported by basic research grants of MOST 104-2221-E-035-079- and MOST 105-2221-E-035-091- from Taiwan’s Ministry of Science and Technology (MOST), to which the authors express their gratitude. The authors appreciate the Precision Instrument Support Center of Feng Chia University in helping the SEM measurements of our works.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, LT., Wu, MC., Yang, CT. et al. Studies of inherent mixing and physical properties for green polymer blends comprising natural polyphenol and biodegradable polymer with aliphatic-aromatic backbone. J Polym Res 23, 255 (2016). https://doi.org/10.1007/s10965-016-1153-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-016-1153-8