Abstract

Corrosion tests were carried out by immersion the LaFe12.35-xCo0.65SixC0.15(x = 1.3, 1.4, 1.5) compounds in distilled water for different times. The effect of corrosion is systematically studied in terms of morphology, microstructure, corrosion resistance, and magnetic properties. The results show that after 30-min corrosion, obvious corroded spots appeared on the surface of all compounds. It was also found that Si has an adverse effect on corrosion resistance. With the increase of Si content, the corroded spots are connected. The Ecorr decreased from − 0.57 to − 0.65 V while Icorr increased from 3.91 to 5.08 μA/cm2 with increasing the Si content from 1.3 to 1.5. In continuing to extend the corrosion time to 7 days, a large-scale corrosion area appeared, accompanied by the peeling of the main phase as anode and the retention of α-Fe phase as cathode. Meanwhile, the magnetic entropy change of LaFe10.95Co0.65Si1.4C0.15 compounds decreased from 8.1 to 7.7 J/(kg K) when the corrosion time increased from 0 to 7 days. After 21-day corrosion, the sample surface was completely covered by corrosion products. Furthermore, long-time corrosion has a significant effect on magnetic properties. The Curie temperature increased from 289 to 314 K for 0-day and 21-day corrosion of LaFe10.95Co0.65Si1.4C0.15 compounds, respectively. Significantly, the magnetic entropy change curves showed two peaks in theΔS-Tc curves. Magnetic stability was decreased after long-time corrosion.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

La(Fe,Si)13 compounds with cubic NaZn13-type structure (1:13 phase) are promising materials for magnetic refrigeration due to their excellent soft ferromagnetism, high magnetization, abundant resource reserve, and low cost [1,2,3]. As we all know, the 1:13 phase is the magnetocaloric phase of La(Fe,Si)13 alloys [4]. However, it is very difficult to obtain a single 1:13 phase because of the intrinsic characteristics of peritectic reaction Fe + LaFeSi → La(Fe,Si)13 [5]. A certain amount of secondary phases are retained in most annealed La(Fe,Si)13 compounds [6,7,8]. Multiphase structure and large corrosion potential difference between phases lead to poor corrosion resistance [9,10,11]. From previous literature, the maximum magnetic entropy change of La(Fe0.94Co0.06)11.7Si1.3 decreased about 16% after 15-day corrosion in distilled water [12]. Corrosion will shorten the service time of magnetic refrigerator, and corrosion precipitate will deteriorate the heat exchange performance. The corrosion resistance can be enhanced by partial substituting Co, Cr, B for Fe and reducing dissolved oxygen concentration in aqueous solution [13,14,15,16]. The magnet can also be isolated from the corrosive medium by surface treatment to improve the corrosion resistance. Zhao et al. [17] reported the corrosion behavior and magnetocaloric effect of LaFe11.6Si1.4/Sn with FeNi coatings by hot pressing. The high-permeability FeNi permalloy can enhance the corrosion resistance and magnetocaloric effect. The LaFe11.5Si1.5 particles with Cu coatings prepared by electroless plating method also can have better corrosion resistance and lower magnetic hysteresis loss [18]. You et al. [19] demonstrated that the compressive strength and corrosion resistance can be significantly increased with Cu coating by magnetron sputtering machine. However, no matter what kind of anti-corrosion method is adopted, it is necessary to understand the corrosion behavior to carry out effective corrosion protection. What’s more, it is very important for application to investigate the influence of corrosion on magnetic properties. In this paper, we studied the corrosion behavior of LaFe12.35-xCo0.65SixC0.15 magnets when the Si content changed from 1.3 to 1.5 and investigated the impact of corrosion on the magnetic properties by immersing the LaFe10.95Co0.65Si1.4C0.15 compounds in the distilled water for different times.

2 Experimental Details

LaFe12.35-xCo0.65SixC0.15 (x = 1.3, 1.4, 1.5) ingots used in the present experiments were systematically investigated previously [20]. The ingots were annealed at 1373 K for 4 days.

A DX-2600 X-ray powder diffractometer (Cu-K radiation) was used to determine phase constitution and crystal structure. The microscopic surface morphologies and elemental compositions were carried out using a scanning electron microscope (SEM) with energy-dispersive spectrometry (EDS). Electrochemical tests were conducted by VersaSTAT MC electrochemical analyzer/workstation. Each measurement was performed in a standard three-electrode cell consisting of LaFe12.35-xCo0.65SixC0.15 working electrode, saturated calomel reference electrode (SCE), and a Pt counter electrode. Polarization curves for specimens in the test solution were recorded at a sweep rate of 1 × 10−3 V/s. All the corrosion studies were carried out in distilled water in an air environment at room temperature. The employed amplitude of the sinusoidal signal was ± 5 mV and the tested frequencies ranged from 100 kHz to 100 mHz. Magnetic properties of the samples were measured by Quantum Design VersaLab with a vibrating sample magnetometer (VSM) option. The magnetic entropy change was calculated from magnetization data by using the Maxwell relation.

3 Results and Discussion

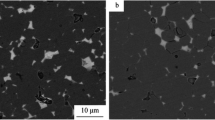

To study the corrosion behavior of LaFe12.35-xCo0.65SixC0.15 (x = 1.3, 1.4, 1.5) compounds, the surface morphology of LaFe12.35-xCo0.65SixC0.15 compounds after being immersed in distilled water for different times (Fig. 1) was obtained. Figure 1a shows SEM image of the LaFe10.95Co0.65Si11.4C0.15 compound before corrosion. The black areas, white areas, and gray areas represent α-Fe phase, La-rich phase, and 1:13 phase, respectively (analyzed by EDS). The number of secondary phases is small. The XRD results also showed that all samples were mainly composed of the NaZn13-type phase (not shown here). Figure 1b–d show the surface morphology of the compounds with different Si content after immersion for 30 min. After a short time of corrosion, all compounds show obvious corroded spots, and the number of corroded spots does not change significantly with the different Si content. However, it should be noted that with the increase of Si content, the corroded spots show a connecting trend on the surface. Figure 1e–h present the surface morphology of LaFe10.95Co0.65Si1.4C0.15 compounds after being immersed in distilled water for different time. As can be seen from these figures, a large range of corrosion zone has been formed on the surface of the compound after 7-day corrosion (Fig. 1e). The corrosion product film is relatively loose, and the 1:13 phase particles are spalled off obviously. A small amount of α-Fe phase is observed in and around the corroded spots after the 1:13 phase falls off (Fig. 1f). After 21-day corrosion, the compounds have been completely covered by corrosion products (Fig. 1g). The corrosion product film becomes denser than that after 7 days, but also has many cracks (Fig. 1h).

Surface morphology of LaFe12.35-xCo0.65SixC0.15 (x = 1.3, 1.4, 1.5) compounds after being immersed in distilled water for different times (a) Backscattered electron image of LaFe10.95Co0.65Si1.4C0.15 before corrosion; (b-d) Backscattered electron image of the different compounds after being immersed for 30 min: LaFe11.05Co0.65Si1.3C0.15 (b), LaFe10.95Co0. 65Si1.4C0.15 (c), LaFe10.85Co0.65Si1.5C0.15 (d); (e-f) Second electron image of the different corrosion zone for LaFe10.95Co0. 65Si1.4C0.15 after being immersed for 7 days; (g-h) Second electron image of the different corrosion zone for LaFe10.95Co0. 65Si1.4C0.15 after being immersed for 21 days

To further understand the effect of Si on corrosion behavior, the electrochemical behaviors were systematically investigated. Figure 2 shows the potentiodynamic polarization curves for LaFe12.35-xCo0.65SixC0.15(x = 1.3, 1.4, 1.5) compounds in distilled water. The results show that the anodic reaction of all samples exhibited active dissolution. This behavior indicates that the corrosion product film does not provide sufficient protection for the compound. With the increase of Si content, the polarization curves were shifted to the lower potential region, and the anodic and cathodic sections of the polarization curves were shifted to the region of higher current density. As Si content increased from x = 1.3 to 1.5, Ecorr decreased from −0.57 to −0.65 V while Icorr increased from 3.91 to 5.08 μA/cm2, indicating that the corrosion resistance of the compound became worse with the increase of Si content. This is probably because the corroded spots of the compound with high Si content are easier to connect, the corrosion product film is not suitable to form, resulting in faster corrosion rate.

Figure 3 shows the temperature dependence of the magnetization for LaFe10.95Co0.65Si1.4C0.15 compounds after corrosion compared to the parent sample (before corrosion). The Curie temperature Tc, defined as the temperature at the minimum of dM/dT of the heating M-T curves, are 289 K, 290 K, and 314 K for 0-day, 7-day, and 21-day corrosion, respectively. The maximum magnetization of the sample varies irregularly because the low applied magnetic field cannot make the sample reach saturation state. There is no significant difference in Tc between 0-day and 7-day corrosion. Therefore, 7-day corrosion has little effect on Tc. However, after 21-day corrosion, the Tc increased significantly. The ferromagnetic paramagnetic transitions of the 0-day and 7-day corroded compounds are completed in a narrow temperature zone, while the transition temperature zone of the sample corrosion for 21 days becomes wider, and there is an obvious thermal hysteresis phenomenon. The M-T curve of the compound after 21-day corrosion shows that the residual magnetization in the high-temperature zone is much higher than zero, indicating the existence of residual magnetization of α-Fe phase. It can also be seen from the above scanning photos that after a long time of corrosion, the 1:13 main phase was corroded as the anode, leaving a certain number of α-Fe phases as the cathode.

The isothermal magnetization curves of LaFe10.95Co0.65Si1.4C0.15 compounds corroded for 0 days, 7 days, and 21 days are shown in Fig. 4a–c, respectively. Figure 4a, b display an excellent reversible behavior in the magnetic cycle, and almost no magnetic hysteresis during the increase and decrease of fields. However, there is an obvious hysteresis phenomenon in Fig. 4c. Furthermore, M-H curves of Fig. 4c have bending phenomena in the low field range when temperatures are higher than Tc of 1:13 phase. It is due to the contribution of soft magnetic α-Fe phase, which is remained as cathode during corrosion.

Magnetization isotherms of LaFe10.95Co0.65Si1.4C0.15 compounds measured at various temperatures around Tc and in the magnetic field 3 T (a) M-H curves of LaFe10.95Co0.65Si1.4C0.15 compound before corrosion; (b) M-H curves of LaFe10.95Co0.65Si1.4C0.15 after being immersed for 7 days; (c) M-H curves of LaFe10.95Co0.65Si1.4C0.15 after being immersed for 21 days

Figure 5 shows the variation curve of magnetic entropy change with temperature of LaFe10.95Co0.65Si1.4C0.15 compounds before and after corrosion. After only 7-day corrosion, the maximum magnetic entropy change decreased by 5%. The magnetic properties of La(Fe,Si)13 magnet are closely related to its microstructure. As the main source of magnetic entropy change of magnets, the 1:13 phase was corroded and peeled off after 7-day corrosion, as shown in Fig. 1. After 21-day corrosion, not only the magnetic entropy change but also the stability of LaFe10.95Co0.65Si1.4C0.15 compounds decreased. Two peaks (at 289 K and 308 K) appeared in the ΔS-Tc curves. Rare earth elements have a strong affinity for hydrogen atoms. Soaking the compound in non-deoxygenated water will lead to hydrogen absorption behavior. The non-uniform hydrogen absorption in the corrosion process of the compound leads to the instability of magnetism.

4 Conclusions

In summary, we studied the corrosion behavior of LaFe12.35-xCo0.65SixC0.15(x = 1.3, 1.4, 1.5) compounds in distilled water for different times. It was found that the corrosion resistance decreased with the increase of Si content. More importantly, corrosion has a great influence on the morphology, microstructure, and magnetic properties. Only after 30-min corrosion, a large number of corrosion spots appear on the surface of LaFe12.35-xCo0.65SixC0.15(x = 1.3, 1.4, 1.5). After 7-day corrosion, the main phase as anode peeled off. A wide range of corrosion zone appeared in the LaFe10.95Co0.65Si1.4C0.15. After 21-day corrosion, the LaFe10.95Co0.65Si1.4C0.15 was all covered by corrosion film. However, the film was not dense enough and there were many cracks, so it could not effectively protect the compounds. Short-time corrosion caused the decrease of magnetic properties. After 7-day corrosion, the maximum entropy change of LaFe10.95Co0.65Si1.4C0.15 decreased about 5%. Long-time corrosion not only reduces the magnetic entropy change, but also leads to the instability of magnetic properties. After 21-day corrosion, two peaks (at 289 K and 308 K) appeared in the magnetic entropy change curve due to the heterogeneous hydrogen absorption. From the perspective of practical application, the corrosion behavior deserves sufficient attention in the use of La(Fe,Si)13 as magnetic refrigerant.

References

Hu, F.X., Shen, B.G., Sun, J.R., et al.: Influence of negative lattice expansion and metamagnetic transition on magnetic entropy change in the compound LaFe11.4Si1.6[J]. Appl. Phys. Lett. 78, 3675–3677 (2001)

Hu, F.X., Qian, X.L., Sun, J.R., et al.: Magnetic entropy change and its temperature variation in compounds La(Fe1−xCox)11.2Si1.8[J]. J. Appl. Phys. 92, 3620–3623 (2002)

Fujita, A., Fujieda, S., Hasegawa, Y., et al.: Itinerant-electron metamagnetic transition and large magnetocaloric effects in La(FexSi1−x)13compounds and their hydrides[J]. Phys. Rev. B. 67, 104416 (2003)

Gschneidner, K.A., Mudryk, Y., Pecharsky, V.K.: On the nature of the magnetocaloric effect of the first-order magnetostructural transition[J]. Scripta. Mater. 67, 572–577 (2012)

Niitsu, K., Kainuma, R.: Phase equilibria in the Fe–La–Si ternary system[J]. Intermetallics. 20, 160–169 (2012)

Zhong, X.C., Peng, D.R., Dong, X.T., et al.: Improvement in mechanical and magnetocaloric properties of hot-pressed La(Fe, Si)13/La70Co30 composites by grain boundary engineering[J]. Mater. Sci. Eng. B 263, 114900 (2021)

Yang, L., Li, J., Zhou, Z., et al.: Direct formation of La(Fe, Si)13 phase with enhanced mechanical property of off-stoichiometric La1.7Fe11.6Si1.4 alloys by directional solidification[J]. J. Alloys Compd. 817, 152694 (2020)

Yang, L., Zhou, Z., Feng, S., et al.: Microstructure and magnetic property of LaFe11.6Si1.4 magnetocaloric alloys by a novel short time heat treatment[J]. Intermetallics. 105, 1–5 (2019)

Zhang, E.Y., Chen, Y.G., Tang, Y.B.: Investigation on corrosion and galvanic corrosion in LaFe11.6Si1.4 alloy[J]. Mater. Chem. Phys. 127, 1–6 (2011)

Xue, J., Long, Y., Wang, Y., et al.: Corrosion behavior of nonstoichiometric La(Fe, Si)13-based alloys[J]. J. Phys. Chem. C. 123, 28898–28906 (2019)

Klimecka-Tatar, D., PawŁOwska, G., Radomska, K., et al.: Electrochemical comparative characteristics of La(Fe, Si)13 type materials with different content of Co in acidified phosphate environment in presence of Cl- ions[J]. Mater. Sci. 25, 265–269 (2019)

Zhang, M., Long, Y., Ye, R.C., et al.: Corrosion behavior of magnetic refrigeration material La–Fe–Co–Si in distilled water[J]. J. Alloy. Compd. 509, 3627–3631 (2011)

Fujieda, S., Fukamichi, K., Suzuki, S.: Suppression of aqueous corrosion of La(Fe0.88Si0.12)13 by reducing dissolved oxygen concentration for high-performance magnetic refrigeration[J]. J. Alloys Compd. 600, 67–70 (2014)

Xue, J., Long, Y., Wang, Y., et al.: Corrosion behavior and phase formation of LaFe13−xSixBy alloys[J]. Mater. Des. 129, 1–8 (2017)

Zhang, M., Sun, W., Long, Y., et al.: Effect of chromium on magnetic properties and corrosion resistance of LaFe11.5Si1.5 compound[J]. J. Rare Earths. 31, 69–72 (2013)

Hu, J., Zhang, M., Long, Y., et al.: Corrosion behavior and ΔS-Tc relation of LaFe13−x−yCoxSiyCz compounds near room temperature[J]. J. Magn. Magn. Mater. 377, 368–372 (2015)

Zhao, X., Fang, P., Tang, Y.B., et al.: Corrosion behavior and magnetocaloric effect of FeNi (1J85) coated LaFe11.6Si1.4 /Sn composites[J]. J. Rare Earths. (2019)

Tian, N., You, C.Y., Gao, B., et al.: Magnetic hysteresis loss and corrosion behavior of LaFe11.5Si1.5 particles coated with Cu[J]. J. Appl. Phys. 113, 103909 (2013)

You, C.Y., Zhang, J., Yang, N.N., et al.: Improvement of magnetic hysteresis loss, corrosion resistance and compressive strength through spark plasma sintering magnetocaloric LaFe11.65Si1.35/Cu core-shell powders[J]. AIP Adv. 6, 1–7 (2016)

Hu, J., Dong, Z.Q., Shen, Y.M., et al.: Effect of excess lanthanum on corrosion and magnetocaloric property of LaFe11.5Si1.5 compounds[J]. J. Rare Earths. 37, 1116–1120 (2019)

Funding

This work is supported by the Natural Science Foundation of Hebei Province (Grant No. E2019210159) and the Hebei Provincial Education Department Project (Grant No. ZD2017066).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, J., Zhang, X., Liu, H. et al. Microstructure, Corrosion Resistance, and Magnetic Properties of LaFe12.35-xCo0.65SixC0.15(x = 1.3, 1.4, 1.5) Compounds after Corrosion in Distilled Water. J Supercond Nov Magn 35, 1569–1574 (2022). https://doi.org/10.1007/s10948-022-06214-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-022-06214-8