Abstract

The effects of Ta doping on the magnetic properties, temperature stabilities, phase constituents, intergranular exchange interactions, and microstructures of (Nd0.8Ce0.2)13.5Fe80.5−xTaxB6 (x = 0–1.5) nanoribbons are investigated in this paper. It is found that Ta doping increased the coercivity of the alloys, while the remanence remained nearly unchanged. The temperature stability of the alloys improved significantly as the absolute value of temperature coefficient of coercivity β enhanced from 0.48%/K for Ta-free alloy to 0.38%/K for the alloys with 0.3–1.5 at.% Ta addition. The lattice constants (a, c), unit cell volume, and phase transition temperatures (Tsr, TC) of the alloys changed by adding Ta into the alloys. Comprehensive best magnetic properties of Hcj = 16.0 kOe, Br = 7.65 kG, and (BH)max = 12.60 MGOe are obtained in (Nd0.8Ce0.2)13.5Fe79.6Ta0.9B6 ribbon. The improvement in magnetic properties is mainly attributed to refined and uniform microstructure of the Ta-doped alloys.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

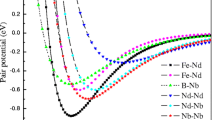

Nd-Fe-B-based permanent magnetic materials have been extensively used in the last four decades as the strongest permanent magnets [1]. The ever increasing demand followed by supply restrictions of critical rare earth elements Nd, Pr, Dy, and Tb has resulted in large price fluctuations in the last few years [2]. Hence, the replacement of Nd/Pr by more abundant and low-cost RE elements such as Ce and La is widely studied in recent years. The partial replacement of Nd by abundant and economical element Ce has been suggested to reduce the cost of Nd-Fe-B-based permanent magnets [3, 4]. The intrinsic properties, i.e., saturation magnetization (μoMs) = 1.17 T, magnetocrystalline anisotropy (Ha) = 30 kOe, and Curie temperature (TC) = 424 K of Ce2Fe14B compound, are lower than the intrinsic properties μoMs = 1.6 T, Ha = 72 kOe, and TC = 585 K of Nd2Fe14B compound [5]. Thus, the extrinsic magnetic properties, intrinsic coercivity (Hcj), remanence (Br), and maximum energy density (BH)max of CeFeB alloys are much lower than those of the NdFeB alloys [6, 7]. Some recent studies have reported that partial replacement of Nd by Ce would not decrease the magnetic properties of Nd-Fe-B-based magnets [8, 9]. The addition of Ce, however, decreases the thermal stability and TC of the alloys due to low anisotropy field and low TC of Ce2Fe14B compound [10]. It is, therefore, technologically important to develop NdCeFeB-based magnets that could be used at elevated temperatures. One commonly used approach to improve the thermal stability of these type of alloys is to increase the TC by partially substituting Co for Fe, but this type of substitution reduces the Br and Hcj [3, 7]. Another approach to improve the thermal stability is to improve the Ha by heavy RE element substitution which ultimately reduces the Br and (BH)max values due to antiferromagnetic coupling with Fe moments of RE elements [11]. The second approach for the improvement of magnetic properties is to improve the microstructure-dependent properties such as Hcj, Br, and (BH)max. Two types of dopant elements usually serve this purpose, i.e., low melting point elements and high melting point elements. The low melting point elements Al, Ga, Sn, and Cu modify the grain boundaries to decouple the main phase grains and improve the coercivity, but, as can be expected, the remanent magnetization of the alloys reduces [12, 13]. The high melting point elements Ti, Cr, W, V, Nb, Zr, and Mo refine the microstructure, form pinning center in the alloys, and partially or completely suppress the formation of deleterious α-Fe phase [14,15,16,17,18,19,20]. The Hcj of Nd-Fe-B ribbons is reported to increase as the nanograin size is reduced unless the alloys become amorphous, and the high melting point elements are very effective in reducing the grain size [21,22,23]. The high melting point elements are useful in improving the temperature stability of the Nd-Fe-B alloys [15,16,17,18]. The effects of Nb, Zr, Hf doping on magnetic properties and microstructure of Nd-Ce-Fe type alloys have been found beneficial for improving the magnetic properties of the alloys specifically at elevated temperatures [8, 15, 20].

Chin et al. [24] found that Ta addition to Nd-Dy-Fe-Co-B alloys improve the coercivity at room temperature while Liu et al. [25] found that Ta improves the room temperature properties of Nd9Fe86B5 alloys. Furthermore, Ta has been applied to soft magnetic materials like Fe and Fe-Co for improving glass forming ability and thermal stability [26, 27]. In our recent work we found that Ta doping improves the Hcj values of Nd-Fe-B alloys without deteriorating the Br values [27]. However, to the best of our knowledge no dedicated paper is available on Ta doping on Nd-Ce-Fe-B type alloys. In this paper we report the effects of Ta on the microstructure, magnetic properties, phase transition temperature and intergranular exchange interactions of (Nd0.8Ce0.2)13.5Fe80.5−xTaxB6 alloys. It is found that the addition of Ta refines the microstructure of the alloys and hence improves the magnetic properties significantly specifically at high temperatures. The reported magnetic properties in the current manuscript are better than the previous studies on Nd-Ce-Fe-B type alloys of near or same composition [8, 16, 21, 27].

2 Experimental Techniques

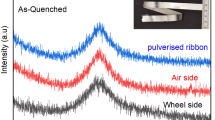

The precursor alloys, (Nd0.8Ce0.2)13.5Fe80.5−xB6Tax (x = 0.0–1.5 at.%) were fabricated by melting pure elements (99.95%) in electric arc furnace five times under Ar. gas protection. The ingot fragments of about 7 g were loaded in quartz tube and were melt-spun onto Cu crucible rotating at angular speed 16 to 25 ms−1. The quartz tube ejection nozzle and ejection pressure were kept constant at ~0.8 mm and 0.1 MPa, respectively. The Cu wheel was polished with fine scale grit paper to obtain smooth ribbons. The magnetic properties of the alloys were measured by applying magnetic field of 4.0 T in PPMS (Quantum Design, USA) equipped with VSM module. The crystal structures were characterized by using D8-advance (Bruker/AXS, Germany) X-ray diffractometer (XRD) using monochromatic Cu-Kα radiation. The XRD patterns were analyzed by applying Rietveld refinement in Rietica software. The low-temperature M-T curves were obtained in PPMS applying 0.1 T field in the temperature range 5–300 K. The Curie temperatures of the alloys were determined obtaining DSC curves in the temperature range 300–630 K. The nanostructures of selected alloys were analyzed and compared by using TEM (Tecnai G2 F20).

3 Results and Discussion

The room temperature (RT) demagnetization curves of (Nd0.8Ce0.2)13.5Fe80.5−xTaxB6 (x = 0.0–1.5 at.%) alloys are depicted in Fig. 1a, while Fig. 1b displays the demagnetization curves of (Nd0.8Ce0.2)13.5Fe80.5−xTaxB6 alloys at 400 K. The coercivity (Hcj), remanence (Br), and energy density (BH)max of Ta-free ribbons are 14.9 kOe, 7.64 kG, and 12.59 MGOe respectively, which are comparable or better than the Br values reported previously [8, 15, 20]. The Hcj gradually and linearly increase from 14.9 kOe for standard alloy to 16.1 kOe for 1.2 at.% Ta. The remanent magnetization Br remains nearly constant for 0.0 to 0.9% Ta, and decreases slightly for 1.2% Ta and further reduces for 1.5% Ta addition. This reduction in magnetic properties might be due to the formation of nonmagnetic phases such as TaB and TaB2 [28]. The (BH)max = 12.66 MGOe is obtained for (Nd0.8Ce0.2)13.5Fe80.2Ta0.3B6 alloy. The best comprehensive magnetic properties of Hcj = 16.0 kOe, Br = 7.65 kG, and (BH)max = 12.60 MGOe are obtained in (Nd0.8Ce0.2)13.5Fe79.6Ta0.9B6 alloy. The Hcj values obtained in our current work are significantly higher than those obtained in our previous studies, while the Br and (BH)max values are comparable with the previously obtained results [8, 15, 20]. All the alloys with or without Ta doping have quite high saturation remanence ratio of above 0.6 suggesting strong exchange coupling effect. To observe the effects of Ta doping on temperature stability, the M-H curves were obtained at 400 K. The demagnetization curves at 400 K are shown in Fig. 1b. The Hcj = 7.8 kOe, Br = 6.63 kG, and (BH)max = 8.84 MGOe for the Ta-free sample are comparable with the values reported in the previous works [15, 20]. The Hcj at 400 K significantly improve with the addition of Ta into the alloys. The Hcj of all Ta-doped alloys are higher than the Hcj of Ta-free alloy. The room temperature of Hcj (Nd0.8Ce0.2)13.5Fe79Ta1.5B6 is lower than that of (Nd0.8Ce0.2)13.5Fe80.5Ta0B6 alloy, but significantly higher at 400 K which gives strong evidence that the temperature stability is improved by Ta doping. It is important to note that the magnetic properties were obtained at 300 K and at 400 K using the same samples. The best comprehensive magnetic properties Hcj = 9.95 kOe, Br = 6.80 kG, and (BH)max = 9.90 MGOe at 400 K are obtained in (Nd0.8Ce0.2)13.5Fe79.3Ta1.2B6 ribbons. These magnetic properties at 400 K are comparable with the magnetic properties of NdFeB ribbons without Ce substitution [4, 27]. The effect of Ta on the thermal stability of NdCeFeB type alloys is more prominent than that of Nb, Zr, and Hf [8, 15, 20].

The temperature coefficient of remanence (α) and temperature coefficient of coercivity (β) of the alloys were calculated by using the formulae \( \alpha =\frac{B_{\mathrm{r}}\left({T}_1\right)-{B}_{\mathrm{r}}\left({T}_0\right)}{B_{\mathrm{r}}\left({T}_0\right)\left({T}_{1-}{T}_0\right)}\times 100\% \) and \( \beta =\frac{H_{\mathrm{cj}}\left({T}_1\right)-{H}_{\mathrm{cj}}\left({T}_0\right)}{H_{\mathrm{cj}}\left({T}_0\right)\left({T}_{1-}{T}_0\right)}\times 100 \) where T1 = 400 K and To = 300 K. The α and β values of the investigated alloys are presented in Table 1. It can be seen that the temperature stability of the Ta-doped alloys is much better than the alloys without Ta doping.

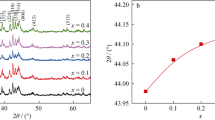

The XRD patterns of (Nd0.8Ce0.2)13.5Fe80.5−xTaxB6 (x = 0–1.5 at.%) alloys are shown in Fig. 2. The major peaks have been identified and indexed. Rietveld refinement using Rietica software was applied to determine the lattice constants as depicted in Fig. 2b. The calculated lattice constants a and c of 2:14:1 phase are shown in Table 1. It can be noted that the lattice constants gradually increase with the addition of Ta indicating that some Ta may have entered into the main phase to substitute Fe sites. In addition to 2:14:1 phase, small amount of α-Fe was observed in XRD patterns which gradually decreased by adding Ta into the alloys. The α-Fe disappeared in the alloys containing ≥ 0.9 at.% Ta. Furthermore, the peaks slightly broaden and weaken with the addition of Ta which indicates that Ta doping reduces the grain size of the alloys. Chin et al. [24, 25] and Liu et al. [29] concluded that Ta and Ta-containing compounds can only be detected in XRD if they form large phases/inclusions. It is speculated on the basis of XRD results and TEM micrographs that Ta does not form large phases due to its small concentration, and hence could not be detected.

The spin reorientation temperature Tsr of RE-Fe-B-based magnets is an intrinsic property of the 2:14:1 phase that occurs due to a decrease of first-order anisotropy constant K1 with decreasing T, and tilting from c-axis to the cone configuration with a cone angle of 30° at 4.2 K. The spin reorientation temperature of Nd2Fe14B phase is reported to be 135 K [30]. The spin reorientation temperature disappears in Ce2Fe14B phase [31, 32], thus making the Ce2Fe14B phase more suitable for low-temperature applications. It is well known that Tsr, being an intrinsic property, changes when the composition of the main phase is altered [31]. The partial (20%) replacement of Nd by Ce reduces the spin reorientation temperature to 118 K (from 135 K for Nd2Fe14B), which further reduces as a result of Ta doping, and reaches 112 K for (Nd0.8Ce0.2)13.5Fe79Ta1.5B6 alloy ribbon as shown in Fig. 3. The inset in Fig. 3 shows the dM/dT-T curve for (Nd0.8Ce0.2)13.5Fe80.2Ta0.3B6 alloy. The low Tsr as a function of Ta doping indicates that some Ta enters into the NdCeFeB (2:14:1) main phase. Thus, the partial replacement of Ce for Nd and doping of Ta for Fe makes the alloys more suitable for low-temperature applications.

Another important intrinsic property of Nd-Fe-B type alloys is the Curie temperature (TC). The TC of Nd2Fe14B compound depends on the strength of exchange interactions between Fe atoms. Any atom which enters into the 2:14:1 phase alters the Fe-Fe exchange interaction and ultimately changes the TC. Therefore, elements like Ga are reported to increase the TC by reducing the Fe-Fe distance and hence increasing the Fe-Fe interaction, and elements like Zr and Hf decrease the TC by increasing the Fe-Fe distance and reducing their interaction [20, 33]. Figure 4 depicts the Curie temperature of (Nd0.8Ce0.2)13.5Fe80.5−xTaxB6 (x = 0–1.5) alloys. The TC of (Nd,Ce)2Fe14B is lower than the TC of pure Nd2Fe14B (~ 585 K), precisely because of the lower TC of Ce2Fe14B (~ 424 K). It is shown that the addition of Ta linearly decreases the TC of the alloys which further confirms that Ta enters into the main phase and increases the distance between Fe-Fe atoms, ultimately reducing the Curie temperature of the alloys.

Intergranular exchange interactions via the magnetic moments at the grain interfaces are usually described by Henkel plot defined in mathematical equation as follows [34]:

where Md (H) is the reduced magnetization and Mr (H) is the reduced remanent magnetization as a function of external field, and Mr (∞) is the remanent magnetization corresponding to the maximum applied external field [35]. The Henkel plots of (Nd0.8Ce0.2)13.5Fe80.5−xTaxB6 alloys plotted by using Eq. (1) are shown in Fig. 5. It can be seen that all plots have positive values which indicates strong intergranular exchange interaction [35]. The peaks of the plot slightly reduce as a function of Ta which indicates that some very small Ta-containing inclusions may reside at grain boundaries and reduce the intergranular interaction. There is a slight anomalous increase in the interaction for the best alloy ribbon, (Nd0.8Ce0.2)13.5Fe79.6Ta0.9B6. This anomaly may be attributed to the more ideal microstructure which develops for the optimized Ta doping.

The room temperature superior magnetic properties of NdFeB type alloys mainly originate from intrinsic magnetic properties, i.e., high spontaneous magnetization and strong magnetocrystalline anisotropy. However, the extrinsic properties, Hcj and Br and (BH)max, largely depend on microstructure of the alloys. Refined microstructure is known to benefit the magnetic properties of the alloys [36, 37]. The transmission electron micrographs of the selected alloys are depicted in Fig. 6. The average grain size of the alloys without Ta doping is determined to be ~ 76 nm, while the alloy with 0.9 at.% Ta addition has an average grain size of ~ 40 nm. The grains below 250 nm behave as single domain [31], so the grains of the ribbons are well within the single domain limit. The addition of Ta has greatly reduced the grain size and has refined the grains by suppressing the formation of large grains as can be seen in Fig. 6b. The improved magnetic properties and thermal stabilities of the Ta-doped alloys are mainly attributed to the refined microstructure.

4 Conclusion

The effects of Ta doping on the magnetic properties, thermal stabilities, phase transition temperatures, intergranular exchange interactions, and microstructure were investigated. It is found that Ta doping enhanced the coercivity of the alloys. The coercivity of the alloys improved from 14.9 to 16.1 kOe, while the Br reduced marginally. The addition of Ta greatly enhanced the thermal stability of the alloys. The overall improvement in magnetic properties by Ta doping is higher than the improvement obtained in our previous studies by Nb, Zr, and Hf substitution. All Ta-doped alloys depicted better Hcj values at elevated temperatures as compared with Ta-free alloy. The lattice parameters and phase transition temperatures of the alloys changed as a function of Ta indicating that some Ta atoms entered into the main phase to substitute Fe atoms. The average grains size of the alloys reduced as a result of Ta addition. The improved properties of the investigated alloys are mainly attributed to the refined and uniform microstructure. This work may be helpful in the development of Ce containing NdFeB-type alloys with improved magnetic properties and thermal stabilities.

References

Zhao, L.Z., Zhang, J.S., Ahmad, G., Liao, X.F., Liu, Z.W., Greneche, J.M.: Sci. Rep. 8(1), 6826 (2018)

Zhao, L.Z., Yu, H.Y., Guo, W.T., Zhang, J.S., Zhang, Z.Y., Hussain, M., Liu, Z.W., Greneche, J.M.: IEEE Trans Magn. 53(11), 1 (2017)

Pathak, A.K., Khan, M., Gschneidner Jr., K.A., McCallum, R.W., Zhou, L., Sun, K., Dennis, K.W., Zhou, C., Pinkerton, F.E., Kramer, M.J., Pecharsky, V.K.: Adv. Mater. 27, 2663 (2015)

Jiang, Q., Lei, W., He, L., Zeng, Q., Rehman, S.U., Zhang, L., Liu, R., Ma, S., Zhong, Z.: J. Alloys Compd. 775, 449 (2019)

Herbst, J.F.: Mod Phys. 63(63), 819 (1991)

Fan, X., Guo, S., Chen, K., Chen, R., Lee, D., You, C., Yan, A.: J. Magn. Magn. Mater. 419, 394 (2016)

Rehman, S.U., Ouyang, H., Jiang, Q., Liu, K., He, L., Song, J., Wang, L., Luo, X., Ma, S., Zhong, Z.: J Magn Magn Mater. 486, 165252 (2019)

Wang, L., Quan, Q., Zhang, L., Hu, X., Rehman, S.U., Jiang, Q., Du, J., Zhong, Z.: J. Appl. Phys. 123, 113904 (2018)

Pei, K., Zhang, X., Lin, M., Yan, A.: J Magn Magn Mater. 398, 96 (2016)

Jurczyk, M., Wallace, W.E.: J. Magn. Magn. Mater. 59, L182 (1986)

Woodcock, T.G., Zhang, Y., Hrkac, G., Ciuta, G., Dempsey, N.M., Schrefl, T., Gutfleische, O., Givord, D.: Scr. Mater. 67, 536 (2012)

Kurt Buschow, H.: Jürgen. Handb. Magn. Mater. 10, 463 (1997)

Kim, A.S., Camp, F.E.: J. Appl. Phys. 79, 5035 (1996)

Sagawa, M., Tenaud, P., Vial, F., Hiraga, K.: IEEE Trans. Magn. 26, 1957 (1990)

Quan, Q., Zhang, L., Jiang, Q.Z., Lei, W., Zeng, Q., Hu, X., Wang, L., Yu, X., Du, J., Fu, G., Liu, R., Zhong, M., Zhong, Z.C.: J. Magn. Magn. Mater. 442, 377 (2017)

Raviprasad, K., Ravishankar, N., Chattopadhyay, K., Umemoto, U.: J. Appl. Phys. 83, 1916 (1998)

Hirosawa, S., Tomizawa, H., Mono, S., Hamamura, A.: IEEE Trans Magn. 26, 1660 (1990)

Zhang, P.Y., Hiergeist, R., Albrecht, M., Braun, K.F., Sievers, S., Ludke, J., Ge, H.L.: J. Appl. Phys. 106, 073904 (2009)

Leonowicz, M.: J. Magn. Magn. Mater. 83, 211 (1990)

Zhang, L., Jiang, Q., Wang, L., Quan, Q., Rehman, S.U., Lei, W., He, L., Zeng, Q., Hu, X., Liu, R., Zhong, Z.: J. Magn. Magn. Mater. 474, 305 (2019)

Pollard, R.J., Parker, S.F.H., Grundy, P.J.: J. Magn. Magn. Mater. 75, 239 (1988)

Zhang, M., Li, Z., Shen, B., Hu, F.: J Sun J Alloys Compd. 651, 144 (2015)

Chang, W.C., Wu, S.H., Ma, B.M., Bounds, C.O.: J. Magn. Magn. Mater. 167, 65 (1997)

Chin, T.S., Lin, C.H., Huang, Y.H., Yau, J.M.: IEEE Trans. Magn. 29, 2788 (1993)

Chin, T.S., Huang, S.H., Yau, J.M.: Appl. Phys. Lett. 59, 2046 (1991)

Bekker, V., Seemann, K., Leiste, H., Magn, J.: Magn Mater. 296, 37 (2006)

Liu, Z.W., Liu, Y., Yan, L., Tan, C.Y., Ong, C.K.: J. Appl. Phys. 99, 043903 (2006)

Rehman, S.U., Jiang, Q., Lei, W., Zeng, L., Tan, Q., Ghanzanfar, M., Awan, S.U., Ahmad, T., Zhong, M., Zhong, Z.C.: J. Phys. Chem. Solids. 124, 261 (2019)

Liu, Z.W., Liu, Y., Deheri, P.K., Ramanujan, R.V., Davies, H.A.: J. Magn. Magn. Mater. 321, 2290 (2009)

Zhang, J.S., Li, W., Liao, X.F., Yu, H.Y., Zhao, L.Z., Zeng, H.X., Peng, D.R., Liu, Z.W.: Journal of mater. For. Sci. Technol. 35, 1877 (2019). https://doi.org/10.1016/j.jmst.2019.05.007

Chui, W.B., Takashashi, Y.K., Hono, K.: Acta Mater. 59, 7768 (2011)

Pathak, A.K., Khan, M., Gschneidner Jr., K.A., McCallum, R.W., Zhou, L., Sun, K., Kramer, M.J., Pecharsky, V.K.: Acta Mater. 103, 211 (2016)

Rehman, S.U., Jiang, Q., Liu, K., He, L., Ouyang, H., Zhang, L., Wang, L., Ma, S., Zhong, Z.C.: J. Phys. Chem. Solids. 132, 182 (2019)

Ashfaq, A., Matsuura, M., Sakurai, M.: Appl. Phys. Lett. 73(17), 2512 (1998)

Kelly, P.E., O’Grady, K., Mayo, P.I., Chantrell, R.W.: IEEE Trans Magn. 25, 3881 (1989)

Wohlfarth, E.P.: J. Appl. Phys. 29(3), 595 (1958)

Jiang, Q., Zhong, M., Quan, Q., Zhang, J., Zhong, Z.C.: J Alloys Compd. 688, 363 (2016)

Acknowledgments

Sajjad Ur Rehman dedicates the paper to the memory of his father.

Funding

This work was financially supported by the National Natural Science Foundation of China (Grant nos. 51564037, 51661011, and 51671097), the Outstanding PhD Dissertation Project (Grant no. 3105500032-Sajjad Ur Rehman), and Graduate Innovation Fund (Grant no. XS2018-B003-Sajjad Ur Rehman), Jiangxi University of Science and Technology, Ganzhou, China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ur Rehman, S., Song, J., Jiang, Q. et al. Magnetic Properties, Phase Transition Temperatures, Intergranular Exchange Interactions and Microstructure of Ta-Doped Nd-Ce-Fe-B Nano ribbons. J Supercond Nov Magn 33, 877–882 (2020). https://doi.org/10.1007/s10948-019-05259-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-019-05259-6