Abstract

Magnesium-substituted Ni-ferrite (MgxNi1 − xFe2O4; 0 ≤ x ≤ 1) nanoparticles were prepared by sol-gel method and were annealed at 550 °C and 900 °C in air. All the as-prepared samples and the samples annealed at 550 °C were single phase whereas some additional peaks of α-Fe2O3 was observed for the samples annealed at 900 °C. Lattice constant increased with the increase in Mg2+ concentration. Crystallite size did not show any systematic variation with the increase in Mg2+ concentration and was increased after annealing in these nanoparticle samples. The highest MS values of 42 and 46 emu/g were observed at 300 and 60 K respectively for the as-prepared sample with x = 0.05 and the lowest values of 21 and 26 emu/g were observed at 300 and 60 K respectively for the 550 °C-annealed sample with x = 1. The magnetization and coercivity decreased with the increase in Mg2+ concentration. The non-saturation behavior was found to be increased with the increase in Mg2+ concentration in these samples. The observed magnetic behavior can be understood on the basis of increase in nonmagnetic Mg2+ concentration, cation distribution in the lattice sites, growth of crystallite size, and the decrease in anisotropy with the increase in Mg2+ concentration in these nanoparticle samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ni-ferrites (NiFe2O4) with several interesting properties like moderate saturation magnetization, low coercivity, low electrical losses, high electrical resistivity, and good chemical stability find many applications in technology, environmental, and biomedical fields [1, 2]. Ni-ferrite has inverse spinel structure with 8 Fe3+ in the tetrahedral A-sites and the rest 8 Fe3+ together with 8 Ni2+ in the octahedral B-sites in the unit cell [3]. When these ferrites are prepared in nanoscale, its physical properties are modified due to smaller crystallite sizes and their distribution in the nanomaterial samples. The magnetic properties of these ferrites can also be modified by substituting different cations and site occupancy of these cations in the spinel structure. Mg2+ is a nonmagnetic ion with no unpaired electron and prefers to occupy the B-site in the spinel structure. So, the substitution of Mg2+ in place of Ni2+ is expected to modify the super-exchange interaction and the physical properties of Ni-ferrite [4,5,6].

Substitution of Mg2+ has been reported to modify the electrical, optical, electrochemical, and photocatalytic properties of Ni-ferrite nanoparticles. Hirthna et al. reported the decrease in dielectric properties and increase in electrical conductivity with increasing Mg2+ concentration in MgXNi1−XFe2O4 nanoparticles [4]. The dielectric properties of MgxNi1 − xFe2O4 nanoparticles have also been studied by many other researchers [7,8,9]. Shobana et al. suggested from their electrochemical study that Mg2+ substituted Ni-ferrite nanoparticles can be used as anode material for rechargeable batteries [10]. Nadumane et al. studied that Mg2+ substituted Ni-ferrite nanoparticles show better photocatalytic properties than the Ni-ferrite nanoparticles [11]. In the present work, we studied the effect of Mg2+ concentration and annealing temperature on the magnetic behavior of MgxNi1 − xFe2O4 nanoparticles prepared by sol-gel method.

2 Experiments

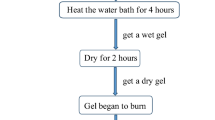

Magnesium-substituted nickel ferrite (MgxNi1 − xFe2O4; 0 ≤ x ≤ 1) nanoparticles were synthesized by sol-gel autocombustion method. Metal nitrates of nickel and magnesium were used as the starting salts, and ethylene glycol was used as solvent. The detailed synthesis method has been reported elsewhere [12]. After auto-combustion, the powders were collected at room temperature. The powders were ground well using agate mortar pestle and were subsequently annealed at 550 °C and 900 °C in air for 2 h. Structural properties were studied by a Rigaku Miniflex 600 X-ray diffractometer with Cu-Kα radiation (λ = 1.5406 Å) in θ/2θ mode. Microstructural studies were carried out using Carl Zeiss Sigma field emission gun scanning electron microscope (FEG-SEM). Magnetic properties were studied by a vibrating sample magnetometer (VSM) of Quantum Design Versa Lab Physical Property Measurement System by applying maximum magnetic field up to ± 30 kOe at different temperatures.

3 Results and Discussion

3.1 Structural and Microstructural Properties

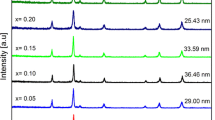

Figure 1 shows the X-ray diffraction patterns of the as-prepared (asp) and the samples annealed at 900 °C. All the observed peaks were indexed with the help of standard JCPDS data of Ni-ferrite (PDF card No. 742081) and Mg-ferrite (PDF Card No.732410). As seen in Fig. 1a, all the asp samples were of single phase, whereas for the samples annealed at TA = 900 °C with x ≤ 0.25, one peak corresponding to α-Fe2O3 was observed in addition to the Ni-ferrite phase as seen in the Fig. 1b. Lattice constant increased with the increase in Mg2+ concentration in both the asp and annealed samples and was found to be in the range of 8.309 to 8.456 Å for these nanoparticle samples compared to the standard value of 8.337 Å and 8.376 Å for Ni-ferrite and Mg-ferrite respectively. Crystallite size of these nanoparticle samples was calculated by Scherrer’s formula using the most intense peak [13]. It did not show any systematic variation with the increase in Mg2+ concentration and was found to be 16 ± 2, 19 ± 4, and 38 ± 9 nm for the asp, 550 °C, and 900 °C-annealed samples respectively.

Figure 2a, b, c, d show the FEG-SEM images with different magnifications of the asp and annealed (TA = 900 °C) MgxNi1 − xFe2O4 nanoparticle samples with x = 0.85. As seen in Fig. 2a, c, the crystallite size of the asp sample is very small. After annealing, bigger crystallites were observed (see Fig. 2b, d) in the sample. This observation corroborates our XRD observation about the growth of crystallites after annealing.

3.2 Magnetic Properties

Magnetic hysteresis (M-H) loops of the asp and annealed (TA = 900 °C) MgxNi1 − xFe2O4 nanoparticle samples with x = 0.05, 0.50, 0.85 are shown in Fig. 3. As seen in Fig. 3, the loops did not saturate up to the highest magnetic field of 30 kOe. Moreover, one can see that the loops of the annealed samples are better saturated than the asp samples. The magnetization values of all the samples were obtained by extrapolating the M-H loop at high field to the zero applied fields. The spontaneous magnetization (MS) and coercivity (HC) values obtained from the M-H loops are shown with the increase in Mg2+ concentration in Fig. 4. For the asp sample with x = 0, i.e., for Ni-ferrite sample, the MS values of 38 and 42 emu/g were observed at 300 and 60 K respectively. As seen in Fig. 4a, b, for the asp and 550 °C-annealed samples, the MS value slightly increases for x = 0.05 than that for x = 0; then it decreases with further increase in Mg2+ concentration both at 300 K and 60 K. Hirthna et al. also observed increase in the MS value up to x = 0.6 in MgxNi1 − xFe2O4 nanoparticle samples [4]. However, many researchers reported monotonic decrease of MS value with the increase in Mg2+ concentration [5, 6, 8]. Chavan et al. [5] observed the highest MS of 64.5 emu/g at room temperature for x = 0, i.e., for Ni-ferrite nanoparticles. Naidu et al. [6] observed the maximum MS value of 44.4 emu/g at 300 K for x = 0. Moradmard et al. [8] reported the maximum MS value of 28.8 emu/g for x = 0 at room temperature. We observed the highest MS values of 42 and 46 emu/g at 300 and 60 K respectively for x = 0.05. Moreover, the MS value for the 550 °C-annealed samples is lower than that for the asp sample for all x values. For the samples annealed at 900 °C, MS value continuously decreased from 37 emu/g observed for x = 0 to 29 emu/g for x = 0.25 at 300 K. With further increase in x value to 0.50, the MS value slightly increased to 31 emu/g and then decreased with further increase in Mg2+ concentration. Similar trend was also observed at 60 K for the samples annealed at 900 °C. The lowest MS values of 21 and 26 emu/g at 300 and 60 K respectively were observed for the sample annealed at 550 °C with x = 1, i.e., for Mg-ferrite. It is also seen in Fig. 4a, b that for x = 0.05 and 0.25, the MS value monotonically decreased with increase in TA. For higher Mg2+ concentration x ≥ 0.05, the MS value was the lowest for the sample annealed at TA = 550 °C.

As seen in Fig. 4c, d, HC decreased with the increase in Mg2+ concentration both at 300 K and 60 K. It is interesting to note that at 300 K, for the 900 °C-annealed samples, the HC values were always the highest compared to those observed for the asp and 550 °C-annealed samples. However, at 60 K, though the HC values were enhanced, it was the lowest for the 900 °C-annealed samples. The lowest HC of ~ 10 Oe was observed at 300 K for the asp and 550 °C-annealed samples with x = 1, and the highest HC of 340 Oe was observed at 60 K for the asp sample with x = 0.

The decrease in saturation magnetization with the increase in Mg2+ concentration in MgxNi1 − xFe2O4 nanoparticles can be understood as follows. Ni2+ has two unpaired electrons in the valence shell and Mg2+ has no unpaired electron. Considering only spin contribution, Ni2+ has magnetic moment 2 μB and Mg2+ has 0 μB. As discussed earlier, both Mg2+ and Ni2+ prefer to occupy the B-site in the spinel structure. When Mg2+ ion is substituted into Ni-ferrite, it occupies B-site by replacing Ni2+ ion in the B-site and hence the effective magnetic moment in the B-site decreases. As a result, net magnetization decreases with the increase in Mg2+ concentration. The initial increase in magnetization for lower concentration of Mg2+, i.e., for x = 0.05, may be due to the occupancy of some Mg2+ in the A-site [5, 14]. When some Mg2+ ions occupy the A-site and equal amount of Fe3+ ions are displaced to the B-site, the magnetization is higher in B-site compared to the A-site leading to increase in net magnetization value. As mentioned above, MS value decreased with the increase in annealing temperature at 300 K for lower Mg2+concentration, i.e., for x = 0.05 and 0.25. However, for higher Mg2+concentration, i.e., for x ≥ 0.50, MS value initially decreases for TA = 550 °C than that for asp sample and then increased with further increase in TA to 900 °C. Similar trend was also observed at 60 K. With the increase in TA, two factors control the magnetization in these nanoparticle samples. First one is that with the increase in crystallite size, volume contribution increases compared to the surface contribution in these nanoparticles which support enhancement in the magnetization with the increase in TA. Another fact is that the Mg2+ ions present in the A-site moved to their preferred B-site with the increase in annealing temperature and crystallite size which results decrease in magnetization. As the crystallite size was not increased appreciably for the samples annealed at TA = 550 °C, it can be understood that for x = 0.05 and 0.25, the migration of Mg2+ ions from A-site to the B-site results decrease in magnetization in these samples compared to the asp samples. For the samples annealed at TA = 900 °C with x ≥ 0.50, the crystallite growth is responsible for increase in magnetization. With the decrease in measurement temperature, the decrease in thermal energy enhances the magnetization at lower temperature.

Coercivity in the nanomaterials is controlled by many factors like crystallite size, canting, magnetocrystalline, surface, and exchange anisotropies. Mg2+ has no anisotropy as it has zero orbital angular momentum (L) and zero spin angular momentum (S) compared to Ni2+ and Fe3+. When Mg2+ concentration increases, magnetocrystalline anisotropy decreases in the sample. So, the HC value decreases with the increase in Mg2+ concentration. The samples annealed at 900 °C contain α-Fe2O3 which is antiferromagnetic. Exchange anisotropy arises due to the interaction between the ferrimagnetic and antiferromagnetic grains in these samples. We believe that this exchange anisotropy in dominating in these samples leading to higher HC at 300 K. Coercivity increases with the increase in single domain crystallite size up to the critical size and decreases with further increase in crystallite size due to the formation of multidomain. One can see that for the samples annealed at 900 °C, the HC was not increased much at 60 K compared to the asp and 550 °C-annealed samples. The crystallite sizes are very small for the asp and 550 °C-annealed samples compared to the samples annealed at 900 °C. The surface anisotropy is dominating in these smaller crystallites compared to the bigger crystallites at low temperature [15]. Moreover, in the sample annealed at 900 °C, crystallite size is larger. With the increase in crystallite size, the surface anisotropy decreases. So, the HC decreases with the increase in TA at 60 K and the lowest value was observed for the samples annealed at 900 °C.

As mentioned earlier, the M-H loops were not saturated even at the highest applied field. So, for understanding the non-saturation behavior in detail, we used the method of law of approach to saturation [16]. We have fitted the initial curve of the M-H loop from 20 to 30 kOe to the equation

where M (∞) is the magnetization at infinite applied field and H* gives the information about non saturation related to the point like defects and anisotropy fluctuation at atomic level. Our experimental data was fitted well with this equation (see supplementary data). The variation of M (∞) and H* values with the increase in Mg2+ concentration is shown in Fig. 5. It is seen from Figs. 5a and 5b that, M (∞) values slightly increased for lower concentration of Mg2+ ions (for x = 0.05) both at 300 and 60 K, and then it decreased with further increase in Mg2+ concentration as observed in the variation of MS values shown in Fig. 4a, b. It is also observed in Fig. 5 that the M (∞) values of the asp samples were the highest and decreased with the increase in TA for the sample with x ≤ 0.7. The highest M (∞) values of 50 and 54 emu/g were observed for the asp sample with x = 0.05 at 300 K and 60 K respectively. For the asp samples and the samples annealed at 550 °C, H* value initially decreases as the “x”value increases from 0 to 0.05 both at 300 K and 60 K as seen in Fig. 5c, d. For x > 0.05, there is an overall increase in H* value with the increase in Mg2+ concentration. For the samples annealed at 900 °C, H* values were always the lowest both at 300 and 60 K. Moreover, the H* values were almost constant with increase in Mg2+ concentration both at 300 and 60 K for these samples.

The non-saturation in magnetic nanoparticles can be due to several factors like spin canting, cation distribution, presence of super-paramagnetic grains, and different anisotropies in the material [16]. As mentioned earlier for the asp samples and the samples annealed at 550 °C, MS value slightly increased when “x” value increased from 0 to 0.05 and is due to the possible cation redistribution of Mg2+ and Fe3+ ions in the A- and B-sites. We also noticed that for the same samples, H* value initially decreases as “x” value increased from 0 to 0.05. So, the initial decrease in the H* value for the lower concentration of Mg2+ is due to the cation distribution in the spinel structure. With the increase in Mg2+ concentration x > 0.05, the increase in nonsaturation with increase in Mg2+ concentration for the asp samples, and the samples annealed at 550 °C may be due to the spin canting in the antiferromagnetically coupled lattice sites in the spinel structure. In these samples, the crystallite sizes are very small. So, the presence of super-paramagnetic grains in these samples also contributes to the non-saturation. As mentioned earlier, surface anisotropy plays significant role in smaller grains; it may also contribute to the non-saturation of magnetic moments and the increase in H* in the asp samples and the samples annealed at 550 °C. The lowest H* values were observed for the samples annealed at 900 °C, and there is not much change in the H* values with the increase in Mg2+ concentration and with the decrease in temperature from 300 to 60 K. The decrease in surface defects and canting decreases the H* values with the increase in crystallite size for the samples annealed at 900 °C.

Zero-field-cooled (ZFC) and field-cooled (FC) magnetization curves of the asp and annealed (TA = 900 °C) samples with x = 0.50 are shown in Fig. 6. It is seen in Fig. 6 that the magnetization of FC curves of both asp and annealed samples decreases with the increase in temperature. As seen in Fig. 6a, a peak was observed around 227 K in ZFC curve for the asp sample. In the annealed sample, the peak was shifted to 116 K. A small kink was also observed around 261 K in this sample which may be due to the Morin transition of α-Fe2O3 present in the annealed samples [17, 18]. Both ZFC and FC curves meet, i.e., irreversible temperature (Tirr) was observed in both the asp and annealed samples around ~ 310 K.

4 Conclusion

MgxNi1 − xFe2O4 nanoparticles were prepared by sol-gel method and were annealed at 550 °C and 900 °C in air. For the as-prepared samples and the samples annealed at 550 °C, the highest magnetization values were observed for Mg2+ concentration x = 0.05, and for samples annealed at 900 °C, there was an overall decrease in magnetization values with the increase in Mg2+ concentration. At 300 K, the highest magnetization value of 42 emu/g was observed for the as-prepared sample with x = 0.05, and the lowest value of 21 emu/g was observed for the sample annealed at 550 °C with x = 1. The coercivity decreased with the increase in Mg2+ concentration both at 300 K and 60 K. It was always the highest at 300 K and the lowest at 60 K for the samples annealed at 900 °C. Non-saturation of magnetization increased with the increase in Mg2+ concentration for the as-prepared samples, and the samples annealed at 550 °C with x values lie between 0.05 and 1, i.e., for 0.05 ≤ x ≤ 1 where as it was almost constant for the samples annealed at 900 °C. Crystallite size, decrease in ionic magnetic moment, cation distribution in the spinel structure, decrease in anisotropy with the increase in Mg2+ concentration explain the observed magnetic behavior in these nanoparticle samples.

References

Jacob, J., Khadar, M.A.: J. Appl. Phys. 107, 114310 (2010)

Azizi, A., Sadrnezhaad, S.K.: Ceram. Int. 36, 2241 (2010)

Smit, J., Wijin, H.P.J.: Ferrites. Cleaver – Hume Press Ltd., London (1959)

Hirthna, Sendhilnathan, S.: Ceram. Int. 43, 15477 (2017)

Chavan, P., Naik, L.R., Belavi, P.B., Chavan, G., Ramesha, C.K.: J. Electron. Mater. 46, 188 (2017)

Naidu, K.C.B., Madhuri, W.: J. Magn. Magn. Mater. 420, 109 (2016)

Varshney, D., Verma, K.: Mater. Chem. Phys. 140, 412 (2013)

Moradmard, H., Farjami Shayesteh, S., Tohidi, P., Abbas, Z., Khaleghi, M.: J. Alloys Compd. 650, 116 (2015)

Chavan, P., Naik, L.R.: Vaccum. 152, 47 (2018)

Shobana, M.K., Kim, K., Kim, J.: Phys. E Low-Dimensional Syst. Nanostructures. 108, 100 (2018)

Nadumane, A., Shetty, K., Anantharaju, K.S., Nagaswarupa, H.P., Rangappa, D., Vidya, Y.S., Nagabhushana, H., Prashantha, S.C.: J. Sci. Adv. Mater. Devices. 4, 89 (2018)

Chithra, M., Anumol, C.N., Sahu, B., Sahoo, S.C.: J. Magn. Magn. Mater. 401, 1 (2016)

Cullity, B.D., Graham, C.D., Introduction to magnetic materials, Second edi, A John wiley & sons (2009)

Ateia, E.E., El-Bassuony, A.A.H., Abdellatif, G., Mohamed, A.T.: Silicon. 10, 1687 (2018)

Mozul, K.A., Ol, L.P., Sizova, Z.I., Bludov, A.N., Pashchenko, V.A., Baumer, V.N., Vashchenko, V.V.: Low Temp. Phys. 39, 365 (2013)

Chithra, M., Anumol, C.N., Sahu, B., Sahoo, S.C.: J. Magn. Magn. Mater. 424, 174 (2017)

Pastor, J.M., Pérez-Landazbal, J.I., Gmez-Polo, C., Recarte, V., Larumbe, S., Santamarta, R., Fernandes Silva, M., Gmez Pineda, E.A., Winkler Hechenleitner, A.A., Lima, M.K.: Appl. Phys. Lett. 100, 063102 (2012)

Wang, J., Aguilar, V., Li, L., gen Li, F., zhong Wang, W., meng Zhao, G.: Nano Res. 8, 1906 (2015)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 2168 kb)

Rights and permissions

About this article

Cite this article

Anumol, C.N., Chithra, M., Rout, S. et al. Effect of Magnesium Substitution on Structural and Magnetic Properties of Nickel Ferrite Nanoparticles. J Supercond Nov Magn 33, 1611–1617 (2020). https://doi.org/10.1007/s10948-019-05192-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-019-05192-8