Abstract

Soft magnetic Co40Fe40B20 films with different tilt angle were successfully deposited on silicon substrates by using oblique sputtering technique. Different oblique angles are achieved by controlling the position of samples. The corresponding static magnetic properties of these samples were then systematically investigated. Interestingly, with the oblique angle increasing from 38° to 55°, the MOKE hysteresis loop of the thin films displays a unique and special performance with double hard axes. Meanwhile, despite of the measurement magnetic field along PR or AR direction, both of the hysteresis loops have two-stage magnetization reversal that means there are two comparably strong anisotropies in the CoFeB films. Moreover, rotating samples from in-plane to out-of-plane, the hysteresis loops demonstrate the perpendicular anisotropy exist in CoFeB films. The cross-section SEM characterizations further verify that the residual field from the magnetic cylinder will strongly impact the microstructures of thin film.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, thin ferromagnetic films possessing a uniaxial magnetic anisotropy have been widely researched [1,2,3,4]. For example, thin films with a uniaxial perpendicular anisotropy can be used in magnetic recording media, while thin ferromagnetic films owning an in-plane uniaxial anisotropy are becoming important for applications in spintronics field [5, 6]. Therefore many methods to induce anisotropy have been employed, such as applied in situ magnetic field during deposition, post-annealing under magnetic field oblique sputtering or compositional gradient sputtering [7,8,9,10], etc. The mechanism of the induced anisotropy are attributed to the formation of short-range ordering of ferromagnetic atoms for the first two methods, titled columnar structure of the grains for oblique sputtering and uniaxial stress for compositional gradient.

As an effective method to induce uniaxial anisotropy, oblique sputter is strongly influenced by atomic shadowing and then forms columnar structure of thin films [11,12,13]. As a result, the effective magnetic anisotropy is increased significantly. In general, the easy axis of hysteresis loop is along the radial direction [14,15,16]. In this article, getting a big uniaxial anisotropy through oblique sputtering is the original purpose. However, during the experiment, special and unique property of hysteresis loops with double hard axes was found. Proper understanding of the origins of the phenomenon is of vital importance for the thin film’s application. Therefore, in this paper, we discussed the magnetic anisotropy in RF sputter-deposited CoFeB films on silicon substrate. At the same time, the MOKE hysteresis loops and cross-section SEM images also have been investigated.

2 Experiment

A series of soft magnetic CoFeB thin films were deposited by RF magnetron sputtering at oblique incidence: no magnetic field was applied during deposition, and the residual field from the sources was about 20 Oe at the sample position. The alloy sputter target of Co40Fe40B20 (at.%) was used. The substrate size is 10 mm × 10 mm × 0.5 mm (length × width × height). The base pressure is 5 × 10− 5 Pa and thin film deposition is performed in an Ar pressure of 0.3 Pa. A schematic of the oblique sputtering setup is shown in Fig. 1. By adjusting the position of substrate, the oblique angle is varied from 38° to 55° corresponding to the sample ID of sample 1 to sample 4. In Fig. 1, we define the thickness gradient along the AR direction and the thickness is uniform along PR direction.

Magnetic characterization of the samples was performed at room temperature using longitudinal magneto-optical Kerr effect (MOKE). The film crystalline property is characterized using X-ray diffraction (XRD, D1 System, Bede). A vibrating sample magnetometer (BHV525, IWATSH, Japan) was used to record the hysteresis loop for the sample which was rotated from in-plane to out-of-plane during the test. A scanning electron microscope (SEM, LEO 1550, Germany) is also employed to characterize the cross-section images.

3 Results and Discussion

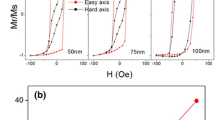

In Fig. 2, the static magnetic properties (MOKE hysteresis loops) for all samples are characterized following the thin film deposition. As the oblique angle increases, when the measurement magnetic field is along PR direction, the coercivity gradually decreased and the anisotropic field continued to increase. Meanwhile, the hysteresis loop along PR direction displays a hard axis performance that is totally different from normally oblique sputtering [17]. Generally, along the PR direction (radial direction), thickness of thin film is homogeneous and the M-H curve should demonstrate a good easy axis property. Of course, in this article, the tilted columnar structure induced by oblique sputtering will produce an in-plane uniaxial anisotropy that is responsible for the increase of anisotropic field when the measurement field is applied along PR direction.

Similarly, when the measurement field is along AR direction the hysteresis loops also have totally different performance than normally oblique sputtered M-H curve. Due to the thickness gradient along the AR direction, the intrinsic stress orientation is arranged along this direction. Therefore a uniaxial magnetic anisotropy will be formed and the film will perform hard axis property along AR direction. However, in Fig. 2a, the hysteresis loop along AR direction shows easy axis property. Certainly, in Fig. 2b–d the hysteresis loops display hard axis property. Therefore, with the oblique angle increase, the hysteresis loops own double hard axis performance.

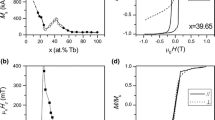

According to the magnetic hysteresis loops, remnant magnetization ratio (M r/M s) of the CoFeB films deposited with different oblique angles can be obtained, which was shown in Fig. 3a. With the applied field along PR direction, the M r/M s ratio (green curve) keep falling and the downward trend slowed down when the oblique angle further increased. Finally the M r/M s ratio declined to 3%. On the other hand, the M r/M s ratio (orange curve) also gradually declined from 62% to 10% (the lowest value) when the measurement field is along AR direction. Apparently, with the oblique angle arising to 55°, the M r/M s ratio suddenly increased probably because of two anisotropy competition.

a Remnant magnetization ratio (M r/M s) of the CoFeB films deposited with different oblique angle. The green (orange) curve displays field along PR (AR) direction. b Prototypical MOKE hysteresis loop with 51° oblique angle. The zero-field reversible slope S (diagonal line) and shift field H s (vertical line) features are indicated

In Fig. 3b, the typical MOKE magnetic hysteresis loop was displayed. The zero-field reversible slope S (green curve) represents a coherent rotation of magnetization (M), while the vertical curve (blue) represents abrupt changes in magnetization direction. The two-stage magnetization reversal is caused by two comparable anisotropies that are oblique sputtering induced volume anisotropy and magnetic field-induced volume anisotropy. As we know, oblique sputter will form tilted columnar structure that is the origin of the volume anisotropy. At the same time, in our sputtering device as the target distance is relatively small, the residual field from magnetic cylinder was about 20 Oe at the sample position. It is like an in situ magnetic field and can induce a weak volume anisotropy which may modify the effective magnetic anisotropy constants in some way. Whatever the volume anisotropy is induced by oblique sputtering or residual field, the azimuthal symmetry breaking mechanism during the film deposition is the origin of the uniaxial magnetic anisotropy [18, 19]. Certainly, despite the measurement fields along AR or PR direction, the MOKE hysteresis loops all have two-stage magnetization reversal and there are no easy axes in these curves. It is noted that the MOKE curves may also have perpendicular anisotropy that is one reason for the performance of double hard axis.

In this magnetic thin film, the inplane magnetic anisotropy may have three outcomes: (1) magnetocrystalline anisotropy origin of spin-orbit coupling and reflecting crystal symmetry; (2) oblique sputter-induced volume anisotropy due to azimuthal symmetry breaking mechanism during the film deposition; and (3) residual field from magnetic cylinder-induced anisotropy. Figure 4 shows the XRD line scans recorded in the Bragg-Brentano mode for the CoFeB films with different oblique angle. There is no distinct diffraction peak indicating that the CoFeB film remains amorphous. Thus, the possible contribution from the enhanced magnetocrystalline energy can be excluded.

In order to further research the perpendicular anisotropy, rotating sample from in-plane direction to out-of-plane was executed and results were shown in Fig. 5. With the rotating angle increased from 0° to 60°, the M r/M s ratio gradually decreased despite of the applied field along AR or PR direction. Of course, the saturation magnetization is also declining. Because the projection of the magnetization vector in the plane decreases as the rotating angle increases. It proves that the perpendicular anisotropy actually exists in CoFeB amorphous films. The reason may come from the thickness of thin film which has exceeded the critical thickness. Therefore, perpendicular magnetization component will be produced.

All the above research aims to clarify the reason of double hard axes of hysteresis loops. The perpendicular magnetization component caused a low M r/M s ratio despite the applied field along AR or PR direction which has been proven in Fig. 5. Meanwhile, the residual field penetrates through sputter target and then causes an in situ magnetic field at sample position. We believe that this residual field must change the microstructural performance of thin film that drives the cross-section SEM picture shown. In Fig. 6a, there are some tinily tilted columnar structures caused by shadow effect and large sheet structures caused by in situ field. The coexistence of these two microscopic structures strongly demonstrate that there are two different microstructures caused by different mechanisms. However, in Fig. 6b, only the obvious columnar structure can be seen. The difference between Fig. 6a, b should derive from bigger oblique angle and smaller in situ field.

4 Conclusion

In summary, using oblique sputtering technique, special and unique double hard axis performance was achieved. Despite the applied field along AR or PR direction, the hysteresis loops possess a two-state magnetization reversal. The anisotropy induced by oblique sputter and residual field should be the reason of causing this phenomenon. Meanwhile, probably because of the thickness of thin film exceeding critical thickness, there are some perpendicular magnetic components along out-of-plane direction. Hence, the M r/M s ratio of in plane always keeps low that is one reason for double hard axes. This special phenomenon could further develop understanding of anisotropy.

References

Tang, Z., Ni, H., Lu, B., Zheng, M., Huang, Y., Lu, S., Tang, M., Gao, J.: Thickness dependence of magnetic anisotropy and domains in amorphous Co40Fe40B20 thin films grown on PET flexible substrates. J. Magn. Magn. Mater. 426, 444–449 (2017)

Wen, D., Zhang, H., Yang, X., Lv, Q., Bai, F.: Electrical-field tuned anisotropy in the FeSiBC/PMN-PT heterostructures with different history of induced uniaxial anisotropy. J. Alloy. Compd. 690, 836–840 (2017)

Li, S., Huang, Z., Duh, J., Yamaguchi, M.: Ultrahigh-frequency ferromagnetic properties of FeCoHf films deposited by gradient sputtering. Appl. Phys. Lett. 92, 092501 (2008)

Wen, D., Zhang, H., Hui, X., Wang, Y., Zhong, Z., Bai, F.: Large in-plane uniaxial magnetic anisotropy in the ferromagnetic/ferroelectric heterostructures. IEEE Trans. Magn. 50, 2801804 (2014)

Ou, Y., Ralph, D.C., Buhman, R.A.: Strong perpendicular magnetic anisotropy energy density at Fe alloy/HfO2 interfaces. Appl. Phys. Lett. 110, 192403 (2017)

Stupakiewicz, A., Sxerenos, K., Afanasiev, D., Kirilyuk, A., Kimel, A.V.: Ultrafast nonthermal photo-magnetic recording in a transparent medium. Nature 542, 71–74 (2017)

Wang, Y., Zhang, H., Wen, D., Zhong, Z., Bai, F.: Magnetic and high frequency properties of nanogranular CoFe-TiO2 films. J. Appl. Phys. 113, 17A316 (2013)

Yang, Q., Zhang, H., Liu, Y., Wen, Q.: Effect of post-annealing on the magnetic properties of Bi: YIG film by RF magnetron sputtering on Si substrates. IEEE Trans. Magn. 43, 3652–3655 (2007)

McMichael, R.D., Lee, C.G., Bonevich, J.E., Chen, P.J., Miller, W., Egelhoff, W.F.: Strong anisotropy in thin magnetic films deposited on obliquely sputtered Ta underlayers. J. Appl. Phys. 88, 5296–5299 (2000)

Phuoc, N.N., Ong, C.K.: Anomalous temperature dependence of magnetic anisotropy in gradient-composition sputtered thin films. Adv. Mater. 25, 980–984 (2013)

Robbie, K., Brett, M.J.: Sculptured thin films and glancing angle deposition: growth mechanics and applications. J. Vac. Sci. Technol. A 15, 1460–1465 (1997)

Tang, F., Liu, D.L., Ye, D.X., Zhao, Y.P., Lu, T.M., Wang, G.C., Vijayaraghavan, A.: Magnetic properties of Co nanocolumns fabricated by oblique-angle deposition. J. Appl. Phys. 93, 4194–4200 (2003)

Sit, J.C., Vick, D., Robbie, K., Brett, M.J.: Thin film microstructure control using glancing angle deposition by sputtering. J. Mater. Res. 14, 1197–1199 (1999)

Li, S., Cai, Z., Xu, J., Cao, X., Du, H., Xue, Q., Gao, X., Xie, S.: Enhancement of ferromagnetic resonance in Al2O3-doped Co2FeAl Heusler alloy film prepared by oblique sputtering. Chin. Phys. B 23, 106201 (2014)

Li, X.Y., Sun, X.J., Wang, J.B., Liu, Q.F.: Microstructure and magnetic properties of iron nitride granular thin films obtained by oblique RF reactive sputtering. J. Alloy. Comp. 592, 185–188 (2014)

Cai, Z., Li, S., Cao, X., Du, H., Xue, Q., Gao, X., Xie, S.: High-frequency performance of Co2FeAl half-metallic films prepared by oblique sputtering under various deposition conditions. Mater. Sci. Forum. 787, 368–372 (2014)

Wang, G., Dong, C., Wang, W., Wang, Z., Chai, G., Jiang, C., Xue, D.: Observation of rotatable stripe domain in permalloy films with oblique sputtering. J. Appl. Phys. 112, 093907 (2012)

Hindmarch, A.T., Arena, D.A., Dempsey, K.J., Henini, M., Marrows, C.H.: Influence of deposition field on the magnetic anisotropy in epitaxial Co70Fe30 films on GaAs(001). Phys. Rev. B 81, 100407 (2010)

Hindmarch, A.T., Rushforth, A.W., Campion, R.P., Marrows, C.H., Gallagher, B.L.: Origin of in-plane uniaxial magnetic anisotropy in CoFeB amorphous ferromagnetic thin films. Phys. Rev. B 83, 212404 (2011)

Funding

The authors would like to acknowledge financial support by the National Key Research and Development Program of China (No. 2016YFA0300801), the National Nature Science Foundation of China (Nos. 51672036, 51602036, and 51402041), and Sichuan Science and Technology projects under Grant No. 2014GZ0091.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wen, D., Zhang, H., Li, J. et al. Double Hard Axes of Hysteresis Loop in Wide-Angle Obliquely Sputtered CoFeB Amorphous Films. J Supercond Nov Magn 31, 2393–2397 (2018). https://doi.org/10.1007/s10948-017-4490-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-017-4490-x