Abstract

The effect was investigated of nitrogen impurities on the morphology and magnetoresistance properties of Co–N and Ni–N thin films. The films were electroplated onto aluminum substrates, at room temperature, using the same electrodeposition parameters (pH = 3 and temperature 30 ∘C) for all experiments. The films were compared with similar samples obtained in the absences of nitrogen impurities. Scanning electron microscopy, X-ray photoelectron spectroscopy, and magnetoresistance measurements were utilized to characterize the studied films. The presence of nitrogen in the electrodeposited films have a significant influence on the morphology and magnetoresistance of electrodeposited films. Incorporation of a small amount of nitrogen into electrodeposited films increases the magnetoresistance up to 0.21 % for Co–N thin films and respectively 0.65 % in the case of Ni–N films. We suppose that the shape of the magnetoresistance curves is influenced by the interaction between the magnetic moment of the neighboring Co or Ni grains (with ferromagnetic behavior) separated by the nonmagnetic regions. Interfacial complexities of a ferromagnetic metal/oxide interface in studied thin films could force the interfacial spins to align ferromagnetically or antiferromagnetically. They could be useful for technological applications in electronics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Over the past decade, there is an increasing demand for new types of materials with different structures and improved functional properties susceptible to be used for technological applications (e.g., magnetic recording media, magnetoresistive sensors, or miniaturized devices). Many studies have been carried out to develop binary or ternary alloys based on Co and Ni system with additions because of their magnetic [1–4] or magnetoresistive properties [5–9]. In particular, they display properties of interest in applications ranging from magnetic recording to microelectromechanical systems [10–13].

Co and Ni based films, grown on various substrates using different methods, are the subject of extensive study [5, 6, 14–19]. The most frequent techniques for the processing of nanostructured magnetic materials are vapour techniques (PVD, CVD), sputtering, laser ablation, molecular beam epitaxy (MBE), or chemical methods and it was shown that the physical properties depend on the production methods. However, obtaining high-quality, well-controlled deposits with these methods is challenging. In the last few years, electrodeposition has emerged as a useful tool for preparation of magnetic and magnetoresistive materials [1, 2, 7–9, 18].

A few literature references can be found about the incorporation of nitrogen in binary or ternary alloys of iron group elements (e.g., Refs. [20–22]). The effect of incorporated nitrogen on the microstructure [20], magnetic [20–22], and transport properties [23] was investigated by different authors.

The functional properties of Co- and Ni-based films depend greatly on their composition, which should be turning strongly affected by deposition parameters. We used electrodeposition method for preparation of Co, Ni, Co–N, and Ni–N thin films because it is a low-price procedure and the alloy deposits can be easily prepared by this technique related to other methods. In this study, we report on the experimental investigation of the influence of nitrogen impurities on the surface morphology and magnetoresistance (MR) properties of cobalt and nickel thin films. The correlation between these properties and the preparation conditions could be useful for technological applications.

2 Materials and Methods

2.1 Samples Preparation

All the films studied in this paper were prepared by electrodeposition. The bath composition and the electrodeposition conditions were set accordingly to our previous paper [7]. The electrodeposition was done in galvanostatic regime (with the current density of 12.75 mA/cm 2), by using an electrolytic cell (300 ml solution) and a three-electrode system consisting of a nickel foil anode, a working electrode of aluminum disk, and a quasi-reference electrode made of platinum wire embedded in a glass tube (having the contact surface with the electrolytic solution of 0.06 mm 2). The anode and the cathode in the form of disks, with an area of 3.14 cm 2 in contact with the electrolyte solution, are placed vertically within the electrolytic cell at a distance of 1.5 cm apart. Before each experiment, the aluminum substrates were mechanically polished, degreased with acetone, and washed in distilled water. As a source for nitrogen inclusion in the films, sodium nitrate was used. In all experiments, the temperature was kept at 30 ∘C and pH = 3.

In order to study the effect of the nitrogen impurities on the morphology and magnetoresistance properties of the electrodeposited thin films, four series of samples were prepared and we used the following notations: the series containing nickel electrodeposited on the aluminum substrate were labeled SI; the symbol SII was used for the series containing nickel and nitrogen (Ni–N); the samples prepared by electrodeposition from solution containing cobalt sulfate heptahydrate and specific additives were labeled SIII; and for the series containing cobalt and nitrogen (Co–N), the symbol SIV was used.

2.2 Sample Characterization

The morphological analyses of the surface and chemical composition of the studied thin films were made by using a scanning electron microscope SEM VEGA II LSH model, produced by Czech TESCAN, coupled with an energy-dispersive X-ray EDAX detector type QUANTAX QX2 (using MnK α radiation), produced by BRUKER/ROENTEC Germany. X-ray photoelectron spectroscopy (XPS) measurements have been carried out on a Physical Electronics PHI 5000 VersaProbe instrument, equipped with a mono-chromated AlK α X-ray source (h ν=1486.7 eV). The sputter cleaning of the surface was done under ultra high vacuum (UHV) conditions on a 3×3 mm 2 area by using an Ar + ion beam (1 μA, 2 kV, 12 s). The take-off angle of the photoelectrons was 45∘(angle of the sample surface with the direction in which the electrons are analyzed). All the XPS peak positions in the survey spectra were calibrated with respect to the C1s peak at binding energy (BE) 284.6 eV.

The measurements of the magnetoresistance were carried out with an HM8112-2 programmable multimeter at room temperature, with the conventional four-point-in-line method, working in the regime of a constant current. The DC magnetic field was applied in the plane of the film perpendicular to the electric current (current in-plane transversal configuration) and varied between −220 and + 220 kA/m.

3 Results and Discussions

3.1 Morphology of the Deposits (SEM)

The deposits showed a variety of morphologies from very fine nodular grain (Ni and Ni–N films) to highly acicular grain shapes (Co and Co–N films). All films adhered well to the substrate. Also, the working area was completely coated at the end of each deposition process. For the sake of clarity, we compare morphologies of the electrodeposited films obtained at the same current density (12.75 mA/cm 2) (Fig. 1). Figure 1a–d shows the SEM images of the samples SI (Ni), SII (Ni–N), SIII (Co), and SIV (Co–N) prepared by electrodeposition onto aluminum substrates.

SEM measurements show that the morphology of the electroplated films is different for nickel and cobalt films. The SEM images from Fig. 1a show a granular structure for the sample SI (96.39 wt% Ni, 3.23 wt% O, 0.38 wt% Al) consisting of nodular grains not well defined. The effect of nitrogen impurities on nickel film morphology (sample SII—89.57 wt% Ni, 5.11 wt% N, 5.10 wt% O, 0.22 wt% Al) can be observed in Fig. 1b. The grains retained their spherical shape but tended to occur in clusters rather than as individual grains, became finer, and the boundaries between the clusters are better defined. The morphology of the studied samples (SI and SII) is similar with nickel films plated onto Si [13], Cu substrate [19], or prepared by magnetron sputtering [14].

The deposits obtained from the sample SIII (97.08 wt% Co, 2.61 wt% O, 0.31 wt% Al) (Fig. 1c) mostly consisted of acicular crystalline grains with different dimensions distributed to the area of the aluminum support. By addition of nitrogen impurities in the film, the cathode surface is completely covered with a lot of fine crystallites. In the case of the sample SIV (83.81 wt% Co, 7.39 wt% N, 8.57 wt% O, 0.23 wt% Al), the grains retained their acicular shape (Fig. 1d) and a tendency of particle to occur in clusters could be observed in SEM micrographs. The films morphology in the case of the samples SIII and SIV is similar with Co films prepared by electrodeposition [24, 25].

3.2 X-ray Photoelectron Spectroscopy (XPS) Studies

The studied samples were subjected to XPS analysis in order to determine the oxidation state of the particular elements in the deposits. The analysis was performed immediately after electrodeposition in order to reduce the contact of the sample with atmospheric oxygen. The surface to be examined was sputtered with Ar + ions to remove any oxidation products and surface impurities (mainly carbon). Surface analysis of the studied films by XPS after including the nitrogen impurities in the films shows that nitrogen is enriched at the surface by cationic catalysis [7, 26]. The XPS survey spectra taken from samples SII and SIV are shown in Fig. 2a–d.

In an attempt to obtain a clearer picture of the chemical states of nitrogen in the electrodeposited film, the Nls spectra were deconvoluted by two peaks in the case of the sample SII (Ni–N) and by three peaks, respectively, in the case of the sample SIV (Co–N). The curve-deconvoluted spectra are shown in Fig. 2c, d. The peak located at low binding energy N(1) at 397.8±0.1 eV (Fig. 2c) and 398.0±0.1 eV (Fig. 2d) is assigned to nitride [27] and oxynitrides phases [28], respectively, incorporated in the film.

In the N1s spectrum (Fig. 2d), the intermediate binding energy peak N(2) at 399.3 eV of relative intensitie 42 % corresponds to nitrogen bonded essentially to cobalt under the form of an N–H which is incorporated in the electrodeposited film. The XPS parameters are presented in Table 1.

The N1s peaks observed at higher binding energies N(3) at 400.1±0.1 eV (Fig. 2c) and 400.9±0.1 eV (Fig. 2d) correspond to nitrogen species located on the surface of the electrodeposited thin films, which are produced at least in part by reaction with the electrolyte. The peak located at these binding energy (400.1±0.1 eV and respectively, 400.9±0.1 eV) may originate from N–H or N–O [27, 29]; also, it is possible that the peak located at these binding energy to originate from nitrogen which may be under the form of NH\(_{4}^{+}\) [29], although complementary experiments are still required in order to confirm this aspect and will be clarified in detail in the near future.

3.3 Magnetoresistance Measurements

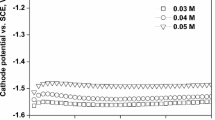

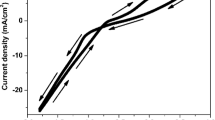

The effects of the physical microstructure have a significant influence on the transport properties. The presence of nitrogen in the alloy apparently have a significant influence on the morphology and magnetoresistance properties of electrodeposited films. In the following, we will present briefly results on the measurements of magnetoresistance. The magnetoresistance measurements were performed using a four-point probe method. The DC magnetic field (varied in the domain ±220 kA/m) was applied in the film plane perpendicular to the current, in the so-called CIP transversal configuration (CIP-T). The measurements of the film resistance (R) were carried out with an HM 8112-2 programmable multimeter at room temperature. For the electric transport measurements, magnetoresistance was calculated using the (1):

in which R(H) denotes the film resistance measured in the field H and R(H max) denotes the resistance in the maximum positive applied magnetic field. The variation of magnetoresistance (MR) with applied magnetic field (H) for the studied samples is presented in Fig. 3.

The curves are symmetrical versus the sign of magnetic field. Analyzing the curves for different studied samples, one can observe that the MR values are larger for the samples containing nitrogen as impurities Fig. 3b, d. A large change in MR is produced at low fields (lower than 50 kA/m), and this low field magnetoresistance is caused through spin disorder by the tunneling process at the grain boundaries and at the interface between embedded nitrogen impurities and Co or Ni matrix. When a magnetic field is applied, the spin disorder is suppressed, resulting in the high MR, especially at low field ∼ ±50 kA/m. An analysis of Fig. 3 shows that with the increase in the magnetic field from −220 to 220 kA/m, the value of MR for samples containing nitrogen impurities content in films (Fig. 3b, d) is larger than for Ni (Fig. 3a) and Co film (Fig. 3c).

The observed values of MR in CIP-T configuration are 2.13 % for the sample SI (Fig. 3a) and 3.04 % for the sample SIII (Fig. 3c), while for the samples containing nitrogen impurities, the MR values are 2.79 % (sample SII—Fig. 3b) and 3.25 % in the case of sample SIV (Fig. 3d), respectively.

So the change in MR is greater in the electrodeposited thin films containing nitrogen impurities as compared to cobalt or nickel films prepared by electrodeposition from solution without sodium nitrate as source of nitrogen in our films, which indicates that the enhancement in MR basically comes through the inclusions in the films of these kind of impurities. We suppose that the shape of the magnetoresistance curves is strongly influenced by the interaction between the magnetic moment of the neighboring Co or Ni grains (with ferromagnetic behavior) separated by the nonmagnetic regions. Interfacial complexities of a ferromagnetic metal/oxide interface in studied thin films could force the interfacial spins to align ferromagnetically or antiferromagnetically.

4 Conclusions

In this work, we studied some aspects regarding the influence of the nitrogen addition in the electrolytic solution on the morphology and magnetotransport properties of the electrodeposited cobalt and nickel thin films. We prepared by electrodeposition (working in galvanostatic regime with the current density of 12.75 mA/cm 2) a series of samples from solutions without and with sodium nitrate as a source for nitrogen inclusion in the films. The films were compared with similar samples obtained in the absences of nitrogen impurities.

By incorporation of nitrogen impurities in the films, the surface morphology of the studied samples is gradually changed. The deposits showed a variety of morphologies from nodular grain shapes to highly acicular grains. The Ni films show a granular structure consisting of nodular grains not well defined. By addition of nitrogen impurities in the film by cationic catalysis, the cathode surface is completely covered with fine crystallites with spherical shape. The Co films show acicular crystalline grains with different dimensions distributed to the area of the aluminum substrate. Scanning electron micrographs of electrodeposited Co–N thin films had a morphology consisting of acicular grains well defined. The grains retained their acicular shape (as in the case of Co film), and it was observed (by SEM measurements) a tendency of particle to occur in clusters rather than as individual grains; the grains became finer and the boundaries between the clusters became better defined. It can be related to a modification of the competition between nucleation and crystal growth of the film in the presence of nitrogen in the films.

The XPS analysis testifies the existence of nitrogen impurities in electrodeposited thin films. The effects of the physical microstructure have a significant influence on the transport properties. The studied samples display a MR effect in the range of 2.13–3.25 %. From the magnetoresitance measurements, we have found that the incorporation of a small amount of nitrogen into electrodeposited films increases the magnetoresistance up to 0.65 % for Ni–N film and, respectively, 0.21 % for electrodeposited Co–N film. The nitrogen impurities seem to control the morphology and spin-dependent grain–matrix interface scattering of electrons, with the two showing a correlation. It is economical and easy and to produce Ni–N and Co–N thin films using electrodeposition technique. They could be useful for technological applications in electronics.

References

Ohgai, T., Tanaka, Y., Fujimaru, T.: J. Appl. Electrochem. 42, 10 (2012)

Xu, X., Zangari, G.: J. Appl. Phys, 99 (2006)

Hiep, V.V., Chau, N., Hong, D.M., Luong, N.H.: J. Magn. Magn. Mater. 310 (2007)

He, X., Yue, G., Hao, Y., Xu, Q., Wei, Q., Zhu, X., Kong, M., Zhang, L., Li, X.: J. Crystal Growth 310 (2008)

Chen, X., Qiu, H., Wu, P., Pan, L., Wang, F.: Nanoscience 11, 1 (2006)

Jesche, A., Gorbunoff, A., Mensch, A., Stöcker, H., Levin, A.A., Meyer, D.C.: J. Appl. Phys. 107, 2 (2010)

Tanase, S.I., Pinzaru (Tanase), D., Pascariu, P., Dobromir, M., Sandu, A.V., Georgescu, V.: Mater. Chem. Phys. 130, 1–2 (2011)

Garcia-Torres, J., Vallés, E., Gómez, E.: Mater. Lett. 65, 12 (2011)

Tanase, S.I., Pinzaru (Tanase), D., Dobromir, M., Georgescu, V.: Appl. Surf. Sci. 257, 24 (2011)

Duch, M., Esteve, J., Gómez, E., Pérez-Castillejos, R., Vallés, E.: J. Micromech. Microeng. 12(4) (2002)

Myung, N.V., Park, D.-Y., Yoo, B.-Y., Sumodjo, P.T.A.: J. Magn. Magn. Mater. 265(2) (2003)

Sverdlov, Y., Rosenberg, Y., Rozenberg, Y.I., Zmood, R., Erlich, R., Natan, S., Shacham-Diamand, Y.: Microelectron. Eng. 76 (2004)

Luo, J.K., Pritschow, M., Flewitt, A.J., Spearing, S.M., Fleck, N.A., Milne, W.I.: J. Electrochem. Soc. 153, 10 (2006)

Yi, J.B., Zhou, Y.Z., Ding, J., Chow, G.M., Dong, Z.L., White, T., Gao, X.Y., Wee, A.T.S., Yu, X.J.: J. Magn. Magn. Mater. 284 (2004)

Pauleau, Y., Kukielka, S., Gulbinski, W., Ortega, L., Dub, S.N.: J. Phys. D: Appl. Phys. 39 (2006)

Manhabosco, T.M., Müller, I.L.: J. Mater. Sci. 44 (2009)

Liao, Z.-M., Lu, Y., Zhang, H.-Z., Yu, D.-P.: J. Magn. Magn. Mater. 322, 15 (2010)

Szmaja, W., Kozłowski, W., Polański, K., Balcerski, J., Cichomski, M., Grobelny, J., Zieliński, M., Miėkoś, E.: Mater. Chem. Phys. 132 (2012)

Sassi, W., Dhouibi, L., Berçot, P., Rezrazi, M., Triki, E.: Electrochimica Acta 117 (2014)

Maeda, H.: J. Appl. Phys. 53 (1982)

Ishida, S., Kitawatase, K.: J. Magn. Magn. Mater 104-107 (1992)

Heryadi, D., Schwingenschlögl, U.: Chem. Phys. Lett. 523 (2012)

Chattopadhyay, S.K., Meikap, A.K., Lal, K., Biswas, D., Chatterjee, S.K., Ghosh, M., Baba, K., Hatada, R.: Solid. State Commun. 108, 12 (1998)

Golodnitsky, D., Rosenberg, Y., Ulus, A.: Electrochimica Acta 47 (2002)

Gang, Wu, Li, N., Zhou, D., Mitsuo, K.: Surf. Coat. Technol. 176 (2004)

Tanase, S.I., Tanase, D., Pascariu, P., Vlad, L., Sandu, A.V., Georgescu, V.: Mater. Sci. Eng. B 167 (2010)

Marcus, P., Bussell, M.E.: Appl. Surf. Sci. 59, 10 (1992)

Bhattacharyya, S., Kurian, S., Shivaprasad, S.M., Gajbhiye, N.S.: J. Nanopart. Res. 12 (2010)

Clayton, C.R., Rosenzweig, L., Oversluizen, M.: Y. C. Lu. In: McCafferty, E., Brodd, R.J. (eds.) Surfaces, Inhibition and Passivation, p 323. The Electrochemical Society, Pennington (1986)

Authors’ contributions

S.I.T. and D.T. prepared the samples, performed magnetoresistance measurements and analyzed the data. M.D. carried out the XPS studies and A.V.S. performed SEM measurements. V.G. supervised the samples preparation and magnetoresistance measurements. S.I.T., D.T. and V.G. co-wrote the manuscript. All authors discussed the results and commented on the manuscript.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Tanase, S.I., Tanase, D., Dobromir, M. et al. SEM, XPS Studies, and Magnetoresistance Properties of Co, Ni, Co–N, and Ni–N Thin Films Prepared by Electrodeposition. J Supercond Nov Magn 29, 469–475 (2016). https://doi.org/10.1007/s10948-015-3269-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-015-3269-1