Abstract

A series of Mg0.5Mn0.5Fe2−x Co x O4 (0 ≤ x ≤ 0.5) samples were synthesized by citrate precursor method. The impact of replacing Fe ions by Co on the structural parameters and magnetic properties of the system was investigated utilizing X-ray diffraction and M–H magnetic measurements at room and low temperatures. Phase analysis revealed a single-phase spinel for all samples, and cation distribution was suggested using data of magnetization loops, Rietveld analysis and then confirmed by Bertaut method. Both saturation magnetization and coercivity increase with Co content up to x = 0.3, then decrease slightly. The variation of lattice parameter, the interatomic distances, and the bond angles upon increasing the Co content was determined and then correlated with cation distribution and the magnetic behavior.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Spinel ferrites are highly versatile materials with applications in various technological fields; they are characterized by unique magnetic and electrical properties. Of these materials, the Mg–Mn ferrites have high initial permeability, high dc resistivity, low loss factor, high saturation magnetization with a rectangular hysteresis loop, high-frequency response, and relatively high Curie temperature, thereby quite beneficial for applications like memory and switching circuits, hyperthermia, resonance magnetic imaging and magnetic fluids [1–4]. For high frequency applications, the main desirable characteristics of ferrites are high dc resistivity, low dielectric losses, high initial permeability, and low saturation magnetization [5]. High initial permeability and high resistivity were obtained upon substituting In3+ in Mg–Mn ferrite [6]. Improvement in the dc resistivity has been observed at the expense of deterioration in the magnetic properties of Al3+ and Cr3+ substituted Mg–Mn ferrites [7].

Magnetic properties depend mainly on the cation distribution among the crystallographic sites available in the material lattice. On the other hand, the distribution of cations among the lattice sites depends on the procedure of material’s preparations [8–10]. Spinel ferrites crystallize in the space group \(Fd\bar {3}m\) with a unit cell containing 32 oxygen atoms. The unit cell contains 32 octahedral (16c and 16 d) and 64 tetrahedral (8a, 8b, and 48 f) sites. Among those available sites, only one eighth of the tetrahedral and half of the octahedral are occupied. Taking the center of symmetry at (1 /4 1 /4 1 /4), cations may occupy the tetrahedral site 8a at (000) (A site) and/or the octahedral site 16d at (3 /8 3 /8 3 /8) (B site). For Mg0.5Mn0.5Fe2O4 ferrite, Mg ions have a strong preference for occupying the octahedral B sites, while Mn ions prefer the tetrahedral A sites [11, 12]. Normally, Co ions prefer the B-site; nevertheless, partially inverse Co ferrite was reported depending on the synthesis process [13].

In the present study, X-ray powder diffraction (XRD) with Rietveld analysis, transmission electron microscope (TEM), and magnetic measurements at room and low temperatures have been performed to find out the effect of Co doping in nanocrystalline Mg0.5Mn0.5Fe2−x Co x O4, (0 ≤ x ≤ 0.5; step 0.1) on the microstructural parameters, cation distribution among the A and B sites, and the magnetic parameters of the system.

2 Experimental

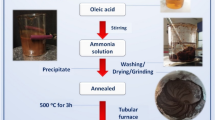

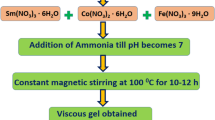

Mg0.5Mn0.5Fe2−x Co x O4 (0 ≤ x ≤ 0.5; step 0.1) samples were synthesized using stoichiometric amounts of iron, magnesium, and cobalt nitrates, manganese acetate, and citric acid using deionized water as a solvent. The solution was heated with stirring till the water evaporates. The gel was dried at 180 °C for 1 h, sintered at 400 °C for another hour, and then cooled to room temperature [14, 15]. X-ray diffraction patterns were collected using PANalytical diffractometer (X’pert MPD) with Cu-Kα radiation. The X-ray powder diffraction patterns of the samples were collected on a Philips diffractometer (X’pert MPD) with a goniometer using Cu-Kα radiation and a step-scan mode (step size 2θ = 0.02°; counting time 2 s) in the angular range 2θ = 10–80°. LaB6 standard was used to correct instrumental broadening. The crystal structure and microstructure were refined by applying Rietveld profile method [16], using MAUD program [17]. The powder morphology was recorded using transmission electron microscope (TEM, JEOL JEM-100CX) with an accelerating voltage up to 100 kV. Magnetic measurements were carried out with the Quantum Design Model 6000 Vibrating Sample Magnetometer (VSM) option for the physical properties measurement system (PPMS) in magnetic field interval up to 4 T at 10 and 300 K.

3 Results and Discussion

3.1 Structural and Microstructure Analysis

The X-ray diffraction patterns obtained for the prepared samples Mg0.5Mn0.5Fe2−x Co x O4 (0 ≤ x ≤ 0.5) are shown in Fig. 1, where broad diffraction peaks indicate the nano nature of the prepared samples. Phase analysis revealed a single-phase spinel for all samples. The obtained diffraction patterns were used for structural and microstructural analysis applying Rietveld method; the obtained refined structural parameters are given in Table 1 and Fig. 2. X-ray is a poor tool in distinguishing between the atoms close to each other in the periodic table, e.g., Co and Fe. In Rietveld analysis, we used the cation distribution among the A and B sites obtained from magnetic analysis (in next section) as starting values for the refinement process. In order to confirm this suggested cation distribution for the single-phase samples, Bertaut method [18] was applied. Bertaut method relies on the choice of some of few reflections known to be sensitive to cation distributions, such as I 220/ I 400, I 220/ I 422, and I 422/ I 440. The refinements of these chosen reflections were done, by minimizing the R factor defined as [18] follows:

All the observed intensities (I obs) for the corresponding planes have to be corrected first by using Buerger formula [19]:

where Fis the structure factor, P is the multiplicity factor, and L p is the Lorentz polarization factor for each (hkl) [20]. The displacement parameter corrections were neglected due to its small values. The best cations distribution obtained from Bertaut method were subjected to further refinements using Rietveld method and are shown in Table 1, the obtain cation distributions quite match with those obtain from magnetic measurements. Inspecting these cation distributions, one can notice the preference of Mg and Co to reside at the octahedral B site as expected [13, 21].

Figure 2 shows that upon replacing Fe3+ by Co2+, the refined lattice parameter (a) firstly decreases for x = 0.1 and then increases continuously with increasing x. In addition, the crystallite size is reduced from 10.2 nm for x = 0.0 to 5.8 nm for x = 0.1, and then retain more or less the same value (≈5 nm) for the remaining samples. To achieve better view concerning the crystallite size and the morphology, the TEM image of Mg0.5Mn0.5Fe2O4 ferrite nanocrystals was obtained (Fig. 3). From the microstructure, it is clear that the nanoparticles are almost regular in shape and tend to agglomerate due to their mutual magnetic interactions. The matching between the crystallite size revealed from the TEM image and that obtained from Rietveld analysis is quite reasonable.

The ideal value of the positional parameter u is 0.375 for which the arrangement of O2− ions is exactly a cubic closed packing. In actual spinel lattice, this ideal pattern is slightly deformed. For the present Mg0.5Mn0.5Fe2−x Co x O4 system, u < 0.375 (see Table 1) indicating that O2− ions move toward the cations in the tetrahedral A site along the 〈111〉 directions, which means that the tetrahedral interstices contract with a corresponding expansion of the octahedral B sites.

The bond lengths between cations (Me–Me) (b, c, d, e, and f), cations–anion (Me–O) (p, q, r, and s), and the bond angles (θ 1, θ 2, θ 3, θ 4, and θ 5) between the cations and cation–anion (Fig. 4) are given by following relations [22]:

The values of the interatomic distances between cation–anion (Me–O) and cation–cation (Me–Me) for Mg0.5Mn0.5 Fe2−x Co x O4 samples are listed in Table 2. Inspection of Table 2 reveals that the interatomic distances between the cation–anion (p, q, r, and s) and those between the cations (b, c, d, e, and f) change by increasing the Co concentration. This can lead to a change in the superexchange strength (wave function overlapping) with a resulting in the magnetic properties. Table 3 shows the estimated bond angles. From the results, the angles θ 1, θ 2, and θ 5 decrease, while θ 3 and θ 4 increase with higher Co2+ content. The angles θ 1, θ 2, and θ 5 suggest the weakening of the A–B and A–A interactions, while the decrease in θ 3 and θ 4 is indicative strengthening of the B–B interaction in the system. Generally, in ferrimagnetic materials, the increase in A–B (θ 1 and θ 2 angles) decreases the superexchange strength [22]. As Co2+ ions substitute iron in Mg0.5Mn0.5Fe2−x Co x O4 matrix, the above situation are reverse; A–B (θ 1 and θ 2 angles) decrease; hence, superexchange strength is enhanced.

3.2 Magnetic Measurements

Magnetic characterization of the Mg0.5Mn0.5Fe2−x Co x O4 samples was achieved through tracing room-temperature (RT) M–H curves (Fig. 5a) and hysteresis loops at 10 K (Fig. 5b), where both illustrate the variation of the magnetization as a function of the applied magnetic field extending up to 40 kOe. For both cases, the saturation point was not approached. This could be explained when considering the superparamagnetic nature of the produced samples. Hysteresis loops traced at 10 K were used to obtain the saturation magnetization (M s) and the coercive field (H c); values of M s being deduced from the extrapolation of the M vs. 1/H curves to 1/ H → 0 [23]. The variation of saturation magnetization and coercivity with Co2+ content is also illustrated in Fig. 6 where they showed similar trend, despite the inverse proportionality between H c and M s according to Brown’s relation: H c = 2 k 1/ M s [24], where k 1 is the magnetocrystalline anisotropy constant. This may be attributed to the dominating effect of increasing magnetocrystalline anisotropy with increasing Co2+ content.

Saturation magnetization of our samples is controlled mainly by the cation distribution of four elements with three of them being magnetic, namely Fe, Co, and Mn. In addition, the presence of more than one valence state for each of those three elements makes the matter more complicated. During the autocombustion process, oxidation of Mn2+ to Mn3+ [25–27] and Co2+ to Co3+ [28] is quite probable, while electron neutrality allows the subsequent presence of larger radius and less magnetic Fe2+ cation. The crystallite size for the whole samples is quite similar, and the combined effect of surface and local spin canting could be attributed to single canting angle for the magnetic moment of the B site, M B. Spin canting effects highly explain the observed small M s values of the present samples compared to the estimated ones. This behavior was reported for other ferrites and was interpreted in the light of core–surface model [29, 30] According to this model, the crystal grain can be divided into two parts, namely the core and the surface, with significantly different magnetic properties. For the grain surface, the spins possess highly random coordination, which frustrates the superexchange interaction, resulting in a canted spin configuration on the surface. Hence, it does not align completely in the direction of the applied magnetic field. For the core, it has a normal crystal structure, in which the single domain is formed. When the grain size equals the domain size, the observed magnetization originates mainly from the spin rotation of the core.

The M s data at 10 K were used to evaluate approximate values for the experimental magnetic moment per unit formula \(n_{B}^{\text {obs}}\) in units of the Bohr magneton μ B, using the following formula [31]:

These values and the values of lattice parameters (a XRD) were all used to suggest a cation distribution of the samples of this work, as illustrated in Table 4. Values of \(n_{\mathrm {B}}^{\text {obs}} \) are to be compared with the theoretical ones n Neel= M B − M A (obtained from the proposed cation distribution), where M A and M B are the A and B site sublattice magnetic moments, respectively. The values of the magnetic moments of the system constituent elements in terms of μ B are 5, 4, 5, 4, 3, and 0 for Fe3+, Fe2+, Mn2+, Mn3+, Co2+, and others, respectively. In fact, substituting the trivalent Fe ion with the divalent Co ion provides a significant source of nonstoichiometry of the prepared samples. However, the possibility of the oxidation of Mn2+ and/or Co2+ to Mn3+ and Co3+ reduces this effect. Comparison between the variation of both n Neel and \(n_{\mathrm {B}}^{\text {obs}}\) with Co2+ content is illustrated in Fig. 7, which shows a quite similar trend.

The increase of \(n_{\mathrm {B}}^{\text {obs}}\) with x ≤ 0.3 and its subsequent decrease for x > 0.3 could be explained as follows. Substituting Fe3+ with Co2+, which has strong preference of occupying the B site, produces two competing effects. First, it displaces more nonmagnetic Mg2+ cations from the B site to A site and more magnetic Mn2+ from the A site to B site, and thus enhancing magnetization. On the other hand, substituting more Co2+ content increases nonstoichiometry and enhances the probability of producing the nonmagnetic Co3+ with the associated less magnetic Mn3+and Fe2+ cations, all of which occupy the B site. Moreover, the small observed values of \(n_{\mathrm {B}}^{\text {obs}} \) compared to those of n Neel is attributed to the surface and local spin canting effects related to the small crystallite sizes of the present samples. The Yafet–Kittel [32] magnetic ordering of the local moments may further explain the small values of \(n_{\mathrm {B}}^{\text {obs}} \).

The saturation magnetization in Yafet–Kittle model is given by M s= M B cos θ Y−K − M A, where θ Y−K is a Yafet–Kittel canting angle, which is estimated for our samples and are listed in Table 4, where their large values are attributed to the small crystallite sizes.

Further confirmation of the suggested cation distribution was obtained by applying a theoretical estimation of the lattice parameter for each composition and comparing it with that obtained by XRD analysis. For each sample, the average ionic radii per molecule of the tetrahedral and octahedral sites, r A and r B were calculated based on the suggested cation distribution of Table 4, using the following formulae [23]:

where α i is the concentration of the element i of ionic radius r i on the respective side. The ionic radii for Mg2+ (0.57 and 0.72 Å), Mn2+ (0.66 and 0.83 Å), Fe3+ (0.49 and 0.645 Å), and Co2+ (0.58 and 0.745 Å) are taken with reference to both sites, with the first value corresponds to that of the A site. Both Mn3+ (0.645 Å), Co3+ (0.61 Å), and Fe2+ (0.78 Å) were assumed to occupy only the B site. Values of r A and r B are shown in Fig. 8, where the variation of r A with Co content is quite similar to that of \(n_{\mathrm {B}}^{\text {obs}} \), which supports the suggested cation distribution. Theoretical values of the lattice parameter were then calculated from the following relation [23]:

where R O is the ionic radius of oxygen. The lattice parameters estimated from the suggested cation distribution match to less than 0.0001 % of that acquired from Rietveld analysis.

4 Conclusion

Single-phase nanocrystalline Mg0.5Mn0.5Fe2−x Co x O4 (0 ≤ x ≤ 0.5) samples were synthesized by citrate precursor method. Rietveld analysis revealed that the present system is neither normal nor inverse with a clear preference of Mg and Co to reside at the octahedral B site and Mn to reside at the A site as expected. The suggested cation distribution (obtained from Rietveld analysis then confirmed by Bertaut method and theoretical lattice parameter) accounts quite well for magnetization behavior and the variation of lattice parameter. The crystallite size decreases upon increasing Co content, while the refined lattice parameter (a) firstly decreases for x = 0.1 and then increases continuously for the higher values. Both saturation magnetization and coercivity increase with Co content up to x = 0.3 then decrease slightly. The bond angles θ 1, θ 2, and θ 5 decrease, while the angles θ 3 and θ 4 increase with introducing Co2+ in the matrix Mg0.5Mn0.5Fe2−x Co x O4.

References

Iftikhar, A., Islam, M.U., Awan, M.S., Ahmad, M., Naseem, S., Iqbal, M.A.: J. Alloy. Comp. 601, 116 (2014)

Jeyadevan, B., Chinnasamy, C.N., Shinoda, K., Tohji, K.: J. Appl. Phys 93, 8450 (2003)

Azadmanjiri, J.: J. Non-Cryst. Solid 353, 4170 (2007)

Gubbala, S., Nathani, H., Koizol, K., Misra, R.D.K.: Physica B 348, 317–328 (2004)

Bradley, F.N.: Materials for magnetic functions. Hayden Book Co. Inc., New York (1971)

Puri, B.K., Singh, M., Sud, S.P.: J. Mater. Sci. 29, 2182–2186 (1994)

Singh, M., Sud, S.P.: Mater. Sci. Eng. B83, 180 (2001)

Heiba, Z.K., Hascicek, Y.S.: J. Appl. Cryst 38(2), 306 (2005)

Heiba, Z.K., Arda, L., Bakr Mohamed, M., Al-Jalali, M.A., Dogan, N.: J. Supercond. Nov. Magn. 26, 3299 (2013)

Heiba, Z.K., Bakr Mohamed, M., Fuess, H.: Cryst. Res. Technol. 47, 535 (2012)

Kumar, G., Kanthwal, M., Chaulan, B.S., Singh, M.: Indian J. Pure Appl. Phys. 44, 930 (2006)

Verma, S., Chand, J., Batoo, Kh.M., Singh, M.: J. Alloys Comp. 551, 715 (2013)

Heiba, Z.K., Mostafa, N.Y., Abd-Elkader, O.H.: J. Magn. Magn. Mater. 368, 246 (2014)

Heiba, Z.K., Mohamed Bakr Mohamed, M.A., Ahmed, M.A.A., Moussa, H.H., Hamdeh, J.: Alloy. Comp. 586, 773 (2014)

Heiba, Z.K., Bakr Mohamed, M., Hamdeh, H.H., Ahmed, M.A.: J. Alloy. Comp. 618, 755 (2015)

Lutterotti, L.: Maud 2.33, http://www.ing.unitn.it/~maud/

Rodriguez-Carvajal, J.: PhysicaB(Amsterdam) 192, 55 (1993)

Weil, L., Bertaut, E.F., Bochirol, L.: J. Phys. Radium 11, 208 (1950)

Buerger, M.J.: Crystal structure analysis. Wiley-Interscience, New York (1960)

Cullity, B.D.: The elements of X-ray diffraction. Addison Wesley), Reading (1956)

Ichiyanagi, Y., Kubota, M., Moritake, S., Kanazawa, Y., Yamada, T., Uehashi, T.: J. Magn. Magn. Mater. 310, 2378–2380 (2007)

Karimi, Z., Mohammadifar, Y., Shokrollahi , H., KhamenehAsl, Sh., Yousefi, Gh., Karimi, L.: J. Magn. Magn. Mater. 361, 150 (2014)

Maher Wahba, A., Bakr Mohamed, M.: Ceram. Int. 40, 6127 (2014)

Bakr Mohamed, M., Yehia, M.: J. Alloy. Comp. 615, 181 (2014)

Rath, C., Sahu, K.K., Anand, S., Date, S.K., Mishra, N.C., Das, R.P.: J. Magn. Magn. Mater. 202, 77 (1999)

Thakur, A., Mathur, P., Singh, M.: J. Phys. Chem Solids 68, 378 (2007)

Bakr Mohamed, M., Maher Wahba, A.: Ceram. Int. 40, 11773 (2014)

Bakr Mohamed, M., Maher Wahba, A., Yehia, M.: Mater. Sci. Eng. B 90, 52 (2014)

Li, J., Yuan, H., Li, G., Liu, Y., Leng, J.: J. Magn. Magn. Mater. 322, 3396 (2010)

Bakr Mohamed, M., El-Sayed, K.: Mater. Res. Bull 48(5), 1778 (2013)

Shaikh, P.A., Kambal, R.C., Rao, A.V., Kolekar, Y.D.: J. Alloys Compd. 492, 590 (2010)

Alvarez, G., Montiel, H., Barron, J.F., Gutierrez, M.P., Zamorano, R.: J. Magn. Magn. Mater. 322, 348 (2010)

Author information

Authors and Affiliations

Corresponding author

Additional information

Compliance with Ethical Standards

We declare that this is an original manuscript, and has not submitted to any other scientific journal inside the country or outside. In addition, we declare that this article has been written by us (the stated authors). We are aware of its content and approve its submission. We confirm that this manuscript (if accepted), will not be published in the same form, in any language, without the written consent of the publisher.

Conflict of interests

There is no conflict of interest.

Rights and permissions

About this article

Cite this article

Heiba, Z.K., Mohamed, M.B., Wahba, A.M. et al. Magnetic and Structural Properties of Nanocrystalline Cobalt-Substituted Magnesium–Manganese Ferrite. J Supercond Nov Magn 28, 2517–2524 (2015). https://doi.org/10.1007/s10948-015-3069-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-015-3069-7