Abstract

The structure modification of metal–organic frameworks (MOFs) is a promising technique to enhance its selective adsorption of carbon dioxide at room temperatures. However, to date, little is known on the structure-property relationship of MOFs for carbon capture. In this work, the effects of chemical composition of MOFs on selective adsorption of carbon dioxide were studied systematically. A series of aluminum-based MIL-53 with similar formula units but different organic ligands, Al(OH)BDC-X [BDC = terephthalate, X = H, NH2, NO2, 2(CH3)], were prepared and employed to the selective adsorption of CO2/N2. It was found that the Al(OH)BDC-X series with various organic ligands affected the CO2 capacity significantly. The decorations of functional groups with strong polarity on the BDC links remarkably enhanced the CO2 uptakes. The experimental results were in good agreement with the equivalent adsorption heat calculations, which showed that the CO2 affinity of the ligands with polarity groups were thermodynamically more favored than those with non-polarity ones on the MOF structures. The interesting findings could provide a potential way to fabricate new metal organic frameworks with high carbon dioxide capture capacities at room temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Rising levels of atmospheric CO2 from anthropogenic emissions have motivated the development of new technologies for CO2 capture and conversion. Designing and developing materials for CO2 capture is one of the grand challenges in the 21st century, among which the separation of CO2 from N2 in flue gas is particularly important [1,2,3,4,5,6]. At present, the state-of-the-art technology is to use alkanolamine aqueous solution to capture CO2 from the post-combustion flue gas [7]. However, this process involves the formation of carbon-nitrogen bonds via the chemical interaction between amine functional groups and CO2, causing the high cost for the regeneration of the adsorbent (the amine solution). Therefore, it is urgent to develop efficient materials and related processes for CO2 capture that can effectively reduce the regeneration cost. Compared with amine-based absorption systems, physical sorbents is a more promising energy-efficient alternative. Therefore, great efforts have been devoted to developing physical sorbents for this purpose recently [8,9,10,11,12,13,14]. Still, limit material is capable of satisfying the criteria of 90% CO2 capture at less than 35% increase in the cost of electricity, established by the Department of Energy (DOE)/National Energy Technology Laboratory (NETL) [15,16,17].

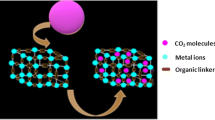

Several classes of materials, including ionic liquids (ILs), zeolites, porous carbons, porous organic polymers, covalent organic frameworks (COFs) and metal–organic frameworks (MOFs), have been developed for CO2 capture and conversion applications [18,19,20,21,22,23,24,25,26,27,28]. Particularly, MOFs have shown as a new class of crystalline porous materials with excellent performance in CO2 capture, owing to their unique structural features and tunable physical and chemical properties. Especially, the functionalizable linkers, allowing for the incorporation of different capture sites, enable a fine-tuned properties of MOFs, making them promising materials for CO2 capture. Enhancement of the interactions between the frameworks of MOFs and CO2 has been developed as an efficient approach for CO2 capture from CO2/N2 gas mixtures.

A large number of MOFs have been claimed as promising materials for CO2 capture, but only a few MOFs have real industrial interests [29,30,31,32]. Compared with other MOFs, Aluminum-based MIL-53 stands out thanks to their high stability (for water, NOx, SOx, O2), low-cost and nontoxic [31, 33, 34]. Another attractive aspect is that the adsorption and separation performance of CO2/N2 can be improved by introducing suitable functional groups [32, 35,36,37]. To understand the key factors that affect the CO2 capture in essence, Study the adsorption mechanism of MOFs materials is needed. However, to date, such a systematic study on the effects of structural and surface properties of MOFs is scarce [38].

Here we attempt to disclose the correlation between the chemical composition of MOFs (e.g., organic linker) and the CO2/N2 selective adsorption. To achieve this, we chose a series of terephthalate-based MOFs (MIL-53 s) that had very close surface areas and chemical formula units. Four MIL-type MOFs, with similar formula unit (Al(OH)BDC-X, X = H, NH2, NO2, and 2(CH3), BDC = terephthalate) were investigated to elucidate the influence of organic ligands on CO2/N2 selective adsorption. The CO2 and N2 adsorption isotherms of the Al(OH)BDC-X series materials were measured at 273 and 243 K. In comparing their CO2 and N2 uptake, correlations with their chemical compositions were discussed. Through this undertaking, the surface requirements of MOFs for a high CO2/N2 selective adsorption may be formulated, and such understanding will facilitate a more rational design of new MOF materials for CO2/N2 selective adsorption.

2 Experimental

The reagents used in materials preparation were commercially available and without further purification. These MOF materials were initially synthesized and activated according to the previous reports [35,36,37].

2.1 Synthesis of Al(OH)BDC -X [X = H, NO2, NH2, 2(CH3)] materials

2.1.1 MIL-53(Al) (Al(OH)BDC-H)

The MIL-53(Al) material was synthesized hydrothermally under autogeneous pressure according to the reported procedures [35]. In a typical synthesis, the metal salt of Al(NO3)3·9H2O was heated with terephthalic acid (H2BDC) in H2O with the molar ratio reported in the literature. The resultant solution was introduced into a teflon-lined stainless steel autoclave and then heated at 493 K for 72 h. The obtained MIL-53(Al) solids were dried overnight under vacuum at 573 K.

2.1.2 MIL-53(Al)-2CH3 (Al(OH)BDC-2(CH3))

The MIL-53(Al)-2(CH3) material was synthesized hydrothermally under autogeneous pressure according to the reported procedures with slight changes [36]. In a typical synthesis, the metal salt of AlCl3·6H2O was heated with 2,5-dimethylterephthalic acid (BDC-2(CH3)) in H2O with the molar ratio reported in the literature. The resultant solution was introduced into a teflon-lined stainless steel autoclave and then heated at 483 K for 12 h. The obtained MIL-53(Al)-2CH3 solids were dried overnight under vacuum at 423 K.

2.1.3 MIL-53(Al)-NH2 (Al(OH)BDC-NH2)

The MIL-53(Al)-NH2 material was synthesized hydrothermally under autogeneous pressure according to the reported procedures [37]. In a typical synthesis, the metal salt of Al(NO3)3 was heated with 2-aminoterephthalic acid (HBDC-NH2) in H2O with the molar ratio reported in the literature. The resultant solution was introduced into a teflon-lined stainless steel autoclave and then heated at 403 K for 72 h. The obtained MIL-53(Al)-NH2solids were dried overnight under vacuum at 423 K.

2.1.4 MIL-53(Al)-NO2 (Al(OH)BDC-NO2)

The MIL-53(Al)-NO2 material was synthesized hydrothermally under autogeneous pressure according to the reported procedures [38]. In a typical synthesis, the metal salt of Al(NO3)3·9H2O was heated with 2-nitroterephthalic acid (HBDC-NO2) in H2O with the molar ratio reported in the literature. The resultant solution was introduced into a teflon-lined stainless steel autoclave and then heated at 443 K for 12 h. The obtained MIL-53(Al)-NO2 solids were dried overnight under vacuum at 423 K.

2.2 Characterization techniques

Powder X-ray diffraction (PXRD) patterns of the samples were obtained on a PW3040/60 X’ Pert PRO (PANalytical) diffractometer using Cu Kα radiation (40 kV, 40 mA, λ = 0.15432 nm). IR spectra were recorded on an ATI Matheson Genesis in the spectral range 4000 − 400 cm−1 using the KBr disk method. Thermogravimetric (TG) analyses were carried out in air (75 mL/min, 35–800 °C, 4 °C/min) on a Netzsch STA-409CD. The BET surface area measurements were performed with N2 adsorption/desorption isotherms at 77 K on a Belsorp-max instrument. The samples were outgassed under vacuum at 423 K for 24 h prior to measurements.

2.3 Gas adsorption measurements

Carbon dioxide and nitrogen adsorption isotherm at 273 and 243 K was measured using a static volumetric technique with an automatic adsorption apparatus (Belsorp-max, Japan). The sample holder was immersed in an ice water bath at 273 K (± 0.2 K) or ethanol water bath at 243 K(± 0.2 K). The 243 K constant temperature bath is made by mixing ethanol and water (70/30, v/v) in dewar flask and then cooling it to 243 K with liquid nitrogen. The good thermal insulation performance of dewar flask can keep the ethanol water bath at 243 K for 12 h. Typically, approximately 200 mg of sample was used for each gas adsorption measurement. Prior to the introduction of CO2 or N2 (99.99%), the samples were degassed in vacuum (at 10− 4 torr) at 423 K for at least 12 h to remove any residual guest molecules in order to obtain the highest gas adsorption capacity.

2.4 Equivalent adsorption heat calculations

The equivalent adsorption heat of the Al(OH)BDC -X series materials was calculated by fitting the static adsorption isotherm and using Clausius-Claperyron equation. The equivalent adsorption heat (Qst, kJ/mol) was calculated using the following equation (Eq. 1).

where p is the equilibrium adsorbate pressure (kPa), T is the adsorption temperature (K), R is the molar gas constant (8.314 J/(mol K)), and na is the adsorption capacity (cm3/g).

3 Results and discussion

3.1 Characterization of Al(OH)BDC-X series materials

Powder XRD patterns for different Al(OH)BDC-X (X = H, NO2, NH2, 2(CH3)) materials are shown in Fig. 1. All the materials show a characteristic structure of the MIL-53(Al) [39, 41]. The diffraction peaks of Al(OH)BDC-X (X = H, NO2, NH2, 2(CH3)) materials were sharp and intense, indicating their highly crystalline nature. No impurity peaks were observed, confirming the high purity of the products.

The FT-IR spectra of the Al(OH)BDC-X (X=H, NO2, NH2, 2(CH3)) materials are shown in the Figs. S1–S4 (see supporting information). In the IR spectra of all the compounds, the strong absorption bands due to asymmetric and symmetric CO2 stretching vibrations of the coordinated BDC-X linkers are located in the regions 1597–1616 cm−1 and 1415–1463 cm−1, respectively [35]. The C–H stretching vibration of the -CH3 group attached with the BDC-2CH3 linker exhibits weak absorption bands at about 2970 and 2930 cm−1 in the IR spectra of Al(OH)BDC-2(CH3) [36]. The broad signals between 3000 and 2500 cm−1 in the IR spectra of Al(OH)BDC-NH2 are due to the aminoterephthalic acid in the pores [37].

To examine the thermal stability of all Al-MIL-53-X compounds, thermogravimetric analyses (TGA) were performed on all the compounds in air atmosphere. On the basis of the TG analyses, all the compounds are thermally stable up to 325–450 °C. In the TG curves of all the compounds (Supporting Information, Figs. S5–S8), any weight loss step that occurs below the decomposition temperature of the frameworks can be assigned to the removal of the occluded guest molecules (H2O, H2BDC-X linkers).

The specific surface areas of the Al(OH)BDC-X (X = H, NO2, NH2, 2(CH3)) were determined by N2 physisorption measurements at 77 K (Fig. 2). The isotherms are identified as type I, which is characteristic of micro-porous materials. The BET surface areas, Langmuir surface areas, pore size and micro-pore volume of the different samples are summarized in Table 1. Except Al(OH)BDC-2(CH3), other Al(OH)BDC-X (X = H, NO2, NH2) showed similar N2 isotherms with a similar BET surface area and micro-pore volume in the range of 850–1100 m2/g and 0.31–0.38 cm3/g. The BET surface area and micro-pore volume of the Al(OH)BDC-2(CH3) was 741 m2/g and 0.19 cm3/g, which is slightly lower than the value obtained by Norbert Stock and coworkers on the material [36, 40].

Nitrogen adsorption (solid symbols) and desorption (empty symbols) isotherms for Al(OH)BDC-X (X = H, NO2, NH2, 2(CH3)) measured at 77 K. Al(OH)BDC-H (black, squares), Al(OH)BDC-NH2 (red, down triangles), Al(OH)BDC-NO2 (blue, up triangles) and Al(OH)BDC-2(CH3) (magenta, circles) (Color figure online)

Figure 3 is the pore size distributions of the Al(OH)BDC-X series materials calculated by the density functional theory (DFT) model, it shows that most of the pores fall into the size range of 0.6 to 0.8 nm. Among them, Al(OH)BDC-NO2 and Al(OH)BDC-2(CH3) have the smallest pore size, and the pore size of Al(OH)BDC-H (~ 0.8 nm) is coincident with the literature data [42,43,44].

3.2 Nitrogen and carbon dioxide isotherms

Figure 4 shows the nitrogen and carbon dioxide adsorption isotherms at 273 and 243 K for the Al(OH)BDC-X (X = H, NO2, NH2, 2(CH3)) samples. The N2 and CO2 sorption properties of the Al(OH)BDC-X materials at 100 kPa are summarized in Table 2. It can be seen that the Al(OH)BDC-X series with various organic ligands affected the CO2 and N2 capacity significantly. Al(OH)BDC with functional groups can improve the adsorption capacity of N2 and CO2 simutaneously, with a more significant enhancement of CO2 adsorption. It should be noted here that it seems ostensibly that the adsorption capacity of the Al(OH)BDC-2(CH3) is lower than that of Al(OH)BDC-H, but the specific surface area and micro-pore volume of Al(OH)BDC-2(CH3) synthesized in this paper are much lower than those of Al(OH)BDC-H, and the micro-pore volume of the Al(OH)BDC-2(CH3) is even only half of the Al(OH)BDC-H, while the N2 and CO2 uptake of the Al(OH)BDC-2(CH3) is more than half of the Al(OH)BDC-H. Therefore, it proves that the introduction of CH3 can improve the adsorption capacity of Al(OH)BDC-H for CO2 and N2. A similar conclusion was drawn in Zhong and co-works study, where the framework charges of the MOFs can effectively increase its adsorption capacity of CO2 [45]. The high CO2 adsorption capacity is attributed to the synergistic effect of pore structure and surface chemical properties of materials, and abundant micro-pores and nitrogen sites can significantly increase CO2 adsorption capacity [46,47,48]. This is also confirmed by the adsorption-desorption experiment (Fig. S9) and repeated performance experiment (Fig. S10) of Al(OH)BDC-NH2.

Table 2 showed the descending order of CO2 uptake values at 100 kPa and 273 K is Al(OH)BDC-NH2 (110 cm3/g, 21.6 wt%) > Al(OH)BDC-NO2 (90.1 cm3/g, 17.7 wt%) > Al(OH)BDC-H (35.7 cm3/g, 7.0 wt%) > Al(OH)BDC-2(CH3) (26.7 cm3/g, 5.2 wt%). The CO2 sorption capacities of the Al(OH)BDC-NH2 is larger than the value of the Kim and co-works (90 mg/g equal to 9 wt%) [49]. Except Al(OH)BDC-H and Al(OH)BDC-2(CH3), the adsorption capacity of the Al(OH)BDC-X materials in this paper were higher than that of the Norbert group (4-NO2 (10.8 wt%), 298 K) [36] and the Abid group (-NH2 (75 cc/g), 273 K) [50]. The adsorption capacity of Al(OH)BDC-H is also lower than that of references [51,52,53] (6.58wt% at 303 K [51], 7.4 wt% at 288 K [52], 64 cm3/g at 273 K [53]),and Al(OH)BDC-2(CH3) is also lower than that of the Norbert group (6.8 wt% at 298 K) [36], which may be due to the fact that its micro-pore volume is half of that in the literature, because the linker of the Al(OH)BDC-2(CH3) in this paper is 2,5-dimethyl-1,4-Benzenedicarboxylicacid, while 2-Methylterephthalic acid is used by the Norbert group.

The order of CO2 adsorption capacity of Al(OH)BDC-X series materials at 100 kPa and 243 K is consistent with that at 273 K, Al(OH)BDC-NH2 > Al(OH)BDC-NO2 > Al(OH)BDC-H > Al(OH)BDC-2(CH3). The adsorption capacity of CO2 at low pressure (100 kPa) is closely related to the polarity of surface groups. The experimental results show that the materials modified by functional groups can improve their CO2 adsorption capacity, and even the introduction of methyl with weak polar group can improve the CO2 adsorption capacity of materials, which may be due to the fact that the introduction of methyl can enhance the interaction force between CO2 and aromatic hydrocarbons, which is also confirmed by theoretical calculation [47]. Among them, Al(OH)BDC-NH2 has the highest CO2 adsorption capacity, which may be due to the strong dipole-quadrupole interaction between Al(OH)BDC-NH2 and CO2 molecules with high polarizability and fourth-order moment. Torrisi and Vaidhyanathanalso reported similar results that the nitrogen-containing materials can produce strong dipole-quadrupole interaction with CO2 [41, 54].

In addition, the interaction between the functional group on the pore surface and CO2 will also increase the selectivity of CO2. It is an indisputable fact that functionalized MOFs can improve its selective adsorption performance for CO2 [55, 56]. Table 3 shows the comparison of CO2/N2 selection factors of Al(OH)BDC-X series materials [49,50,51, 49,50,51]. The order of selective separation coefficient of CO2/N2 is that the separation coefficient of polar functional groups is higher than that of nonpolar or weakly polar ones, which is mainly because the polarity and fourth moment of CO2 are higher than that of N2, resulting in higher interaction force between CO2 and material surface than that of N2 [46, 59]. Table 3 also shows that the selectivity in this paper is similar to that in most literatures, but lower than that in the Abid group [50]. They used different co-solvents to synthesize a series of amine-MIL-53 materials, the separation factors of amine-MIL-53 series materials for CO2/N2 are quite different, which indicates that the solvent in the synthesis of the amino-MIL-53 material has a great influence on the CO2/N2 selectivity of the materials. In summary, introducing functional groups into MOF materials will enhance the CO2/N2 separation performance of the materials, especially the introduction of amino group.

Figure 5 show that the adsorption ratio of the Al(OH)BDC-X series material for CO2 at 273 K is greater than that at 243 K. This is mainly due to the weakening of the interaction force between Al(OH)BDC-X and CO2 at low temperature, which increases the influence of micro-pore volume and pore size on CO2 adsorption capacity, and pore diameter has a greater influence on CO2 adsorption capacity.

The Henry’s law constants for CO2 adsorption is shown in Table 4, The Henry’s constant KH in the Henry’s law region was calculated by the standard procedures [60]. The Henry constant in Table 4 is expressed in three different units to facilitate comparison with previous experimental results. The Henry constant of CO2 in this paper is larger than that of most Silica, Silicalite, MOF, ZIF and MIL in the room temperature range, but smaller than X-type zeolites [61, 62]. So compared with the literature, Al(OH)BDC-X series materials used in this paper have high Henry constant for CO2, which also proves that these materials have strong interaction with CO2 and are good CO2 adsorbents.

3.3 The equivalent adsorption heat

The experimental equivalent adsorption heat of N2 showed the following order in terms of appended functional groups (Fig. 6a): -NH2 (18–20 kJ/mol) > -NO2 (17–18 kJ/mol) > -H (15–17 kJ/mol) > -2(CH3) (14–15 kJ/mol). It is also showed that at zero coverage, Al(OH)BDC-X shows a high equivalent adsorption heat, and then drops sharply. The variation in N2 sorption could potentially also arise from a difference in pore size distribution, with small pore sizes known to increase the adsorption capacity, as mentioned before. In particular, Al(OH)BDC-NO2 has the highest zero adsorption heats, which may be due to its smallest pore diameter (0.65 Å). This extremely small pore size leads to stronger host guest interactions. In addition, it could be possible that NO2-groups of adjacent linker molecules could interact with the gas molecules.

The experimental equivalent adsorption heat of CO2 showed the following order in terms of appended functional groups (Fig. 6b): -NH2 (30–32 kJ/mol) ≈ -NO2 (30–32 kJ/mol) > -H (24–26 kJ/mol) > -2(CH3) (18–19 kJ/mol). It shows that with the increase of surface coverage, the adsorption heat of Al(OH)BDC-X series materials for CO2 decreases sharply at first, and then tends to be flat. The adsorption heat by Al(OH)BDC-NH2 is the highest in this series at zero coverage (ca. 57 kJ/mol). This is similar to the value of Kim’s team (60 kJ/mol) [49], but higher than Abid’s team (28 kJ/mol) [53]. The Qst values of MIL-53(Al) obtained from the Sips and Toth models (Table 3) for CO2 (25 kJ/mol) and N2 (13 kJ/mol) are in agreement with previously published data [51, 62, 63]. It is noteworthy that the nitro and amine group functionalized network, show the highest adsorption heat for CO2. The results show that the polar groups in the materials can effectively improve the adsorption heat of CO2, increase the adsorption capacity of CO2, and then effectively separate CO2/N2. This is consistent with the experimental and theoretical results in the literature [46, 59, 64].

In a word, the adsorption heat of Al(OH)BDC-X series materials for CO2 is closely related to its functional group’s polarity. The greater the polarity, the greater the adsorption heat, so it is very important to choose appropriate functional groups to improve the adsorption capacity of CO2 and the selectivity of CO2/N2, which is similar to that reported in literature [59]. At the same time, their adsorption heat is between 25 and 35 kJ/mol, this medium adsorption heat is suitable for gas adsorption and separation application. This adsorption heat higher than that generated by physical adsorption (usually ~ 20 kJ/mol) is attributed to rich micro-pores and strong dipole-quadrupole interaction between CO2 molecule and micro-porous polar framework.

4 Conclusions

The effects of organic ligand of MOFs on the selection adsorption of CO2/N2 of the materials have been elucidated. A series of MOFs, Al(OH)BDC with formula units but different organic linkers were prepared and employed as the receptors for carbon dioxide. It was found that the MOFs with different organic ligand affected the storage capacities of MOFs significantly. The decoration of functional groups with strong polarity on the organic linkers in MOFs could facilitate the adsorption of carbon dioxide on the ligands and thus enhance the carbon dioxide uptakes. The experimental results were in line with the equivalent adsorption heat calculations, which showed that the adsorption heat of the MOFs with polarity groups were much higher than those with non-polarity ones. Our findings could provide a potential way to fabricate new metal organic frameworks with high selective adsorption.

References

Z. Zhang, Y. Zhao, Q. Gong, Z. Li, J. Li, Chem. Commun. 49, 653 (2013)

Z. Shi, Y. Tao, J. Wu, C. Zhang, H. He, L. Long, Y. Lee, T. Li, Y.-B. Zhang, J. Am. Chem. Soc. 142, 2750 (2020)

A. Kumar, D.G. Madden, M. Lusi, K.J. Chen, E.A. Daniels, T. Curtin, J.J. Perry, M.J. Zaworotko, Angew. Chem. Int. Ed. 54, 14372 (2015)

I. Luz, M. Soukri, M. Lail, Chem. Sci. 9, 4589 (2018)

H. Daglar, S. Keskin, J. Phys. Chem. C 122, 17347 (2018)

Z. Li, G. Xu, B. Liu et al., Energies 8, 11531 (2015)

G.T. Rochelle, Science 325, 1652 (2009)

P. Murge, S. Dinda, S. Roy, Langmuir 35, 14751 (2019)

A.M. Alloush, M.M. Abdelnaby, K.E. Cordova, N.A.A. Qasem, B.A. Al-maythalony, A. Jalilov, Y. Mankour, O. Hamouz, Micro. Meso. Mater. 305, 110391 (2020)

Z. Yuan, M.R. Eden, R. Gani, Ind. Eng. Chem. Res. 55, 3383 (2016)

J.M. Yu, L.H. Xie, J.R. Li, Y.G. Ma, J.M. Seminario, P.B. Balbuena, Chem. Rev. 117, 9674 (2017)

J. Li, P.M. Bhatt, J. Li, M. Eddaoudi, Y. Liu, Adv. Mater. 32, 2002563 (2020)

O.F. Altundal, C. Altintas, S. Keskin, J. Mater. Chem. A 8, 14609 (2020)

J.R. Li, J. Sculley, H.C. Zhou, Chem. Rev. 112, 869 (2012)

R.K. Pachauri, A. Reisinger, IPCC Fourth Assessment Report (Intergovernmental Panel on Climate Change, 2007)

S. Krachuamram, K. Chayakul, N. Kamonsutthipaijit, Micro. Meso. Mater. 310, 110632 (2021)

K. Sumida, D.L. Rogow, J.A. Mason, T.M. McDonald, E.D. Bloch, Z.R. Herm, T.H. Bae, J.R. Long, Chem. Rev. 112, 724 (2012)

B. Zheng, J. Bai, J. Duan, L. Wojtas, M.J. Zaworotko, J. Am. Chem. Soc. 133, 748 (2011)

G. Sneddon, A. Greenaway, H.H.P. Yiu, Adv. Energ. Mater. 4, 1301873 (2014)

J. Wang, S. Zhang, G. Cui, Chem. Soc. Rev. 45, 4307 (2016)

Y. Li, L. Li, J. Yu, Chem. 3, 928 (2017)

Y. Xie, T.T. Wang, X.H. Liu et al., Nat. Commun. 4, 1960 (2013)

Z. Zhang, Y. Zhao, Q. Gong, Z. Li, J. Li. Chem. Commun. 49, 653 (2013)

Z. Qiao, K. Zhang, J. Jiang, J. Mater. Chem. A 4, 2105 (2016)

R. Vaidhyanathan, S.S. Iremonger, G.K.H. Shimizu, P.G. Boyd, S. Alavi, T.K. Woo, Science 330, 650 (2010)

M.J. Lashaki, S. Khiavi, A. Sayari. Chem. Soc. Rev. 48, 3320 (2019)

H.R. Abid, Z.H. Rada, X. Duan, H. Sun, S. Wang, Energ. Fuel 32, 4502 (2017)

H. Yin, J. Wang, Z. Xie et al., Chem. Commun. 50, 3699 (2014)

G. Singh, J. Lee, A. Karakoti, R. Bahadur, J. Yi, D. Zhao et al., Chem. Soc. Rev. 49, 4360 (2020)

C.A. Trickett, A. Helal, B.A. Al-Maythalony, Z.H. Yamani, K.E. Cordova, O.M. Yaghi, Nat. Rev. Mater. 2, 17045 (2017)

L. Liang, C. Liu, F. Jiang et al., Nat. Commun. 8, 1233 (2017)

A.S. Munn, R.S. Pillai, S. Biswas et al., Dalton Trans. 45, 4162 (2016)

A. Vimont, A. Travert, P. Bazin et al., Chem.Commun. 43, 3291 (2007)

S. Vaesen, V. Guillerm, Q. Yang et al., Chem. Commun. 49, 10082 (2013)

T. Loiseau, C. Serre, C. Huguenard, G. Fink, F. Taulelle, M. Henry, T. Bataille, G. Férey, Chem. Eur. J. 10, 1373 (2004)

S. Biswas, T. Ahnfeldt, N. Stock, Inorg. Chem. 50, 9518 (2011)

T. Ahnfeldt, D. Gunzelmann, T. Loiseau et al., Inorg. Chem. 48, 3057 (2009)

X. Yan, T. Xue, Y. Liu et al., New Chem. Mater. 44, 85 (2016)

C. Falaise, C. Volkringer, J. Facqueur et al., Chem. Commun. 49, 10320 (2013)

W. Cao, Y. Li, L. Wang et al., J. Phys. Chem. C 115, 13829 (2011)

A. Torrisi, R.G. Bell, C. Mellot-Draznieks, Micro. Meso. Mater. 168, 225 (2013)

C. Serre, F. Millange, C. Thouvenot, M. Nogues, G. Marsolier, D. Louer, G. Ferey, J. Am. Chem. Soc. 124, 13519 (2002)

T. Loiseau, C. Serre, C. Huguenard, G. Fink, F. Taulelle, M. Henry, T. Bataille, G. Ferey, Chem.-Eur. J. 10, 1373 (2004)

W. Wang, L. Lin, H. Qi, W. Cao et al., Chin. J. Catal. 42, 824 (2021)

C. Zheng, D. Liu, Q. Yang, C. Zhong, J. Mi, Ind. Eng. Chem. Res. 48, 10479 (2009)

A. Torrisi, C. Mellot-Draznieks, R.G. Bell, J. Chem. Phys. 132, 044705 (2010)

A. Torrisi, C. Mellot-Draznieks, R.G. Bell, J. Chem. Phys. 130, 194703 (2009)

M.A. Hussain, Y. Soujanya, G.N. Sastry, J. Phys. Chem. C 119, 23607 (2015)

J. Kim, W.Y. Kim, W.S. Ahn, Fuel 102, 574 (2012)

H. Abid, Z.H. Rada, X. Duan et al., Energ. Fuel 32, 4502 (2018)

B.C.R. Camacho, R.P.P.L. Ribeiro, I. A. A. C. Esteves. et al., Sep. Purif. Technol. 141, 150 (2015)

S. Couck, J.F.M. Denayer, G.V. Baron et al., J. Am. Chem. Soc. 131, 6326 (2009)

H.R. Abid, Z.H. Rada, J. Shang, S.B. Wang, Polyhedron 120, 103 (2016)

R. Vaidhyanathan, S.S. Iremonger, G.K.H. Shimizu et al., Science 330, 650 (2010)

P. Deria, S. Li, H. Zhang, R.Q. Snurr, J.T. Hupp, O.K. Farha, Chem. Commun. 51, 12478 (2015)

J.R. Li, J. Yu, W. Lu, L.B. Sun, J. Sculley, P.B. Balbuena, H.C. Zhou, Nat. Commun. 4, 1538 (2013)

S. Couck, E. Gobechiya, C.E.A. Kirschhock et al., ChemSusChem 5, 740 (2012)

P. Mishra, H.P. Uppara, B. Mandal, S. Gumma, Ind. Eng. Chem. Res. 53, 19747 (2014)

R. Dawson, D.J. Adams, A.I. Cooper, Chem. Sci. 2, 1173 (2011)

S.A. Peter, J. Sebastian, R.V. Jasra, Ind. Eng. Chem. Res. 44, 6856 (2005)

M. Pera-Titus, Chem. Rev. 114, 1413 (2014)

P. Rallapalli, K.P. Prasanth, D. Patil, R.S. Somani, R.V. Jasra, H.C. Bajaj, J. Porous Mater. 18, 205 (2011)

J. Möllmer, M. Lange, A. Möller, C. Patzschke, K. Stein, D. Lässig, J. Lincke, R. Gläser, H. Krautscheid, R. Staudt, J. Mater. Chem. 22, 10274 (2012)

A. Torrisi, R.G. Bell, C. Mellot-Draznieks, Cryst. Growth Des. 10, 2839 (2010)

Acknowledgements

This work was supported by the Educational Commission of Hunan Province (19B463), the Research Startup Foundation of Jishou University (No.21), and the Collaborative Innovation Center of Manganese-Zinc-Vanadium Industrial Technology (MXF202001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

cao, W., Yuan, B., Zhuo, O. et al. Selective adsorption of CO2/N2 promoted by polar ligand functional groups of metal–organic frameworks. J Porous Mater 29, 63–71 (2022). https://doi.org/10.1007/s10934-021-01141-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-021-01141-w