Abstract

Herein, we report the synthesis and application of mesoporous siliceous MCM-41-nPr-NHSO3H, which was characterized by XRD, IR, TGA and nitrogen physisorption measurements. MCM-41-nPr-NHSO3H was used as an efficient heterogeneous catalyst for the one-pot synthesis of imidazoles derivatives under solvent free conditions with good to excellent yields. The present methodology offers several advantages such as less waste, simplicity of procedure, short reaction time, easy and quick isolation of the products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The application of silica and silica-based materials to life-science technologies is attracting attention from numerous research fields, including biotechnology, and nanomaterial science. These materials have been assessed as drug or gene delivery systems, bio-separation agents, diagnostic agents, and as sensors due to their high surface areas and straightforward surface modification [1–8].

Mesoporous silicates have attracted much attention in the field of separation, adsorption and catalysis activities due to their remarkable features such as high surface area, high pore volume, regular structure, uniform pore size distribution and high thermal stability [9–12]. They offer the possibility of active site immobilization on their surface. This can be achieved via isomorphous substitution of silicon atoms with transition metals or via surface incorporation of organic functionalities and allows mesoporous materials to be used for heterogeneous catalysis [13]. The importance of the silica-based materials is their robustness and their high specific surface area (200–1500 m2g−1) and a three-dimensional structure made of highly open spaces interconnected to each other. These properties cause the selection of a target analyte with a large number of accessible binding sites, which is a key factor in designing sensor devices with high sensitivity [14]. MCM-41 (Mobil Composition of Matter No. 41) as a mesoporous material consists of a hexagonal array of unidi-rectional pore structures. This material is neutral in charge and exhibits only weak hydrogen-bonding type sites which limit its application in catalysis [15–19]. Therefore, in order to activate its surface an appropriate moiety should be linked.

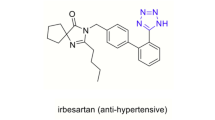

Imidazoles are a class of heterocyclic compounds that contain nitrogen and are currently under intensive focus due to their wide range of applications, because they have many pharmacological properties and play important roles in biochemical processes [20, 21]. They also serve as useful building blocks for the synthesis of other classes of compounds. Owing to the wide range of pharmacological and biological activities, the synthesis of imidazoles has become an important target in the recent years.

2 Experimental

2.1 Chemicals and instruments

The reagents and solvents used in this work were obtained from Fluka or Merck chemical companies and used without further purification. Powder XRD was collected with a Rigaku-Dmax 2500 diffractometer with nickel filtered Cu Ka radiation (λ = 1.5418 Å, 40 kV). FT-IR measurements were performed using KBr disc using a NICOLET impact 410 spectrometer. N2 adsorption/desorption isotherms were recorded at 196 °C with a Micromeritics ASAP 2020. Before measurements, the samples were out gassed at 120 °C for 12 h. The specific surface area was calculated using the Brunauer–Emmett–Teller (BET) method and the pore size distributions were measured using Barrett–Joyner–Halenda (BJH) analyze from the desorption branch of the isotherms. The thermogravimetric analysis (TGA) curves were recorded using a Shimadzu DTG-60 instrument. TEM images were recorded using a microscope operating at 200 kV.

2.2 Preparation of MCM-41-nPr-NHSO3H

MCM-41 silica was prepared using the hydrothermal method described by Chen et al. [16]. TEOS and CTAB were used as template. The typical process was followed: 3.64 gr of CTAB and 1.2 gr of NaOH were solved in 108 gr of deionized water and mixed in a stainless steel autoclave, and then 20.41 gr of tetraethyl orthosilicate (TEOS) were added to the solution, which was stirred for 60 min at room temperature. Then, the sol was aged during 1 h and placed in an oven at 110 °C during 96 h. After 96 h, the resulting white precipitate was filtered and washed with deionized water and 50 mL of ethanol. The resulting powder was dried for 2 h at 80 °C. To remove the CTAB template, the resulting powder was mixed with 0.5 ml of HCl (37 wt%) and 20 ml of ethanol. The mixture was stirred at 60 °C for 90 min, washed with deionized water, dried at 70 °C for 6 h, and then calcined at 550 °C for 5 h (heating rate of 2 °C/min). Subsequently, 3-aminopropyltriethoxysilane fabricated on MCM-41 by adding 4.8 gr 3-aminopropyltriethoxysilane to 4.8 gr of MCM-41 in 96 mL n-hexane and the reaction mixture was stirred under reflux condition at 80 °C for 24 h under nitrogen atmosphere. Then the resulting white solid was filtered, washed with n-hexane and dried at room temperature for 24 h to achieve aminofunctionalized-MCM-41 [MCM-41-(CH2)3NH2]. Subsequently 0.5 gr of synthesized MCM-41-(CH2)3NH2 was dissolved in n-hexane and 0.04 mL Et3N was added. The mixture kept at room temperature for 15 min with vigorous stirring. In the next step, chlorosulfonic acid (0.07 mL) was added drop wise over a period of 30 min at room temperature. Hydrogen chloride gas evolved from the reaction vessel immediately. The mixture was stirred for 2 h until HCl gas evolution stopped. The resulting solid was filtered and washed with n-hexane and then with ethanol and water to remove the unreacted chlorosulfonic acid. It was dried under vacuum at room temperature to give the corresponding solid sulfamic acid-functionalized MCM-41-(CH2)3NH2(MCM-41-nPr-NHSO3H) [Scheme 1].

2.3 General procedure for the synthesis of tri- and tetra-substituted imidazoles

A mixture of benzil (1 mmol), an aromatic aldehyde (1 mmol), ammonium acetate (2.5 mmol), and MCM-41-nPr-NHSO3H (0.1 gr) was heated in the oil bath at 130 °C for the certain period of time. The progress of reaction was monitored by thin-layer chromatography (TLC). Upon completion, the reaction mixture was cooled to room temperature, hot absolute ethanol was added and filtered. The combined filtrate was concentrated by half and allowed to stand at room temperature. The precipitated solid was collected by filtration, dried overnight and recrystallized from absolute ethanol to give substituted imidazole product.

Identical procedure was employed for the synthesis of 1,2,4,5-tera-substituted imidazoles using benzil (1 mmol), aryl aldehyde (1 mmol), a primary amine (1 mmol), ammonium acetate (2.5 mmol) and 0.1 gr of MCM-41-nPr-NHSO3H as catalyst under solvent free condition at 130 °C.

1H and 13C NMR of 4 m: 1H NMR (400 MHz, CDCl3): δ = 7.32–7.50 (m, 10 H), 7. 96 (d, J = 7. 2 Hz, 4H), 7.93 (d, J = 8.8 Hz, 2H), 8.02 (d, J = 8. 4 Hz, 2H), 8.50 (s, 1H), 9.87 (br, 1H) ppm; 13C NMR (100 MHz, CDCl3): δ = 143.6, 131.5, 131.1, 129, 128.6, 128.5, 127.9, 127.5, 126.6, 125.8, 125.4, 125 ppm.

3 Results and discussion

In continuation of our investigation about application of heterogeneous catalysis in organic synthesis [22–26], herein we describe the preparation of a new heterogenised catalyst by functionalization of MCM-41 with 3-aminopropyl triethoxysilane and subsequent immobilization of sulfonic acid group on the synthesized MCM-41-(CH2)3NH2. Resulting MCM-41-nPr-NHSO3H was applied as a new heterogeneous catalyst for the one-pot synthesis of multisubstituted imidazole compounds.

3.1 Catalyst characterization

3.1.1 X-ray diffraction

Figure 1 shows XRD patterns for MCM-41, MCM-41-(CH2)3NH2 and MCM-41-nPr-NHSO3H. XRD patterns illustrate typical peaks corresponding to diffraction at (100), (110) and (200) plane of hexagonal phase. This proves that the framework structure does not deteriorate seriously during treatment with aminopropyltriethoxysilane and chlorosulfonic acid. Collectively, the XRD pattern of the functionalized MCM-41 also suggest not only a significant degree of short range ordering of the structure and well-formed hexagonal pore arrays of the samples, but also the maintenance of the structural order of the synthesized materials after functionalization.

3.1.2 Thermo gravimetric analysis (TGA)

The thermo gravimetric analysis (TGA) curves of MCM-41, MCM-41-(CH2)3NH2 and MCM-41-nPr-NHSO3H show the mass loss of the organic materials as they decompose upon heating (Fig. 2). The initial weight loss from the MCM-41 (25–120 °C) is due to the removal of physically adsorbed water (the weight loss about 4.25 %). The weight loss (1.6 %) between 120 and 840 °C is attributed mainly to the condensation of silanol groups and removal of chemically adsorbed water. MCM-41-(CH2)3NH2 shows four-step weight loss behavior. Weight loss of MCM-41-(CH2)3NH2 appears about 16.82 % at 120–700 °C, which is contributed to the thermal decomposition of the 3-aminopropyl groups. For MCM-41-nPr-NHSO3H, there is a well-defined mass weight loss of 28.16 % between 130 and 700 °C related to the breakdown of the nPr-NHSO3H moieties. Above 700 °C, samples exhibit about (0.7–0.85 %) weight loss due to the dehydroxylation of the silicate networks. On the basis of these results, the well grafting of aminopropyltriethoxysilane and SA groups on the MCM-41 is verified.

3.1.3 N2 Adsorption–desorption isotherm

N2 adsorption isotherm of the samples is recorded. The irreversible type IV adsorption isotherms of MCM-41, MCM-41-(CH2)3NH2 and MCM-41-nPr-NHSO3H with H1 hysteresis loop defined by IUPAC are observed, that is a typical feature of mesoporous materials (Fig. 3a). The Brunauer–Emmett–Teller (BET) specific pore volume and surface area of MCM-41-(CH2)3NH2 and MCM-41-nPr-NHSO3H reduce remarkably compared to calcined MCM-41. The BET surface area of the MCM-41 obtained using N2 adsorption–desorption isotherm was found out to be 986.16 m2/g and pore volume is 0.711 cm3/g.

When 3-aminopropyl was modified on the inner surface of MCM-41, its BET pore volume and surface area reduce to 0.340 cm3/g and 694.98 m2/g, respectively; also these contents reduce remarkably for MCM-41-nPr-NHSO3H (0.176 cm3/g and 205.36 m2/g). The pore size distribution calculated from the adsorption branch of the N2 isotherm by using the BJH method for the MCM-41, MCM-41-(CH2)3NH2 and MCM-41-nPr-NHSO3H are mentioned in Fig. 3b.

As shown in Fig. 3b the BJH pore diameter, BET surface, and pore volume of functionalized MCM-41 decreased with the increasing substances anchored on the surface of MCM-41.These results are attributed to the occupation of organic molecules on the inner surface of the pores.

3.1.4 Transmission electron microscopy (TEM)

Figure 4a shows some representative TEM micrographs of the starting mesoporous calcined MCM-41. Transmission electron microscopy (TEM) image showed the uniform sizes of the pores and channels, which exhibited a hexagonal array of lattice fringes as well as parallel fringes corresponding to the side-on view of the pores. The dimension of the pores estimated by TEM is roughly 3.47 nm that is in agreement with the nitrogen adsorption data, which was discussed above.

3.1.5 Scanning electron microscopy (SEM)

SEM characterization shows that the starting MCM-41 material is composed of particles with size around 5 µm and without regular morphology (Fig. 4b).

3.1.6 Ft-ir

MCM-41, MCM-41-(CH2)3NH2 and MCM-41-nPr-NHSO3H were analyzed by FT-IR in the 4000–400 cm−1 region (Fig. 5). The wide bands at 1240–1030 cm−1 are typically regarded as Si–O–Si bands of the condensed silica network. The peak 806 cm−1 can be assigned to the symmetric stretching vibration of Si–O. When comparing MCM-41 (a spectrum) with MCM-41-(CH2)3NH2 (b spectrum), the peak at 1524 and 1638 cm−1 indicates successful incorporation of the amine moiety. This peak (assigned to N–H stretch) is absent in the MCM-41 spectrum that provides evidence for the incorporation of the amine functional group onto the silica surface. Reaction of MCM-41-(CH2)3NH2 with chlorosulfonic acid produces MCM-41-nPr-NHSO3H, which the stretching and out of plane bending of acidic O–H group observed at 2700–3500 (c spectrum).

3.1.7 Evaluation of the catalytic activity of MCM-41-nPr-NHSO3H through the synthesis of 2,4,5-trisubstituted imidazoles

To achieve suitable conditions for the synthesis of 2,4,5-trisubstituted imidazoles, various reaction conditions have been investigated in the reaction of 4-hydroxy benzaldehyde, benzil, and ammonium acetate as a model reaction.

Reactions in various molar ratios of substrates in the presence of MCM-41-nPr-NHSO3H showed that the best conditions were solvent-free at 130 °C and molar ratio of aryl-aldehyde: benzyl :ammonium acetate: of 1:1:2.5 and 0.1 gr of MCM-41-nPr-NHSO3H (entry 4). No product could be detected in the absence of the catalyst (entry 6), it means that the catalyst is absolutely necessary for this condensation. The results are summarized in Table 1.

Using the optimized reaction conditions, this combination was explored by the wide range of substituted and structurally divers aldehydes to synthesize the corresponding products in high to excellent yields (Table 2; Scheme 2).

As shown in Table 2, aldehydes bearing either electron-withdrawing or electron-donating groups perform equally well in the reaction and all imidazoles were obtained in good to excellent yields.

Also same methodology was extended for the synthesis of the tetra-substituted imidazoles in the similar reaction conditions via one-pot, multi-component condensation of benzil (1 mmol), aldehyde (1 mmol), amine (1 mmol) and ammonium acetate (2.5 mmol) that catalyzed by 0.1 gr of MCM-41-nPr-NHSO3H under solvent-free conditions at 130 °C as depicted in Scheme 2.

As indicated in Table 3, in all cases the reaction gives the products in high yields under solvent-free conditions and prevents problems which many associate with solvent use such as cost, handling, safety and pollution.

The substrate scope of the reaction was then evaluated using a variety of structurally diverse aldehydes. The obtained results are illustrated in Table 3.

Furthermore, we found that this catalyst demonstrated good recoverability and reusability. The catalyst can be efficiently recovered after completion of reaction by simple filtration. Reusability and recycling of the catalyst (MCM-41-nPr-NHSO3H) was examined through a series of sequential condensations of p-Cl-benzaldehyde, benzil and NH4OAC as a model reaction. In a typical reaction, the catalyst was recovered by simple filtration from the reaction mixture and reused for five cycles. No observation of any appreciable loss in the catalytic activity of catalyst was observed (Table 2, entry 1). The unchanged nature of the recovered catalyst was demonstrated by XRD after one used (Fig. 1).

4 Conclusions

In conclusion, an efficient and environmentally friendly procedure has been developed for the preparation of imidazoles derivatives in the presence of catalytic amounts of MCM-41-nPr-NHSO3H. This new methodology offers several advantages including high yields, mild reaction conditions, short reaction time, simple work-up procedure and use of non-toxic catalyst. Furthermore, the catalyst could be isolated with simple filtration and the yields achieved above 90 % after reused at five cycles.

References

F. Torney, B.G. Trewyn, V.S.Y. Lin, K. Wang, Nat. Nanotechnol. 2, 295 (2007)

I.I. Slowing, B.G. Trewyn, S. Giri, V.S.Y. Lin, Adv. Func. Mater. 17, 1225 (2007)

M. Han, X. Gao, J.Z. Su, S. Nie, Nat. Biotechnol. 19, 631 (2001)

L. Josephson, J.M. Perez, R. Weissleder, Angew. Chem. Int. Ed. 40, 3204 (2001)

L. Babes, B. Denizot, C. Tangguy, J. Jacques, L. Jeune, P. Jallet, J. Colloid Interface Sci. 212, 474 (1999)

J. Allouche, M. Boissiere, C. Helary, J. Livage, T. Coradin, J. Mater. Chem. 16, 3120 (2006)

X.D. Tong, B. Xue, Y. Sun, Biotechnol. Prog. 17, 134 (2001)

M.D. Cuyper, M. Hodenius, Z.G.M. Lacava, R.B. Azevedo, M.D. Silva, P.C. Morais, M.H.A. Santana, J. Colloid Interface Sci. 245, 274 (2002)

C.T. Kresge, M.E. Leonowicz, W.J. Roth, J.C. Vartuli, J.S. Beck, Nature 359, 710 (1992)

M. Hajjami, F. Ghorbani, F. Bakhti, Appl. Catal. A Gen. 470, 303 (2014)

S. Biz, M.L. Occelli, Catal. Rev. Sci. Eng. 40, 329 (1998)

J.A.A. Soler-Illia, C. Galo, B. Sanchez, J. Lebeau, Patarin. Chem. Rev. 102, 4093 (2002)

E.A. Sujandi, M.A. Prasetyani, S.C. Lee, S.E. Park, Microporous Mesoporous Mater. 118, 134 (2009)

M.R. Ganjali, M. Asgari, F. Faridbod, P. Norouzi, A. Badiei, J. Gholami, J. Solid State Electrochem. 14, 1359 (2010)

J. Deutsch, H.A. Prescott, D. Muller, E. Kemnitz, H. Lieske, J. Catal. 231, 269 (2005)

D. Zhao, Q. Huo, J. Feng, B.F. Chmelka, G.D. Stucky, J. Am. Chem. Soc. 120, 6024 (1998)

W. Zhang, T.R. Pauly, T.J. Pinnavaia, Chem. Mater. 9, 2491 (1997)

A. Galarneau, D. Desplantier-Giscard, F. Di Renzo, F. Fajula, Catal. Today 68, 191 (2001)

V.Y. Gusev, X. Feng, Z. Bu, G.L. Haller, J.A. O’Brien, J. Phys. Chem. 100, 1985 (1996)

J.G. Lambardino, E.H. Wiseman, J. Med. Chem. 17, 1182 (1974)

A. Puratchikody, M. Doble, Bioorg. Med. Chem. Lett. 15, 1083 (2007)

A. Ghorbani-Choghamarani, G. Azadi, J. Iran. Chem. Soc. 8, 1082 (2011)

A. Ghorbani-Choghamarani, M. Hajjami, H. Goudarziafshar, M. Nikoorazm, S. Mallakpour, F. Sadeghizadeh, G. Azadi, Monatsh. Chem. 140, 607 (2009)

A. Ghorbani-Choghamarani, T. Taghipour, G. Azadi, J. Chin. Chem. Soc. 60, 1202 (2013)

A. Ghorbani-Choghamarani, M. Norouzi, Bull. Korean Chem. Soc. 32, 1399 (2011)

M.A. Zolfigol, K. Amani, M. Hajjami, A. Ghorbani-Choghamarani, Monatsh. Chem. 139, 895 (2008)

S.S. Pandit, S.K. Bhalerao, U.S. Aher, G.L. Adhav, V.U. Pandit, J. Chem. Sci. 123, 421 (2011)

R. Hekmatshoar, H. Jahanbakhshi, F. Mousavizadeh, R.G.U. Rahnamafar, J Sci. 25, 29 (2012)

S. Samai, G.C. Nandi, P. Singh, M.S. Singh, Tetrahedron 65, 10155 (2009)

H.R. Shaterian, M. Ranjbar, K. Azizi, J. Iran. Chem. Soc. 8, 1120 (2011)

S.V. Bhosale, M.B. Kalyankar, S.V. Nalage, D.S. Bhosale, S.L. Pandhare, T.V. Kotbagi, S.B. Umbarkar, M.K. Dongare, Synth. Commun. 41, 762 (2011)

J. Safari, S.D. Khalili, S.H. Banitaba, J. Chem. Sci. 122, 437 (2010)

A. Marzouk, A.M. Abbasov, V.H. Talybov, Chem. J. 2, 179 (2012)

K. Niknam, A. Deris, F. Naeimi, F. Majleci, Tetrahedron Lett. 52, 4642 (2011)

B. Sadeghi, B.B.F. Mirjalili, M.M. Hashemi, Tetrahedron Lett. 49, 2575 (2008)

K. Bahrami, M.M. Khodaei, A. Nejati, Monatsh. Chem. 142, 159 (2011)

G. Mohammadi Ziarani, A. Badiei, N. Lashgari, Z. Farahani, J. Saudi Chem. Soc. (2013) in press

A. Teimouri, A. Najafi, Chermahini. J. Mol. Catal. A Chem. 346, 39 (2011)

Acknowledgments

This work was supported by the research facilities of Ilam University, Ilam, Iran.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghorbani-Choghamarani, A., Ghorbani, F., Yousofvand, Z. et al. Mesoporous MCM-41-nPr-NHSO3H as novel and effective nanoreactor catalyst for the synthesis of multi-substituted imidazoles under solvent-free conditions. J Porous Mater 22, 665–673 (2015). https://doi.org/10.1007/s10934-015-9939-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-015-9939-3