Abstract

With the aim to enhance the tensile properties and thermal stability of waterborne polyurethane (WPU) film, a comparative study was conducted to investigate the use of unfunctionalized lignin and 3-aminopropyltriethoxy silane functionalized lignin as natural reinforcing filler. The ultimate tensile strength of the WPU film that filled with 0.5 wt% functionalized lignin was found elevated by 9% compared to the unfunctionalized lignin, which was only increased by 0.3%. The functionalized lignin-filled WPU films also becomes more flexible and possess higher deformation resistance (lower Young’s modulus and higher elongation at break) compared to the one filled with unfunctionalized lignin. In addition, the functionalized lignin is proven to reinforce the fabricated bio-composite films without significantly compromising their thermal stability, since the initial degradation temperature (296.79 °C) is comparable to the pristine WPU film (297.40 °C). The Fourier-transform infrared and morphological analyses confirm the formation of extra carbamate, urea and hydrogen bonds between the functionalized lignin and WPU is the main reason for the functionalized lignin to reinforce the fabricated films without significantly compromising their thermal stability. Ultimately, the current findings and proposed chemical reaction between the functionalized lignin and WPU, also serve as a guideline to facilitate the future design and development of other functionalized lignin-based products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1. Introduction

Global plastic film market outlook shows increasing trend in recent year. According to the latest market research, the global plastic film and sheets market is forecasted to reach USD 157.5 billion by the year 2025 [1]. Among the polymeric materials, polyurethane is one of the potential candidates that can be used as the raw material for the plastic films. Few examples of the applications of polyurethane film are wound dressing (medical), adhesive coated product, fire retardant film, medical bag, safety glass/optically clear film and surface protection film [2].

With the aim to overcome the environmental concerns on the release of organic solvents from the utilization of traditional solvent borne polyurethane, the aqueous based counterpart, waterborne polyurethane (WPU) has been developed. There are several features that make WPU attractive. The most important features that offered by WPU is non-toxic and less pollution to the environment compared to the traditional solvent borne polyurethane due to the relatively lower volatile organic compound (VOC) content. Moreover, WPU also possesses good adhesion and excellent rheological properties. Other features such as non-flammable, absence of external emulsifier and good behavior at low temperature further increase the comparability of WPU [3, 4]. Nonetheless, WPU is inferior to its solvent-based counterpart in terms of surface properties and chemical resistance, poor wettability and limited thermal, mechanical and electrolytic stability [3, 5, 6].

Filler incorporation is one of the methods which can be applied to tackle the shortcomings of WPU to produce the end-products with the desired specifications. The utilization of green plant-derived bio-polymers as filler has gained much attention due to the environmental and economic reasons. For instance, rice straw [7, 8], kenaf fiber [9], sago waste [10, 11], corn starch [12], durian skin fiber [13], pineapple leaf fiber [14], microcrystalline cellulose [15], corn waste [16], wood chips [17], kapok [18], tree pruning waste [19] and oil palm mesocarp [20], these green plant-derived bio-polymers have demonstrated their potential to reinforce the properties of the developed polymer bio-composites with or without subjecting to the functionalization process by using a coupling agent. Some of these bio-polymers have even been proven can be used as the substituents to produce different eco-friendly end-products, for instance, tree-free papers [21,22,23,24,25], soil cover [26], textile [27] and nanowires [28]. Lignin is the second most abundant green plant-derived bio-polymer on Earth which is exceeded only by cellulose [29]. Lignin can be extracted through lignocellulose separation process. One of the biggest producers of lignin is paper and pulp industry whereby approximately 50 million ton of lignin is being produced annually [30, 31]. Owing to its low cost and ample natural availability, lignin is recognized as a suitable adsorbent material for adsorption process to remove pollutants [32]. In fact, lignin is a macromolecule which is made up of three different types of cinnamyl alcohols (monolignols), namely p-coumaryl alcohol, coniferyl alcohol and sinapyl alcohol. Thus, the abundant functional groups that can be found in these components have made lignin to be a reactive bio-polymer which is not only can be used for the development of derma products, drug delivery systems, engineering devices [33], but also holds potential to reinforce the fabricated polymer bio-composites without the use of coupling agent. It is even to be expected that the reinforcing effect can be intensified when the lignin is further functionalized by using the adaptive coupling agent.

With the aforementioned, the main aim of this study is to investigate and report the potential use of lignin as a reinforcing filler for the development of WPU films with enhanced tensile properties without compromising their thermal stability. Lignin recovered from the Kraft pulping process, which is also known as Kraft lignin, was utilized in this study since the Kraft process is the most common pulping method and it contributes 85% of the total lignin production in the world [34, 35]. A comparative study was conducted to discuss the reinforcing effect of lignin, with and without subjecting to the functionalization process by using 3-aminopropyltriethoxy silane (APTES) as the functionalizing agent, on the performance of the fabricated WPU bio-composite films. In the present study, APTES was selected as the functionalizing agent since it was expected that the interaction between the hydroxyl groups of APTES (upon hydrolysis) and lignin would provide an extra functional group (amino group) to the lignin, which makes the lignin becomes more compatible with WPU, and thus, the performance of the fabricated bio-composite films. Moreover, the investigation of the tensile properties, thermal stability, Fourier-transform infrared spectroscopy (FTIR) and surface morphology was also expected to provide insight into the extent of lignin and functionalized lignin on the properties enhancement of WPU films. These findings are not only filling up the knowledge gaps, but also serve as a guideline for the development of lignin-based green products.

2. Materials and Methods

2.1 Materials

The aliphatic WPU dispersion, which was utilized as the polymer matrix of the fabricated films, was synthesized based on the use of a proprietary method. Kraft lignin with an average particle size of 29.45 μm (CAS number: 8068-05-1) was purchased from Sigma Aldrich 3-aminopropyltriethoxy silane 99% (APTES, CAS number: 919-30-2) was purchased from Fisher Scientific.

2.2 Functionalization of Lignin

To prepare the medium of functionalization process, 2 wt% of APTES was hydrolyzed by using 100 mL of distilled water. Afterwards, the lignin powder was added into the medium and stirred at 200 rpm (room temperature) for 40 min. The functionalized lignin was then filtered through a filter paper and fully dried in an oven at 80 °C. The dried and functionalized lignin was then grounded by using a mortar and pestle before storing. The APTES functionalized lignin is termed as functionalized lignin throughout the works.

2.3 Fabrication of WPU Films

The prepared WPU dispersion was mixed with lignin or functionalized lignin at different proportion (0, 0.5, 1.0, 1.5 and 2.0 wt%) under magnetic stirring condition at a speed of 850 rpm for 30 min. The mixing process was carried out at room temperature without external heating. After the mixing process, small amount of the stirred solution was immediately poured onto a piece of release paper with the dimension of 28.5 cm x 22 cm. A 100 μm coating bar was used to spread the mixture on the release paper. After the spreading process, the mixture was air dried at room temperature to produce the WPU films.

2.4 Tensile Properties

The tensile properties (ultimate tensile strength, Young’s modulus and elongation at break) of the pristine WPU film, lignin-filled WPU bio-composite films and functionalized lignin-filled WPU bio-composite films were determined based on the ASTM D 882. The evaluation was conducted by using a universal tensile machine (Instron Model 5969). According to ASTM D 882, the rectangular shaped samples with dimension 100 mm x 10 mm x 0.1 mm and gauge length of 50 mm were tested under a crosshead speed of 500 mm/min at room temperature. The average value of 5 horizontal cut samples and 5 vertical cut samples was reported for each formulation.

2.5 Thermal Stability

The thermal stability of lignin, functionalized lignin, pristine WPU film, lignin-filled WPU bio-composite films and functionalized lignin-filled WPU bio-composite films were investigated by using a thermogravimetric analyzer (Model TGA 8000 from Perkin Elmer). The sample with a mass of 5 mg was placed in a ceramic crucible of the thermogravimetric analyzer and heated from room temperature to 700 °C at a heating rate of 10 °C/min with nitrogen purging at 20 mL/min.

2.6 Fourier-transform Infrared Spectroscopy (FTIR)

FTIR spectroscopy was carried out by using an attenuated total reflectance (ATR)-FTIR spectrometer (Model Spectrum 100 from Perkin Elmer) to identify the chemical interaction between the lignin or functionalized lignin with the WPU. The spectra were obtained in the frequency range of 4000 cm− 1 to 525 cm− 1 at a resolution of 4 cm− 1 and accumulations 16 scans. The peak assignments were done based on the works reported by other scholars [36,37,38,39,40,41].

2.7 Scanning Electron Microscopy

Scanning electron microscopy was adopted to examine the dispersion of lignin and functionalized lignin in the fabricated WPU bio-composite films. The samples were coated with a thin layer of platinum using an auto fine coater (Model Q150R S from Quorum) before the surface examination. After that, the surface morphology of the samples was examined by using a variable pressure scanning electron microscope (Model S-3400 N from Hitachi) at 30X, 200X, 1000X and 2000X magnification with a voltage of 10 kV and pressure of 90 Pa.

3. Results and Discussion

3.1 Tensile Properties

Figure 1 shows the ultimate tensile strength of WPU films filled with lignin or functionalized lignin. As depicted in Fig. 1, the ultimate tensile strength of pristine WPU is 8.05 MPa, which is mainly contributed by the polyurethane backbones through the combination of polyisocyanates and polyols in the films. With the incorporation of lignin, the highest ultimate tensile strength (8.07 MPa) is achieved when 0.5 wt% of lignin was incorporated into WPU film. In other words, the ultimate tensile strength of the WPU film is increased by 20 kPa. However, beyond that, adverse effect on the ultimate tensile strength of the bio-composite films is observed. These observations indicate that the ultimate tensile strength of the WPU films can be enhanced through the incorporation of lignin, up to 0.5 wt%. The increase in ultimate tensile strength might be due to the formation of the lignin-WPU interaction. Beyond 0.5 wt%, the ultimate tensile strength of the bio-composite film decreases with the increase in lignin loading. This phenomenon can be explained by the agglomeration of lignin particles at high loading amount. The agglomeration of lignin particle decreases the total surface area of the filler which resulted in the reduction of tensile strength due to the less efficient stress transfer mechanism. This argument can be supported by the measurement of filler size, which would be discussed in Sect. 3.4 (scanning electron microscopic analysis).

On the other hand, the ultimate tensile strength of the WPU bio-composite films that filled with the functionalized lignin is higher than those reinforced with unfunctionalized lignin, regardless of the lignin loading. The enhancement in the ultimate tensile strength is attributed to the functionalization process, which confers the additional capabilities by changing the surface chemistry of the lignin to improve the surface interaction, and thus, the interfacial adhesion and contact with WPU. This argument can be supported by the FTIR spectroscopic analysis and scanning electron micrographic analysis in Sect. 3.3 and 3.4. A better interfacial adhesion helps to achieve better stress distribution on the bio-composite films when the external force is applied, which then leads to the increase in ultimate tensile strength. With the incorporation of 0.5 wt% of functionalized lignin, the resulting bio-composite film is able to achieve 9% higher in ultimate tensile strength compared to the pristine WPU films (8.05 MPa). By ignoring the different functionalization and fabrication process, the reinforcing effect of the functionalized lignin in this work is slightly higher compared to the polylactic acid composites fabricated by Zhu and co-workers [42], whereby the tensile strength is increased by 3.2% using the similar APTES-functionalized lignin.

Based on Fig. 2, an increase in Young’s modulus of WPU films is observed with the incorporation of lignin as natural reinforcing filler. The increase in Young’s modulus is mainly attributed to the complex structure of lignin, which restrict the mobility of WPU polymer chains and provide greater stiffness to the bio-composite films. The ability of lignin in providing greater stiffness is further supported by the decrease in elongation at break (Fig. 3). Similar observation is also observed by the scholars in Thailand [43], where the kraft lignin acted as stiffener in thermoplastic starch polymer matrix.

In contrast, the functionalized lignin-filled WPU bio-composite film has lower Young’s modulus (Fig. 2) and higher elongation at break (Fig. 3) compared to the lignin-filled WPU bio-composite film. The improvement in the interfacial adhesion contributes to the enhancement in the elongation at break. Better interfacial adhesion result in the reduction of stress concentration, which leads to the increase in the elongation of the fabricated bio-composite film. In other words, the WPU films exhibit better deformation when functionalized lignin is used as the reinforcing filler. The characteristic is in line with the works reported by Lv and co-workers [44], since the similar observation was observed when the bio-composite was prepared based on the functionalized wood flour.

As shown in Figs. 1 and 2., the standard deviation reflects the fluctuation range of the ultimate tensile strength and Young’s modulus of the bio-composite films is broad. This phenomenon can be rationalized by the polymer chains orientation in the films during the fabrication process. Although the casting method was adopted in this research, but the WPU was manually spread over the release papers with the aid of a coating bar to form the bio-composite films. Owing to the force applied during the manual spreading process, the WPU was stretched top-down over the release papers in one direction. Consequently, the WPU polymer chains were aligned in that direction to give rise to the anisotropic behavior in the fabricated films. According to Spragg [45], the mechanical properties of polymer films depend strongly on the orientation of the polymer chains. Basically, the mechanical properties are greater in a direction parallel to the polymer chains than in directions normal to them. Owing to the tensile properties of the WPU bio-composite films were evaluated based on the method recommended by ASTM D 882, the average value of 5 vertical cut samples (parallel to the principal axis of anisotropy) and 5 horizontal cut samples (normal to the principal axis of anisotropy) is used as the representative to represent the performance of each formulation. For this reason, the pronounced difference between the tensile properties of vertical and horizontal cut samples have given rise to the broad standard deviation for the reported findings.

3.2 Thermal Stability

The thermal stability of lignin, functionalized lignin as well as the WPU films filled with lignin or functionalized lignin was investigated by using a thermogravimetric analyzer. Based on the TGA thermograms, the initial degradation temperature is identified and tabulated in Tables 1 and 2. As shown, the thermal stability of the WPU films filled with lignin is found to be lower than the pristine one. It is observed that the initial degradation temperature of the fabricated bio-composite films decreases with the increase in lignin loading. This is attributed to the lignin has lower initial degradation temperature (253.94 °C) as compared to WPU (297.40 °C). Owing to this reason, the addition of lignin weakens the thermal stability of the WPU film. On the other hand, the functionalized lignin filled-WPU bio-composite films exhibit better thermal stability compared to the one filled with the unfunctionalized lignin. This phenomenon is attributed to the improved surface interaction and bonding formation between the APTES functionalized lignin and WPU. Theoretically, the APTES serves as a coupling agent to promote the interaction between the lignin and WPU through the formation of carbamate, urea and hydrogen bonds. These intermolecular bonds increase the amount of thermal energy required to break the bonds, and thus, enhance the thermal stability of the fabricated bio-composite films. Moreover, the improved surface interaction between the lignin and WPU through the APTES functionalization process also reduces the voids in the bio-composite films to hinder the heat diffusion, and thus, delay the thermal degradation. For this reason, the incorporation of APTES functionalized lignin can reinforce the fabricated bio-composite films without significantly decreasing their thermal stability. These arguments are supported by the temperature at the maximum degradation rate (Tmax) of the fabricated films (Table 2). Basically, the Tmax of the functionalized lignin filled-WPU bio-composite films is higher than the one prepared with unfunctionalized lignin. The elevation of the Tmax further confirms the massive weight loss of the bio-composite films took place at higher temperature. These phenomena imply that the functionalization process is not only enhance the ultimate tensile strength and flexibility of the resulting films, but it also improves their thermal stability and make them only slightly lower compared to the pristine WPU films.

3.3 Fourier-transform Infrared Spectroscopic Analysis

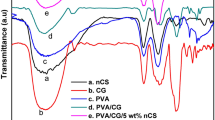

Figure 4 shows the Fourier-transform infrared spectra for the pristine WPU film as well as the films filled with lignin and functionalized lignin. As reflected by the spectra, the C-H stretching and C-O-C stretching of the WPU polymer chains were recorded at 2942.9 cm− 1 and 1234.9 cm− 1, respectively. For the pristine WPU film and lignin-filled WPU bio-composite film, the formation of carbamate (urethane) bond can be observed through the absorption peak at 1711.2 cm− 1 and 1531.0 cm− 1. These absorption peaks are attributed to the carbonyl group (C = O) and N-H of carbamate bond via the polymerization between the isocyanate and hydroxyl groups (O-H) of WPU dispersion. Moreover, the formation of intermolecular hydrogen bonds via the interaction between the (i) hydroxyls groups (O-H) of polyols and N-H of carbamate bonds, (ii) hydroxyls groups (O-H) among the polyols, and (iii) N-H among the carbamate bonds in the WPU, was also recorded at 3303.8 cm− 1. These carbamate bond and hydrogen bond are important to confer the intrinsic strength to the WPU films to withstand the applied external force. Even so, the spectrum of pristine WPU film has similar absorption peaks and intensity with the one filled with lignin. This phenomenon implies that the incorporation of unfunctionalized lignin may not reactive enough to reinforce the WPU. The observation is even in line with the ultimate tensile strength reported in Sect. 3.1, whereby the strength is only increased by 0.3% when 0.5 wt% of lignin was incorporated into the WPU film.

In contrast, the functionalization process has improved the interaction between the lignin and WPU, which can be observed through the spectrum of functionalized lignin-filled WPU bio-composite film. As recorded, the APTES that utilized in the functionalization process gives rise to the absorption at the frequencies of 1234.9 cm− 1 (Si-CH2CH2CH2), 1170.5 cm− 1 (Si-O-C), 1034.4 cm− 1 (Si-O-C) and 778.3 cm− 1 (C-O of Si-O-C). The detection of Si-O-C confirms that extra carbamate bonds were formed in the fabricated film via the chemical reaction between the hydroxyl groups (Si-OH) of silane and isocyanate (N = C = O) of WPU. In addition, the interaction between the amine group (-NH2) of silane and isocyanate (N = C = O) of WPU is also observed through the formation of urea bond (N-C-N) at frequency of 1461.1 cm− 1. The formation of extra carbamate and urea bonds are supported by the increasing peak intensity at 1531.0 cm− 1 and 1310.0 cm− 1, which are attributed to the -C(= O)-NHR bend and stretching, since the -C(= O)-NHR can only be found in carbamate and urea bonds. On the other hand, the increase in the peak intensity at 3303.8 cm− 1 also suggests that the functionalized lignin has improved the formation of hydrogen bonding with the WPU polymer chains, which in turns, accompanied by the reduction in absorption band of the free and unassociated hydroxyl groups (-OH) at 3781 cm− 1. In other words, the Fourier-transform infrared spectroscopic analysis has confirmed that the functionalized lignin possess higher reactivity to interact with the WPU. The functionalized lignin promotes the formation of carbamate, urea, and hydrogen bonds, which increase the thermal stability as well as to facilitate the stress distribution on the bio-composite film, as reflected by the increase of initial degradation temperature and ultimate tensile strength reported in Sect. 3.2 and 3.1.

The identified chemical bonding that involve among the lignin, APTES and WPU in the bio-composite film has also enabled the coupling reaction to be proposed, as shown in Fig. 5.

3.4 Scanning Electron Microscopic Analysis

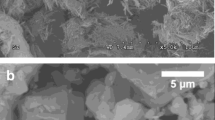

The surface morphology of the lignin, functionalized lignin, pristine WPU film as well as the bio-composite films was examined and discussed in this section. The microstructure of lignin is affected after the APTES functionalization process, as shown in Fig. 6. The surface of the functionalized lignin (Fig. 6(b)) is rougher compared to the unfunctionalized one (Fig. 6(a)) due to the interaction with the APTES in the functionalization process. This observation further supports that the lignin particles is successfully activated by using APTES, and thus, improve the surface interaction with the WPU.

As shown in Fig. 7 (a), the surface morphology of the pristine WPU film is homogenous which indicates the good surface interaction between hard segments and soft segments of the WPU. Based on Fig. 7 (b) and (c), it can be observed that the dispersion of lignin in 0.5 wt% lignin-filled WPU bio-composite film is better than 2.0 wt% lignin-filled WPU bio-composite film. Besides that, it is also discovered that the average lignin particle size in 2.0 wt% lignin-filled WPU bio-composite film is significantly larger than the one in 0.5 wt% lignin-filled WPU bio-composite film. This indicates that the lignin agglomerate with each other to form bigger size when the lignin loading is high. Owing to this reason, the size of lignin in the fabricated bio-composite film was measured for the bio-composite films. The result shows that the average size of lignin in 0.5 wt% and 2.0 wt% lignin-filled WPU bio-composite films was 28.63 and 40.3 μm, respectively. Similar trend is also observed in the functionalized lignin-filled WPU bio-composite films, as shown in Fig. 7 (d) and (e) where the average size of the functionalized lignin was measured at 62.87 and 72.39 μm, respectively.

The agglomeration is attributed to the hydrophobic nature of lignin. Owing to the WPU is synthesized by using water as the synthesis medium, the hydrophobic lignin has a high tendency to react with each other during the mixing process. For this reason, the lignin agglomerate when their hydroxyl groups react with each other and form hydrogen bonds. In contrast, the hydrophobicity of the functionalized lignin is lower than the unfunctionalized lignin due to the presence of amino group by using APTES as the functionalizing agent. The functionalized lignin is more soluble in the mixture and tend to react with WPU during the mixing process, and thus, better surface interaction. Meanwhile, the functionalization process also makes the functionalized lignin become more reactive compared to the unfunctionalized lignin. In other words, the lignin can react with each other and agglomerate readily during the mixing process. Consequently, the size of functionalized lignin is larger than the one prepared by using unfunctionalized lignin.

Figure 8 illustrates the interaction between lignin/functionalized lignin and WPU in the fabricated bio-composite films. As shown in the micrographs, unlike the surface morphology of lignin-filled WPU bio-composite film (Fig. 8 (a)), the visible gap between the functionalized lignin and WPU in the bio-composite film is significantly smaller, suggesting better surface interaction between the functionalized lignin and WPU polymer chains. This observation further confirms the findings of tensile properties, thermal stability and FTIR analysis, whereby the functionalization process further improves the reinforcing effect of lignin in improving the properties of WPU.

4. Conclusions

The WPU bio-composite films filled with lignin and functionalized lignin were successfully fabricated in this work. The ultimate tensile strength of the lignin-filled WPU bio-composite film reaches its optimum point when 0.5 wt% of lignin is incorporated. The increase in the lignin loading leads to the increase in Young’s modulus and decrease in elongation at break and thermal stability of the resulting bio-composite film. In contrast, the APTES functionalized lignin has demonstrated a pronounced reinforcing effect through the formation of extra carbamate, urea and hydrogen bonds with the WPU, as evidenced in the FTIR spectra and scanning electron micrographs. The optimum ultimate tensile strength of the resulting bio-composite film is still identified at 0.5 wt%. However, the ultimate tensile strength of the bio-composite films has increased by 9%. The functionalized lignin-filled WPU bio-composite films also becomes thermally more stable through the improved surface interaction. The present study confirms the use of lignin as a reinforcing filler for the development of WPU bio-composite films. The fabricated films even possess better performance when the APTES functionalized lignin is used as the reinforcing filler.

Data Availability

All data generated or analyzed during this study are included in this published article.

Code Availability

Not applicable.

References

Grand View Research (2017) Plastic films & sheets market size worth $157.5 billion by 2025. https://www.grandviewresearch.com/press-release/global-plastic-films-and-sheets-market. Accessed 28 April 2018

Transcontinental United Kingdom (2018) Advanced polyurethane films for quality medical care. http://www.coverisadvancedcoatings.com/coveris-products/inspire-medical-components/product-constructions/polyurethane-films/. Accessed 29 April 2018

Hercule K, Yan Z, Christophe MM (2011) Preparation and characterization of waterborne polyurethane crosslinked by urea bridges. Int J Chem 3(2):88–96

Lambourne R, Strivens TA (1999) Paint and surface coatings - theory and practice second edition. Woodhead Publishing, Sawston

She Y, Zhang H, Song S, Lang Q, Pu J (2013) Preparation and characterization of waterborne polyurethane modified by nanocrystalline cellulose. BioResources 8(2):2594–2604

Liu H, Cui S, Shang S, Wang D, Song J (2013) Properties of rosin-based waterborne polyurethanes/cellulose nanocrystals composites. Carbohydr Polym 96(2):510–515

Low JH, Andenan N, Wan Abdul Rahman WA, Rusman R, A.Majid R (2017) Evaluation of rice straw as natural filler for injection molded high density polyethylene bio-composite materials. Chem Eng Trans 56:1081–1086

Low JH, Andenan N, Wan Abdul Rahman WA (2018) The influence of crosslink chemicals on the mechanical strength and water absorption of rice straw-based green composites. J Nat Fibers 15:122–130

Datta J, Kopczyńska P (2015) Effect of kenaf fibre modification on morphology and mechanical properties of thermoplastic polyurethane materials. Ind Crops Prod 74:566–576

Ghazali SK, Lee SL, Low JH, Wan Abd Rahman WA (2019) In: Che Man SH, Baharulrazi N (eds) Biomaterial based polymer composites: properties and characterization. Penerbit UTM Press, Johor Bahru

Toh WY, Lai JC, Wan Abdul Rahman WA (2011) Mechanical and water absorption properties of poly(vinyl alcohol)/sago pith waste biocomposites. J Compos Mater 45(11):1201–1207

Wan Omar WNA, Ghazali SK, Low JH, Wan Abd Rahman WA (2019) In: Che Man SH, Baharulrazi N (eds) Biomaterial based polymer composites: properties and characterization. Penerbit UTM Press, Johor Bahru

Pang MM, Aaron Y, Koay SC, Low JH, Choo HL, Tshai KY (2019) Soil burial, hygrothermal and morphology of durian skin fiber filled polylactic acid biocomposites. Adv Environ Biol 13:21–25

Manzine Costa LM, Molina de Olyveira G, Cherian BM, Leão AL, Souza SF, Ferreira M (2015) Bionanocomposites from electrospun PVA/pineapple nanofibers/Stryphnodendron adstringens bark extract for medical applications. Ind Crops Prod 41:198–202

Pang MM, Koay SC, Low JH, Buys YF, Tshai KY(2018) Study on the plasticiser type for biobased microcrystalline cellulose filled polylactic acid composite. IOP Conference Series: Materials Science and Engineering 458:1–6

Chong TY, Law MC, Chan YS (2021) The potentials of corn waste lignocellulosic fibre as an improved reinforced bioplastic composites. J Polym Environ 29(2):363–381

Ayrilmis N, Yurttaş E, Durmus A, Özdemir F, Nagarajan R, Kalimuthu M, Kuzman MK (2021) Properties of biocomposite films from pla and thermally treated wood modified with silver nanoparticles using leaf extracts of oriental sweetgum. J Polym Environ 29:2409–2420

Mwaikambo LY, Martuscelli E, Avella M (2000) Kapok/cotton fabric-polypropylene composites. Polym Test 19(8):905–918

Cruz-Estrada RH, Guillen-Mallette J, Cupul-Manzano CV, Balam-Hernandez JI (2020) Potential use of waste from tree pruning and recovered plastic to obtain a building material: case study of Merida. Mexico Waste Management & Research: The Journal for a Sustainable Circular Economy 38(11):1222–1230

Aris NF, Ghazali SK, Mohamad Z, Jamaluddin J, Adrus N, Abdul Aziz A, Low JH, Majid A R (2022) The effects of alkaline treatment on the oil residue, thermal properties and surface morphology of oil palm Mesocarp fiber. Environ Qual Manag. https://doi.org/10.1002/tqem.21871

Low JH, Ghanbari T, Wan Abdul Rahman WA, Majid A R (2018) Preparation and characterization of kenaf papers reinforced with tapioca starch: physicomechanical and morphological properties. J Nat Fibers 15:191–203

Majid A, Rusman R, Mohamad R, Zulkornain ZA, Halim AA, Abdullah N, Low M JH (2018) Development of tea waste/kapok fiber composite paper. Chem Eng Trans 63:457–462

Rusman R, Majid A, Wan Abd Rahman R, Low WA JH (2017) Carboxymethyl Cassava starch/polyurethane dispersion blend as surface sizing agent. Chem Eng Trans 56:1171–1176

Low JH, Lee ZX, Yoon LW, Pang MM, Wong S (2019) Exploration of tree pruning waste for papermaking. AIP Conf Proc 2137(1):0200081-020008-6

Lim HP, Wan Abdul Rahman WA, Low JH (2020) Properties characterization of Napier grass (Pennisetum purpureum) as the non-wood substitution for natural fiber papermaking. J Adv Mech Eng Appl 1(1):27–35

Sarah S, Rahman WAWA, Majid RA, Yahya WJ, Adrus N, Hasannuddin AK, Low JH (2018) Optimization of pineapple leaf fibre extraction methods and their biodegradabilities for soil cover application. J Polym Environ 26(1):319–329

Low JH, Jusoh@Taib ER, Wan Abdul Rahman WA, S. W (2019) In: Che Man SH, Baharulrazi N (eds) Biomaterial based polymer composites: properties and characterization. Penerbit UTM Press, Johor Bahru

Beh JH, Lai JC, Lim TH, Low JH(2019) In: Fangueiro R (ed) Proceedings of the 4th international conference on natural fibers - smart sustainable solutions. TecMinho - Associação Universidade-Empresa para o Desenvolvimento, Porto

Dias OAT, Negrão DR, Silva RC, Funari CS, Cesarino I, Leao AL (2016) Studies of lignin as reinforcement for plastics composites. Mol Cryst Liq Cryst 628(1):72–78

Hu J, Zhang Q, Lee D-J (2018) Kraft lignin biorefinery: a perspective. Bioresour Technol 247:1181–1183

Teoh SW, Yoon LW, Wong WY, Low JH (2022) Application of black liquor derived carbonaceous compound as fuel in direct carbon fuel cell. Int J Integr Eng 14(2):146–156

Haldar D, Purkait MK (2022) Thermochemical pretreatment enhanced bioconversion of elephant grass (Pennisetum purpureum): insight on the production of sugars and lignin. Biomass Convers Biorefinery 12:1125–1138

Duarah P, Haldar D, Purkait MK (2020) Technological advancement in the synthesis and applications of lignin-based nanoparticles derived from agro-industrial waste residues: a review. Int J Biol Macromol 163:1828–1843

Chen H (2015) Lignocellulose biorefinery engineering. Woodhead Publishing, Sawston

Cheremisinoff NP, Rosenfeld PE (2010) Best practices in the wood and paper industries. William Andrew, Norwich

Merck(2019) IR Spectrum Table & Chart. https://www.sigmaaldrich.com/technical-documents/articles/biology/ir-spectrum-table.html. Accessed 12 January 2020

Low JH, Wan Abdul Rahman WA (2017) In: Kozlowski RM, Muzyczek M (eds) Natural fibers: properties, mechanical behavior, functionalization and applications. Nova Science Publishers, Inc, New York

Nilwala K, Chanaka S, Piyumi P, Nadeesh M, Veranja K (2014) Modified layered nanohybrid structures for the slow release of urea. Nanosci Nanotechnol - Asia 4(2):94–102

Oh T, Choi C (2010) Comparison between SiOC thin films fabricated by using plasma enhanced chemical vapor deposition and SiO2 thin films by using Fourier transform infrared spectroscopy. J Korean Phys Soc 56(4):1150–1155

Pardini OR, Amalvy JI (2008) FTIR, 1H-NMR spectra, and thermal characterization of water-based polyurethane/acrylic hybrids. J Appl Polym Sci 107(2):1207–1214

Lin-Vien D, Colthup NB, Fateley WG, Grasselli JG (1991) The handbook of infrared and Raman characteristic frequencies of organic molecules. Academic Press Limited, London

Zhu J, Xue L, Wei W, Mu C, Jiang M, Zhou Z (2015) Modification of lignin with silane coupling agent to improve the interface of poly(L-lactic) acid/lignin composites. BioResources 10(3):4315–4325

Kaewtatip K, Thongmee J (2013) Effect of kraft lignin and esterified lignin on the properties of thermoplastic starch. Mater Des 49:701–704

Lv S, Tan H, Gu J, Zhang Y (2015) Silane modified wood flour blended with poly(lactic acid) and its effects on composite performance. BioResources 10(3):5426–5439

Spragg R(2014) Measuring orientation in polymer films.Spectrosc Suppl29(8)

Acknowledgements

This work was financially supported by (i) Taylor’s University [Project Code: TRGS/ERFS/1/2018/SOE/030] through the Emerging Research Funding Scheme [Budget Code: 320201-SR67-429-C31] and (ii) Ministry of Higher Education (MoHE) Malaysia, under the Fundamental Research Grant Scheme (FRGS) (FRGS/1/2019/TK02/TAYLOR/02/1).

Funding

This work was financially supported by (i) Taylor’s University [Project Code: TRGS/ERFS/1/2018/SOE/030] through the Emerging Research Funding Scheme [Budget Code: 320201-SR67-429-C31] and (ii) Ministry of Higher Education (MoHE) Malaysia, under the Fundamental Research Grant Scheme (FRGS) (FRGS/1/2019/TK02/TAYLOR/02/1).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, data analysis and manuscript preparation were performed by Qi Yuan Ng and Jiun Hor Low. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of interest/Competing Interests

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ng, Q.Y., Low, J.H., Pang, M.M. et al. Properties Enhancement of Waterborne Polyurethane Bio-composite Films with 3-aminopropyltriethoxy Silane Functionalized Lignin. J Polym Environ 31, 688–697 (2023). https://doi.org/10.1007/s10924-022-02595-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-022-02595-y