Abstract

Bioactive biodegradable films are emerging biomaterials in the food packaging field. This study aims to investigate the effect of different Cenostigma nordestinum extracts (leaves, bark, and exudate bark) on the antioxidant, antimicrobial, and some physicochemical properties of chitosan films. Different concentrations of the extracts were added to the film matrix and the resulting incorporated films were evaluated for their bioactive, optical, mechanical, and water vapor barrier properties. The extracts of C. nordestinum proved to be natural sources of promising bioactive compounds with good antioxidant and antimicrobial properties. The films incorporated with C. nordestinum extracts were opaquer, more resistant to tension, and less permeable to water vapor when compared to chitosan-control films. The incorporation of 300 µg mL−1 of the bark extract in the chitosan film increased the tensile strength from 113.97 ± 0.42 to 164.82 ± 0.85 MPa, and reduced the water vapor permeability from 2.11 ± 0.02 to 1.51 ± 0.04 × 10−10 g (m s Pa)−1. Additionally, the incorporated films presented excellent antioxidant capacity and discrete antimicrobial activity. The ongoing results demonstrate that bioactive chitosan-films incorporated with different C. nordestinum extracts are quite promising for the production of ecologically sustainable packaging for the food industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Synthetic polymers have been used in the manufacture of packaging due to interesting characteristics, such as smoothness, lightness, and transparency [1]. Data related to the use of plastic materials reported that its consumption has grown around 5% each year; meanwhile, the world production of plastics exceeds 50 million tons annually. From 22 to 43% of the waste generated from plastics is disposed of in landfills. Beyond the impact caused to the environment, a large part of these materials is not biodegradable, is rich in lethal additives, and decomposes in around 500 years. Because of this, the soils' infertile is increasing concomitantly to the manufacture and consumption of plastics [2].

Packaging is the biggest polymer processing industry with the food sector using about 40% of all plastic produced [3]. In view of this problem, many studies have been directed for exploring new materials for packaging and preserving food; among them are biodegradable edible coatings or films based on biopolymers [4], which represent a potential alternative to replace synthetic plastics and simultaneously cause low environmental impact [5, 6].

Chitosan, one of the most used materials for film/coating production [7], is a linear polysaccharide composed of d-glucosamine and N-acetyl-d-glucosamine units linked by β-1,4 bonds. As chitosan is biocompatible, biodegradable, and biofunctional, in addition to presenting film-forming capacity and antimicrobial activity, it is considered a viable alternative for food packaging production [8]. Chitosan is also very versatile, i.e., when the extraction protocol is optimized or the deacetylation process is modified, different materials can be obtained, and new functional properties can be displayed. The mixture of biopolymers with film-forming properties and bioactive molecules is promising for the development of new materials for the food packaging field [9]. The addition of natural compounds, such as plant extracts or isolated molecules, can confer antioxidant and/or antimicrobial activities to the packaging, thus depicting the new formulations as excellent alternatives to replace the synthetic preservatives usually added to foods [5, 10].

Cenostigma nordestinum is an endemic tree in the caatinga, where it is popularly known as catingueira, black pig catinga, or rat wood. It has a medium-sized tree habit with yellow flowers arranged in clusters and is widely distributed in the Northeastern semi-arid region [11]. It is often confused with C. pyramidale (previously described as Caesalpinia pyramidalis or Poincianella Pyramidalis), which has the same popular name due to the identical unpleasant odor of the first one. Both of them are important due to the characteristics of the wood (construction, firewood, coal), and its use by popular medicine. Its barks, flowers, and leaves are indicated for pyelonephritis, hepatitis, hypertension, intestinal colic, indigestion, and infant teeth' discomfort [12, 13]. Differently from C. pyiramidale, the biochemical composition, and the bioactive activities of C. nordestinum were not studied. Also, no work reported the incorporation of extracts derived from the parts of this plant in polymeric matrices.

In this context, the present study investigated the antioxidant, and the antimicrobial potential of methanol extracts obtained from the leaves, bark and exudate bark of C. nordestinum on the properties of a bioactive and biodegradable chitosan film. For this, the effect of the incorporation of different concentrations of the extracts were evaluated in terms of bioactive, optical, mechanical and barrier properties.

Materials and Methods

Materials

Chitosan with 90% deacetylation and a molecular weight of 3.4 × 105 Da was purchased from Aqua Premier Co. Ltd (Thailand). Diammonium 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonate) (ABTS) and 2,2-diphenyl-1-picrilhidrazil (DPPH) were obtained from Sigma-Aldrich (USA). Brain Heart Infusion (BHI) agar, and solvents were purchased from Merck (Germany). All other reagents were analytical grade.

Collect and Identification of Plant Material

Leaves, bark, and exudate bark of C. nordestinum (Fig. 1) were collected in December 2019 at the Universidade Federal de Campina Grande in the city of Patos-PB (7° 03′ 33.3″ S and 37° 16′ 30.0″ W). The botanical identification was carried out, and the vouches deposited at the Herbarium Rita Baltazar de Lima of the Universidade Federal de Campina Grande under 7458 number of registration. The register of access to Sistema Nacional de Gestão do Patrimônio Genético e do Conhecimento Tradicional Associado (SisGen) of the Ministry of the Environment (Brazil) has the registration number ABF5334.

Extracts' obtention

After the collection, leaves, bark, and exudate bark of C. nordestinum were dried in an oven at 45 °C until constant weight, and then crushed using a knife mill (Tecnal TE-625), obtaining the powder for the preparation of the extracts. Extracts of the bark (EB), exudate bark (EEB), and leaves (EL) of C. nordestinum were obtained by the maceration technique using the eluotropic series: hexane, chloroform, ethyl acetate, and methanol [14]. The extract was obtained with 100 g of the powder being placed with the extracting solvent in the proportion of 1:10 (w/v) for 24 h. At the end of the extraction process for each sample, the material was filtered through a Whatman No. 1 filter, and rotary-evaporated to eliminate the solvent. For this, only methanolic extracts were used.

Characterization of the Extracts

Qualitative Phytochemical Analysis

The extracts were subjected to a series of phytochemical characterization reactions to detect the presence of secondary metabolites. The methodology was performed according to Matos [15] as described below.

The saponin prospecting test submitted the samples to a vigorous agitation, and allowed the evaluation of the saponin's presence by the formation of a foam. The presence of phenolic compounds was characterized by the reaction of the extracts (2 mg mL−1) with FeCl3 (3% w/v) under stirring. The color modification from blue to red indicated a positive result for phenolic compounds, while the formation of precipitate suggested the presence of tannins. The identification of flavonoids (anthocyanins, anthocyanidins, xanthones, chalcones, aurones, flavones, and flavonols) was performed by observing color modifications induced when the pH of the solutions varied. Extracts' ethanolic solutions (2 mg mL−1) were prepared, and then alkalinized or acidified using sodium hydroxide 20% (w/v) and hydrochloric acid 10% (v/v), respectively. Table 1 shows the identification of flavonoids considering the relation between color and pH changes.

Antioxidant Activity and Total Phenolic Content of the Extracts

DPPH

The antioxidant activity of the extracts was evaluated using the 2,2-diphenyl-1-picryl-hydrazil (DPPH) radical elimination method described by de Veras et al. [16]. Analyzes were performed in triplicate, and inhibition activities were calculated based on the percentage of removed DPPH. A vitamin E analog (Trolox®) was used as a standard. The inhibition percentage (I%) was calculated using the following equation: I% = [(Ac − As)/(Ac)] × 100, where Ac is the absorbance of the control, and As is the absorbance of the sample. The IC50 of DPPH was calculated based on the linear regression of the remaining DPPH percentage in relation to the sample concentration. The classification described by Melo et al. [17] allowed the interpretation of the results. Briefly, high activity is related to an IC50 up to three-fold the value of the inhibitory concentration of the standard (ICS); moderate activity is associated when the IC50 ranges from three to seven times the ICS, and low activity as the IC50 exceeded the ICS seven times.

ABTS

The antioxidant activity of the extracts by the ABTS assay (2,2′-azino-bis 3-ethylbenzothiazoline-6-sulfonic acid) was based on the production of the cationic chromophore radical obtained from the ABTS oxidation [16]. Analyzes were performed in triplicate, and inhibition activities were calculated based on the percentage of removed ABTS. Trolox® was also used as a standard, and the percentage of inhibition (I%) was calculated using the same equation for the DPPH assay. Again, the IC50 was calculated based on the linear regression of the remaining compound (in this case the ABTS) percentage in relation to the sample concentration.

Total Antioxidant Capacity (TAC)

The extracts' TAC was determined by the phosphomolybdenum method [18]. The test was based on the reduction of molybdenum+6 to molybdenum+5 and subsequent formation of a greenish phosphate/molybdenum+5 complex. Tubes containing extracts and reagents (0.6 M sulfuric acid, 28 mM sodium phosphate, and 4 mM ammonium molybdate) were gently mixed, and incubated at 100 °C for 90 min. After that, the absorbance of each sample was measured at 695 nm against a blank. Ascorbic acid was used as a reference, and the total antioxidant capacity (TAC) was calculated using the same equation for DPPH and ABTS assays. This time, the IC50 of the TAC was calculated based on the regression activity of the film in relation to the concentration of the sample. All tests were performed in triplicate.

Determination of the Total Phenolic Content

The total phenolic content was determined by the Folin-Ciocalteu method as described in Reis et al. [19] with some modifications. Initially, 500 µg of each extract was mixed with 1.5 mL of distilled water, 1.5 mL of sodium carbonate (7.5% w/v), and 100 µL of the Folin-Ciocalteu reagent (2 M). Then, the mixture was incubated in a water bath at 37 °C for 30 min, and the absorbances measured at 765 nm. Gallic acid was used as a standard, and the quantification of polyphenols was performed by using a standard curve (correlation coefficient, R2 = 0.996). The results were expressed in mg equivalent of Gallic acid (EAG) g−1.

Antimicrobial Activity of the Extracts

Microorganisms and Inoculum Preparation

Strains of Salmonella typhimurium (ATCC 10,028), Listeria monocytogenes (ATCC 7644), Pseudomonas aeruginosa (ATCC 8626), Staphylococcus aureus (ATCC 6538), Bacillus cereus (ATCC 14,579), and Escherichia coli (ATCC 8739) were grown on Brain Heart Infusion (BHI) agar. After the incubation period, the colonies of each strain were aseptically transferred to a sterile saline (NaCl 0.85% w/v) solution. The turbidity of the solutions was standardized with the 0.5 Mac Farland standard (106 UFC mL−1).

Minimum Inhibitory Concentration (MIC) and Minimum Bactericidal Concentration (MBC)

The MIC and MBC of the extracts were determined according to the standards of the Clinical and Laboratory Standards Institute (CLSI) [20] by the microdilution method using a 96-well microplate and a ramp concentration from 2 to 1024 µg mL−1. Briefly, 100 µL of each extract, 100 µL of BHI broth, and 10 µL of the inoculum (106 CFU mL−1 of each strain) were pipetted into each well of the microplate and incubated at 37 °C for 24 h. Subsequently, aliquots from the wells where no visible growth (turbidity) was observed were transferred to Petri dishes containing BHI agar medium and incubated at 37 °C for 24 h. MBC was considered the lowest concentration after which no microbial growth was observed after culture, while MIC is the lowest concentration where growth was observed after cultivation in the solid medium, but not in the liquid medium. Azithromycin and sterile saline were used as a positive and negative control, respectively.

The interpretation of the MIC was performed as described by Snoussi et al. [21]. Values between 0.05 and 0.5 mg mL−1 were associated with the high antimicrobial activity; those ranging from 0.51 to 1.5 mg mL−1 to moderate activity, and the ones higher than 1.5 mg mL−1 to low antimicrobial activity.

Preparation of the Films

The filmogenic solution of chitosan was prepared as described by por Souza et al. [22] with some modifications. Briefly, 1 g of chitosan was dissolved in 100 mL of acetic acid (1%, v/v) under agitation using a magnetic stirrer at 200 rpm for 16 h at room temperature (25 °C). Sorbitol [0.3% (w/v)] was added to this filmogenic solution using the same conditions for more 2 h of stirring. Each methanolic extract (EB, EEB, EL) was added to the filmogenic solution at concentrations of 100, 200, and 300 µg mL−1 (10, 20, and 30 mg of each extract per g of chitosan) under magnetic stirring for 2 h. The films were obtained by the bench casting method, in which 8 mL of each filmogenic solution was transferred to a Petri dish (90 mm in diameter), and dried in an oven with air circulation at 50 °C for 8 h. The control film, i.e., the one based on chitosan, was named CF, while films containing 100, 200, and 300 µg mL−1 of EB, EEB, and EL were named EBF100, EBF200, EBF300, EEBF100, EEBF200, EEBF300, ELF100, ELF200, and ELF300, respectively. The dry films were stored in desiccators at 25 °C and 54% relative humidity [obtained using a saturated solution of Mg (NO3)2·6H2O] until the subsequent analyses.

Films Characterization

Color and Opacity

Color and opacity were determined using a digital colorimeter (CR 400; Minolta, Japan), and the parameters L* (L* = 0 [black] and L* = 100 [white]), a* (− a* = green and + a* = red), and b* (– b* = blue and + b* = yellow). Chroma and opacity (Y) were determined using the following equations [22, 23]:

where (Yp) is the opacity of the film in the black pattern, and (Yb) is the relative opacity in the white pattern. Five measurements were randomly taken for each film replicate, and the experiment was performed in triplicate, totaling fifteen readings per type of film. The average of the obtained values was presented in the results.

Thickness

The thickness of the films was determined using a digital micrometer (Digimess, Brazil) by choosing five different and random points of measurement [22].

Water vapor permeability (WVP)

WVP was determined gravimetrically as described by Souza et al. [22]. Each film (CF, EBF100, EBF200, EBF300, EEBF100, EEBF200, EEBF300, ELF100, ELF200, and ELF300) was used to seal the top of a permeation cell containing distilled water (100% relative humidity, vapor pressure at 2337 Pa, and 20 °C); then, the system was placed in a desiccator containing silica at 20 °C and 0% relative humidity (water vapor pressure at 0 Pa). The cells were weighed for 10 h, always at 2 h intervals. The slope of mass loss versus time was obtained by linear regression. WVP was expressed in g m−2 s−1 Pa−1, and calculated using the following equation: where WVTR is the rate of water vapor transmission (gm−2 s−1) through the film, L is the average film thickness (m), and ΔP is the partial difference in water vapor pressure (Pa) through the two sides of the film.

Mechanical Properties

The maximum tensile strength (TS), elongation at break (EB), and elasticity modulus (also called Young's modulus, YM) were performed on a Universal Testing Machine (EMIC-DL-500) following the guidelines of ASTM D882-12 [24]. Film strips with dimensions of 50 mm in length and 10 mm in width were used, and the average film thickness was measured as previously described in ‘Thickness’. The initial grip separation was set at 10 mm, and the traction speed was set at 5 mm min−1. The data of the stress curves (MPa) versus deformation (%) were collected and treated using the equipment’s software. The Young’s modulus was obtained considering the tangent of the elastic region of the stress versus strain curves. The values of EB were calculated as the ratio of the final length at the point of the sample to the initial length of a sample (10 mm) and expressed as a percentage. The films were kept for two days in a controlled environment at 25 °C, and 54% relative humidity (obtained using a saturated solution of Mg(NO3)2·6H2O) until the above-mentioned analyses, which were repeated 10-times per film.

Films Bioactivity

Antioxidant Activity of the Films

The antioxidant activity of each film (CF, EBF100, EBF200, EBF300, EEBF100, EEBF200, EEBF300, ELF100, ELF200, and ELF300) was evaluated using the 2,2-diphenyl-1-picryl-hydrazil (DPPH) radical capture method as described by Souza et al. [25] with minor modifications. Briefly, rectangular samples of each film (20 mg) were placed in tubes containing 1 mL of DPPH methanolic solution (60 µM), and the system was mixed on a rotary shaker (150 rpm) for 30 min at room temperature and dark. The DPPH solution was used as control. Then, 200 µL of each sample were transferred to a 96-well microplate and submitted to absorbance measurements at 515 nm (ELISA reader, Bio-Rad). The percentage of free radical scavenging by each sample was calculated according to the following equation:

where Abs515sample corresponds to the absorbance of the tubes containing the films (CF, EBF100, EBF200, EBF300, EEBF100, EEBF200, EEBF300, ELF100, ELF200, and ELF300), and Abs515control is the absorbance of the DPPH solution (control). All measurements were performed in triplicate, and the results were expressed as mean ± standard deviation.

Antibacterial Activity of the Films—Agar Diffusion Method

The antibacterial activity of each film (CF, EBF100, EBF200, EBF300, EEBF100, EEBF200, EEBF300, ELF100, ELF200, and ELF300) was evaluated using the agar diffusion method as described by Souza et al. [22] with minor modifications. Briefly, the standardized inoculum (corresponding to a 0.5 on the Mc Farland scale) was placed as a mat on the surface of Petri dishes containing BHI agar medium with the aid of a sterile swab. Film samples with 5.0 mm in diameter were placed on the plates. Paper disks containing azithromycin (1028 µg mL−1) and autoclaved saline (0.85% w/v) were used as positive and negative controls, respectively. The inoculated plates were incubated at 37 °C for 24 h, and then submitted to a visual analysis by measuring the diameter of the growth inhibition zone around the film. All tests were performed in triplicate.

Statistical Analysis

All experiments were performed in triplicate, and the results were expressed as mean ± standard deviation. The means were compared using one-way analysis of variance (ANOVA) followed by Tukey test using the GraphPad Prisma software. Statistical data were considered significant with p < 0.05.

Results and Discussion

Characterization of the Extracts

Phytochemical Analysis

The phytochemical screening of C. nordestinum extracts suggests the presence of phenolic substances such as tannins and flavonoids (Table 2). Anthocyanins and anthocyanidins were found in the leaves while saponins were observed in the bark. Flavones, flavonols, xanthans, and flavononols were present in the bark and the exudate bark; the obtained results demonstrate some differences in the synthesis, accumulation, and distribution of secondary metabolites in relation to the different parts of the plant [26].

In what concerns the best of our knowledge, it is the first time that a phytochemical analysis is performed for the extracts of C. nordestinum; however, it is important to mention that the presence of diterpenes, flavonoids, and other phenolic compounds is characteristic of this genus and family [27]. For example, methanolic extracts from C. pyramidalis leaves were demonstrated to be rich in bioflavonoids, such as loniflavone, amentoflavone, 5’-hydroxialamentoflavone, podocarpusflavone, agatisflavone, and taxifoline [28]. The leaves and exudate bark of C. pyramidalis were also phytochemically studied and demonstrated the presence of flavonoids, sitosterol, and cinnamic derivatives [29]. Additionally, tannins, catechins, condensed protocyanidins, and compounds such as 4,4′-dihydroxy-2′-methoxicalcon, syringaresinol, and methyl gallate were detected in the bark of this very plant [27, 29, 30].

Antioxidant Activity and Total Phenolic Content

The results of the antioxidant activity and total phenolic content are displayed in Table 3. The total phenolic content was higher for the extracts obtained from the bark, followed by them obtained from the exudate bark, and the lowest values were from the leaf’s extracts. All of the results presented significant differences (p > 0.05) between them. It is known that phenolic compounds have hydroxyl groups that facilitate the elimination of free radicals; thanks to this fact, they have redox properties responsible for the antioxidant activity found in different extracts [31].

This is the first study to present data for the antioxidant activity of C. nordestinum extracts. The extracts obtained from the bark showed the most significant antioxidant activity, followed by those obtained from the leaves, and the extracts from the exudate bark the least efficient. When compared to the standards Trolox® and ascorbic acid, the activity of capturing free radicals from all of the extracts were lower than Trolox® and higher than vitamin C (p > 0.05).

Other authors studied the antioxidant activity of extracts obtained from this genus and family; for example, Melo et al. [17] evaluated the antioxidant activity of the methanol extract from the leaves of C. pyramidalis using the DPPH method and obtained an IC50 of 42.95 ± 1.77 µg mL−1, a similar result to that described in this work. In another study, the antioxidant activity of the hydroalcoholic extract (70% ethanol) from the bark of C. pyramidalis showed an IC50 of 16.98 ± 1.34 µg mL−1, a better result than the one obtained from the leaves extract with an IC50 of 38.93 ± 0.71 µg mL−1 [32]. According to the classification of Melo et al. [17], EL and EEB have good antioxidant activity, while EB has moderate activity.

Some studies have reported the relation between total phenolic content and antioxidant activity of plant products [31, 32], which was not achieved in this very study (Table 3); in our case, the differences displayed by the extracts obtained from each part of C. nordestinum could explain the heterogeneity of phenolic content and antioxidant activities. As already reported in ‘Phytochemical Analysis’ (phytochemical results), the distribution pattern of the different secondary metabolites is not uniform among the different parts of the plant, which corroborates the significant differences obtained for the antioxidant activity of the extracts from bark, leaf, and exudate bark of C. nodestinum in this study. Tannins, for example, are usually found in the bark or exudate bark and may represent up to 40% of the metabolites present in the bark of some species [33]. It is important to mention that antioxidant molecules have different mechanisms of action, including chelation of transition metal ions, radical elimination, and donation and acceptance of electrons. The antioxidant capacity also depends on several other factors, such as the size and steric accessibility of the antioxidant molecule. In view of this, different plants or different parts of the same plant can present antioxidant activity based on various mechanisms, due to several molecules [34].

The antioxidant activity observed for the extracts of C. nodestinum can be attributed to the phenolic molecules, flavonoids, tannins, anthocyanins, anthocyanidins, and other compounds, which are well-known as antioxidants due to their functional groups and the ability to act as reducing agents [31, 34,35,36]. From these results, C. nodestinum can be presented as a new source of antioxidant compounds.

Antimicrobial Activity

The results for MIC and MBC are presented in Table 4. The strains tested in this study are known for their deteriorating action and the ability to cause food poisoning problems; thanks to this, they are of high interest to the food industry. Our results demonstrated that all of the strains were sensible to the positive control (azithromycin). It is also possible to observe that EL showed high inhibition activity (MIC) against S. typhimurium, P. aeruginosa, L. monocytogenes, B. cereus, and S. aureus, in addition to a moderate inhibition of the growth of E. coli. EEB showed high activity for all of the strains, while EB demonstrated high antibacterial activity against P. aeruginosa, L. monocytogenes, B. cereus, and S. aureus, and a moderate activity against S. typhimurium and E. coli.

Despite the high activity (MIC) demonstrated by EEB against all Gram-positive and Gram-negative bacteria, i.e., its bacteriostatic activity, the bactericidal activity of EL was greater because of the lower concentration of extract required for the death of most of the strains tested in this study. As expected, EB was the least efficient antimicrobial.

Up to this moment, the mechanisms associated with the antimicrobial activity of phenolic compounds are still little known by the scientific community. The hypothesis is that they can modify the permeability of cell membranes, increase the loss of cell wall integrity, and cause changes in intracellular functions by enzyme linkages [37, 38]. The differences observed for the antimicrobial activity of the three extracts of C. nordestinum may be associated with the amount of reducing agents of each extract, as well as the mechanism of antioxidant action of their functional groups [39]. As already reported in the phytochemical screening (‘Phytochemical Analysis’, Table 2), there are several groups of secondary metabolites in EL, EEB, and EB, which may preliminarily explain the broad spectrum of antimicrobial action obtained for the extracts against the tested strains.

As the report for the phytochemical analysis and the antioxidant activities of the extracts of C. nordestinum, this is the first study investigating the antimicrobial activity of EL, EEB, and EB. Other studies were conducted for plants from the same family and currently classified in the same genus. For instance, C. pyramidalis was studied by Saraiva et al. [29] in terms of the evaluation of the antimicrobial activity of the methanolic extracts obtained from different parts of this plant (leaves, bark, flower, seed, and fruits) against twenty-one strains of S. aureus, being two standard strains (ATCC) and nineteen clinical isolates. The extracts of leaves and bark showed MIC results varying from 500 to 2000 µg mL−1, which are higher than those described in this work (256 µg mL−1). Additionally, hydroalcoholic extract (50% ethanol) of C. pyramidalis showed no antibacterial activity against standard strains (ATCC) and clinical isolates of E. coli, P. aeruginosa, and K. pneumoniae [40]. However, when 125 µg mL−1 of the above-mentioned extract was combined with synthetic antibiotics, it significantly increased the activity of the different classes of antibiotics and reduced the MIC for multidrug-resistant strains [40].

Characterization of the Films

Appearance, Thickness, Color, and Opacity

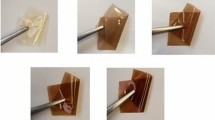

The appearance of the films is presented in Fig. 2. Considering the visual aspect of the films, all of them presented a smooth, shiny, and uniform surface, with good structural integrity and no visible cracks or pores. In addition, they were easily removed from the surface used for polymerization. Control films (CF) were transparent and bright, while chitosan films incorporated with different extracts concentration (EBF100, EBF200, EBF300, EEBF100, EEBF200, EEBF300, ELF100, ELF200, and ELF300) were colored from brown to yellow, depending on the extract and the concentration added to the film.

Films incorporating C. nordestinum extracts. (CF) Chitosan film; (EEBF100) chitosan film with 100 µg mL−1 of exudate bark extract; (EEBF200) chitosan film with 200 µg mL−1 of exudate bark extract; (EEBF300) chitosan film with 300 µg mL−1 of exudate bark extract; (EBF100) chitosan film with 100 µg mL−1 of bark extract; (EBF200) chitosan film with 200 µg mL−1 of bark extract; (EBF300) chitosan film with 300 µg mL−1 of bark extract; (ELF100) chitosan film with 100 µg mL−1 of leaf extract; (ELF200) chitosan film with 200 µg mL−1 of leaf extract; (ELF300) chitosan film with 300 µg mL−1 of leaf extract

Thickness is an important parameter and must be controlled in the production of the films since it directly affects the mechanical properties, water vapor permeability, and the opacity of the films [41]. Concerning thickness results, CF film obtained a value of 0.043 ± 0.007 mm, and no significant differences (p < 0.05) were observed for the thickness of the films incorporated with the extracts from leaves (EL), exudate bark (EEB), and bark (EB) of C. nordestinum. The hypothesis is that the small concentration of extracts added to the chitosan film did not influence the thickness of the incorporated films. Chitosan films were also incorporated with purple pulp sweet potato extract at low concentration (0.1% w/v) and, as expected, no significant changes in thickness results were observed [42]. Oppositely, the incorporation of 0.5 and 1% of diatomite into chitosan films increased the values of thickness of the films produced by Akyuz et al. [43].

The color and opacity parameters of the films are presented in Table 5. CF was bright with a strong whiteness tendency as presented by L*; additionally, it showed a negative result for a* and positive for b*, corresponding to green and yellow components, respectively. Considering the association of the results of L*, a*, and b*, they indicate that CF presented a light-yellow hue tending to transparency. Chitosan films with a negative a* coordinate, a positive b*, result and L* greater than 90 were also obtained by Yong et al. [41].

The incorporation of EL, EEB, and EB of C. nordestinum in the chitosan film influenced the coordinates a* and b*, thus increasing the redness and the yellowness of the incorporated films, respectively. EEBF300 presented a significant increase in a*, which can be explained by a greater content of polyphenols capable of selectively absorbing some low wavelengths, thus leading to a film more reddish in color [44]. The yellow tendency associated with higher values of b* can be attributed to the presence of flavonoids in the extracts. Similar results were obtained by Kan et al. [45] working with films based on chitosan and gelatin incorporated with the hydroalcoholic extract from Crataegus pinnatifida fruits. It is also possible to observe that the luminosity (represented by L*) decreased with the incorporation of the extracts, confirming the films' appearance already reported in Fig. 2. The darkness pattern of the incorporated films is probably associated with the crosslinking in chitosan chains due to the presence of polyphenols [44].

One can see that the values of Chroma for all of the films increased by increasing the concentration of the extracts obtained from C. nordestinum (regardless of the type of incorporated extract). Similar behavior was observed with the incorporation of thyme extract (Thymus serpyllum L.) in a chitosan matrix; an increase in the extract concentration led to the formation of more saturated colors and a higher chroma value for the film [44].

The incorporation of 300 µg mL-1 of EL and EB significantly increased (p > 0.05) the values of opacity (Y) of the incorporated films (ELF and EBF, respectively) when compared to CF. When EEB was incorporated, a significant increase (p > 0.05) was observed for concentrations of 200 and 300 µg mL-1. These results are probably associated with an increase in the scattering of light in the polymeric chitosan network that interferes with the transmission of light through the film as the extract is added to the matrix [45].

Other natural extracts, such as sweet potato extract, purple eggplant extract, oak extract (Quercus robur), hop extract (Humulus lupulus), and brown algae extract (Laminaria hyperborean) were incorporated in chitosan films and, in agreement with our results, led to an improvement in the light barrier properties [41, 42, 46]. These results are important because packages are compatible with a barrier to UV-Vis light, thus acting on the delay of the oxidation of lipids and preserving the organoleptic properties of packaged foods [22, 45].

Mechanical Properties and Water Vapor Permeability

The results of the mechanical properties of the films are presented in Table 6. This characterization represents the films' ability to maintain the integrity and support external stresses during the processing, transport, handling, and storage of packaged foods [45]. The values obtained for tensile strength (TS), elongation at break (EB), and Young's modulus (YM) demonstrate that all of the films have a rigid and inelastic behavior.

Regarding TS results, it is important to highlight the value obtained for CF (113.97 ± 0.42 MPa), which is 3 to 5-fold higher than the ones reported in the literature for chitosan films; for example, Kan et al. [45], Zhang et al. [47], and Qin et al. [48] obtained TS values of 20.02, 33.7, and 20.8 MPa, respectively. The incorporation of EL, EEB, and EB of C. nordestinum in the chitosan film increased TS values when compared to CF. This effect is probably associated with the formation of a more stable and denser polymer matrix as electrostatic interactions are formed by the hydrogen bonds between phenolic compounds and chitosan [49]. Similar behavior was observed for other extracts incorporated into chitosan-based films, for example, those obtained from Crataegus pinnatifida and Thymus serpyllum [44, 45].

The exception was for the film with 300 µg mL-1 of EB (EBF300), whose TS value was lower than all of the other films. The hypothesis is that this extract agglomerated and dispersed heterogeneously into the film in a different way than the other extracts. The loss of cohesion in the polymeric matrix of the films incorporated with EE influenced the mechanical properties of the matrix, thus decreasing TS values and, as expected, also decreasing EB values.

Regarding EBF results, the incorporation of the extract did not alter (p < 0.05) these values when compared to CF. However, particular differences were observed among the films with different concentrations of the same extract. In general, values of EB decreased with increasing the extract concentration. Similar behavior was observed for the incorporation of Chlorella defatted biomass by up to 25%, which significantly decreased TS and EB of biodegradable films based on chitosan [50]. An opposite behavior was observed when C. sativa seed oil was incorporated in a chitosan matrix, decreasing the intermolecular forces between polymer chains, thus resulting in films more fragile and flexibles, that is, with a decreased TS and an increased EB [51].

YM is related to the stiffness of the material in low deformations [44]. It is possible to predict that the crosslinking action of the phenolic compounds into the polymeric chain of chitosan led to an increase in the stiffness of the films, thus influencing elastic modulus results. It is not possible to demonstrate a relationship between elasticity and extract concentration; however, the results are consistent with those obtained for EB and the increased stiffness (higher YM) and tensile strength (TS) for incorporated films, thus confirming the reinforcing effect of the extracts into the chitosan matrix.

The increase observed in tensile strength (TS) and Young’s modulus was also observed with the addition of cellulose nanocrystals in chitosan films, caused by electrostatic interactions between the chitosan cationic chains and the anionic cellulose nanocrystals [52]. In contrast, the incorporation of 0.5 and 1% (w/v) of diatomite in chitosan films decreased the number of cross-links in the polymeric structure, thus decreasing TS and YM and increasing EB values [43].

WVP determines the ability of the films to interact with water and to protect packaged foods from dehydration or rehydration processes. Therefore, it is important to obtain values of WVP as low as possible [22, 53]. CF showed a WVP of 2.11 ± 0.02 × 10−10 g. (m.s.Pa)−1, corroborating the results obtained by Souza et al. [22] [2.33 ± 2.84 × 10−10 g. (m.s.Pa)−1]. With the addition of the extracts, a significant decrease (p > 0.05) was observed in WVP results for EEBF100, EEBF200, EEBF300, ELF200, ELF300, EBF200, and EBF300 (Table 6).

As already discussed for TS results, it is believed that the incorporation of the extracts increased the crosslinking into the chitosan chain, thus reducing the free volume in the polymeric matrix and reinforcing the structure of the film; thanks to this, we hypothesize that the denser structure of the incorporated films is associated with decreased values of WVP. Another explanation is that the reduction in WVP values of incorporated films occurs by the formation of a more tortuous path with the addition of the extracts, thus decreasing the diffusivity of water molecules through the chitosan matrix [45]. Similar behavior has been reported for chitosan films containing polyphenols from apple peel or purple eggplant extract [41, 53].

Films Bioactivity

Oxidation reactions and the growth of microorganisms are the main factors associated with food degradation. The incorporation of antioxidants and antimicrobials in packaging materials can prolong its shelf life, in addition to improve the quality and safety of the food [22]. Several synthetic products have been used for this purpose; however, they are more associated with health risks than products sourced from natural origin, for instance, plant extracts, whose bioactivities are gaining much attention in the last three decades [54].

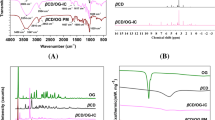

Results of the antioxidant activity of the films are presented in Fig. 3. CF did not show antioxidant activity, corroborating the results obtained by Souza et al. [22] when they studied films containing 1% (w/v) of chitosan. Some works report that chitosan-based films may have antioxidant activity due to the ability to eliminate free radicals from the amino groups present in C-2 of the glycosamine units of the polysaccharide chain [41, 53, 55]. Thus, the antioxidant activity of chitosan depends on its molecular weight and degree of deacetylation, which are reflected in the availability of amino groups throughout the polymeric matrix, i.e., the more amino groups, the greater the antioxidant activity of the film [23].

Regarding DPPH results, it is possible to observe that the addition of the extracts into the chitosan matrix increased the DPPH elimination capacity of the incorporated films (Fig. 3); furthermore, the antioxidant activity increased in a dependent-way in relation to the concentration of the extracts (regardless the type of incorporated extract). One can attribute this behavior to the increase in antioxidant phytochemicals, i.e., the phenolic content of the extracts. As mentioned by Kaya et al. [56], the addition of a small amount of plant extract into the chitosan film enhanced the antioxidant properties. ELF100, ELF200, ELF300, EB100, EB200, EB300, EEB100, EEB200, and EEB300 contain, respectively, about 2.72, 5.46, 8.72, 7.72, 15.44, 23.16, 5.28, 10.56, and 15.84 mg of phenolic compounds per 1 g of chitosan. Kaya et al. [57] attributed the antioxidant activity of chitosan films containing methanol extracts from the stem, leaves, and seeds of Pistacia terebinthus to the high phenolic content present in the extracts. Koc et al. [55] also attributed the antioxidant activity of the chitosan film containing a fungal extract of Tricholoma terreum to the polyphenolic compounds found in the extract.

The differences observed for the results of antioxidant activity (in relation to the ability to capture free radicals) is associated with the complex composition of the three types of extracts. As expected, the films containing EB were the most efficient antioxidants, thus corroborating the results obtained for the free extract (‘Antioxidant Activity and Total Phenolic Content’, Table 3). Considering the films containing EEB and EL, it is possible to observe a different pattern; ELF presented the better antioxidant activity (p > 0.05) when incorporated with the high extract concentration (300 µg. mL−1), while no significant (p < 0.05) differences were observed between EEBF and ELF when they were incorporated with 100 and 200 µg. mL−1 of the extracts.

Ruiz-Navajas et al. [58] incorporated essential oils of Thymus moroderi and Thymus piperella in chitosan films and observed that their ability to capture DPPH radicals occurred in a concentration-dependent manner. Similar behavior was also observed by Yong et al. [42] with the incorporation of purple pulp sweet potato extract in a chitosan matrix.

In what concerns the results of antimicrobial activity, all strains were sensible to azithromycin (positive control), with zones of inhibition ranging from 16.3 ± 0.57 to 21.6 ± 0.57 mm, and the negative control (with saline) did not present inhibition zones. The control film (CF) did not show antimicrobial activity, which is expected for chitosan films already reported by the literature. For example, Xu, Chen and Liu [59]demonstrated that the chitosan matrix was not effective against any of the four strains of bacteria tested in their work, including E. coli and L. monocytogenes. Ballester-Costa [60] also reported no antimicrobial activity for the studied chitosan-based film. The effective antimicrobial action of chitosan is close related to the positively charged amino groups in its monomer units, which react with the anionic groups on the bacterial cell surface [58].

None of the developed films was able to inhibit the growth of S. typhimurium and E. coli; additionally, all of the films containing extracts at 100 µg mL-1 concentration were ineffective against the tested strains. The incorporation of the extracts into the chitosan matrix produced new systems whose antimicrobial activity was lower than the positive control (azithromycin); however, it is important to mention that the absence (or small zone of inhibition) observed for the incorporated films could be associated with the amount of extract added to the matrix. It is possible that better results of antimicrobial activity could be obtained for concentrations higher than 300 µg mL-1 of the extracts from C. nordestinum.

The incorporation of 3330 µg mL−1 (a concentration 11.1 times greater than the highest concentration used in our study) of methanolic extracts obtained from the stem, leaves, and seeds of Pistacia terebinthus in chitosan films was able to inhibit the growth of Gram-negative bacteria, such as P. microbilis, P. vulgaris, P. aeruginosa, and E. coli with zones of inhibition ranging from 28.19 ± 0.92 to 21.33 ± 0.74 mm [57].

ELF exhibited antimicrobial activity against P. aeruginosa and S. aureus at 300 µg mL−1 of concentration, with inhibition zones of 6.5 ± 0.5 mm and 7.5 ± 0.5 mm (p < 0.05), respectively. The incorporation of EEB inhibited the growth of P. aeruginosa, S. aureus, and L. monocytogenes at 200 and 300 µg mL−1 of concentration, with a diameter ranging from 6.5 ± 0.5 to 7.5 ± 0.5 mm (p < 0.05). The results of antimicrobial activity of fims incorporated with EB were more expressive than those obtained for films with EEB and EL. EBF showed zones of inhibition of 5.5 ± 0.5 and 9.5 ± 0.0 mm against P. aeruginosa at 200 and 300 µg mL−1 of concentration, respectively. Regarding the zones of inhibition for L. monocytogenes and S. aureus, they varied from 7.5 ± 1.5 to 9.0 ± 0.5 mm and from 6.5 ± 0.5 to 8 ± 1.0 mm (p < 0.05), respectively. Furthermore, the inhibition of the growth of P. aeruginosa and L. monocytogenes by EBF300 was higher (p > 0.05) than the results observed for EEBF300 and ELF300; this very film (EBF300) was the only one capable of inhibiting the growth of B. cereus, with an inhibition zone of 7.5 ± 0.5 mm.

According to the results, it is possible to observe that a greater number of Gram positive strains were sensible to chitosan films incorporating C. nordestinum extracts when compared to Gram negative. The last one strains are often less susceptible to antimicrobials due to the protective effect provided by their relatively impermeable outer membrane [61].

Conclusions

The extracts of C. nordestinum described here for the first time are natural sources of promising bioactive compounds, and have the potential to be used in the production of ecologically sustainable packaging for the food industry. The incorporation of the extracts (obtained from different parts of the plant) into chitosan films led to the development of bioactive packaging, with excellent antioxidant capacity and discrete antimicrobial activity; additionally, the incorporated films presented better mechanical, optical, and water vapor barrier properties than the pure chitosan film.

In the future, the promising films developed in this very work are suggested to be used as active packaging to extend the shelf life of food products, as well as to minimize the environmental impacts caused by the use of conventional (synthetic) materials. However, for its effective use, further research is needed to fully-elucidate the chemical composition of the extracts. It is also necessary to carry out studies to assess the effect of these new packages on different types of food.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

Janik H, Sienkiewicz M, Przybytek A et al (2018) Novel biodegradable potato starch-based compositions as candidates in packaging industry, safe for marine environment. Fibers Polym 19:1166–1174. https://doi.org/10.1007/s12221-018-7872-1

Verma R, Vinoda KS, Papireddy M, Gowda ANS (2016) Toxic pollutants from plastic waste—a review. Procedia Environ Sci 35:701–708. https://doi.org/10.1016/j.proenv.2016.07.069

Landim APM, Bernardo CO, Martins IBA et al (2016) Sustentabilidade quanto às embalagens de alimentos no Brasil. Polimeros 26:82–92. https://doi.org/10.1590/0104-1428.1897

Al-Tayyar NA, Youssef AM, Al-Hindi RR (2020) Edible coatings and antimicrobial nanoemulsions for enhancing shelf life and reducing foodborne pathogens of fruits and vegetables: a review. Sustain Mater Technol 26:e00215. https://doi.org/10.1016/j.susmat.2020.e00215

Baygar T (2019) Bioactivity potentials of biodegradable chitosan/gelatin film forming solutions combined with monoterpenoid compounds. J Polym Environ 27:1686–1692. https://doi.org/10.1007/s10924-019-01465-4

Gao HX, He Z, Sun Q et al (2019) A functional polysaccharide film forming by pectin, chitosan, and tea polyphenols. Carbohydr Polym 215:1–7. https://doi.org/10.1016/j.carbpol.2019.03.029

Breda CA, Morgado DL, Assis OBG, Duarte MCT (2017) Processing and characterization of chitosan films with incorporation of ethanolic extract from “pequi” peels. Macromol Res 25:1049–1056. https://doi.org/10.1007/s13233-017-5143-4

Hemalatha T, UmaMaheswari T, Senthil R et al (2017) Efficacy of chitosan films with basil essential oil: perspectives in food packaging. J Food Meas Charact 11:2160–2170. https://doi.org/10.1007/s11694-017-9601-7

Mir SA, Dar BN, Wani AA, Shah MA (2018) Effect of plant extracts on the techno-functional properties of biodegradable packaging films. Trends Food Sci Technol 80:141–154. https://doi.org/10.1016/j.tifs.2018.08.004

Leceta I, Guerrero P, Cabezudo S, De la Caba K (2013) Environmental assessment of chitosan-based films. J Clean Prod 41:312–318. https://doi.org/10.1016/j.jclepro.2012.09.049

Carlos R, Carvalho S, Lúcia S (2015) Bioatividade da raiz de Poincianella bracteosa (Tul.) L. P. Queiroz (Fabaceae) sobre larvas do Aedes aegypti (Linnaeus, 1762) (Diptera : Culicidae). 259–264. https://doi.org/http://www.ufrgs.br/seerbio/ojs/index.php/rbb/article/view/3399

Monteiro JM, De Souza JSN, Neto EMFL et al (2014) Does total tannin content explain the use value of spontaneous medicinal plants from the Brazilian semi-arid region? Rev Bras Farmacogn 24:116–123. https://doi.org/10.1016/j.bjp.2014.02.001

de Sousa LMS, Santos BNG, Medeiros M, das GF et al (2021) Poincianella pyramidalis (Tul) L.P. Queiroz: a review on traditional uses, phytochemistry and biological-pharmacological activities. J Ethnopharmacol 264:113181. https://doi.org/10.1016/j.jep.2020.113181

Azmir J, Zaidul ISM, Rahman MM et al (2013) Techniques for extraction of bioactive compounds from plant materials: a review. J Food Eng 117:426–436. https://doi.org/10.1016/j.jfoodeng.2013.01.014

Matos FJA (2009) Introdução à fitoquímica experimental. UFC, Fortaleza

De Veras BO, Queiroz Y, Granja F et al (2019) Algrizea Minor Sobral, Faria & Proença antinociceptive, antimicrobial and antioxidant activity of essential oil. Nat Prod Res 0:1–5. https://doi.org/10.1080/14786419.2019.1602832

De Melo JG, De Sousa Araújo TA, De Almeida Castro VTN et al (2010) Antiproliferative activity, antioxidant capacity and tannin content in plants of semi-arid northeastern Brazil. Molecules 15:8534–8542. https://doi.org/10.3390/molecules15128534

Prazeres LDKT, Aragão TP, Brito SA et al (2019) Antioxidant and Antiulcerogenic Activity of the Dry Extract of Pods of Libidibia ferrea Mart. ex T. (Fabaceae). 23 p. https://doi.org/10.1155/2019/1983137

dos Reis AS, Diedrich C, de Moura C et al (2017) Physico-chemical characteristics of microencapsulated propolis co-product extract and its effect on storage stability of burger meat during storage at – 15°C. LWT Food Sci Technol 76:306–313. https://doi.org/10.1016/j.lwt.2016.05.033

CLSI (2018) Performance standards for antimicrobial susceptibility testing. 28th. Clinical Laboratory Standards Institute, Wayne

Snoussi M, Noumi E, Najla RP (2018) Antioxidant properties and anti-quorum sensing potential of Carum copticum essential oil and phenolics against Chromobacterium violaceum. J Food Sci Technol. https://doi.org/10.1007/s13197-018-3219-6

Souza MP, Vaz AFM, Silva HD et al (2015) Development and characterization of an active chitosan-based film containing quercetin. Food Bioprocess Technol 8:2183–2191. https://doi.org/10.1007/s11947-015-1580-2

Hamdi M, Nasri R, Li S, Nasri M (2019) Bioactive composite films with chitosan and carotenoproteins extract from blue crab shells: biological potential and structural, thermal, and mechanical characterization. Food Hydrocoll 89:802–812. https://doi.org/10.1016/j.foodhyd.2018.11.062

ASTM- American Society for Testing and Material (2016) ASTM D882- 12: standard test method for tensile properties of thin plastic sheeting. ASTM, West Conshohocken

Souza MP, Vaz AFM, Costa TB et al (2018) Construction of a biocompatible and antioxidant multilayer coating by layer-by-layer assembly of κ-carrageenan and quercetin nanoparticles. Food Bioprocess Technol 11:1050–1060. https://doi.org/10.1007/s11947-018-2077-6

Li Y, Kong D, Fu Y et al (2020) The effect of developmental and environmental factors on secondary metabolites in medicinal plants. Plant Physiol Biochem 148:80–89. https://doi.org/10.1016/j.plaphy.2020.01.006

Thiago PC, Joanda PReS, de Francinalva D et al (2015) Traditional use, phytochemistry and biological activities of Poincianella pyramidalys (Tul.) LP Queiroz. Afr J Biotechnol 14:3350–3358. https://doi.org/10.5897/ajb2015.14794

Bahia MV, David JP, David JM et al (2010) Occurrence of biflavones in leaves of Caesalpinia pyramidalis specimens. Quim Nova 33:1297–1300

Saraiva AM, Saraiva CL, Gonçalves AM et al (2012) Antimicrobial activity and bioautographic study of antistaphylococcal components from Caesalpinia pyramidalis Tull. Braz J Pharm Sci 48:147–154. https://doi.org/10.1590/S1984-82502012000100016

Bahia MV, Dos Santos JB, David JP, David JM (2005) Biflavonoids and other phenolics from Caesalpinia pyramidalis (Fabaceae). J Braz Chem Soc 16:1402–1405. https://doi.org/10.1590/S0103-50532005000800017

Aryal S, Baniya MK, Danekhu K et al (2019) Total Phenolic content, Flavonoid content and antioxidant potential of wild vegetables from western Nepal. Plants 8. https://doi.org/10.3390/plants8040096

Da Silva CHTP, Da Silva Peixoto Sobrinho TJ, De Almeida E, Castro VTN et al (2011) Antioxidant capacity and phenolic content of Caesalpinia pyramidalis Tul. and Sapium glandulosum (L.) morong from northeastern Brazil. Molecules 16:4728–4739. https://doi.org/10.3390/molecules16064728

Trugilho PF, Akira FM, Tarcísio JL et al (2003) Determinação do teor de taninos na casca de Eucalyptus spp. Cerne 9:246–254

Neupane P, Lamichhane J (2020) Estimation of total phenolic content, total flavonoid content and antioxidant capacities of five medicinal plants from Nepal. Vegetos 33:360–366. https://doi.org/10.1007/s42535-020-00116-7

Benzidia B, Barbouchi M, Hammouch H et al (2019) Chemical composition and antioxidant activity of tannins extract from green rind of Aloe vera (L.) Burm. F. J King Saud Univ Sci 31:1175–1181. https://doi.org/10.1016/j.jksus.2018.05.022

Procházková D, Boušová I, Wilhelmová N (2011) Antioxidant and prooxidant properties of flavonoids. Fitoterapia 82:513–523. https://doi.org/10.1016/j.fitote.2011.01.018

Hauser C, Peñaloza A, Rodríguez F et al (2014) Promising antimicrobial and antioxidant extracts of Murta leaves (Ugni molinae Turcz): Shelf-life extension and food safety. Food Packag Shelf Life 1:77–85. https://doi.org/10.1016/j.fpsl.2014.01.003

Olszewska MA, Gędas A, Simões M (2020) Antimicrobial polyphenol-rich extracts: Applications and limitations in the food industry. Food Res Int 134:109214. https://doi.org/10.1016/j.foodres.2020.109214

Hemeg HA, Moussa IM, Ibrahim S et al (2020) Antimicrobial effect of different herbal plant extracts against different microbial population. Saudi J Biol Sci. https://doi.org/10.1016/j.sjbs.2020.08.015

Chaves TP, Fernandes FHA, Santana CP et al (2016) Evaluation of the interaction between the Poincianella pyramidalis (Tul.) LP Queiroz extract and antimicrobials using biological and analytical models. PLoS ONE 11:1–23. https://doi.org/10.1371/journal.pone.0155532

Yong H, Wang X, Zhang X et al (2019) Effects of anthocyanin-rich purple and black eggplant extracts on the physical, antioxidant and pH-sensitive properties of chitosan film. Food Hydrocoll 94:93–104. https://doi.org/10.1016/j.foodhyd.2019.03.012

Yong H, Wang X, Bai R et al (2019) Development of antioxidant and intelligent pH-sensing packaging films by incorporating purple-fleshed sweet potato extract into chitosan matrix. Food Hydrocoll 90:216–224. https://doi.org/10.1016/j.foodhyd.2018.12.015

Akyuz L, Kaya M, Koc B et al (2017) Diatomite as a novel composite ingredient for chitosan film with enhanced physicochemical properties. Int J Biol Macromol 105:1401–1411. https://doi.org/10.1016/j.ijbiomac.2017.08.161

Talón E, Trifkovic KT, Nedovic VA et al (2017) Antioxidant edible films based on chitosan and starch containing polyphenols from thyme extracts. Carbohydr Polym 157:1153–1161. https://doi.org/10.1016/j.carbpol.2016.10.080

Kan J, Liu J, Yong H et al (2019) Development of active packaging based on chitosan-gelatin blend films functionalized with Chinese hawthorn (Crataegus pinnatifida) fruit extract. Int J Biol Macromol 140:384–392. https://doi.org/10.1016/j.ijbiomac.2019.08.155

Bajić M, Ročnik T, Oberlintner A et al (2019) Natural plant extracts as active components in chitosan-based films: a comparative study. Food Packag Shelf Life 21:100365. https://doi.org/10.1016/j.fpsl.2019.100365

Zhang X, Lian H, Shi J et al (2020) Plant extracts such as pine nut shell, peanut shell and jujube leaf improved the antioxidant ability and gas permeability of chitosan films. Int J Biol Macromol 148:1242–1250. https://doi.org/10.1016/j.ijbiomac.2019.11.108

Qin YY, Zhang ZH, Li L et al (2015) Physio-mechanical properties of an active chitosan film incorporated with montmorillonite and natural antioxidants extracted from pomegranate rind. J Food Sci Technol 52:1471–1479. https://doi.org/10.1007/s13197-013-1137-1

Silva-Weiss A, Bifani V, Ihl M et al (2013) Structural properties of films and rheology of film-forming solutions based on chitosan and chitosan-starch blend enriched with murta leaf extract. Food Hydrocoll 31:458–466. https://doi.org/10.1016/j.foodhyd.2012.11.028

Deshmukh AR, Aloui H, Khomlaem C et al (2021) Biodegradable films based on chitosan and defatted Chlorella biomass: Functional and physical characterization. Food Chem 337:127777. https://doi.org/10.1016/j.foodchem.2020.127777

Gursoy M, Sargin I, Mujtaba M et al (2018) False flax (Camelina sativa) seed oil as suitable ingredient for the enhancement of physicochemical and biological properties of chitosan films. Int J Biol Macromol 114:1224–1232. https://doi.org/10.1016/j.ijbiomac.2018.04.029

Mujtaba M, Salaberria AM, Andres MA et al (2017) Utilization of flax (Linum usitatissimum) cellulose nanocrystals as reinforcing material for chitosan films. Int J Biol Macromol 104:944–952. https://doi.org/10.1016/j.ijbiomac.2017.06.127

Riaz A, Lei S, Akhtar HMS et al (2018) Preparation and characterization of chitosan-based antimicrobial active food packaging film incorporated with apple peel polyphenols. Int J Biol Macromol 114:547–555. https://doi.org/10.1016/j.ijbiomac.2018.03.126

Mira-sánchez MD, Castillo-sánchez J, Morillas-ruiz JM (2019) Health Sciences PhD program, Universidad Católica de Murcia UCAM, Campus de los Jerónimos Food Technology & Nutrition Dept ., Universidad Católica San Antonio de Murcia (UCAM). Food Chem 125688. https://doi.org/10.1016/j.foodchem.2019.125688

Koc B, Akyuz L, Cakmak YS et al (2020) Production and characterization of chitosan-fungal extract films. Food Biosci 35:100545. https://doi.org/10.1016/j.fbio.2020.100545

Kaya M, Ravikumar P, Ilk S et al (2018) Production and characterization of chitosan based edible films from Berberis crataegina’s fruit extract and seed oil. Innov Food Sci Emerg Technol 45:287–297. https://doi.org/10.1016/j.ifset.2017.11.013

Kaya M, Khadem S, Cakmak YS et al (2018) Antioxidative and antimicrobial edible chitosan films blended with stem, leaf and seed extracts of Pistacia terebinthus for active food packaging. RSC Adv 8:3941–3950. https://doi.org/10.1039/c7ra12070b

Ruiz-Navajas Y, Viuda-Martos M, Sendra E et al (2013) In vitro antibacterial and antioxidant properties of chitosan edible films incorporated with Thymus moroderi or Thymus piperella essential oils. Food Control 30:386–392. https://doi.org/10.1016/j.foodcont.2012.07.052

Xu D, Chen T, Liu Y (2020) The physical properties, antioxidant and antimicrobial activity of chitosan–gelatin edible films incorporated with the extract from hop plant. Polym Bull. https://doi.org/10.1007/s00289-020-03294-1

Ballester-Costa C, Sendra E, Fernández-López J, Viuda-Martos M (2016) Evaluation of the antibacterial and antioxidant activities of chitosan edible films incorporated with organic essential oils obtained from four Thymus species. J Food Sci Technol 53:3374–3379. https://doi.org/10.1007/s13197-016-2312-y

Shariatinia Z, Fazli M (2015) Mechanical properties and antibacterial activities of novel nanobiocomposite films of chitosan and starch. Food Hydrocoll 46:112–124. https://doi.org/10.1016/j.foodhyd.2014.12.026

Funding

This work was supported by the National Council for Scientific and Technological Development (CNPq), Grant Number 423993/2018-6.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Soares, J.M.A., da Silva Júnior, E.D., Oliveira de Veras, B. et al. Active Biodegradable Film Based on Chitosan and Cenostigma Nordestinum' Extracts for Use in the Food Industry. J Polym Environ 30, 217–231 (2022). https://doi.org/10.1007/s10924-021-02192-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02192-5