Abstract

Bacterial infection from medical devices is a significant problem and accounts for an increasing number of deaths and high medical costs. Surgical sutures are a major source of nosocomial infection through surgical wound contamination and the rates of which are increasing globally. One efficient way to prevent this is by modifying the surface of the sutures in such a way that no bacterial adhesion can occur. In this investigation, biodegradable polymer sutures with excellent antibacterial properties were developed. Antibacterial properties were achieved by coating nanosilver incorporated biopolymer polycaprolactone material on the surface of the sutures. Biocompatible polyethylene glycol was selected as the solvent for the dispersion of nanosilver particles, which improved the mechanical properties of the sutures. The nanoparticle coating was found to be uniform and more effective with the electrospinning method. The mechanical property of the coated suture was analysed using the Universal Test Method, and the results were in agreement with the standard results. The surface morphology of coated sutures becomes uniform on adding nanosilver particles, confirmed by scanning electron microscope studies. A comparative study of force–displacement, hardness, and reduced modulus as a function of contact depth indentation tests were performed on coated and uncoated suture samples using a Nanoindentation Test Machine. In-situ Scanning Probe Microscopy images were captured for coated and uncoated suture materials. These studies confirmed a new strategy in developing antibacterial sutures suitable for wound closure following surgery.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bacterial infection from medical devices is a major problem and accounts for an increasing number of deaths as well as high medical costs [1, 2]. This is particularly true in the case of implantation of a synthetic medical device. Surgical sutures are sterile filaments used to close wounds and provide support during a healing process [3]. A suture is made up of either natural (catgut, silk, linen, steel) or synthetic material (polyglycolic acid, polyglactin, polydioxone, polyglyconate, polyamide, polyester, polypropylene).

Sutures can be a source of surgical wound contamination due to bacterial adherence [4]. Bacteria like Escherichia coli, Staphylococcus aureus, and enterococci etc. that are common in wound site find sutures as a comfortable place and form microbial biofilms which in turn leads to chronic infections and may require prolonged treatment [5]. Once suture material becomes contaminated, local mechanisms of wound decontamination become ineffective [6]. Many different strategies have been developed to decrease the incidence of infections related to medical device [7, 8]. One way to prevent such infections is by modifying the surface of the devices in such a way that no bacterial adhesions can occur [9, 10].

Antimicrobial compounds gain interest from research and industry due to their potential to provide quality and safety benefits to various materials and environments depending on the type of application. Sutures impregnated or coated with antibacterial agents have been developed to reduce bacterial adherence and colonization of suture materials [11, 12]. Incorporating antimicrobial agents in the bulk material or as a surface coating has been considered a viable alternative for the systemic application of antibiotics [13]. Although several advances in aseptic principles of surgery happened and the ongoing improvements of sterile surgical techniques, the association between microbes and surgical site infections continue to increase [14, 15].

In the last decade, there have been several studies on the use of nanosilverparticles as an antimicrobial agent on a range of different medical devices [16]. Silver was considered the best one of the most versatile, safe, and effective antimicrobial agents, mainly because it does not show drug-resistance [17, 18] and not toxic to mammalian cells and tissues [19, 20]. However, retention of silver on the surface of medical devices requires surface modification with suitable hosting agents to achieve efficient auto-sanitizing [21]. Silver that is released sutures can promote repairing ability of wound site and they can prevent inflammation. Recently, works on developing antibacterial agent incorporated sutures have been focused on surface coating [22].

The latter aspect is highly relevant because the antibacterial materials currently being used in surgical sutures are suspected of carcinogenic effects in the human body [23]. This paper describes the development of environmentally safe and biodegradable, antibacterial surgical sutures, based on a new strategy in surgical site infections and thus, suitable for healthcare-related applications.

Materials and Methods

Materials and Characterization Techniques

Polyglycolic acid suture (PGA) [HINCRYL] is obtained from HLL Lifecare Trivandrum. Nanosilver powder (AgNPs) (Auto Fiber Cast, India, 99% pure) Polycaprolactone, Mn 70,000–90,000 (PCL), Polyethylene glycol (PEG 400) from Sigma Aldrich, India.

Preparation of Suture Coating: Electrospinning

Homogeneously dispersed nanosilver loaded spinning solution was prepared by mixing 50 mg of polycaprolactone and 50 μg of nanosilver powder in 10 ml polyethylene glycol. Nanosilver was coated over biodegradable sutures using an electrospinning setup purchased from E-Spin Nanotech Pvt. Ltd, India. This solution was transferred to a 10 ml plastic syringe having a needle diameter of 22 gauges by cautiously avoiding air bubbles. The syringe was placed horizontally on the syringe pump. The flow rate of the feed solutions was controlled by the syringe pump to get a consistent flow of 2 ml/min while electrospinning. The electric potential of 10 kV was applied between tip and collector by the high voltage power supply maintained at a distance of 15 cm. The metal collector was covered by aluminium foil, and the suture material was fixed on it, which was used as a substrate for deposition. The electrospinning process was carried out for 3 h in the enclosed electrospinning apparatus at room temperature (27 °C) and 65% relative humidity.

Characterization

Mechanical Measurement

Tensile Test

Tensile strength is a critical measure of performance during and after surgical procedures. Tensile strength evaluation of nanosilver-coated biodegradable suture in comparison with that of uncoated suture was conducted by a knot-Pull test. A universal testing machine (UTM; Shimadzu 10 AGX-10kN) with a maximum force limit of 50Kgf under a cross-head speed of 300 mm/min. was used to test Knot pull tensile strength of the materials. The test was performed as per USP <881>, which is the industry standard for testing tensile strength of surgical suture.

The Knot pull tensile strength of three samples (nanosilver-coated biodegradable suture) were determined according to the thickness of the suture at ambient temperature. The samples were tested in each experiment, and the average is reported.

Nanoindentation (Nanomechanical) Studies

The Nanoindentation experiments have been performed on a Hysitron Triboscope (TI 950 TriboIndenterTM) using a conospherical diamond indenter probe. Indentation tests were performed on three sutures: uncoated (control material) and two nanosilver-coated biodegradable sutures. The loading function was the same for all tests, consisting of a five-second loading to a peak force followed by two-second hold at that force, followed by a five-second unloading. Series of indents were performed with the maximum force varying from 40 to 160 μN. The instrument’s in-situ Scanning Probe Microscopy (SPM) imaging capability was used to create the topographical and gradient image of each sample. These images together with the Piezo Automation feature of the instrument were used to indent the samples at particular locations, chosen by the operator. This is particularly important due to the specific nature of the samples: non-flat surface of the suture, so the precise positioning of the experiment is crucial for obtaining quantitative measurements. Force and displacement were measured continuously throughout each test, and the resulting force- displacement curves were analyzed to calculate the Hardness (H) and Reduced Modulus (Er). In-situ SPM images have the following parameters: scan size of 5 μm × 5 μm obtained at the rate of 0.5 Hz with a set-point force of 2 μN.

Transmission Electron Microscopy (TEM) and Scanning Electron Microscopy (SEM)

A transmission electron microscope (JEOL, JEM-1011; Japan) was used to determine the size, shape and the size distribution of the nanosilverparticles. Samples were prepared by placing a drop of working solution on a carbon-coated standard copper grid (300 mesh) operating at 80 kV.

Scanning Electron Microscopy of sutures (uncoated and coated) gives information about the sample surface topography, compositions and morphological studies. Fracture surfaces of the sample after the mechanical studies were used for the morphological studies.

The surface morphology of uncoated and coated samples was examined using a HITACHI S2400 scanning electron microscope. The samples were sputter-coated with an Au–Pd mixture to ensure conductivity.

Antibacterial Activity

The antibacterial property of the nanosilver particles and nanosilver coated biodegradable suture was first studied against bacterial strains. The extent of destruction of bacteria will be evaluated. The Disc Diffusion method (Kirby–Bauer method) was adopted for testing the antimicrobial activity of nanosilver. Muller Hinton agar plates were prepared, 24 h E. coli culture was inoculated into the MHA plates using lawn culture method. Then, filter paper discs (about 6 mm in diameter), containing different concentrations of (40 µl, 60 µl, and 80 µl) are placed on the agar surface. Meanwhile, nanosilver-coated biodegradable suture was placed on another agar plates. Uncoated sutures are kept as control and plates were incubated at 37 °C for 24 h. After 24 h incubation, the plates were observed for the zone formation around the wells. This technique is used to determine by measuring the sensitivity of pathogenic organisms by measuring the diameter of zone of inhibition that results from the diffusion surrounding the medium.

Results and Discussion

Flexibility

The suture was found very flexible after nano coating through the electrospinning method. Nanosilver-coated biodegradable suture showed a similar physical appearance as uncoated ones and retained the flexible nature very well (Fig. 1).

Mechanical Measurement

Tensile Test

Nanosilver-coated biodegradable suture showed a greater knot pull tensile strength of 7.17 kgf (n = 3) compared with that of uncoated suture which is 5.08kgf (n = 3). Thus it could conclude that coating of nano silver increased the tensile strength of biodegradable suture. The degradation nature and poor mechanical properties of the suture were overcome by using more biocompatible solvents like polyethylene glycol. The proper incorporation of antibacterial agent to the suture was finally successful with solvent PEG.

Nanoindentation (Nanomechanical) Studies

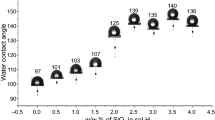

Optical Micrographs and in-situ SPM images (Figs. 2, 3) were captured for nanosilver- coated biodegradable suture and uncoated suture respectively. Figure 4 showed the Hardness and Reduced Modulus as a function of contact depth for nanosilver-coated biodegradable suture uncoated suture. From the comparative studies, coated sutures showed good mechanical properties in the required range than that of the uncoated suture.

Table 1 gives a summary of the results (reduced modulus Er (GPa) (Average) and hardness, H (GPa) (Average) obtained for both coated and uncoated samples.

Morphological Analysis

Transmission Electron Microscopy: The nanosilverparticles were characterized by TEM analysis (Fig. 5). The image shows agglomerates of small grains and some dispersed nanoparticles. The particles range in size from 30 to 54 nm, with max distribution at 40 nm.

Scanning Electron Microscopy

The SEM micrographs of nanosilver coated biodegradable suture and uncoated suture at low and high magnification have shown in Fig. 6. A uniform layer of nanosilverparticles is deposited on the surface of the poly glycolic acid sutures.

Antibacterial Activity

The antibacterial activity of the nanosilver particle was first studied against bacterial strains E. coli and S. aureus (Fig. 7). The diameter of the zone formed is tabulated in Table 2.

The microbiological characterizations were performed on nanosilver-coated biodegradable suture and uncoated suture as a control against bacterial strains (Fig. 8). Results can be read by measuring the clear zones after the overnight incubation of the plate.

The presence of nanosilver on suture was confirmed by antimicrobial test, and the coating with PCL/AgNPs/PEG system promotes antimicrobial action of suture and delays degradation. Surface coatings lead to a decrease in the degradation rate compared to uncoated material [24].

Conclusion

Nanosilver coated biodegradable polymer sutures with excellent antibacterial properties were developed and studied. Polyethylene glycol was selected as the solvent for the proper dispersion of nanosilver particles instead of water, thereby achieved improvement in mechanical properties like high tensile strength, knot strength and reduced degradation. Uniformity in the coating was achieved through electrospinning. Studies with coated sutures showed clear inhibition zone with good antibacterial activity. Treatment of absorbable suture with polyethylene glycol medium retains the tensile property and makes them stable. The morphology of the coated sutures was evaluated using SEM, which confirmed the uniform coating of nanosilver particles over the suture. In order to assess the feasibility and safety of using nanosilver coated biodegradable polymer sutures, we have carried out the in-vitro and in-vivo biocompatibility studies as per ISO10993 and found to be nontoxic, which will be reported later.

References

Mangram AJ, Horan TC, Pearson ML, Silver LC, Jarvis WR (1999) Am J Infect Control 27:97134

Suárez GJ, De Toro CM, Docobo DF, Rubio CC, Martín CJ, Docobo PF (2007) Cir Esp 8:324–329

Huang L, Taylor H, Gerber M, Orndorff PE, Horton JR, Tonelli A (1999) J Appl Polym Sci 74:937–947

Jennifer RL, Patchen D (2016) Hosp Med Clin 5:319–333

Joseph B, George A, Gopi S, Kalarikkal N, Thomas S (2017) Int J Pharm 524(1–2):454–466

Leknes KN, Roynstrand IT, Selvig KA (2005) J Periodontol 7:634–642

Raveendran P, Jie F, Wallen SL (2003) J Am Chem Soc 125:13940–13941

Scott VE, John GY (2016) Shock 46(6):597–608

Leaper D, McBain AJ, Kramer A (2010) Ann R Coll Surg Engl 92:453–458

Hranjec T, Swenson BR, Sawyer RG (2010) Surg Infect 11:289–294

Edmiston CE, Seabrook GR, Goheen MP, Krepel CJ, Johnson CP, Lewis BD, Brown KR, Town JB (2006) J Am Coll Surg 203:481–489

Wang L, Chen DD, Sunt JQ (2009) Langmuir 25:7990–7994

Levy SB, Marshall B (2004) Nat Med 10:122–129

Yan L, Kushi NK, Jeffrey MD, Meagan C, Richard WS, Klaus N, Gregory NT (2012) Langmuir 28(33):12134–12139

Li W-R, Xie X-B, Shi Q-S, Zeng H-Y, Ou-Yang Y-S, Chen Y-B (2010) Appl Microbiol Biotechnol 85:1115–1122

Menno LWK, Leo HK (2011) Polymers 3:340–366

Sondi I, Salopek-Sondi B (2004) J Colloid Interface Sci 275:177–182

Ip M, Lui SL, Poon VKM, Lung I, Burd A (2006) J Med Microbiol 55:59–63

Chen J, Han CM, Lin XW, Tang ZJ, Su SJ (2006) Chin J Surg 44:50–63

Cohen MS, Stern JM, Vanni AJ, Kelley RS, Baumgart E, Field D, Libertino JA, Summerhayes IC (2007) Surg Infect 8:397–403

López SF, Flores RG, López SJ, Magariños B, Alvarez LC, Concheiro A, Bucio E (2018) Eur Polymer J 100:290–297

Padmakumar S, Joseph J, Neppalli MH, Mathew SE, Nair SV, Shankarappa SA, Menon D (2016) ACS Appl Mater Interfaces 8(11):6925–6934

Justinger CI, Schuld J, Sperling J, Kollmar O, Richter S, Schilling MK (2011) Langenbecks Arch Surg 396:845–850

Marcjanna MG, Björn W, Valérie D, Thomas E, Regine WR (2018) Materials 11(12):2561

Acknowledgements

The financial support of HLL Lifecare Ltd is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

James, B., Ramakrishnan, R. & Aprem, A.S. Development of Environmentally Safe Biodegradable, Antibacterial Surgical Sutures Using Nanosilver Particles. J Polym Environ 29, 2282–2288 (2021). https://doi.org/10.1007/s10924-021-02048-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02048-y