Abstract

An efficient method for chemical recycling of bio-based polymers Poly(3-hydroxybutyrate) (PHB) wastes was established from the perspective of biorefinery. This methanolysis reaction archived successfully transformation PHB into corresponding monomer catalyzed by imidazolium-based Fe-containing ionic liquid, 1-butyl-3-methylimidazolium tetrachloroferrate ([Bmim]FeCl4). Compared with FeCl3 or ionic liquid [Bmim]Cl, this ionic liquid showed excellent catalytic performance. The obtained product methyl 3-hydroxybutyrate (M3HB) with high purity, as a chemical raw material, can be used in various fields. Investigation also indicated that the thermal stability of catalyst played an important role in this reaction, this ionic liquid could be reused for six times without apparent decrease in the conversion of PHB or yield of M3HB. Furthermore, the effects of experimental factors, such as temperature, time, catalyst dosage and methanol dosage on the methanolysis results of PHB were examined. Kinetic study indicated that this reaction was first-order kinetic reaction with activation energy of 27.44 kJ/mol. Additionally, a possible mechanism of PHB methanolysis was proposed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the development of economy and technology, plastic products have been widely used in all aspects, which makes our lives convenient, and at the same time leads to the serious social and environmental problems [1]. Poly(3-hydroxybutyrate) (PHB) or poly(β-hydroxybutyrate) as a kind of biodegradable and biocompatible materials [2], can be used in food packages, biomedical, tissue engineering and many other fields [3,4,5,6]. In the near future, PHB will have great potential to replace the traditional plastics. With the rapid growth of PHB materials production and consumption, PHB wastes will become more and more. Although PHB can be degraded naturally in the environment, its degradation period is much longer. Therefore, the technology of chemical recycling PHB has attracted much more attention by researchers [7, 8].

Recently, various methods for recycling PHB, such as pyrolysis [8,9,10], hydrolysis [11,12,13,14] and alcoholysis [15,16,17,18], have been reported in many previous references. However, it was very difficult to recover the corresponding monomers or high value-added products in those reported methods. Such as thermal pyrolysis [8], the reaction temperature was carried out from 170 to 300 °C, the obtained products were mixtures, including crotonic acid (CA) and well-defined oligomers and cyclic oligomers. The hydrolysis of PHB does not need high temperature and high pressure, but a large amount of inorganic acid or alkali was used as catalyst. They need to be neutralized, washed and other operations, which leaded to process cumbersome, equipment corrosion, environmental pollution and other issues [13]. Moreover, these catalysts cannot be reused for the next time [14]. Enzyme was used as catalyst in degradation of PHB had been reported [19, 20], but the final products containing a large of enzyme, which was very difficult to separate. Compared with the above mentioned methods, photocatalytic degradation of PHB could overcome those shortcomings [21, 22], but its degradation period was too long and the composition of the obtained product was also complex.

Ionic liquids (ILs) as a new kind of medium and soft functional materials, they are developed under the framework of “green chemistry”. Due to their unique properties [23,24,25], such as non-volatile, low flammability, excellent thermal stability, good solubility, adjustable physical and chemical properties, they have been widely used in many chemical reactions, for instance organic synthesis [26, 27], catalysis [28], extraction [29, 30], electrochemistry [31, 32] and other fields. Recently, ILs have been used to catalyze the degradation of polymers, such as polyethylene (PE) [33], polyamide (PA) [34], poly(ethylene terephthalate) (PET) [35,36,37], polycarbonate (PC) [38, 39] and poly(lactic acid) (PLA) [40, 41]. Science 2010, metal-containing ILs have attracted much more attention by some researchers. Wang et al. [35] and Yue et al. [36] used Fe or Zn-containing ILs, Al-Sabagh et al. [37] reported Cu- and Zn-acetate containing ILs in the PET glycolysis, which also showed higher catalytic activity. In this study, a series of imidazolium-based Fe-containing magnetic ILs with different molar fraction were synthesized, and used as catalysts in the methanolysis of PHB, a higher conversion of PHB and yield of M3HB were obtained. Compared with the Brønsted acidic IL 1-methyl-3-(3-sulfopropyl)-imidazolium hydrogen sulfate ([HSO3-pmim][HSO4]) [42], 1-butyl-3-methylimidazolium tetrachloroferrate ([Bmim]FeCl4) showed better catalytic activity in the methanolysis of PHB. The influences of reaction parameters on the conversion of PHB and the yield of M3HB were discussed in detail. Additional, the mechanism of methanolysis was proposed, and the reaction kinetics was also investigated.

Experimental

Materials and Instruments

Pure PHB pellets (3.0 mm × 2.8 mm × 3.0 mm) were obtained from Ningbo Tianan biological material Co. Ltd., China. The weight-average molecular weight, number-average molecular weight and PDI of PHB were 430,000 g/mol, 204,000 g/mol and 2.11 respectively, which were measured by GPC (Waters-515) in chloroform solution at 25 °C. N-Methyl imidazole (MIM), and anhydrous ferric chloride (FeCl3) were purchased from Shanghai McLean Biochemical Science and Technology Co. Ltd., China. Methanol was purchased from Chinese Medicine Group Chemical Reagent Co. Ltd. All other materials (AR) were used without any further purification.

Varian CP-3800 gas chromatography (GC) with an ENX5 capillary chromatography column (30 × 0.32 mm, 0.25 µm) and a FID hydrogen detector was used for GC analysis. All infrared spectroscopy measurements were performed on a Bruker Tensor-27 Fourier transforms infrared spectroscopy (FT-IR) spectrometer in the range of 4000–400 cm−1 using KBr optics and liquid film. Raman spectra were recorded using a Thermo Scientific DXR Raman Microscope. Mass spectrum was measured by Bruker Maxis Quadruple Ultrahigh Resolution Time-of-Flight mass instrument (Q-TOF MS). 1H NMR was recorded on a Bruker AV 500 Digital NMR Spectrometer using D2O as solvent. Thermogravimetric analysis (TGA) curves were recorded by Mettler-Tolede STAR System TGA/DSC 1SF thermogravimetric analyzer in an atmosphere of nitrogen over a temperature range from 20 to 600 °C at a heating rate of 10 °C/min.

Synthesis of the Fe-Containing Magnetic Ionic Liquid

The different molar fraction of Fe-containing magnetic ionic liquid [Bmim]FeCl4 was synthesized according to the methods described in the previous literatures [36, 41] (Scheme 1). Firstly, the ionic liquid [Bmim]Cl was synthesized according to the following procedures:

In a three-necked flask equipped with a thermometer and a reflux condenser, a certain amount of N-methylimidazole (mim) was added, which was put into an ice-water bath. Under vigorous stirring, the equimolar 1-chlorobutane was slowly added to this flask in the nitrogen atmosphere. After the dropwise was over, the mixture was still stirred for 1.0 h at room temperature, then rapidly heated to 70 °C and refluxed for 72.0 h. When the reaction was completed, the colorless viscous liquid was obtained, using ethyl acetate washed to remove the unreacted 1-chlorobutane. and then dried under vacuum conditions (40 °C, 10 mmHg) for 6 h, the white solid [Bmim]Cl was produced with a yield of 92.4%. The structure of [Bmim]Cl was verified by 1H NMR and FT-IR spectroscopy, and the data were as following:

1H NMR (Fig. S1, 500 MHz, D2O, ppm): 0.89(m, CH3CH2), 1.29(m, CH3CH2), 1.83(m, NCH2CH2), 3.98(s, NCH3), 4.18(m, NCH2CH2), 7.42(s, 1H), 7.47(s, 1H), 8.71(s, 1H). IR (Fig. S2, KBr film): 3050 (υ, C–Hof imidazole ring), 2970, 2870 (υ, –CH2*–CH3*), 3390 (υ, H–OH*), 1570 (υ, –C=N and –C=C of imidazole ring), 1480, 1150 (β, C–H), 1230–1172 (υas, –SOH3*), 853 (γ, –CH2*–CH3*), 748 (γ, C–H of imidazole ring).

Under N2 atmosphere, different molar fraction of [Bmim]Cl and anhydrous FeCl3 were mixed at 30 °C and stirred constantly until FeCl3 solid particles disappear. A dark brown liquid was obtained, which was extracted with dichloromethane. The dichloromethane was removed by rotating evaporation and the dark brown liquid was gotten. After drying in a vacuum oven 60 °C (10 mmHg) for 6 h to obtain the different molar fraction of ionic liquid [Bmim]FeCl4.

General Procedure for the Methanolysis of PHB

A 50 mL autoclave with a thermometer was loaded with PHB (w1), catalyst (w2) and a certain amount of methanol. Under the magnetic stirring, the methanolysis of PHB was heated up to the reaction temperature from 110 to 140 °C for the prescribed of 1.0–3.0 h under autogenous pressure. When the reaction was finished, the mixture was cooled to room temperature rapidly. Then the mixture was distilled to recover the unreacted methanol at atmospheric pressure, and obtained the main product M3HB (w3) by vacuum distillation. The residue (w4) after distillation was mainly undepolymerized PHB and catalyst, which was reused directly as a catalyst for the next cycle reaction without any treatment. The conversion of PHB and yield of main product were calculated by Eqs. (1, 2) as follows.

M1 and M2 are the molar masses of the repeating unit of PHB and the M3HB, respectively.

Results and Discussion

Characterizations of ILs

The synthesized ionic liquid was characterized by MS and Raman spectroscopy. From Fig. 1, it was seen that the peaks up to m/z 139 and 197.8 were ascribed to the positive ion [Bmim]+ and negative ion [FeCl4]− in the ionic liquid. The Raman spectra of different molar fraction ionic liquids were shown in Fig. 2, it was clear from the spectra that there was a strong absorption peak at 330 cm−1 in the each curve, which was belong to the totally symmetric Fe–Cl stretch vibration of [FeCl4]− [35, 42]. The medium absorption peak at 370 cm−1 in the ionic liquid (x = 0.67), which was related to the presence of [Fe2Cl7]−. Other parts of absorption peaks were almost exactly the same in the two spectra, which were assigned to the vibrations of the cation [Bmim]+. Then, results of MS and Raman spectra confirmed the structures of the synthesized ionic liquid.

The acidity determination of ionic liquid by pyridine IR probe method was shown in Fig. 3. As we all known, pyridine has been extensively used as a molecular probe for determination the Lewis acid sites by monitoring the bands in the range of 1700–1400 cm−1 arising from its ring vibration modes [43]. It can coordinate with Lewis acidic substances to form Py-L, their absorption peaks near 1445–1460 cm−1 and 1600–1640 cm−1. In Fig. 3b–d, the presence of a band near 1558 cm−1, 1636 cm−1 showed that Py-L acid sites. When FeCl3 x = 0.33, these absorption peaks were quite weak. With increasing the molar fraction of FeCl3, the peaks at these acid sites became more and more strong.

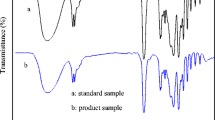

Analysis of the Main Product

The purity and structure of the obtained product were characterized by GC, IR and 1H NMR and the results were shown in Fig. S3 and Fig. 4. From Fig. S3, the only peak was ascribed as the main product, at the retention time is about 1.48 min. From the peak area, the product purity is over 98%. From Fig. 4A, the spectra of the obtained products at different conversion are almost identical, indicating that they were the same compound. The spectra contained a –OH band at 3435 cm−1, a C=O stretching at 1740 cm−1, and C–O bending at 1132 cm−1, which indicated the existence of an ester group. And alkyl bonds of C–H at 2990 cm−1 and 2953 cm−1, a –CH3 bending at 1380 cm−1. In Fig. 4B, the double signal at δ 1.00–1.19 ppm was belonged to the methyl protons of –CH3, the multiple at δ 2.32–2.48 ppm represented the methylene protons of –CH2–, the single signal at δ 3.595 ppm indicated the methyl protons of –OCH3, the multiple at δ 4.15 ppm was ascribed to the methenyl proton of –CH–. Therefore, from these characterizations data of IR and 1H NMR, it can confirm that the structure of the product is M3HB.

Selection of the Catalysts

The catalytic properties of different molar fraction of FeCl3 ionic liquids were shown in Table 1. From Table 1, the PHB methanolysis cannot have happened, when [Bmim]Cl was used as the catalyst (Entry 1). It was maybe that the PHB methanolysis is a transesterification, acidic or alkaline catalyst is beneficial to it, however [Bmim]Cl is a neutral catalyst. With increasing of FeCl3 molar fraction, the conversion of PHB and yield of M3HB were exhibited a significant upward trend. When temperature 140 °C, time 3.0 h and x = 0.67, the conversion of PHB and yield of M3HB reached the maximum values were 94.1% and 85.0%, respectively (Entry 5). But when x > 0.67, there was no apparent increasing in the conversion of PHB and yield of M3HB. The reason was maybe that increasing the molar fraction of FeCl3, the Lewis acidity was enhanced, which was consistent with those results in pyridine IR. So the molar fraction of FeCl3 was 0.67 in the ionic liquid [Bmim]FeCl4 was chosen as a catalyst in the subsequent study.

Effects of Reaction Condition

Table 2 showed the effects of reaction conditions on PHB methanolysis results. From Table 2, we could see that reaction temperature had a great influence on the methanolysis of PHB. When the temperature increased from 110 to 140 °C, the conversion of PHB increased from 68.1 to 94.1%, and the yield of M3HB was added from 63.3 to 85.0%, respectively (Entries 1–4). With prolonging the reaction time, both the PHB conversion and the M3HB yield increased gradually (Entries 4–7). When reaction time was 3.0 h, the PHB conversion and the M3HB yield were 94.1% and 85.0%, respectively (Entry 3). PHB conversion and M3HB yield did not increase significantly, even if the reaction time was extended to 4.0 h (Entry 5). The reason was maybe that this transesterification was a reversible reaction, the equilibrium had been reached at 3.0 h. With adding the methanol amount, the conversion of PHB and the yield of M3HB increased slightly. And at the same condition, their maximum values were 94.1% and 85.0%, when n(CH3OH):n(PHB) = 5.0:1(Entry 4). However, when n(CH3OH):n(PHB) was increased to 6.0:1 (Entry 9), there was an obvious decrease in the conversion of PHB and the yield of M3HB. The reason was that the concentration of catalyst decreased in the mixture, due to an increase in the mixture. Which leaded to an obvious decrease in its catalytic activity. The influences of catalyst dosage on PHB conversion and M3HB were also investigated (Entries 4, 10–11). It was indicated that the methanolysis conversion increased with the amount of catalyst. With the increase in the amount of catalyst, more cations and anions in ionic liquid would interact with the active sites in the substrates (shown in Scheme 2).

Reusability of ILs

Figure 5 shown the reusability performance of IL [Bmim]FeCl4 (x = 0.67), under the conditions: temperature 140 °C, time 3.0 h, n(CH3OH):n(PHB) = 5.0:1 and n(cat):n(PHB) = 0.05:1. As showed in Fig. 5, there was no significantly decrease in the conversion of PHB and yield of the product were decreased slightly, when the catalyst was reused up to six cycles. That is to say, the catalyst exhibited an excellent activity. The IL was characterized by IR and the results were presented in Fig. 6. Comparing the spectrum of the reused IL with that of fresh one, their structures were almost exactly the same. It can be clearly seen that a ring stretching vibration at 1164 cm−1, a C=N stretching vibration at 1566 cm−1, a C=C ring double bond stretching vibration at 1616 cm−1, an alkyl C–H at 2962 cm−1, 2935 cm−1 and a aromatic heterocycle C–H stretching vibration at 3149 cm−1. Figure 7 showed that the TGA curves of the reused IL and that of the fresh one. After six times reused, the thermal stability of ILs had virtually no change. When the temperature was over 100 °C, there was a small mass loss due to a bit of water. At the temperature 425 °C, the weight loss was very obviously, the decomposition temperature of ionic liquid was reached. When the temperature reached 520 °C, the ionic liquid had decomposed completely. However, this methanolysis temperature was only 140 °C, the catalyst could be exist stably. From the two IR spectra and the two TGA curves, there was no change in chemical structure after the ionic liquid was reused for six times. Therefore, [Bmim]FeCl4 (x = 0.67) was an excellent and reusable catalyst for the methanolysis of PHB.

Mechanisam of PHB Methanolysis

In order to study the reaction mechanism of PHB methanolysis catalyzed by Fe-containing magnetic ionic liquid [Bmim]FeCl4 (x = 0.67), the residues of PHB (which were mainly composed of some oligomers) at different conversion were characterized by IR. From Fig. S4, it could be seen that the peak at about 3500 cm−1 was ascribed to the hydroxyl (–OH) group got stronger, when the conversion of PHB was added from 0 to 39.6–73.0%. The peak at 1750 cm−1 was belonged to the carbonyl (–C=O) group also had the same change. This might be due to the cleavage of the C–O bond in the ester group of the substrate, the –OH and –C=O groups were exposed. With increasing the conversion of PHB, some oligomers containing –OH and –C=O groups became stronger increasingly. The main products obtained at different conversions were characterized by IR, and the results were shown in Fig. 4A. It was obviously seen that these three IR curves were almost exactly the same, regardless of the conversion was 39.6% and 73.0%, or 94.1%.

In our previous work, PHB pellets could dissolve or swell in the methanol without any solvent under the same conditions. From Fig. S5, we can see there is not any difference in the IR. So based on the above results, the possible mechanism was proposed and was shown in Scheme 2. After the rigid PHB was dissolved or swelled in the methanol, it was beneficial to react with some small molecule. When Fe-containing magnetic ionic liquid [Bmim]FeCl4 (x = 0.67) was used as catalyst, the synergic effect was presumed to exist between the cation and anion [35]. The cation [Bmim]+ reacted with –C=O in the ester of PHB, which improved the positivity of the carbonyl carbon. At the same time the anion [FeCl4]− reacted with the –H atom in the –OH of methanol, forming a transition state of six-membered ring. These caused the oxygen in the hydroxyl group of methanol to be more electronegative, and attack the carbonyl carbon of the ester easily. Afterwards, the hydrogen atom leaved the methanol and the [Bmim]+ also leaved the six-membered ring, the electrons on the oxygen atom transferred to form C=O. The acyl-oxygen cleaved and the alkoxy group leaved. This transformation was repeated, and the monomer M3HB was obtained.

Kinetics of PHB Methanolysis

The kinetics of PHB methanolysis was also investigated under the optimum conditions. This methanolysis reaction could take place only when the rigid PHB was dissolved or swelled in this mixture, because it is a reaction between a solid polymer macromolecule and a small liquid molecule. And the concentration of PHB would be very low because the PHB cannot dissolve completely in this system, whereas the molar ratio of CH3OH to PHB was 5:1, so the concentration of CH3OH was a greatly excessive. Furthermore, In many literatures of chemical depolymerization polymers [44, 45], the reaction order was usually assumed to be first-order. Therefore, the methanolysis of PHB catalyzed by [Bmim]FeCl4 (x = 0.67) was initially assumed to be controlled by first-order kinetic Eq. (3).

where k represents the rate constant of the reaction, and CPHB represents the concentration of PHB at time t.

where X represents the conversion of PHB, Eq. (3) could be written as follows.

Equation (5) was integrated for time to obtain Eq. (6).

In order to study the kinetics of the PHB methanolysis catalyzed by Fe-containing magnetic IL [Bmim]FeCl4 (x = 0.67), the influences of reaction time on PHB methanolysis from 110 to 140 °C were investigated, under the following conditions of n(CH3OH):n(PHB) = 5.0:1 and n(cat):n(PHB) = 0.05:1. The results were shown in Fig. 8, and the linear regression data were shown in Table 3. It could be clearly seen from Table 3 that the linear correlation coefficients were over 0.98, indicating that ln1/(1 − X) was proportional to time, that is to say, this methanolysis process is first-order kinetics reaction and methanolysis rate constant was proportional to the concentration of PHB in reaction mixture. The four straight lines slopes values were 0.43484 h−1, 0.56463 h−1, 0.63629 h−1, 0.68684 h−1, which were the rate constants of the methanolysis reaction at temperatures of 110 °C, 120 °C, 130 °C and 140 °C, respectively.

Based on these above methanolysis rate constants, the reaction activation energy (Ea) could be calculated from Arrhenius equation Eq. (7).

where A is the pre-exponential factor, R is the gas molar constant (8.31 J/mol K) and T is the thermodynamics temperature in Kelvin. The Arrhenius plot was achieved in Fig. 9, and the activation energy (Ea) of this reaction calculated from the slope was 27.44 kJ/mol.

Conclusions

In summary, the Fe-containing magnetic ionic liquid [Bmim]FeCl4 (x = 0.67) can be used as an efficient and ecofriendly catalyst in the methanolysis of PHB. It was indicated that temperature was an important factor in this reaction. Under the optimum conditions: T = 140 °C, t = 3.0 h, n(cat):n(PHB) = 0.05:1 and n(CH3OH):n(PHB) = 5:1, the PHB conversion and the M3HB yield were 94.1% and 85.0%, respectively. Meanwhile, the catalyst exhibited an excellent reusability, its catalytic activity was not significantly reduced after being reused for six times. The kinetics study indicated that this methanolysis was a first-order kinetic reaction, with an activation energy of 27.44 kJ/mol. Moreover, a possible mechanism indicated that the synergic effect between the cation and anion in the ionic liquid made this nucleophilic substitution occur much easier.

References

Al-Salem SM, Lettieri P, Baeyens J (2010) Prog Energy Combust Sci 36:103–129

Kikkawa Y, Fukuda M, Ichikawa N, Kashiwada A, Matsuda K, Kanesatoa M, Hiraishic T (2013) J Mater Chem A 1:4667–4670

Fakhouri FM, Carvalho M, Barreto PLM, Jesus RCD, Martelli SM (2015) Green Chem 2015:208–226

Lu X, Wang L, Yang Z, Lu H (2013) Adv Biosci Biotechnol 4:731–740

Xavier FL, Olyveira GM, Basmaji P, Costa LM (2013) J Nanosci Nanotechnol 13:4715–4719

Danis O, Ogan A, Tatlican P, Attar A, Cakmakci E, Mertoglu B, Birbir M (2015) Extremophiles 19:515–524

Soroudi A, Jakubowicz I (2013) Eur Polym J 49:2839–2858

Ariffin H, Nishida H, Hassan MA, Shirai Y (2010) Biotechnol J 5:484–492

Ariffin H, Nishida H, Shirai Y, Hassan MA (2009) J Appl Polym Sci 111:323–328

Mamat MRZ, Ariffin H, Hassan MA, Zahari MAKM (2014) J Clean Prod 83:463–472

Bonartsev AP, Boskhomodgiev AP, Iordanskii AL, Bonartseva GA, Rebrov AV, Makhina TK, Myshkina VL, Yakovlev SA, Filatova EA (2012) Mol Cryst Liq Cryst 556:288–300

Cui Y, Barford J, Renneberg R (2007) Anal Lett 40:2915–2924

Yu J, Plackett D, Chen LXL (2005) Polym Degrad Stab 89:289–299

Saeki T, Tsukegi T, Tsuji H, Daimon H, Fujie K (2005) Polymers (Basel) 46:2157–2162

Lee Y, Park SH, Lim IT, Han K, Lee SY (2000) Enzyme Microb Technol 27:33–36

Spekreijse J, Nôtre JL, Sanders JPM, Scott EL (2015) J Appl Polym Sci 132:42462

Dacosta CF, Posada JA, Ramirez A (2016) J Clean Prod 137:942–952

Spekreijse J, Ortega JH, Sanders JPM, Bitter JH, Scott EL (2016) Bioresour Technol 211:267–272

Rodríguez-Contrerasa A, Calafell-Monfort M, Marqués-Calvo MS (2012) Polym Degrad Stab 97:597–604

Ju D, Han L, Bian J, Guo Z, Li F, Chen S, Dong L (2015) RSC Adv 5:5474–5483

Lim J, Kim J (2016) Macromol Res 24:9–13

Pagnan CS, Mottin AC, Oréfice RL, Ayres E, Câmara JJD (2018) J Polym Environ 26:1169–1178

Welton T (1999) Chem Rev 99:2071–2084

Earle MJ, Seddon KR (2000) Pure Appl Chem 72:1391–1398

Welton T, Hallett JP (2011) Chem Rev 111:3508–3576

Xiao Y, Malhotra SV (2005) J Mol Catal A 230:129–133

Vidiš A, Ohlin C, Laurenczy G, Küsters E, Sedelmeier G, Dyson PJ (2005) Adv Synth Catal 347:266–274

Vafaeezadeh M, Alinezhad H (2016) J Mol Liq 218:95–105

Xun S, Zhu W, Zheng D, Zhang L, Liu H, Yin S, Zhang M, Li H (2014) Fuel 136:358–365

Wang H, Xie C, Yu S, Liu F (2014) Chem Eng J 237:286–290

Sun X, Liao C, Shao N, Bell JR, Guo B, Luo H, Jiang A (2013) J Power Sources 237:5–12

Yin K, Zhang Z, Yang L, Hirano S (2014) J Power Sources 258:150–154

Adams CJ, Earle MJ, Seddon KR (2000) Green Chem 2:21–24

Kamimura A, Yamamoto S (2007) Org Lett 9:2533–2535

Wang H, Yan R, Li Z, Zhang X, Zhang S (2010) Catal Commun 11:763–767

Yue Q, Xiao L, Zhang M, Bai X (2013) Polymers (Basel) 5:1258–1271

Al-Sabagh AM, Yehia FZ, Eissa AMF, Moustafa ME, Eshaq G, Rabie AM, ElMetwally AE (2014) Polym Degrad Stab 110:364–377

Iannone F, Casiello M, Monopoli A, Cotugnoa P, Sportelli MC, Piccaa RA, Cioff N, Dell’Annac MM, Nacci A (2017) J Mol Catal A 426:107–116

Song X, Liu F, Li L, Yang X, Yu S, Ge X (2013) J Hazard Mater 244:204–208

Liu H, Song X, Liu F, Liu S, Yu S (2015) J Polym Res 22:135

Liu H, Zhao R, Song X, Liu F, Yu S, Liu S, Ge X (2017) Catal Lett 147:2298–2305

Yue Q, Yang H, Zhang M, Bai X (2014) Adv Mater Sci Eng 2014:1–6

Zhao H, Yu N, Ding Y, Tan R, Liu C, Yin D, Qiu H, Yin D (2010) Microporous Mesoporous Mater 136:10–17

Nostrum CFV, Veldhuis TFJ, Bos GW, Hennink WE (2004) Polymers (Basel) 45:6779–6787

Codari F, Lazzari S, Soos M, Storti G, Morbidelli M, Moscatelli D (2012) Polym Degrad Stab 97:2460–2466

Acknowledgements

This research was supported financially by the National Natural Science Foundation of China (No. 51673106), Shandong Province Natural Science Foundation (No. ZR2015BL027) and the Taishan Scholars Projects of Shandong (ts 201511033).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Song, X., Wang, H., Wang, C. et al. Chemical Recycling of Bio-based Poly(3-hydroxybutyrate) Wastes Under Methanolysis Condition Catalyzed by Fe-Containing Magnetic Ionic Liquid. J Polym Environ 27, 862–870 (2019). https://doi.org/10.1007/s10924-018-1347-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-018-1347-8