Abstract

Herein, we prepared alginate (SA)/carboxymethyl cellulose (CMC) gel beads through Ca2+ and glutaraldehyde (GA) crosslinking and investigated their adsorption performance on lysozyme from aqueous solution. Taking advantage of the abundant active carboxyl groups on SA and CMC, the obtained SA/CMC gel beads present an excellent integrated lysozyme adsorption performance with a high capacity of 236.34 mg g−1, short equilibrium time of 8 h, ease of elution, and good reusability. Furthermore, the resultant SA/CMC gel beads also possess unique selectivity for positively charged proteins, confirmed by the method of sodium dodecyl sulfate polyacrylamide gel electrophoresis. Considering the nature of biopolymers and advantages of favorable physical properties, high efficiency, cost-effectiveness, intriguing adsorption capacity and easier separation from the reaction system, the SA/CMC gel beads may find more potential in protein separation and purification than that of synthetic material.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Highly purified proteins play critical roles and are in great demand in pharmaceutical industry, immunotherapy, scientific research, foodstuffs, and cosmetics [1,2,3]. The efficient adsorption or separation of a single protein type from a mixture containing a multitude of different biomolecules is of great importance for science as well as for technical applications [4, 5]. Therefore, various types of materials and technologies have been developed for purification or separation of target proteins. For example, modified poly(vinyl alcohol) (PVA) [6], ethylene vinyl alcohol (EVOH) [7] and cellulose [8] nanofibrous membranes have been developed for the efficient adsorption of lysozyme. In addition, bentonite tryptophan microcomposite [9], Fe3O4/Au nanoparticles [10], poly(hydroxyethyl methacrylate) magnetic beads [11], and graphene oxide [12] have been developed for efficient adsorption and purification of proteins as well. Our research group has also developed some functionalized poly(vinyl alcohol-co-ethylene) (PVA-co-PE) nanofibrous membranes for selective protein separation [13, 14]. Although many kinds of materials have demonstrated successes in protein adsorption, there has been an increased interest and demand in the use of economically feasible, easily available, and environmentally friendly natural polymers for the efficient adsorption of target species.

Sodium alginate (SA) is a linear water-soluble polysaccharide consisting of monomeric units of 1–4 linked β-d-mannuronate (M) and α-l-guluronate (G) at different proportions in the chain [15, 16]. SA has a unique property of crosslinking in the presence of multivalent cations, which is rather complex with GG sequences in the polymer chain to form the “egg-box” junctions [17, 18]. Carboxymethyl cellulose (CMC) is a chemically modified polysaccharide made up of linear β-(1–4)-linked glycans that exhibit polyelectrolyte characteristics due to the presence of carboxylate groups [19, 20]. SA or CMC microbeads have usually been prepared by dripping an aqueous solution of SA or CMC into a solution containing divalent cations. However, both SA or CMC beads usually exhibit poor mechanical properties, brittleness, and sensitivity to water due to their hydrophilic nature. Therefore, there is a need to prepare SA/CMC blend beads with improved stability, rigidity and porosity characteristics [21, 22]. Furthermore, the presence of negative carboxylate functions along SA or CMC chains ensures its high affinity and binding capacity for charged species, which has been utilized as a naturally available low cost adsorbent for removing dyes [18, 23] or heavy metal ions [24,25,26] from wastewater. However, few attempts have been done on the development of SA/CMC blend beads for protein separation applications.

In order to develop a green sorbent in the facile, intriguing and economic approach, covalently and Ca2+ crosslinked SA/CMC blend beads were prepared and were investigated with respect to protein adsorption from aqueous solutions. The results of this study could lay a solid foundation to develop new bio-based adsorbing materials and would provide useful information for the biomedical application of naturally abundant polysaccharides.

Materials and Methods

Materials

Sodium alginate (pharmaceutical grade, low viscosity, M/G = 6:4) was kindly donated by Qingdao Hyzlin Biology Development Co., Ltd. (China). Sodium carboxymethyl cellulose (average Mw ~ 250,000) was purchased from Sigma-Aldrich Co., USA. Calcium chloride (CaCl2) was of analytical grade and purchased from Spectrum Chemical Co., USA. Glutaraldehyde solution (25%) was purchased from Fisher Bioreagents Co., USA. Lysozyme powder purified from chicken egg white was obtained from Amresco Co., USA. Bovine serum albumin (BSA) was purchased from Fischer Scientific Co., USA. All other chemicals were purchased from Fisher Scientific Fischer Scientific Co., USA. All reagents were used as received without any further purification. All water used in this study was deionized water.

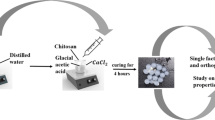

Preparation of SA/CMC Gel Beads

Firstly, various ratios of SA to CMC (10:0, 9:1, 8:2, 7:3, 6:4, 5:5 and 4:6) were dissolved in distilled water to give a final concentration of 2% (w v−1) of polymers. Then, the SA/CMC solution was dropped through a peristaltic pump into 100 mL coagulation solutions containing CaCl2, GA and HCl under continuous stirring for 4 h. The GA and HCl concentration was controlled at 3 and 0.1 wt%, respectively, and the concentration of CaCl2 was 0.16 mol L−1. The crosslinked beads were removed by filtration and then washed at least 6 times with 100 mL of distilled water to remove any free Ca2+ and GA. The beads were allowed to dry at 75 °C for approximately 24 h. The series SA/CMC0, SA/CMC10, SA/CMC20, SA/CMC30 SA/CMC40, SA/CMC50, and SA/CMC60 represent the beads containing 0, 10, 20, 30, 40, 50, and 60% CMC, respectively.

Characterization

Fourier transform infrared (FTIR) spectra were collected by a Nicolet 6700 FTIR spectrometer (Thermo Electron Co., USA) at 4000–400 cm−1 range with 64 scans and a 4 cm−1 resolution. Differential scanning calorimeter (DSC) analysis were carried out using a Shimadzu DSC-60 (Shimadzu Science Instruments, Inc., USA) at a heating rate of 10 °C min−1 from room temperature to 260 °C under a nitrogen atmosphere. Thermogravimetric analyses (TGA) were conducted with a Shimadzu TGA-50 apparatus (Shimadzu Scientific Instruments Inc., USA) with a heating rate of 10 °C min−1 from room temperature to 400 °C under a nitrogen atmosphere. SA and CMC powder as well as SA/CMC20 beads were dried in the same manner (105 °C, 2 h) before the thermal measurement. Water content was determined by weighing a mass of wet beads and its residual (dry) mass after a stabilization period of 24 h at 105 °C. The diameter of SA/CMC gel beads was measured with vernier calipers and average diameter was obtained through the measurements of 20 beads out of approximately 200. Morphologies of dried SA/CMC gel beads were observed by using a scanning electron microscopy (SEM) (SU8010, Hitachi, Japan) at 5 kV accelerating voltage on gold sputter coated samples. The swelling degree (SD) was calculated by using the following equation: SD = (we − wd)/wd, where we and wd are the weights of the wet and dry beads, respectively. The calcium content was determined by inductively coupled plasma optical emission spectrometer (ICP-OES) Optima 8300 (PerkinElmer, Massachusetts, USA). The compressive force of the microspheres was tested by texture analyser (A. XTPlus, Stable Micro System, UK).

Static Adsorption Performance Measurements

Lysozyme (isoelectric point of 10.8) solutions were prepared using phosphate buffer solution and the concentration range of lysozyme used in this study was 0.2–1.4 mg mL−1. The pH values of the lysozyme solution were measured by using a pH meter (XL600, Fisher Scientific Co., USA). To test the static adsorption performance, 50 mg of as-prepared SA/CMC gel beads was immersed in a lysozyme solution (15 mL) for a certain time, subsequently the absorbance intensity change at 280 nm was detected using the UV–Vis spectrophotometer (Evolution 600, Thermo Scientific Co., USA). The UV–Vis spectra were recorded scanning from 240 to 400 nm at room temperature. The adsorption amount was calculated by using the following equation: \({q_t}={V_0}({C_0} - {C_t})/m\), where \({q_t}\) is the adsorption capacity at a given time (mg g−1), \({V_0}\) is the volume of protein solution (mL), \({C_0}\) is the initial protein concentration (mg mL−1), \({C_t}\) is the protein concentration after adsorption for a given time (mg mL−1), and m is the amount of adsorbent (g). The effects of CMC content, adsorption time, initial lysozyme concentration, pH value, ionic strength and radius on the adsorption performance of SA/CMC gel beads were tested.

Selectivity Measurements

To test the selective adsorption, BSA with an isoelectric point of 4.7 was taken as the negatively charged model protein. The adsorption toward lysozyme and BSA (at the concentration of 1 mg mL−1) was performed. In addition, sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE) was used. Electrophoresis was run for 2 h with a voltage of 110 V, and stained with 0.25% (w/v) Coomassie Brillant R 250 in acetic acid/methanol/water solution (1:5:5, v/v/v), and destained in ethanol/acetic acid/water solution (1:4:6, v/v/v). Finally, it was scanned using Beckman appraise densitometer (Bio-rad, GelDoc XR+, USA).

Reusability Measurements

To investigate the reversible adsorption performance of the as-prepared SA/CMC gel beads, the adsorbed beads were incubated in NaCl solution (0.5 M) for 30 min after each cycle to elute the adsorbed lysozyme and then rinsed with distilled water for five times to remove the NaCl. Subsequently, the regenerated SA/CMC gel beads were immersed into the lysozyme solution to be reused for another cycle. The adsorption–desorption cycle was repeated up to seven times.

Results and Discussion

Chemical Characterization

Formation of crosslinked network structure was verified by chemical analysis. Firstly, the FTIR spectra of SA/CMC gel beads crosslinked by Ca2+ and GA were compared with pure alginate and CMC. As illustrated in Fig. 1a, since CMC and SA were basically similar in molecular structure, they have the similar FTIR spectra. The peaks at 3452.5 or 3448.3 cm−1, 1034.7 or 1034.2 cm−1 and 2923.2 or 2925.2 cm−1 were assigned to stretching vibrations of –OH, –C–O–C– and –CH bonds [16, 27, 28]. The strong peak at 1615.7 or 1593.8 cm−1 and a somewhat weaker peak at 1414.0 or 1429.1 cm−1 were attributed to the asymmetric and symmetric stretching vibration of the carboxylate groups, respectively [16, 22]. Obviously, the crosslinking process of SA/CMC with Ca2+ (as illustrated in Fig. 1b) resulted in a shift of the asymmetric –COO– vibrational peak shifted to a lower (from 1615.7 to 1612.4 cm−1) wavenumber and the symmetric –COO– peak shifted to a higher wavenumber (from 1414.0 to 1423.3 cm−1). Since the peak at 1034.0 cm−1, attributed to the acetal ether linkage, formed by the reaction between GA and SA should overlay with the acetal ether linkage in alginate, the new adsorption peak at 1723.1 cm−1 belonging to residual free aldehyde group of the GA can serve as an evidence of crosslinking of the alginate by GA (Fig. 1b), consistent well with previous studies [29, 30]. Moreover, the –OH stretching of SA (3452.5 cm−1) and CMC (3448.3 cm−1) moved to lower wavelength in SA/CMC gel beads (3434.0 cm−1), confirming the intermolecular hydrogen bonding between SA and CMC.

As crosslinking may alter thermal properties of the polymer [30, 31], DSC and TGA can provide some supplementary information about the crosslinking reaction of SA/CMC gel beads. The DSC thermograms of SA, CMC, and SA/CMC gel beads were compared and found that SA, CMC, and SA/CMC20 exhibit an endothermic peak at around 60–90 °C (Fig. S1a), probably related to evaporation of water [32, 33]. Further combined with the TGA and DTG thermogravimetric curves (Fig. S1b and c), this peak was found to be less intense in SA/CMC20, suggesting the presence of covalent crosslinking in SA/CMC gel beads since the GA crosslinking will consume the -OH groups (see Fig. 1b), which is corresponding well to the FTIR results. In addition, for SA, the appearance of exothermic behavior was detected at 240.20 °C, coinciding with the weight loss peak at 250.38 °C on the DTG curves. This was attributed to the decomposition of the SA.

Physical Characterization

The water content is a measurement of the porosity of the SA/CMC gel beads. In all SA/CMC gel beads, a major part (≥ 92.41%) consists of pores, and the total pore (water) volume increased with the increase of CMC proportion (Table 1). As demonstrated in Table 1, with the increase of CMC proportion, the meand diameter and d 90 /d 10 increased while the Feret ratio decreased. This can be explained by the low viscosity and the weak crosslinking capacity of Ca2+ for CMC, as the CMC proportion in SA/CMC gel beads increases, the slower crosslinking rate and lower viscosity of SA/CMC solution drops (Fig. S2) will result in a deformation during stirring in the coagulation bath.

Figure 2a shows a digital photograph of the wet beads, displaying the quasispherical shape and transition to more transparent and larger size with increasing the CMC proportion, which corroborates well with the surmise from particle-size analysis (Table 1). The micromorphology of dried beads was also studied by SEM as shown in Fig. S3. First of all, after air dried to constant weight, SA/CMC gel beads still exhibited spherical nature. Furthermore, detailed examination revealed that the outer surface of the sample SA/CMC20 and SA/CMC40 gel beads was visibly rougher with more wrinkles than that of SA/CMC0 beads. This can be due to the influence of weaker crosslinking capacity of Ca2+ for CMC. The crosslinking density of gel beads decreased with increasing CMC proportion which results in the inward shrinkage of the matrix during the drying process. It is worth noting that the increased wrinkles on the surface may facilitate the SA/CMC gel bead to adsorb more lysozyme directly.

Since the swelling behavior of gel beads will determine the capacity of the beads to absorb water and thus affect the protein adsorption, the swelling degree (SD) and calcium content of the SA/CMC gel beads were investigated. As illustrated in Fig. 2b, c, with the increase of CMC proportion, the SD of SA/CMC gel beads increased (Fig. 2b), while the Ca2+ content showed a decrease (Fig. 2c). Such a result is understandable since CMC has a weak crosslinking performance for Ca2+.

Favorable mechanical properties are also an important factor to the usability of polysaccharide gel based materials. As showed in Fig. 2d, the compressive resistance of SA/CMC gel beads was increased significantly from 0.79 to 1.28 N when the CMC content increased to 10 wt%. This could be possibly due to the increase of interactive strength (through H-bonds) and entanglement between CMC and SA molecules [37, 38]. As the CMC content increased further from 20 to 60 wt%, the compressive force of SA/CMC gel beads decreased, which can be attributed to a lower degree of Ca2+ crosslinking caused by the increasing of CMC content.

Batch Adsorption Performance for Lysozyme

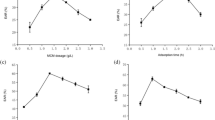

The effect of CMC contents on adsorption capacity was intensively investigated. As illustrated in Fig. 3a, the adsorption capacity of the SA/CMC gel beads exhibited an increasing trend with the increase of CMC concentration. This can be explained by the relative weak Ca2+ crosslinking activity for CMC. As the protein adsorption of SA/CMC gel beads is based on the electrostatic forces between COO– groups on the SA/CMC gel beads and the positively charged residues on the proteins, increasing the proportion of CMC would provide more active COO– points and thereby leads to a higher adsorption capacity.

a Influence of CMC content on the adsorption capacity of SA/CMC gel beads. b Kinetic adsorption performance of SA/CMC20 gel beads. c Effects of pH value on the adsorption capacity of SA/CMC20 gel beads. d Effect of the initial lysozyme concentration on the adsorption capacity of SA/CMC20 gel beads. e Effects of ionic strength on the adsorption capacity of SA/CMC20 gel beads. f Effects of ionic radius on the adsorption capacity of SA/CMC20 gel beads at the ion concentration of 0.2 M

By combining water content, swelling degree, d 90 /d 10 (≤ 1.11), Feret ratio (≥ 0.91) and adsorption performance, the SA/CMC20 gel beads were found to be superior to the other gel beads in terms of porous volume, dimensional stability, appearance uniformity, mechanical properties, and lysozyme adsorption capacity. Therefore, the following tests were all based on the SA/CMC20 gel beads.

Kinetic adsorption performance of SA/CMC gel beads was studied by detecting the amount of adsorbed lysozyme in varying adsorption time (0, 1, 2, 4, 6, 8, 12, and 24 h). It was observed that the lysozyme adsorption increased rapidly at the beginning, then became flattened (Fig. 3b). This kinetics behavior is typical and similar to the results that have been reported in literature for different kinds of sorbents [8, 39]. In addition, the adsorption capacity of SA/CMC20 reached equilibrium within 8 h. Compared with the maleic anhydride in situ grafted cellulose nanofibrous membranes (12 h) with high surface area [8], the adsorption equilibrium time of SA/CMC gel beads is desirable. This very fast adsorption is probably due to the high binding rate and/or strong affinity interactions between the SA/CMC20 gel beads and lysozyme molecules since CMC provides more active COO– groups.

To investigate the controlling mechanism of adsorption process and the potential rate-controlling step, pseudo-first-order and pseudo-second-order kinetic models were employed to analyze the experimental data [40, 41]:

pseudo-first-order kinetics: \({q_t}={q_e}(1 - {e^{ - {k_1}t}})\),

pseudo-second-order kinetics: \({q_t}=q_{e}^{2}{k_2}t/(1+{q_e}{k_2}t)\).

where \({q_t}\) is the adsorption amount at given contact time, \({q_e}\) is the calculated saturation capacity, \({k_1}\) and \({k_2}\) are relevant adsorption rate constants of the two models, and \(t\) is the given contact time. The corresponding kinetic parameters are listed in Table 2.

According to the values in Table 2, the kinetic adsorption process was followed well with the pseudo-second-order kinetic model attributing to the higher correlation coefficients (R2) of 0.9926. These results suggest that the pseudo-second order mechanisms are predominant and that chemisorption might be the rate-limiting step that controls the adsorption process [8, 42]. This observation supports our hypothesis that the adsorption process is affected by a few factors such as diffusion, the conformational state, size, and surface charge distribution of protein molecules [6, 13, 43], here the chemisorption is just an overall reflection of these factors.

The effects of various pH values on the adsorption capacity were studied. As exhibited in Fig. 3c, maximum lysozyme adsorption amount was observed at pH 4.0, and at pH values higher than pH 6.0, the adsorbed amounts of lysozyme decreased significantly. This phenomenon might be explained by the fact that the buffer pH values have great effects on the electrostatic potential of both lysozyme and SA/CMC gel beads. Since the isoelectric point of lysozyme used in this study is approximately 10.8, the positive charges of lysozyme will increase with the decreasing buffer pH from 8 to 4. Conversely, negative charges of the SA/CMC gel beads barely changed because the carbonyl groups existed in the ionic form in this pH range. Therefore, when the pH decreased, the electrostatic forces between lysozyme and carboxyl groups gradually enhanced and the adsorption capacity increased.

To explore the effect of initial protein concentration on the performance of the SA/CMC gel beads, adsorption equilibrium uptakes under varying initial lysozyme concentrations (from 0 to 1.4 mg mL−1) were tested. Figure 3d shows that the adsorption amount of lysozyme on SA/CMC20 beads increased rapidly with increasing lysozyme concentration and then reached maximum adsorption capacity at around 1.0 mg ml−1 initial lysozyme concentration. Furthermore, two classical isotherm models (Langmuir and Freundlich) were used to quantitatively analyze the adsorption process and its mechanism [8, 44]:

Langmuir models: \(1/{q_e}=1/{q_{\hbox{max} }}+1/({q_{\hbox{max} }}{K_a}{C_e})\),

Freundlich models: \(\log {q_e}=(\log {C_e})/n+\log {k_F}\), where q max is the maximum adsorption amount, \({q_e}\)is the lysozyme adsorption amount at different initial concentration, \({C_e}\) is the equilibrium lysozyme concentration, K a is the Langmuir isotherm constant, K F is the Freundlich constant depicting adsorption capacity, and \(1/n\) is a constant indicating adsorption intensity. The calculated isotherm parameters are listed in Table 3.

It was evident that the calculated R2 of the Langmuir model was higher than that of the Freundlich model. This indicated that the Langmuir equation fitted better with the experimental data and the adsorption process obeyed Langmuir monolayer adsorption rather than heterogeneous surface adsorption [6, 7]. The explanation for this phenomenon might be related to the electrostatic attraction between carboxyl groups and lysozyme, because the carboxyl groups were unable to adsorb lysozyme after they were occupied by another lysozyme.

The adsorption was also affected by the salt concentration, as illustrated in Fig. 3e, lysozyme adsorption capacity dramatically decreased with the increment of NaCl concentration, which was matched well with the observations reported in previous studies [13, 45]. This can be explained by the fact that the electrostatic interaction between lysozyme and carboxyl groups was screwed by the salt ions since protein solubility in the adsorption media was reduced with the increasing ionic strength, thus increasing the ionic strength plays a negative role in lysozyme adsorption.

Furthermore, Li+, Na+, and K+ ions with the same charges but different ionic radius were used as model ions to investigate the effects of ionic radius on the adsorption performance. As presented in Fig. 3f, the adsorption capacity of SA/CMC gel beads slightly decreased with the increase of the ionic radius, which may be due to that the ions with the same charges but larger radius could provide stronger shielding effects between lysozyme and carboxyl groups on the SA/CMC gel beads, thus reducing the adsorption capacity.

In order to better evaluate the adsorption capacity of the SA/CMC gel beads, we compared them with the adsorbents which were also used carboxyl groups (–COOH) as the functional groups (Table 4). Although the bentonite–tryptophan microcomposite [9] showed the highest capacity among all and followed by EVOH nanofibrous membrane [7], the as-prepared SA/CMC gel beads achieved a comparative adsorption capacity with other modified materials possessing –COOH. The unique features of tryptophan, including hydrophobic, electrostatic and hydrogen bond structures of the aromatic amino acid, provide strong interactions with lysozyme molecules, while EVOH nanofibrous membranes, having the ultrahigh specific surface area on the fibers in the membranes, enhance the adsorptive functions. For SA/CMC gel beads, the high performance is mainly attributed to the natural possessed abundant active carboxyl groups on SA or CMC chains, which can spontaneous and efficient adsorb lysozyme without any modification. Compared with other nanomembranes or nanoparticles, the preparing method used in this study is simple, convenient, efficient, reliable as well as environment-friendly, which can give a potential of industrially utilize SA/CMC beads.

Selectivity and Reusability of SA/CMC Gel Beads

To investigate the adsorption selectivity, the adsorption toward lysozyme and BSA (at the concentration of 1 mg mL−1) was performed, illustrated in Fig. 4a. It is clear that SA/CMC gel beads could only adsorb lysozyme ascribed to the electrostatic attraction between the positive charge on the lysozyme and the negative charge on SA/CMC gel beads. Moreover, SDS-PAGE was used to determine the adsorption selectivity from a protein mixture of BSA and lysozyme. It is evident that, after adsorption, the band of lysozyme was reduced in intensity (the insert of Fig. 4a). These remarkable results demonstrate the selectivity of the SA/CMC gel beads in adsorption of proteins.

a Adsorption capacity of SA/CMC20 towards lysozyme and BSA. The insert shows the SDS-PAGE analysis of adsorption of a mixture of lysozyme and BSA: lane 1, a protein ladder; lane 2, the protein solution; lane 3, the protein solution after adsorption by SA/CMC20 gel beads. b Change in the adsorption capacity with increasing cycle number using SA/CMC20 gel beads

Reusability is an important factor for evaluating the adsorbents in terms of economy and practical applications. An adsorption capacity drop occurred after the first stripping cycle, which is probably due to conformational changes by the high NaCl salt attack during the first stripping step (Fig. 4b). In the following cycles, the adsorption amount remains quite constant, around 85%. This can be explained by the fact that the adsorption of lysozyme is mainly based on the electrostatic interactions between the carboxyl groups and lysozyme rather than chemical reactions, which usually blocked the active sites and led to poor reusability. As a whole, good regeneration and reversible adsorption capability of the SA/CMC gel beads encourage it to be one of the excellent candidate adsorbents for lysozyme purification.

Conclusions

Taking advantage of the abundant active carboxyl groups on SA and CMC, the obtained SA/CMC gel beads present an excellent integrated protein (take lysozyme as the model protein) adsorption performance with a high capacity of 236.34 mg g−1, short equilibrium time of 8 h, ease of desorption, good selectivity and reusability. Considering the simplicity and cost-effectiveness of the fabrication process, the favorable physical properties, and the excellent adsorption performance, the SA/CMC gel beads have the potential to be applied as green and low cost absorbents for capture/release of target protein.

References

Kubiak-Ossowska K, Mulheran PA (2010) Mechanism of hen egg white lysozyme adsorption on a charged solid surface. Langmuir 26(20):15954–15965

Kubo T, Arimura S, Tominaga Y, Naito T, Hosoya K, Otsuka K (2015) Molecularly imprinted polymers for selective adsorption of lysozyme and cytochromec using a PEG-based hydrogel: selective recognition for different conformations due to pH conditions. Macromolecules 48(12):4081–4087

Zhang Y, Xing LG, Chen XW, Wang JH (2015) Nano copper oxide-incorporated mesoporous carbon composite as multimode adsorbent for selective isolation of hemoglobin. ACS Appl Mater Interfaces 7(9):5116–5123

Alvarez de Eulate E, Arrigan DW (2012) Adsorptive stripping voltammetry of hen-egg-white-lysozyme via adsorption-desorption at an array of liquid–liquid microinterfaces. Anal Chem 84(5):2505–2511

Strasser S, Niegelhell K, Kaschowitz M, Markus S, Kargl R, Stana-Kleinschek K, Slugovc C, Mohan T, Spirk S (2016) Exploring nonspecific protein adsorption on lignocellulosic amphiphilic bicomponent films. Biomacromolecules 17(3):1083–1092

Wang X, Fu Q, Wang X, Si Y, Yu J, Wang X, Ding B (2015) In situ cross-linked and highly carboxylated poly(vinyl alcohol) nanofibrous membranes for efficient adsorption of proteins. J Mater Chem B 3(36):7281–7290

Fu Q, Wang X, Si Y, Liu L, Yu J, Ding B (2016) Scalable fabrication of electrospun nanofibrous membranes functionalized with citric acid for high-performance protein adsorption. ACS Appl Mater Interfaces 8(18):11819–11829

Ma J, Wang X, Fu Q, Si Y, Yu J, Ding B (2015) Highly carbonylated cellulose nanofibrous membranes utilizing maleic anhydride grafting for efficient lysozyme adsorption. ACS Appl Mater Interfaces 7(28):15658–15666

Kalburcu T, Tabak A, Ozturk N, Tuzmen N, Akgol S, Caglar B, Denizli A (2015) Adsorption of lysozyme from aqueous solutions by a novel bentonite–tyrptophane (Bent–Trp) microcomposite affinity sorbent. J Mol Struct 1083:156–162

Zhu X, Zhang L, Fu A, Yuan H (2016) Efficient purification of lysozyme from egg white by 2-mercapto-5-benzimidazolesulfonic acid modified Fe3O4/Au nanoparticles. Mater Sci Eng C 59:213–217

Odaba M, Denizli A (2004) Cibacron Blue F3GA incorporated magnetic poly(2-hydroxyethyl methacrylate) beads for lysozyme adsorption. J Appl Polym Sci 93(2):719–725

Li S, Mulloor JJ, Wang L, Ji Y, Mulloor CJ, Micic M, Orbulescu J, Leblanc RM (2014) Strong and selective adsorption of lysozyme on graphene oxide. ACS Appl Mater Interfaces 6(8):5704–5712

Zhu J, Sun G (2014) Facile fabrication of hydrophilic nanofibrous membranes with an immobilized metal-chelate affinity complex for selective protein separation. ACS Appl Mater Interfaces 6(2):925–932

Zhu J, Yang J, Sun G (2011) Cibacron Blue F3GA functionalized poly(vinyl alcohol-co-ethylene) (PVA-co-PE) nanofibrous membranes as high efficient affinity adsorption materials. J Membr Sci 385–386:269–276

Dumitriu RP, Stoica I, Vasilescu DS, Cazacu G, Vasile C (2017) Alginate/lignosulfonate blends with photoprotective and antioxidant properties for active packaging applications. J Polym Environ. https://doi.org/10.1007/s10924-017-1018-1

Li J, He J, Huang Y, Li D, Chen X (2015) Improving surface and mechanical properties of alginate films by using ethanol as a co-solvent during external gelation. Carbohydr Polym 123:208–216

Tripathy T, Kolya H, Jana S (2017) Selective lead (II) adsorption and flocculation characteristics of the grafted sodium alginate: a comparative study. J Polym Environ. https://doi.org/10.1007/s10924-017-1004-7

Agnihotri S, Singhal R (2017) Synthesis and characterization of novel poly(acrylic acid/sodium alginate/sodium humate) superabsorbent hydrogels. Part II: the effect of SH variation on Cu2+, Pb2+, Fe2+ metal ions, MB, CV dye adsorption study. J Polym Environ. https://doi.org/10.1007/s10924-017-0956-y

Ibrahim SM, El Salmawi KM (2012) Preparation and properties of carboxymethyl cellulose (CMC)/sodium alginate (SA) blends induced by gamma irradiation. J Polym Environ 21(2):520–527

Mansouri S, Khiari R, Bettaieb F, El-Gendy AA, Mhenni F (2014) Synthesis and characterization of carboxymethyl cellulose from tunisian vine stem: study of water absorption and retention capacities. J Polym Environ 23(2):190–198

Kim MS, Park SJ, Gu BK, Kim C-H (2012) Ionically crosslinked alginate–carboxymethyl cellulose beads for the delivery of protein therapeutics. Appl Surf Sci 262:28–33

Swamy BY, Yun YS (2015) In vitro release of metformin from iron (III) cross-linked alginate–carboxymethyl cellulose hydrogel beads. Int J Biol Macromol 77:114–119

Liu L, Gao ZY, Su XP, Chen X, Jiang L, Yao JM (2015) Adsorption removal of dyes from single and binary solutions using a cellulose-based bioadsorbent. ACS Sustain Chem Eng 3(3):432–442

Zhang S, Xu F, Wang Y, Zhang W, Peng X, Pepe F (2013) Silica modified calcium alginate–xanthan gum hybrid bead composites for the removal and recovery of Pb(II) from aqueous solution. Chem Eng J 234:33–42

Wang Y, Luo M, Xu F, Zhang W (2015) Conversion of volcanic tephra to zeolites for calcium ion cross-linked alginate–zeolite composites for enhanced aqueous removal of cu(II) ions. Water Air Soil Pollut 226(9):286

Wang L-Y, Wang M-J (2016) Removal of heavy metal ions by poly(vinyl alcohol) and carboxymethyl cellulose composite hydrogels prepared by a freeze–thaw method. ACS Sustain Chem Eng 4(5):2830–2837

Kim J-S, Pathak TS, Yun J-H, Kim K-P, Park T-J, Kim Y, Paeng K-J (2012) Thermal degradation and kinetics of alginate polyurethane hybrid material prepared from alginic acid as a polyol. J Polym Environ 21(1):224–232

Pathak TS, Yun J-H, Lee S-J, Baek D-J, Paeng K-J (2009) Effect of solvent composition on porosity, surface morphology and thermal behavior of metal alginate prepared from algae (Undaria pinnatifida). J Polym Environ 18(1):45–56

Tahtat D, Mahlous M, Benamer S, Khodja AN, Oussedik-Oumehdi H, Laraba-Djebari F (2013) Oral delivery of insulin from alginate/chitosan crosslinked by glutaraldehyde. Int J Biol Macromol 58:160–168

Lu T, Xiang T, Huang X-L, Li C, Zhao W-F, Zhang Q, Zhao C-S (2015) Post-crosslinking towards stimuli-responsive sodium alginate beads for the removal of dye and heavy metals. Carbohydr Polym 133:587–595

Elnashar MMM, Danial EN, Awad GEA (2009) Novel carrier of grafted alginate for covalent immobilization of inulinase. Ind Eng Chem Res 48(22):9781–9785

Mir S, Yasin T, Siddiqi H, M, Murtaza G (2016) Thermal, rheological, mechanical and morphological behavior of high density polyethylene and carboxymethyl cellulose blend. J Polym Environ 25(4):1011–1020

Prasad P, Guru GS, Shivakumar HR, Sheshappa Rai K (2012) Investigation on miscibility of sodium alginate/pullulan blends. J Polym Environ 20(3):887–893

Rassu G, Salis A, Porcu EP, Giunchedi P, Roldo M, Gavini E (2016) Composite chitosan/alginate hydrogel for controlled release of deferoxamine: a system to potentially treat iron dysregulation diseases. Carbohydr Polym 136:1338–1347

Roosen J, Pype J, Binnemans K, Mullens S (2015) Shaping of alginate–silica hybrid materials into microspheres through vibrating-nozzle technology and their use for the recovery of neodymium from aqueous solutions. Ind Eng Chem Res 54(51):12836–12846

Vecino X, Devesa-Rey R, Cruz J, Moldes A (2015) Study of the physical properties of calcium alginate hydrogel beads containing vineyard pruning waste for dye removal. Carbohydr Polym 115:129–138

Beele H, Meuleneire F, Nahuys M, Percival SL (2010) A prospective randomised open label study to evaluate the potential of a new silver alginate/carboxymethylcellulose antimicrobial wound dressing to promote wound healing. Int Wound J 7(4):262–270

Tong Q, Xiao Q, Lim LT (2013) Effects of glycerol, sorbitol, xylitol and fructose plasticisers on mechanical and moisture barrier properties of pullulan–alginate–carboxymethylcellulose blend films. Int J Food Sci Technol 48(4):870–878

Luo X, Lei X, Cai N, Xie X, Xue Y, Yu F (2016) Removal of heavy metal ions from water by magnetic cellulose-based beads with embedded chemically modified magnetite nanoparticles and activated carbon. ACS Sustainable Chem Eng 4(7):3960–3969

He X, Male KB, Nesterenko PN, Brabazon D, Paull B, Luong JH T (2013) Adsorption and desorption of methylene blue on porous carbon monoliths and nanocrystalline cellulose. ACS Appl Mater Interfaces 5:8796–8804

Zhang M, Ding C, Yang J, Lin S, Chen L, Huang L (2004) Kinetic models of sorption: a theoretical analysis. J Colloid Interface Sci 276:47–52

He X, Male KB, Nesterenko PN, Brabazon D, Paull B, Luong JH (2013) Adsorption and desorption of methylene blue on porous carbon monoliths and nanocrystalline cellulose. ACS Sustain Chem Eng 5(17):8796–8804

Smith SC, Ahmed F, Gutierrez KM, Frigi Rodrigues D (2014) A comparative study of lysozyme adsorption with graphene, graphene oxide, and single-walled carbon nanotubes: Potential environmental applications. Chem Eng J 240:147–154

Che AF, Huang XJ, Xu ZK (2011) Polyacrylonitrile-based nanofibrous membrane with glycosylated surface for lectin affinity adsorption. J Membr Sci 366:272–277

Yu L-L, Sun Y (2013) Protein adsorption to poly(ethylenimine)-modified sepharose FF: II. Effect of ionic strength. J Chromatogr A 1305:85–93

Acknowledgements

This work was partially supported by the China Scholarship Council (201506120259) and Weihai Science and Technology Development Plan Project (2013GNS028).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, J., Wei, X., He, J. et al. Tailored Natural Polysaccharides Beads as Green Sorbents for Efficient Lysozyme Adsorption. J Polym Environ 26, 2803–2812 (2018). https://doi.org/10.1007/s10924-017-1137-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-1137-8