Abstract

Over the years, there has been a growing need for producing cost effective, porous scaffold biomaterials for tissue engineering. Therefore, this study focused on fabrication of β-chitosan based scaffold from the waste of the pen of locally available squid variety Loligo duvauceli (Indian Squid). The scaffold was prepared by the solvent casting method which requires less time and minimum energy. To the best of our knowledge,there are no reports on scaffold preparation from the extracted β-chitosan. The biological properties of extracted chitosan scaffolds C(L) were evaluated and compared with those of commercial chitosan scaffold C(S). The prepared scaffolds were characterized by SEM, swelling property, in vitro enzymatic degradation, and hemo, biocompatibility properties. C(L) scaffolds had an average pore size of 60 µm and the swelling ratio was 16.2 ± 2.2% with mass loss percentage of 20.8 ± 4.5% after 4 weeks of degradation. It has exhibited good hemocompatible properties and thermal stability. Mouse fibroblast 3T3 cells were able to adhere and proliferate well in the extracted β-chitosan C(L) scaffold. All these results indicated that extracted β-chitosan C(L) is a suitable alternative for biomaterials used for tissue engineering purposes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Tissues have limited self-repair capabilities and damage to them is commonly treated by the surgical intervention which involves autologous tissue transposition. But this is limited by the shortage of donor tissue and donor site morbidity. Regeneration of functional tissue in vitro offers an alternative where engineered 3D- scaffold porous matrices are utilized in tissue engineering as frameworks to seed and grow the cells into tissues. Thus, scaffolds must be designed with appropriate structure and properties that support cell adhesion, proliferation and differentiation to produce functional tissue [1]. The role of scaffold during tissue construct development is dependent on the specific characteristics of selected biomaterials. Polymers are exhaustively explored as scaffolds for tissue engineering applications. Naturally derived polymers are of special interest due to their unique chemical and biological similarity with that of natural tissues [2].

The marine environment is considered to be an exceptional reservoir and inspiring framework for the development of novel biomedical products. One such product is chitin, a marine biopolymer. It is the second most ubiquitous natural polysaccharide on earth after cellulose [3]. It occurs primarily as a structural component in the exoskeleton of crabs, shrimps, insects, cuttlebone and squids [4]. Chitosan is obtained by deacetylation of the N-acetyl glucosamine units of chitin. Chitosan has emerged as an advantageous biomaterial due to the proxy structure of glycosaminoglycan, a main component of native extra cellular matrix in tissue that promotes cell adhesion, proliferation, and cell function The unique biological properties of chitosan including biocompatibility, hydrophilicity biodegradability bioactivity, non-toxicity, hemostatic property, antibacterial and wound healing acceleration property [5,6,7,8,9]. Moreover,it has many reactive amino side groups as well as hydroxyl groups, which offer the possibility of chemical modifications, formation of a large variety of useful derivatives that are commercially available. Because of its exceptional biological and chemical qualities, chitosan assures its application in biomedical field.

Three different crystalline forms of chitosan namely α, β, γ forms are recognized so far based on the arrangement of polysaccharide units. The most abundant form is α where chains are associated in an antiparallel fashion are found in crustacean shells, whereas the less abundant β-form has parallel chains and occurs primarily in squid pens, the rarest γ-form consists of two parallel chains alternate with an antiparallel one. Among the three different allomorphs, β-chitosan possess desirable tissue engineering properties and unique functionality such as higher solubility, reactivity, swelling ability toward solvents and lower crystallinity than α-chitosan but the commercial availability of β-chitosan is very limited due to relatively limited source of the raw materials used for extracting them [10] while α-chitosan are extracted from readily accessible crustacean shells. In the present study, β-chitin was extracted from Indian squid (Loligo duvauceli) pens .This species of squid was chosen because of its increased catch and also due to enormous squid pen waste generated from south east coast of Rameshwaram, Tamilnadu, India (an average of 304.72 tonnes of squid wastes is generated per year) [11]. Further, the extracted β-chitin was converted to chitosan through a deacetylation reaction. Though several reports are available for the preparation of chitosan scaffolds using commercial α-chitosan, the present study is focussed on the extraction of β-chitosan from L. duvauceli and evaluation of prepared chitosan scaffolds for tissue engineering purpose.

Experimental

Materials

Seafood waste viz pen of marine seafood variety L. duvauceli (Indian Squid) ,was collected from Rameshwaram, South East Coast of India. The collected samples were washed with tap water and sun dried for 24 h. The dried samples were then pulverized into fine powder. Commercial chitosan with medium molecular weight was purchased from Sigma Aldrich (CAS 44887-7) The sample was labelled as C(S) & C(L), where C indicates chitosan and the alphabet provided in the parenthesis indicating the first letter of the chemical company from which it was procured.The extracted samples were labelled as C(L), where L indicates Lady Doak College, Madurai.

Extraction of Chitosan from Loligo duvauceli

The extraction of chitosan from squid pen of L. duvauceli was carried out using modified method of Takiguchi [12]. Since squid pens possess very low mineral content, demineralisation step was omitted. Other two different steps such as deproteinization and deacetylation was carried out for the extraction of chitosan. Deproteinization was carried out using 1 N NaOH. The deproteinised sample was subjected for deacetylation by constant stirring with 40% (w/v) NaOH. The mixture was washed, dried and stored.

Preparation of Scaffolds by Solvent Casting

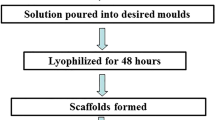

Solvent casted scaffolds were prepared by dissolving 0.2 g of chitosan in 20 ml of 0.35 M acetic acid. The solution was poured into a petridish and then kept in hot air oven at 45 °C till the solvent gets evaporated. Then the mixture was neutralised by the addition of 0.5 M NaOH to obtain the scaffolds.

Characterization of Scaffold

Scanning Electron Microscopy Analysis (SEM Analysis)

The scaffolds were prepared for the SEM by sputter coating them with gold. It was observed under SEM, specifically the JEOL 7000JSM 6390 Japan, with a 15 kV applied voltage to analyze the structure of the prepared scaffolds [13].

In Vitro Enzymatic Degradation

The absolute dry weights (W0) of the chitosan scaffolds were measured after which the samples were placed in phosphate- buffered saline (PBS) buffer solution at a 37 °C. To this 5 µg/ml of lysozyme was added. Then the samples were placed in shaker with temperature set at constant 37 °C for 4 weeks for the measurement of enzymatic degradation. At the end of period, the scaffolds were freeze-dried for 24 h and the weight loss ratio was calculated using the following equation: [13]

Three specimens were tested for each sample and their average values were used for data analysis.

Swelling Ratio

The swelling ratio of the scaffolds was calculated by measuring the weight of the scaffold before and after immersion in 0.05 M PBS buffer, pH 7.4 at a temperature of 37 °C. The swelling ratio of the scaffold was defined as the ratio of weight increase (Ws) with respect to the initial weight (Wd) of dry sample [14]

Thermal Properties

The thermal characteristics of the prepared scaffolds was analysed by thermogravimetric analyser (Model TGA-50, Shimadzu, Japan) at a heating rate of 10 °C/min from 20 to 600 °C in a dynamic nitrogen atmosphere (30 ml/min).

Blood Compatibility Studies

All the procedures were carried out after ethical approval from institutional ethics subcommittee.

Hemolysis Assay

The hemolysis test was performed as recommended by ISO10993-4 [15]. Blood was collected in heparin-coated siliconized vials from healthy volunteers. The scaffolds were equilibrated in normal saline for 30 min at 37 °C before testing. These scaffolds were incubated in a siliconized tube containing 10 ml of heparinized blood. 9 ml of heparinized blood diluted with 1 ml PBS was taken as a negative control. 1 ml heparinized blood diluted with 9 ml distilled water without the scaffold was taken as a positive control. The content were gently mixed and incubated at 37 °C for 1 h. The samples were centrifuged and the absorbance of the supernatant measured at 545 nm using UV–visible spectrophotometer

Platelet Adhesion Test

The platelet adhesion study was performed according to International standard 10993-4 [16]. Whole blood was taken from healthy volunteer in sterile plastic tubes containing 3.8% sodium citrate in PBS to prevent coagulation. Samples were centrifuged at 1300 rpm for 10 min at 4 °C to collect the platelet rich plasma (PRP). The films were punched into circular shape and placed in 24-well polystyrene plates sterilized with 75% ethanol and rinsed thrice with PBS and equilibrated in PBS for 1 h. PRP was warmed to 37 °C for 30 or 120 min and films were rinsed three times with PBS to remove the weakly-absorbed platelets. The platelets on the scaffolds were observed under the microscope after incubation.

Biocompatibility Study

Mouse 3T3 Fibroblast Culture

Experiments were performed with NIH/3T3 fibroblasts, obtained from Aravind Medical Research Foundation (AMRF) Madurai, Tamilnadu. The cells were cultured in Dulbecco Modified Eagle’s Medium (DMEM) (Invitrogen- GIBCO BRL, Grand Island, NY) containing 10% fetal bovine serum (US origin from HyClone, Logan, UT) and 100 U/ml penicillin and 100 pg/ml streptomycin (Invitrogen- GIBCO BRL, Grand Island, NY) at 37 °C in a humidified atmosphere of 5% CO2.

Seeding of 3T3 Cells on Scaffolds

To evaluate the biocompatibility of the scaffolds on 3T3 cells, the uniformly cut (1 mm × 1 mm) and weighed chitosan scaffolds were placed in a 96 well plate in triplicates. 50 µl of DMEM was added and the matrices were kept for sterility check overnight at 37 °C. Before seeding the cells, the scaffolds were washed twice with PBS, once with DMEM and were placed in 96-well plates. The scaffolds were seeded with 5 × 103 3T3 fibroblast cells. Culture media was added and the cells were cultured at 37 °C in a humidified 5% CO2 incubator for 3 days after which the viability of cells was assessed using trypan blue assay [17].

Viability by Trypan Blue Exclusion Test

Trypan blue solution was prepared by dissolving trypan blue powder (Aurolab ,India) in PBS to make a 0.4% solution and the dye solution was then filtered to remove any undissolved particles. 10 µl of the single cell suspension was taken in a 50 µl micro centrifuge tube and was mixed with 10 µl of 0.4% trypan blue dye solution. After keeping for 3 min at RT, 10 µl of the suspension was load`ed onto haemocytometer chamber. The viable (unstained) and non-viable (blue stained) cells were counted separately. The number of cells per ml and percentage of viable cells were given by the formula:

Results and Discussion

Morphology of the Scaffolds

Marine organisms are constituted by materials with a vast range of properties and characteristics that suit their potential application within the biomedical field [18]. One such valuable material is chitosan. Chitosan C(L) was extracted from squid pens of L. duvauceli (Mol wt −3.09 × 105 g/mol) (Fig. 1). The extracted chitosan was characterised by several physico chemical characterisation techniques to confirm its suitability to be used as the biomaterial for biomedical applications. Chitosan scaffolds are considered to be promising materials for the design of tissue engineered systems owing to their low immunogenic activity, controlled biodegradability and porous structure [19,20,21]. Thus, chitosan scaffolds were prepared by solvent casting method (Fig. 2). It is an appealing choice of method for scaffold production since it helps in the production of scaffolds with uniform thickness and optically clear in nature. Moreover, this technique is performed feasibly on a small scale.

The morphology and porous nature of the scaffold is an important parameter to be considered when its application for tissue engineering is envisaged. It is suggested that the pores formed on the scaffolds influence both the mechanical and biological property of the scaffold since it helps in the diffusion of nutrients to the cells when they are grown on them. If pores are too small in the scaffolds cells cannot migrate towards the center of the construct limiting the diffusion of nutrients and removal of waste products whereas if the pores are too large there is a decrease in the specific surface area available thereby limiting cell attachment [22].

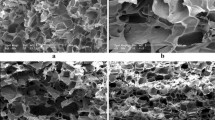

In order to assess the surface morphology and the pore size of the scaffolds, SEM analysis was performed. The SEM micrographs of C(S) revealed irregular, smaller, mean pore size of 4–20 µm (Fig. 3). Mean pore size is an essential aspect of scaffolds for tissue-engineering. If pores are too small, cells cannot migrate in towards the centre of the construct limiting the diffusion of nutrients and removal of waste products. The prepared C(L) scaffolds exhibited a uniform, high degree of interconnectivity porous microstructure with a mean pore size of 20–60 µm (Fig. 4). The scaffold with pore microstructure and the high degree of interconnectivity provides cellular matrix analog that could function as necessary substrate for host cells to infiltrate and a physical support to guide the differentiation and proliferation of cells toward the targeted functional tissue or organ [23]. Moreover, a tightly controlled pore sizes of 30–40 μm in diameter vascularizes rapidly in vivo with reduced fibrotic response [24, 25]. The results suggest that the average pore size of the prepared C(L) scaffold is large enough to facilitate the migration of mammalian cells.

In Vitro Enzymatic Degradation

Scaffolds for tissue engineering,depending on their composition, are usually expected to degrade after successful tissue regeneration [26]. The degradation behaviour of polymer scaffold is tested in vitro, to predict their in vivo behavior when implanted. Thus, it is important to study the structural stability of prepared C(L) scaffolds in order to characterize their potential for application in tissue engineering strategies in vivo. Chitosan is degraded by enzymatic hydrolysis with lysozyme being the primary agent. This enzyme is present in human serum with a concentration in the range of 7–13 mg/l [27]. Thus the prepared scaffolds were incubated with lysozyme for 4 weeks. The weight loss percentage of the C(L) scaffolds was found to be 20.8 ± 4.5% whereas for C(S) 36 ± 5% respectively (Fig. 5). A lower degree of degradation is due to the fact that the extracted chitosan had a higher degree of deacetylation causing lysozyme to have minimal effect on the polymer degradation. It is suggested that the crystalline nature of high DDA chitosan prevents lysozyme from easily accessing the glycosidic bonds between the polymer chains, resulting in slower degradation [28, 29]. Furthermore, the binding site of lysozyme requires a certain number of acetylated residues to be present for degradation [30, 31]. Moreover, since the pore size of C(L) scaffolds was in the range of 20–60 µm only smaller area was available for lysosome to enter thus few chitosan molecules will be cleaved by lysosome. The chitosan matrix with the high degree of acetylation gets broken into pieces after few days of lysozyme treatment whereas the matrix with a low degree of acetylation remains relatively constant for a long time [32,33,34].

Swelling Ratio

The ability of a material to absorb water and its water permeability influence the absorption of body fluids and the transfer of cell nutrients and metabolites throughout the materials [35]. The absorption ability of the scaffolds was determined by swelling ratio. The swelling ratio of C(L) and C(S) scaffold were 16.2 ± 2.2 and 26 ± 0.8% respectively (Fig. 6). The swelling ratio of C(L) scaffold was lesser compared to commercial C(S) scaffold. The low swelling ratio of C(L) scaffolds is attributed to the fact that the high inter-pore connectivity resulted in enhanced rigidity and strength to the scaffolds, allowing it to absorb solution without swelling.

Thermal Property of Scaffold

Thermal stability is considered to be a crucial parameter that describes the decomposition of biomaterials during heating. The higher the temperature needed to decompose a biomaterial, the more thermally stable it is [36]. The thermal degradation of the C(L) chitosan scaffolds was measured using the thermogravimetric method (TGA) (Fig. 7). The thermal degradation of chitosan scaffold occurred in two stages, the initial degradation occurred around 30–90 °C and displayed a mass loss ratio of 10%. It is thought that mass loss is due to the result of the evaporation of water molecules in the structure. Polysaccharides usually have a strong affinity for water and in the solid state these macromolecules are disordered structures which can be easily hydrated. The hydration properties of this polysaccharide mainly depend on the primary and supramolecular structures [37]. The second stage of degradation occurred around 120–230 °C and the mass loss was observed to be 29% which is attributed to vaporization and burning of volatile compounds produced by the thermal degradation of polymeric chain which involves degradation of the polysaccharide structure of the molecule, including the dehydration of saccharide rings followed by the polymerization and decomposition of the acetylated and deacetylated units. The maximum temperature of degradation (DTGmax value) for C(L) was observed to be 300 °C. It is reported that the main degradation temperature of chitosan is around 300 °C [38, 39]. According to these, it is evident that C(L) chitosan scaffolds exhibit significant thermal stability and they can withstand temperatures without affecting its physicochemical properties.

Blood Compatibility Studies

Hemolysis Test

The biocompatibility, especially blood compatibility, is the most important property with regard to biomaterials. When the polymeric scaffold comes in contact with blood it must not induce thrombosis, thromboembolisms, antigenic responses, destruction of blood constituents, plasma proteins, and so forth [40]. Hemolysis test was done to determine the extent of exosomatic hemocytolysis of the biomaterial. The absorbance values of the positive and negative controls were 1.66 and 0.02. These values are regarded as 0 and 100%, respectively, when calculating the relative red cell toxicity. The hemolysis rates of C(L) and C(S) scaffold samples were 1.8 ± 0.3 and 2 ± 0.15%, respectively. In our investigation, the values obtained for hemolysis test are lower than the criterion set by ISO 10993-4 (reference <5%), which strongly suggests that these scaffold materials have no potential to induce hemolysis.

Platelet Adhesion Test

Platelet adhesion ability of the scaffolds was explored in order to determine the hemocompatibility of the scaffolds. When a foreign material comes into contact with blood, the initial blood response is the adsorption of blood proteins, followed by platelet adhesion and the activation of coagulation pathways, leading to thrombus formation [41]. In the present investigation, platelet adhesion was completely inhibited in C(L) scaffolds (Fig. 8) whereas C(S) showed reduced adhesion (Fig. 9). This is attributed to the fact that chitosan induces strong interactions with plasma proteins and this interaction inhibited the adsorption of other procoagulant and proadhesive proteins on scaffolds which limited the platelet adhesion on the surface [42].

Biocompatibility Testing Using 3T3 Fibroblast Cells

Cell Attachment on Scaffolds

Cell viability is an important parameter in tissue engineering and culture studies to evaluate the effect of environmental conditions on cell behavior [43]. Trypan blue dye exclusion method is a simple, rapid and inexpensive and commonly used method to assess cell viability. Trypan blue is a vital stain that leaves nonviable cells with a distinctive blue color when observed under a microscope, while the viable cells appear unstained. Viable cells have intact cell membranes and hence do not take up the dye. On the other hand, nonviable cells do not have an intact and functional membrane and hence take up dye from their surroundings.Hence in the present study cell viability and biocompatibility assessments were carried out using the trypan blue assay. The cells were cultured on the both C(L) and C(S) films for 3 days, and the cell morphology,adhesion, viability, proliferation were determined. The prepared C(S) scaffolds underwent shrinkage with deformation due to higher water absorption ability (Fig. 10) and also due to decreased pore size cells. The attachment of the fibroblast 3T3 cells onto the prepared C(L) scaffold took 4 h after seeding of cells. Trypan blue dye exclusion analysis of the cultured 3T3 cells revealed proliferation and viability (92.5 ± 1.5%) after 72 h when grown in C(L) scaffolds (Fig. 11). In trypan blue assay C(L) scaffold materials exhibited very good biocompatibility with decreased cell death. Results of trypan blue assay with mouse fibroblast 3T3 cells showed that solvent casted C(L) supported the adhesion and proliferation of more number of cells (Fig. 12). The results are in agreement with previous reports suggesting that chitosan based biomaterials can serve as a potent candidate as scaffolds for skin substitutes due to its physico chemical and biological properties [44].

Conclusion

In recent years, chitosan has emerged as a promising biomaterial for the biomedical application due to its natural origin and structural similarity to glycosoaminoglycan present in native tissues in addition to its biocompatibility and biodegradability. Though much of the research work has been carried out using α-chitosan but the use of β-chitosan as potential scaffold biomaterial is limited.The present study was attempted to utilize extracted β-chitosan from Squid pen waste of L. duvauceli for scaffold preparation. The scaffolds prepared showed desirable tissue engineering properties. Further work will be carried out to determine the cytocompatibility of the scaffolds.

References

Dhandayuthapani B, Yoshida Y, Maekawa T, Sakthi Kumar D (2011) Int J Polym Sci 2011:1–19

Archana D, Upadhyay L, Tewari RP, Dutta J, Huang YB, Dutta PK (2013) Indian J. Biotechnol 12(4):475–482

Dutta PK, Ravi Kumar MNV, Dutta J (2002) JMS-Polym Rev C 42:307–354

Dutta PK, Dutta J, Chattopadhyaya MC, Tripathi VS (2004) J Polym Mater 21(3):321–333

Jia Y, Hu Y, Zhu Y ,Che L, Shen Q et al (2011) Carbohydr Polym 83:1153–1161

Singh J, Dutta PK (2009) Int J Biol Macromol 45:384–392

Archana D, Dutta J, Dutta PK (2010) Asian Chitin J 6:45–46

Dutta PK, Dutta J, Tripathi VS (2004) J Sci Ind Res 63:20–31

Kumar S, Dutta J, Dutta PK (2009) Int J Biol Macromol 45:330–337

Jung J, Zhao Y (2013) J Agric Food Chem 61(37):8783–8789

MPEDA (2014) MPEDA Newsletter 5–10

Takiguchi Y (1991) Chitin, Chitosan Jikken Manual Chapter—2, Gihodou Shupan Kaisha, Japan, pp 9–17

Tsai SO, Hsieh YC, Hsieh YC, Wang DM et al (2007) J Appl Polym Sci 105:1774

Sun GM, Zhang XZ, Chu CC (2007) J Mater Sci Mater Med 18(8):1563

Biological Evaluation of Medical Devices. sample preparation and reference materials. ISO 10993

Biological Evaluation of Medical Devices—Part 4: selection of tests for interactions with blood 2002 ISO 10993-4, 2nd edition

Yang F, Murugan R, Wang S, Ramakrishna S (2004) Biomaterials 26:2603

d’Ayala GG, Malinconico M, Laurienzo P (2008) Molecules 13:2069–2106

Jayakumar R, Prabaharan M, Nair SV, Tokura S, Tamura H, Selvamurugan H (2010) Prog Mater Sci 55:675–709

Martion AD, Sittinger M, Risbud MV (2005) Biomaterials 26:5983–5990

Muzzarelli RAA, Muzzarelli C (2005 ) Adv Polym Sci 186:151–209

Murphy CM, O’Brien FJ (2010) Cell Adhes Migr 4(3):377–381

Kurkeu M, Benlidayi ME, Ozyegin LS et al (2008) J Mater Sci 19:50–65

Marshall AJ et al (2004) Polym Prepr 45:100–101

Isenhath SN et al (2007) J Biomed Mater Res A 83:915–922

Charcosset C (2006) Biotechnol Adv 24:482–492

Martins AM, Pereira RC, Leonor IB, Azevedo HS, Reis RL (2009) Acta Biomater 5:3328–3336

Shi C, Zhu Y, Ran X, Wang M, Su Y, Cheng T (2006) J Surg Res 133:185–192

Madihally SV, Matthew HW (1999) Biomaterials 20:1133–1142

Lim SM, Song DK, Oh SH, Lee-Yoon DS, Bae EH, Lee JH (2008) J Biomater Sci Polym Ed 19:453–466

Tomihata K, Ikada Y (1997) Biomaterials 18:567–575

Thein HWW, Kitiyanant Y (2006) J Biomed Mater Res 80B:92–101

Hsu S, Whu SW, Tsai C, Wu Y, Chen H, Hsieh K (2004) J Polym Res 11:141–147

Ren D, Yi H, Zhang H, Xie W, Wang W, Ma X (2006) J Membr Sci 280:99–107

Costa-Pinto RA, Martins MA, Castelhano-Carlos JM, Correlo MV et al (2014) J Bioact Compat Polym 29(2):137–151

Gabbott P (2008) Principles and Applications of Thermal Analysis. Blackwell Publishing Ltd, UK, pp 256–257

Subhapradha N, Ramasamy P, Shanmugam V, Madeswaran P et al (2013) Food Chem 141:907–913

Al Sagheer FA, Al Sughayer MA, Muslim S, Elsabee MZ (2009) Carbohydr Polym 77:410–441

Abdou ES, Nagy KSA, Elsabee MZ (2008) Bioresour Technol 99:1359–1367

Sevastianov VI (1991) In: Szycher M (ed) High performance biomaterials: A comprehensive guide to medical and pharmaceutical applications. Technomic, Lancaster, pp 245–256

Xu CL, Bauer J, Siedlecki AC (2014) Colloids Surf B 124:49–68

Fedel M, Endogan T, Hasirci N, Manigilio D et al (2012) J Bioact Compat Polym 27:295

Dittmar R, Potier E, van Zandvoort M, Ito K (2012) Tissue Eng Part C 18(3):198–204

Kim IY, Seo SJ, Moon HS, Yoo MK, Park IY, Kim BC, Cho CS (2008) Biotechnol Adv 26(1):1–21

Acknowledgements

We gratefully acknowledge the support extended by Department of Biotechnology (DBT) Bioinformatics Infrastructure Facility (BIF) (BT/BI/25/017/2012) for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roshan Ara Begum, E., Bhavani, K., Sheela Kumari, S. et al. Evaluation of Extracted β-chitosan From Loligo duvauceli for the Preparation of Tissue Engineering Scaffolds. J Polym Environ 26, 1231–1238 (2018). https://doi.org/10.1007/s10924-017-1020-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-1020-7