Abstract

Synthesis of sodium alginate-g-poly(acrylamide-co-N-methylacrylamide) [S-III], sodium alginate-g-poly(N-methylacrylamide-co-N,N-dimethylacrylamide) [S-II], sodium alginate-g-poly(acrylamide-co-N,N-dimethylacrylamide) [S-I]. Sodium alginate-g-poly(N,N-dimethylacrylamide) [SAG-g-PDMA] and sodium alginate-g-poly(acrylamide) [SAG-g-PAM] were prepared by solution polymerization technique using potassium peroxydisulfate as the initiator at 70 °C in water medium. The graft copolymers were characterized by FTIR and NMR (1H and 13C) spectroscopy, SEM and XRD studies. All the five graft copolymers were used to remove Pb(II) ions from the aqueous solution and also in flocculation studies of kaolin clay (1.0 wt%), silica (1.0 wt%) and iron ore slime (0.25 wt%) suspensions. A comparative studies of all the five graft copolymers were also made in both the two cases. The Pb(II) ion removal capacity of all the graft copolymers follows the order S-III > SAG-g-PAM > S-II > SAG-g-PDMA > S-I. But the flocculation performance of the graft copolymers follows the order S-II > S-I > S-III > SAG-g-PDMA > SAG-g-PAM. S-III was also used for the competitive metal ion removal with Hg(II), Cd(II), Cu(II) and Zn(II). Pb(II) adsorption of S-III (the best Pb(II) ion adsorber) follows pseudo second order rate equation and Langmuir adsorption isotherm.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water pollution caused by toxic heavy metal ions is now a serious global problem and received much attention in recent years. Such metal ions come into the water bodies mainly by the effluents and waste water from variety of chemical industries. The major toxic metal ions have been found in surface and ground water are Pb(II), Cd(II), Hg(II), Zn(II), Cu(II) and Ni(II) which are non degradable naturally and causing serious health problems in living organisms. Lead(II) is one of the most toxic and harmful metal ion, causes dangerous effects when it enters into the body of any living organism by any source. It damages kidneys, liver and gastrointestinal system and also affects the central nervous system [1]. Diseases like anaemia, headache irritability, hallucination, hepatitis, insomnia and renal damage are the symptoms of Pb(II) accumulation. Lead(II) comes into the environment mainly by the waste of variety of industries like lead batteries, paint and dyes, electroplating, platings etc. [2]. Therefore, the removal of Pb(II) ions from the waste water has got considerable significance from the environmental point of view. There are various methods to remove Pb(II) ions from water medium including chemical precipitation, reverse osmosis, solvent extraction, membrane filtration etc. These methods are relatively expensive. Among the various methods, adsorption is an effective process for the removal of Pb(II) ions and the suspended particulate materials from the water medium where low cost, efficient and easily available adsorbents were used. Therefore, searching materials of low cost, highly effective sorbents for the metal ions and the suspended particulate matters in waste water is an active area of research.

Industrial waste water also contains various toxic elements, suspended solids together with other microbiological and chemical contaminants which are extremely harmful towards human health and aquatic species [3]. Therefore, direct disposal of industrial waste water into the environment without the separation of toxic and harmful elements is not permissible. There are so many waste water treatment methods of which flocculation is an economical and efficient technique for purification and recycling of industrial waste water and effluents [4].

Adsorption of heavy metal ions from aqueous medium by using cost effective efficient metal adsorbing agents is an active area of research now a days [5–8]. Among the various heavy metal ion adsorbents water soluble polymers (polyelectrolytes and polychelatogen) are found to be most effective. The essential requirements for a polymer to act as metal capturing agent are their high water solubility, chemical stability, strong affinity to interact with the metal ions, metal selectivity and can be prepared easily [9]. The most useful polymers bearing such properties are the polysaccharide based graft copolymers containing one or more metal coordinating functionalities. These groups are placed at the side chains of the polysaccharide backbone resulting comb like structures. Polymers containing functional groups capable of coordinating metal ions are called polychelatogens. Carboxylic acids (–COOH) and amides  are two important functional groups present in the polychelatogens [10].

are two important functional groups present in the polychelatogens [10].

There are three different types of amide groups namely primary (–CONH2), secondary (–CONHMe), tertiary (–CONMe2) with varying electron density at the ‘N’ as well as at the ‘O’ centre  . The electron density at the ‘N’ and ‘O’ centres increases on going from primary amide to tertiary because of the increment of electron donating methyl (–CH3) groups. Poly (N,N-dimethylacrylamide) (PDMA) is highly water soluble and biocompatible but graft copolymers based on polysaccharide and dimethylacrylamide (DMA) have poor metal chelating properties because of the steric crowding of two methyl groups at the ‘N’ centre [11]. Poly(N-methylacrylamide) (PNMA) is not water soluble because of the extensive intramolecular hydrogen bonding [12]. Polyacrylamide (PAM) is water soluble and PAM based graft copolymers were used as metal ion adsorbing and flocculating agents. Therefore, the present investigation was undertaken to prepare five graft copolymers containing both –CONH2 (1° amides) and –CONHMe (2° amide), –CONHMe (2° amide) and –CONMe2 (3° amide), –CONH2(1° amide)and –CONMe2 (3° amide) functionalities into the sodium alginate backbone by grafting a mixture of acrylamide (AM) (CH2=CH–CONH2) and N-methylacrylamide (NMA) (CH2=CH–CONHMe), N,N-dimethylacrylamide (DMA) (CH2=CH–CONMe2) and NMA and AM and NMA, and by grafting AM and DMA separately onto the sodium alginate backbone which are to be used as Pb(II) coordinating and flocculating agents. The aim was to investigate the water solubility and hence the effectiveness of the graft copolymers to bind the Pb(II) ions and to act as flocculating agents in water medium. A comparative study was also made in both the two applications.

. The electron density at the ‘N’ and ‘O’ centres increases on going from primary amide to tertiary because of the increment of electron donating methyl (–CH3) groups. Poly (N,N-dimethylacrylamide) (PDMA) is highly water soluble and biocompatible but graft copolymers based on polysaccharide and dimethylacrylamide (DMA) have poor metal chelating properties because of the steric crowding of two methyl groups at the ‘N’ centre [11]. Poly(N-methylacrylamide) (PNMA) is not water soluble because of the extensive intramolecular hydrogen bonding [12]. Polyacrylamide (PAM) is water soluble and PAM based graft copolymers were used as metal ion adsorbing and flocculating agents. Therefore, the present investigation was undertaken to prepare five graft copolymers containing both –CONH2 (1° amides) and –CONHMe (2° amide), –CONHMe (2° amide) and –CONMe2 (3° amide), –CONH2(1° amide)and –CONMe2 (3° amide) functionalities into the sodium alginate backbone by grafting a mixture of acrylamide (AM) (CH2=CH–CONH2) and N-methylacrylamide (NMA) (CH2=CH–CONHMe), N,N-dimethylacrylamide (DMA) (CH2=CH–CONMe2) and NMA and AM and NMA, and by grafting AM and DMA separately onto the sodium alginate backbone which are to be used as Pb(II) coordinating and flocculating agents. The aim was to investigate the water solubility and hence the effectiveness of the graft copolymers to bind the Pb(II) ions and to act as flocculating agents in water medium. A comparative study was also made in both the two applications.

Experimental

Materials

Sodium alginate (SAG), potassium peroxydisulfate (K2S2O8), acrylamide (AM), lead nitrate [Pb(NO3)2], acetone (CH3COCH3), silicon dioxide (suspension zeta potential −52.3 mV at pH 7.2) and N-methylacrylamide (NMA) were procured from Loba Chemie, Bombay, India. N,N-dimethyacrylamide (DMA) was purchased from Aldrich Chemical Company, St. Louis, USA. N,N-dimethylacrylamide was purified by vacuum distillation and the middle fraction was used for this study. Iron ore slime (suspension zeta potential −31.72 mV at pH 7.2) was obtained from TISCO mine, (Jharkhand, India). Kaolin clay (suspension zeta potential −3.9 mV at pH 7.6) was obtained from Famous Minerals and Chemical Pvt. Ltd., Mumbai, India.

Synthesis and Purification of Graft Copolymers

Graft copolymers were prepared in water medium by radical polymerization technique where potassium peroxydisulfate (K2S2O8) was used as a free radical initiator. A typical procedure was as follows; aqueous solution of sodium alginate (SAG) was prepared first by dissolving 2.5 g SAG in 150 ml water into a stoppered conical flask at 90 °C, after which the solution was cooled to 30 °C. Then 8.0 ml of DMA and 7.0 g of AM were added to the SAG solution. The dissolved oxygen was eliminated by purging N2 gas onto the solution for 30 min, then the temperature of the solution was raised to 70 °C. 0.05 g of K2S2O8 was added to the solution and the temperature was fixed at 70 °C. After 6 h of reaction the reaction was terminated by adding saturated solution of hydroquinone. The graft copolymer was isolated by precipitating it from the water medium using acetone as the solvent. The solid polymer after isolation dried in a vacuum oven. After that it was subjected to purification. Similar procedure was followed by preparing SAG-g-poly(DMA-co-NMA) and SAG-g-poly(AM-co-NMA) by taking a mixture of 8.0 ml DMA and 6.5 g NMA, 7.0 g AM and 6.5 g NMA onto 150 ml of aqueous solution of SAG containing 2.5 g SAG in each case separately. The synthetic details are shown in Table 1.

The occulated homo-polymers PDMA and PAM were removed from the graft copolymer by solvent extraction technique in a soxhelet extraction using a mixture of formamide and acetic acid (1:1 by volume) for PAM [12] and methanol for PDMA [13]. Poly(N-methylacrylamide) (PNMA) was removed from the PNMA containing graft copolymer by water treatment, since PNMA is water insoluble. SAG-g-PAM and SAG-g-PDMA were prepared by the similar way using 8 ml of DMA and 7.0 g of AM as the monomers separately in solution containing 2.5 g of SAG in 150 ml of water.

Characterization of the Graft Copolymers

FTIR Spectroscopy Study

All the purified polymers namely S-I, S-II, S-III, SAG-g-PAM and SAG-g-PDMA were subjected to FTIR spectral analysis. KBr pellet method was used and the spectra were carried out in a Perkin Elmer (L16000300 Spectrum Two LiTa, Llantrisant, UK) spectrophotometer. The IR spectra of all the graft copolymers are shown in Fig. 1.

1H and 13C NMR Spectroscopy

NMR instruments (JEOL, Tokyo, Japan) was used for this NMR spectral analysis at 500 MHz for 1H at and 100 MHz for 13C. The spectral analysis of graft copolymers were performed in D2O solvent at 25 °C. The spectra are shown in Fig. 2.

XRD Analysis

The powder XRD analysis of all the graft copolymers was performed in Rigaku, Miniplex 600 (Japan), X-ray diffractometer using CuKα radiation (λ = 0.154056 nm). The XRD plots are shown in Fig. 3.

Pb(II) Adsorption

Adsorption experiments were carried out in batch mode in 50 ml stoppered conical flasks by taking 10 ml (0.04 g) of graft copolymer solution and 30 ml of 0.01 M Pb(II) nitrate solution at pH 5.5 in a flask for each graft copolymer separately. The mixture of each flask was agitated separately by 40 °C/150 rpm for 2 h. After 2 h the Pb(II) adsorbed polymer was separated by centrifugation and the concentration of Pb(II) in the supernatant was analysed using atomic adsorption spectrophotometer (Varian-Spectra, AA55B, Australia). The Pb(II) adsorption capacity of the graft copolymer was calculated by using the following equation [14].

where q represents the Pb(II) ion adsorption capacity at time t or at equilibrium (mg/g). ci and cf are the initial and final concentration of Pb(II) ion (mg/l). v is the volume of Pb(II) solution used (l) and m is the mass of the graft copolymer (adsorbent) used (g).

Desorption of Pb(II) From the Pb(II) Adsorbed Graft Copolymer

Desorption of Pb(II) was carried out by heating with glacial acetic acid [15]. In a 50 ml of conical flask fitted with a condenser 0.3 g of Pb(II) loaded graft copolymer was taken. 30 ml of glacial acetic acid was added to the flask and the mixture was refluxed for 45 min. After refluxation the mixture was cooled and centrifuged. Supernatant was isolated by precipitation using excess quantity of acetone. About 80% of the graft copolymer was regenerated that can be reused and it was found that about 20% adsorption ability was reduced after third cycle.

Adsorption Dynamics

Effect of pH

Pb(II) adsorption by all the graft copolymers were studied in the pH range 1–7 keeping all the parameters affecting the adsorption constant. The result is shown in Fig. 4a.

Effect of the Amount of Graft Copolymer

The amount of adsorbents was varied for studying Pb(II) adsorption from 8 to 52 mg under constant parameters affecting adsorption. The result is shown in Fig. 4b.

Effect of Temperature

The Pb(II) adsorption by all the graft copolymers was studied within the temperature range 25–65 °C keeping other parameters affecting the adsorption constant. The result is shown in Fig. 4c.

Effect of Time

The adsorption of Pb(II) ion by all the graft copolymers were studied at different time intervals (30–150 min) under constant temperature, polymer dose and pH. The result is shown in Fig. 4d.

Competitive Adsorption Studies of Pb(II) and Other Metal Ions by the S-III Graft Copolymer

Relative competitive metal ion absorption studies were carried out in the mixtures Pb(II)/Hg(II), Pb(II)/Cd(II), Pb(II)/Cu(II) and Pb(II)/Zn(II) to evaluate the selectivity of the metal ion adsorption by the graft copolymer S-III. The adsorption studies were carried out by taking 10 ml of 0.1 (M) of each metal ion solution and 10 ml of polymer solution in 50 cc beaker. The solution mixtures were agitated for 15 min in a magnetic stirrer and then were allowed to stand for 2 h to reach equilibrium. After that the reaction mixtures were centrifuged and supernatants of the reaction mixtures were collected to measure the equilibrium metal ion concentrations. From the equilibrium metal ion concentration the static distribution coefficient (KD), selectivity coefficient (α) of the graft copolymer was determined by using the following equations [14].

Static distribution coefficient is,

Selectivity coefficient,

where qe represents the metal ion removal capacity in equilibrium, ce represents the equilibrium concentration of Pb(II) ion. KD1 is the distribution coefficient for Pb(II) ion, KD2 is the distribution coefficient for other competitor metal ions [Cd(II), Cu(II), Hg(II), Zn(II)] and α is the selectivity coefficient of the synthesized graft copolymer. The results are given in Table 2.

Flocculation Study

Flocculation experiments were carried out in a standard Jar apparatus supplied by Scientific Engineering Corporation, New Delhi, India [16]. The turbidity of the solution after flocculation was measured by Digital Nephelo Turbidity Meter (E1 products, Haryana, India; Model 331), The turbidity was expressed in NTU unit. 0.25 wt% iron ore slime, 1.0 wt% SiO2 and 1.0 wt% kaolin clay were used for the flocculation experiments. The detail characterization of iron ore slime, silicon dioxide and kaolin clay was given in our previous communication [12]. A polymer stock solution was prepared by dissolving 0.5 g each graft copolymer in 250 ml distilled water. The solution was prepared by heating the polymer-water mixture at 80 °C for 24 h. In each case the polymer dose was varied from 2 to 16 ppm.

Results and Discussion

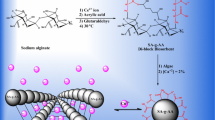

Synthesis

Grafting reactions onto sodium alginate backbone were carried out in water medium by using potassium peroxydisulfate (K2S2O8) as the radical initiator where initially the radical generated by the thermal decomposition by S2O8 = captures electron from –OH groups of sodium alginate forming macro-radical SAG-O·. This macro-radical now react with the monomers forming graft copolymers. The grafting reactions are shown in the following schemes.

Proof of Grafting

FTIR Spectroscopy

Figure 1 shows the FTIR spectra of all the five graft copolymers along with sodium alginate. In all the graft copolymers there is a peak appears at 2900 cm−1 region (2933 cm−1 is for S-I, S-II, and S-III, 2925 cm−1 in SAG-g-PDMA, 2917 cm−1 is SAG-g-PAM) which is absent in SAG which is due to the sp3 C–H stretching vibration for  unit present in the graft copolymers. The peaks at 1662 cm−1 in S-III, 1670 cm−1 in S-II, 1671 cm−1 in S-I are for the υ>C=O stretching frequencies of the amide

unit present in the graft copolymers. The peaks at 1662 cm−1 in S-III, 1670 cm−1 in S-II, 1671 cm−1 in S-I are for the υ>C=O stretching frequencies of the amide  carbonyl groups. In SAG the peak at 1634 cm−1 is for >C=O group of –COO− functionalities which is present in all the graft copolymer with a slight different values. In SAG-g-PAM and SAG-g-PDMA the amide. The >C=O stretching vibration band is superimposed with that of carboxylate (–COO−) groups.

carbonyl groups. In SAG the peak at 1634 cm−1 is for >C=O group of –COO− functionalities which is present in all the graft copolymer with a slight different values. In SAG-g-PAM and SAG-g-PDMA the amide. The >C=O stretching vibration band is superimposed with that of carboxylate (–COO−) groups.

NMR Spectroscopy

The 1H and 13C NMR spectra of S-I, S-II, and S-III are shown in Fig. 2. From Fig. 2 it is evident that the peaks at δ2.0–2.2ppm in all the three cases are due to the methyl protons connected to N. The peaks at δ2.6–3.0ppm are due to the methine protons of the repeating units and the peaks at δ1.0–1.5ppm are due to the protons of –CH2– unit of the  repeating units of the grafted chains. In all the three cases the peaks due to the alkene protons which are at δ5.8ppm are absent rather the peaks for the

repeating units of the grafted chains. In all the three cases the peaks due to the alkene protons which are at δ5.8ppm are absent rather the peaks for the  (saturated carbon) unit appear which suggest an evidence of grafting. In 1H NMR spectrum of SAG-g-PDMA (Fig. 2) the peaks at δ2.5–2.8ppm are the protons of methyl groups connected to the ‘N’ atom (–NMe2) of PDMA chains. In 1H NMR spectrum of SAG-g-PDMA and SAG-g-PAM the peaks are at δ1.0–1.6ppm are due to the protons of the –CH2– groups of the repeating unit. The peaks at δ33.3–3.8ppm are attributed by the methine

(saturated carbon) unit appear which suggest an evidence of grafting. In 1H NMR spectrum of SAG-g-PDMA (Fig. 2) the peaks at δ2.5–2.8ppm are the protons of methyl groups connected to the ‘N’ atom (–NMe2) of PDMA chains. In 1H NMR spectrum of SAG-g-PDMA and SAG-g-PAM the peaks are at δ1.0–1.6ppm are due to the protons of the –CH2– groups of the repeating unit. The peaks at δ33.3–3.8ppm are attributed by the methine  protons of the sodium alginate backbone and also for the

protons of the sodium alginate backbone and also for the  repeating unit.

repeating unit.

From the 13C NMR spectra of all the three graft copolymers (Fig. 2) it is obvious that the peak at highest region (δ190–210ppm) is due to the carbon atom of the carboxylate (–COO−) functionalities of the SAG. The peak at δ176ppm for S-II, δ182ppm for S-III and at δ176ppm for S-I is for the carbonyl carbon of the amide functionalities  present in the grafted chains. The peaks in the middle region (δ70ppm–δ130ppm) are the carbon atoms present in the sodium alginate backbone. The peaks at lower regions (δ30ppm–δ45ppm) are for the carbon atoms present in the

present in the grafted chains. The peaks in the middle region (δ70ppm–δ130ppm) are the carbon atoms present in the sodium alginate backbone. The peaks at lower regions (δ30ppm–δ45ppm) are for the carbon atoms present in the  repeating unit present in the grafted chains and the CH3– groups connected to the nitrogen atoms of amide functionalities. 13C NMR spectra of the graft copolymers show the grafting phenomenon.

repeating unit present in the grafted chains and the CH3– groups connected to the nitrogen atoms of amide functionalities. 13C NMR spectra of the graft copolymers show the grafting phenomenon.

XRD Studies

Figure 3 shows the XRD plots of all the five graft copolymers along with the SAG. It is evident from the figure that the peaks which are originally present in SAG at 2θ = 25° and 2θ = 15° are absent in all the five graft copolymers. More over in the graft copolymers new peaks are observed at 2θ = 17.5° in SAG-g-PAM, 23.6° in SAG-g-PDMA, 22.4° in S-I, 22.5° in S-II, 16.4° in S-III. This is explained by the morphological change of the graft copolymers after grafting onto the SAG backbone, indicating graft copolymerization process.

Adsorption Dynamics

Effect of pH

The adsorption capacity of a polymer is greatly dependent on the pH of the medium. The effect of pH of the Pb(II) ion removal capacity by all the graft copolymers is shown in Fig. 4a. It is evident from the figure that the Pb(II) ion adsorption increases with increasing pH up to 4.5 in all the five graft copolymers after that it remains constant. At low pH the amide functional groups  get protonated and act as positively charged species. Shifting towards higher pH values, deprotonation of amide functional groups occurs and behave like a negatively charged species. Now, they can chelate Pb(II) ions with them, which results in more adsorption capacity of the graft copolymers. After pH 4.5 the equilibrium is reached and the adsorption remains almost constant. The effect of solution pH was studied within the range 3.0–7.5 because after that pH Pb(II) ions precipitated as lead hydroxide.

get protonated and act as positively charged species. Shifting towards higher pH values, deprotonation of amide functional groups occurs and behave like a negatively charged species. Now, they can chelate Pb(II) ions with them, which results in more adsorption capacity of the graft copolymers. After pH 4.5 the equilibrium is reached and the adsorption remains almost constant. The effect of solution pH was studied within the range 3.0–7.5 because after that pH Pb(II) ions precipitated as lead hydroxide.

Effect of Time

Figure 4b depicts the effect of adsorption time on Pb(II) removal efficiency of all the five graft copolymers. The figure shows that the initial rate of Pb(II) ion uptake increases with increasing time and reached a maximum at time 120 min after which it levelled off. This is due to the initial grater number of available adsorbing sites on the surface of the graft copolymer which reduced with increasing time of adsorption. Beyond 120 min no further adsorption occurs because of the non availability of the adsorption sites on the adsorbents’ surface.

Effect of Temperature

The effect of temperature on the adsorption capacity of Pb(II) ion by all the graft copolymers was investigated within the temperature range 20–65 °C (Fig. 4c). The maximum adsorption was found at 35 °C after which it remains constant. The enhancement of the adsorption capacity of the adsorbents when temperature is increased to some extent could be due to increased mobility and also increase in surface activity of the adsorbents and diffusion of the ionic species which is continued up to the equilibrium. So, increase of Pb(II) adsorption occurs with increase in temperature up to the equilibrium value.

Effect of Polymer Dose

The effect of polymer concentration on the Pb(II) ion adsorption by all the graft copolymers is shown in Fig. 4d, which shows that the amount of Pb(II) ion adsorption increases with increasing the amount of polymer initially. After reaching maximum adsorption at 0.04 g of polymer amount the adsorption becomes constant. This is due to increase in adsorption sites with increasing polymer dose before the maximum adsorption, beyond which the adsorption remains more or less same because of the no availability of Pb(II) ions.

Comparison Among the Graft Copolymers in Pb(II) Adsorption

The Pb(II) ion removal capacity and Pb(II) ion removal (%) of all the five graft copolymers namely S-I, S-II, S-III, SAG-g-PAM and SAG-g-PDMA is shown in Fig. 5. From Fig. 5 it is obvious that the Pb(II) removal capacity and removal (%) by the graft copolymers follows the order S-III > SAG-g-PAM > S-II > SAG-g-PDMA > S-I. The graft copolymers containing PDMA chains are inferior to the other. Again it is also obvious from the figure that SAG-g-PAM showed better Pb(II) absorbing performances than SAG-g-PDMA. In the polymer containing amide  functionalities it is the oxygen atom which is responsible for the coordination of the metal ions [17]. Amides are existed in charge delocalised structure

functionalities it is the oxygen atom which is responsible for the coordination of the metal ions [17]. Amides are existed in charge delocalised structure  of which (II) has the significant contribution [18]. Since the oxygen atom becomes electron rich metal ions coordinate with oxygen atom by the electrostatic attraction there by they get adsorbed forming

of which (II) has the significant contribution [18]. Since the oxygen atom becomes electron rich metal ions coordinate with oxygen atom by the electrostatic attraction there by they get adsorbed forming  (M = metal ions). Now going from 1° → 2° → 3° amide i.e. from acrylamide (CH2=CH–CONH2) → N-methylacrylamide (CH2=CH–CONHMe) → N,N-dimethyacrylamide (CH2=CH–CONHMe2), the number of methyl group increases as a result of which the volume of –NH2 → –NHMe → –NMe2 also increases. As the volume near metal coordination sites increases approaching of the Pb(II) ion to coordinate with oxygen atom becomes sterically inhibited, this explains why graft copolymers containing PDMA chains become inferior to Pb(II) adsorption than the others. In S-I the steric crowding surrounding the oxygen atom is greatest because of the presence of PNMA and PDMA chains simultaneously, hence its metal coordination power is lowest. The Pb(II) ion adsorption capacity is greatest for S-III where both PNMA and PAM chains are present. In NMA presence of one methyl group at the ‘N’ centre does not create strong steric crowding rather it increases the electron density at the oxygen centre by the positive inductive effect of the –CH3 group. Due to the greater electron density of ‘O’ centre of PNMA chains its Pb(II) adsorption power is greater than the PAM chains where only –CONH2 functional groups are present. SAG-g-PNMA is water insoluble hence its Pb(II) adsorption performance can not be evaluated. Thus graft copolymer based on the mixture of NMA and AM showed better Pb(II) ion removal capacity than the PAM grafted copolymer, because of the presence more electron denser ‘O’ atom in PNMA moieties. Where as PDMA based graft copolymers are inferior for Pb(II) adsorption because of the steric crowding by the two methyl groups at the ‘N’ centre.

(M = metal ions). Now going from 1° → 2° → 3° amide i.e. from acrylamide (CH2=CH–CONH2) → N-methylacrylamide (CH2=CH–CONHMe) → N,N-dimethyacrylamide (CH2=CH–CONHMe2), the number of methyl group increases as a result of which the volume of –NH2 → –NHMe → –NMe2 also increases. As the volume near metal coordination sites increases approaching of the Pb(II) ion to coordinate with oxygen atom becomes sterically inhibited, this explains why graft copolymers containing PDMA chains become inferior to Pb(II) adsorption than the others. In S-I the steric crowding surrounding the oxygen atom is greatest because of the presence of PNMA and PDMA chains simultaneously, hence its metal coordination power is lowest. The Pb(II) ion adsorption capacity is greatest for S-III where both PNMA and PAM chains are present. In NMA presence of one methyl group at the ‘N’ centre does not create strong steric crowding rather it increases the electron density at the oxygen centre by the positive inductive effect of the –CH3 group. Due to the greater electron density of ‘O’ centre of PNMA chains its Pb(II) adsorption power is greater than the PAM chains where only –CONH2 functional groups are present. SAG-g-PNMA is water insoluble hence its Pb(II) adsorption performance can not be evaluated. Thus graft copolymer based on the mixture of NMA and AM showed better Pb(II) ion removal capacity than the PAM grafted copolymer, because of the presence more electron denser ‘O’ atom in PNMA moieties. Where as PDMA based graft copolymers are inferior for Pb(II) adsorption because of the steric crowding by the two methyl groups at the ‘N’ centre.

Among all the five graft copolymer since S-III showed best Pb(II) ion removal capacity (best absorption performance) adsorption kinetics and adsorption isotherm were studied only with S-III graft copolymer.

Adsorption Kinetics

The adsorption of Pb(II) ions by S-III is well explained [19] by considering the pseudo-second order kinetic rate equation which is,

where qe and qt are the amount (mg/g) of Pb(II) ion adsorbed by S-III at equilibrium and at time ‘t’ respectively. The k2 is the pseudo-second-order rate constant (g/mg/min). Figure 6 shows the pseudo-second-order plot and the parameters k2, qe and R2 (correlation coefficient) values are listed in Table 3.

Adsorption Isotherm

The distribution of Pb(II) ions between the liquid and the solid phase in equilibrium are explained by the adsorption isotherm. The adsorption isotherm of the adsorption of Pb(II) ions by S-III is better explained by the Langmuir isotherm model. The linear mathematical expression of the Langmuir model [20] is

or,

where x is the amount of metal ion adsorbed (mg), m is the amount of Pb(II) adsorbent (g) used. kl (l/g) and al (l/mg) are the Langmuir constants, which are obtained from the plot of \(\frac{{{C_e}}}{{{q_e}}}\) versus ce. From the intercept kl and from the slope \(\frac{{{a_l}}}{{{k_l}}}\) values are obtained. Numerically kl/al is equal to q max i.e. maximum adsorption capacity of the adsorbent.

The feasibility of the adsorption process is calculated using separation factor RL [21] which is defined by following equation:

The category of the isotherm is indicated by the value of RL where RL > 1 means unfavourable, RL = 1 means linear, RL = 0 means irreversible and for favourability 0 < RL < 1.

From Fig. 7 it is evident that the Langmuir isotherm model shows a better fit with the experimental data. The qmax and RL values are given in Table 3. The adsorption capacities for the removal of Pb(II) ion of other reported adsorbents are given in Table 4. It is clear from Table 4 that the prepared adsorbent (S-III) in the present investigation has higher adsorption capacity than some of the other adsorbents reported [14, 15, 22–24].

Selectivity of S-III Graft Copolymer

Figure 8 shows the competitive metal ion removal capacity of the synthesized S-III graft copolymer with the other metal ions. From the figure it is clear that the S-III graft copolymer has higher Pb(II) ion removal capacity over the other metal ions. The distribution coefficient and selectivity coefficient values are given in Table 2. The static distribution coefficient of S-III is higher for Pb(II) ion adsorption over other competitor metal ions. The selectivity coefficients of S-III for Pb(II) ion with Cd(II), Cu(II), Hg(II), Zn(II) metal ions are 2.2, 6.5, 1.4 and 5.4 respectively. These results showed that the synthesized graft copolymer (S-III) has higher recognization power than the other competitor metal ions.

Flocculation Studies

The flocculation performances of all the five graft copolymers were evaluated in 0.25 wt% iron ore slime, 1.0 wt% silica and 1.0 wt% kaolin clay suspensions. The results are shown in Fig. 9. It is obvious from the figure that the flocculation performances follows the order SAG-g-poly(NMA-co-DMA) > SAG-g-poly(AM-co-DMA) > SAG-poly(AM-co-NMA) > SAG-g-PDMA > SAG-g-PAM. The explanation comes in the following way; polymer bridging is the major flocculation mechanism for neutral (unchanged) flocculants. For the effective bridging to occur the polymer chains should have greater flexibility [25] so that they have easy approachability to the contaminant particles in the colloidal particles. It is postulated that [26, 27] because of greater approachability of the dangling grafted chains present in the graft copolymers, graft copolymers showed better flocculation performance over linear polymers. In PAM chains extensive intramolecular hydrogen bonding occurs between the >C=O group of one –CONH2 unit with the –NH2 group of other. As a result of hydrogen bonding the poly(acrylamide) chains become rigid and helical [28] there by lose their flexibility and hence bridging becomes less efficient. In PDMA chains no such hydrogen bonding is possible, which makes the PDMA chains more flexible over PAM chains. Thus the graft copolymer containing PDMA chains showed better flocculation performances in all the three solid suspensions used. In SAG-g-poly(NMA-co-DMA), there remain PNMA and PDMA chains containing –NHMe and –NMe2 groups respectively. The volume of amide grouping having –NMe2 groups are larger than –NH2 groups (present in PAM chains), so strong steric repulsion between adjacently placed –CONMe2 and –CONHMe groupings further increases the flexibility of the dangling grafted chains. As a result of increasing flexibility of the grafted poly(NMA-co-DMA) chains intense bridging among the colloidal particles occurs resulting greatest flocculation performances of SAG-g-poly(NMA-co-DMA). Thus the flocculation performances of the graft copolymer having grafted synthetic polymer chains containing co-monomeric unit increases considerably than that containing grafted chains bearing single monomeric unit.

Conclusion

SAG-g-PAM, SAG-g-PDMA, SAG-g-poly(AM-co-DMA), SAG-g-poly(NMA-co-DMA) and SAG-g-poly(AM-co-NMA) were successfully prepared by solution polymerization technique in water medium using potassium peroxydisulfate as the initiator. All the graft copolymers were used for the Pb(II) removal and flocculation studies and a comparative study were also made. For Pb(II) removal properties the maximum Pb(II) adsorption occurs at pH 4.5, time 120 min, temperature 35 °C and polymer dose 0.048 g (12 ml) in all the five graft copolymers. The Pb(II) ion removal abilities by the graft copolymers follow the order S-III > SAG-g-PAM > S-II > SAG-g-PDMA > S-I. For the flocculation performances of the graft copolymers follows the order S-II > S-III > S-I > SAG-g-PDMA > SAG-g-PAM. For Pb(II) adsorption, steric crowding near the coordination site onto the graft copolymer is important. Higher the crowding lower will be the adsorption characteristics but for flocculation the presence of co-monomeric unit in the grafted chain is important. The flocculation performances of the graft copolymer having grafted synthetic polymeric chains containing co-monomeric unit increases considerably than that having grafted chain bearing single monomeric unit.

References

Kumar PS (2013) Environ Prog Sustain Energy 33:55–64

Wang I, Zhang J, Ahao R, Li Y, Zhang C (2010) Bioresour Technol 101:5808–5814

Deblonde T, Cossu-Leguille C, Hantemann P (2011) Int J Hyg Environ Health 214:442–448

Knoig TN, Shulami S, Rytwo G (2012) Appl Clay Sci 67–68:119–124

Balasubramanian R, Perumal SV, Vijayaraghavan K (2009) Ind Eng Chem Res 48:2093–2099

King P, Rakesh N, Beenalahari S, Kumar Y, Prasad VSRK (2007) J Hazard Mater 142:340–347

Keles E, Ozer AK, Yoruk S (2010) Desalination 253:124–128

Santhy K, Selvapathy P (2004) Sep Sci Technol 39:3331–3351

Rivas BL, Pereira ED, Moreno- Villoslada I (2003) Prog Polym Sci 28:173–208

Rivas RL, Villoslade-moreno I (1998) Macromol Chem Phys 199:1153–1160

Kolya H, Tripathy T (2013) Int J Biomacrmol 62:557–564

Sasmal D, Singh RP, Tripathy T (2015) Colloid Surface A 482:575–584

Kolya H, Tripathy T (2015) Polym Int 64:1336–1351

Luo X, Liu L, Deng F, Luo S (2013) J Mater Chem A 1:8280–8286

Kanwal F, Rehman R, Anwar J, Saeed M (2013) Asian J Chem 25:2399–2404

Bratby J (1980) Coagulation and Flocculation, Chap. 8. Uplands Press, Clayden

Girma KB, Lorenz V, Blaurock S, Edelman FT (2005) Coord Chem Rev 249:1283–1293

Clayden J, Greeves N, Waren S, Wothers P (2001) Organic chemistry. Oxford University Press, Oxford, p 293

Crini G, Peinday NH, Gimbert F, Robert C (2007) Sep Purif Technol 53:97–110

Langmuir I (1918) J Am Chem Soc 40(9):1361–1403

Mackay G (1982) J Chem Technol Biotechnol 32(7–12):759–772

Gueu S, Yao B, Adouby K, Ado G (2007) Int J Environ Sci Technol 4:11–17

M. A. K. Hanaflash, Ibrahim SC, M. Z. A. Yahya (2006) J Appl Sci Res 2:1169–1174

Gupta VK, Ali I (2004) J Collid Interface Sci 271:321–328

Dicninson E, Erikson I (1991) Adv Colloid Interface Sci, 34:1–2

R. P. Singh, Advance turbulent drag reducing and flocculating materials based on polysaccharides (1995), in: P. N. Prasad, J. E. Mark, T. J. Fai (Eds). Polymers and other advance materials, emerging technologies buisiness opportunities. Plenum Press, New York, pp 227–249

Brostow W, Pal S, Singh RP (2007) Mater Lett 61:4381–4384

Kulicke WM, Knievrske R, Klein J (1982) Prog Polym Sci 8:373–468

Acknowledgements

Financial support from Department of Science and Technology (DST), Govt. of West Bengal [868 (sanc)/ST/P/S & T/15G-9/2015 dated 15.01.2016] for carrying out the research work in earnestly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tripathy, T., Kolya, H. & Jana, S. Selective Lead(II) Adsorption and Flocculation Characteristics of the Grafted Sodium Alginate: A Comparative Study. J Polym Environ 26, 926–937 (2018). https://doi.org/10.1007/s10924-017-1004-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-1004-7