Abstract

Wound infection is the primary challenge in the wound care management. To facilitate patients, the health care sector is trying to use the modern technology in the field of wound management. Various cellular processes and biological environments are intertwined in the process of wound repair. The compulsion for the modern dressing is not only to cover the wound but also to facilitate the healing rate of wound. In this research, the hydrogel membranes were prepared by crosslinking poly vinyl alcohol (PVA) with starch by using glutaraldehyde. Turmeric was added as an anti-bacterial agent. 0.5 g of turmeric showed the highest anti-bacterial activity among different turmeric contents used. For physical and mechanical characterization, the hydrogel membrane without turmeric (neat hydrogel) and 0.5 g were selected. FTIR of both hydrogel membranes confirmed the presence of free hydroxyl groups. Moreover, hydrogel membrane containing turmeric resulted stronger hydrogen bond interaction. Mechanical analysis of hydrogel membrane revealed sufficient strength to be used as wound dressing. The SEM images evolved that both hydrogel membranes were dense in nature. The swelling behavior values were greater than 100% for both hydrogel membranes. The water vapor transmission rate for 0.5 g turmeric hydrogel membrane was 52.85 g/m2h.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Over the last 50 years, the membrane technology has gained excessive significance and finds its applications desalination, food processing and in medical field. In medical field the major area of the use of membranes is hemodialysis [1]. Durability is the major issue in most of the applications of polymeric membranes [2]. However, in case of wound dressing, shelf life of a membrane is not the problem, as membrane is used once for a short period.

Wound management covers all the aspects of patient care including primary injury, fluid loss, wound closure and tissue regeneration etc. [3]. The authorities of health care are interested to use modern technologies in the field of wound dressing. There are many wound care products available in the market including shielding layers, metal ion impregnated dressings and artificial skin substitutes [3]. These dressing techniques are costly and time consuming.

In 1960, the Wichterle and Lim were the first to make the hydrogels having medical applications i.e. absorbable suture, contact lenses, osteoporosis, neoplasm and asthma treatment [4]. In 1980s, the Yannas group modernized the hydrogels with natural polymers to be used effectively as wound dressings [5]. In 1992, the Cartmell and Sturtevant synthesized a hydrogel wound dressing which was transparent, thin and flexible. Due to flexibility it was easy to remove and transparency helped to monitor the wound healing [6]. In 2010, the Ma-Ro Hwang synthesized the PVA/dextran hydrogels loaded with gentamicin by freeze thawing cycles. The loading of gentamicin improved the wound healing rate [7].

Millions of people go through accidents, chronic diseases, burns and other serious injuries. These people face the problems in wound healing and have a chance of wound infection. Especially in case of over age people, adults and those suffering from diseases which slows the rate of derma regeneration and wound requires the favorable environment for healing [8]. The patient receiving the wound treatment would desire the way that minimizes trauma and mortality [9].

Hydrogels are the three dimensional hydrophilic structures. The presence of hydrophilic groups allowed it to absorb water from atmosphere. This property of polymeric hydrogel made it strong candidate for biomedical applications including wound dressings [6]. They are capable of absorbing water and other exudates which comes out of the wound and cannot be released under ordinary pressure [10]. They maintain the moist environment that helps in wound healing. Due to water absorption hydrogels gave cushioning and cooling effects [11]. The reason behind the easy removal is the hydrophilic groups of the hydrogel that formed the secondary bonds with the hydrophilic groups present on the surface of wound. The malodor is also reduced because the exudates causing it are absorbed and retained as gel [12].

Hydrogels of natural polymers especially polysaccharides are used recently in medical application because of their advantages like biocompatibility, bio degradability, cost effectiveness and abundance [13]. However polysaccharide hydrogels have problem of instability (mechanical weakness and physicochemical properties) [5]. To overcome this issue, polysaccharides were blended with other polymers, e.g. PVA/sodium alginate [14], PVA/dextran [7] and PVA/chitosan [15] etc.

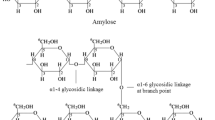

Starch is a natural polysaccharide. It is partially soluble in water, biodegradable and can be modified physically or chemically [16]. Biopolymers are more successful wound healing materials as compared to synthetic polymers [17]. However, starch is not used alone because it does not form the stable hydrogel. Starch has been blended with other polymers to overcome this problem [18]. PVA is one of the most important and applied polymer for hydrogel membrane applications. It could be attributed to its solubility in water, bio compatible, non-toxic, biodegradable, non-carcinogenic and has easy film forming characteristics [19]. The PVA has a simple structure and could easily be chemically modified. The crosslinking agent like glutaraldehyde, is used to chemically crosslink PVA with other polymers like starch, for biomedical applications [20]. To use PVA alone has disadvantages like stiff film formation, in elastic film and limited hydrophilicity. To overcome these problems, PVA is blended with polysaccharides [21]. Plasticizers were added to increase the strength and flexibility of hydrogel membrane like xylitol, sorbitol, and glycerin. They decrease viscosity and density of polymer and at the same time increases resistance to fracture and chain flexibility [22].

The hydrogel membranes used for wound dressings should have anti-bacterial activity to protect wound from bacterial infection. As compared to commercial antibiotics, the natural anti-bacterial products have less side effects and more effective. Different spices used in Asian countries to give color and flavors in food have anti-bacterial activity. E.g. garlic, turmeric and cinnamon [23]. Turmeric is light yellow in color and used in eastern countries in foods. The active component of turmeric responsible for anti-bacterial activity is curcumin. The average content of curcumin in turmeric is 3.14 wt% [24]. The hydrogels used for wound dressing must have some properties i.e. (1) ability to control moist environment (2) absorb the exudates and toxic fluids from the wound (3) put a stop to wound dryness (4) biodegradable, non-toxic and elastic (5) have anti-bacterial activity to prevent wound from infection [25] (6) cost effective.

Keeping this background, the work was designed to develop a biodegradable wound dressing, which helps in wound healing, and prevent from bacterial infection as well. Turmeric was used first time as an antibacterial agent in PVA/starch hydrogels as wound dressing. Moreover, the results of the PVA/starch hydrogel containing turmeric were discussed in detail that has never been reported before. Anti-bacterial effect was analyzed by disc diffusion method. Hydrogel membranes morphology and molecular interaction between polymers were investigated by scanning electron microscope (SEM) and fourier transform infrared spectroscopy (FT-IR), respectively. The physical and mechanical characteristics of hydrogel were also studied to evaluate their practical usefulness as dressings.

Experimental

Materials

Poly vinyl alcohol (PVA), starch, ethanol, glutaraldehyde (GA), glycerin and hydrochloric acid (HCl) were purchased from Daejung Korea. Turmeric was purchased locally in the form of sticks, which was converted to powder form. Distilled water was used throughout the experiments.

Methods

Preparation of Hydrogel Membrane

Polymeric hydrogel membranes were prepared using the method applied by Pal et al. [12] with modifications. 5 g (10% w/v) of PVA was added in 50 ml of water and mixture was heated at 70 °C for 2 h with constant stirring. Again taking 50 ml of water, adding 3.5 g (7% w/v) of starch in it, and heating at 100 °C for 15 min with constant stirring. Different contents of turmeric ranging from 0 to 2.5 g were added in starch solution. Starch solution was allowed to cool and mixed with PVA solution with constant stirring. The chemical crosslinking agent solution was prepared by adding 0.5 ml of GA and 0.05 ml of HCl in 10 ml of ethanol. This solution was added to mixture with constant stirring. Then 2 ml of glycerin was added with constant stirring and the solution was sonicated for 2 h in order to homogenize [26]. The resulting solution mixture was casted in petri dishes (9 cm diameter) and left for overnight drying at room temperature. Next day, the hydrogel membranes were removed from petri dishes with the help of forceps and stored in airtight pouches.

Anti-bacterial Activity Measurement

Disc diffusion method was applied for the measurement of anti-bacterial activity of the hydrogel membrane samples [27]. Bacteria was grown for 24 h in a test tube containing broth, and was placed in shaking water bath at 37 °C. The broth was evenly spread over the agar plate and the hydrogel membrane of 6 mm diameter was placed over the agar plate. The agar plate was placed in an incubator for 18–24 h. After mentioned time, plate was removed from the incubator and diameter of the zone of inhibition was measured. The test was carried out against both gram-negative and gram-positive bacteria i.e. the E. coli (DH5-alpha) and Staphylococcus aureus (MRSA), respectively. All the agar plates, broth, spreader, forceps etc. used in this experiment were autoclaved.

Swelling Behavior Measurement

The swelling behavior was measured against water, 0.9% NaCl, 0.9% MgCl2 [28] and blood. To measure the swelling behavior, the hydrogel membranes were cut in to equal pieces of 1 × 1 cm2 and weighed. Afterwards these pieces were immersed in these solutions for 24 h. After 24 h, the pieces of hydrogel membranes were removed and their surface was cleaned with filter paper to remove any droplets and weighed again. Swelling behavior was measured by using formula [29]:

Ws is the weight of swelled membrane and Wd was the weight of dry membrane.

Tensile Testing

Hydrogel membranes were cut in to pieces of 2 × 2 cm dimension and analysis was performed at a strain rate of 10 N/mm2 [30].The thickness of the samples was measured before each test. Samples of equal thickness were analyzed. The universal testing machine (UTM) was used for mechanical testing. Five samples were used to characterize for each sample.

Water Vapor Transmission Rate (WVT)

To carry out WVT measurements, 29.5 mm mouth diameter bottle was taken and 10 ml of deionized water poured in it. The mouth of the bottle was covered with hydrogel membrane and was air tightened by using Teflon tape. The bottle was weighed and place in an oven for 24 h at 40 °C. After 24 h, the bottle was taken out of the oven and weighed again. The water vapor transmission rate was measured by using formula [25]:

A was the area of the round mouth of bottle; Wi and Wt were the initial and final weight of bottle, respectively.

Moisture Retention Capability

To measure the moisture retention capability, the hydrogel membranes of almost equal thickness were cut in to pieces and weighed. These hydrogel membranes were placed in an oven for 6 h at 40 °C. The moisture retention capability was measured by using formula [31]:

Wi is the initial weight before placing in an oven and Wt is the final weight.

Gel Fraction

To measure gel fraction, the hydrogel membranes were cut in to equal pieces of 1 × 1 cm and placed in a vacuum oven until they attained the constant weight. These samples were weighed and immersed in distilled water for 4 days. After 4 days, these hydrogel membranes were taken out of water and place again in vacuum oven to attain a constant weight. The gel fraction was find by using formula [32]:

Wi was the initial weight after placing in vacuum oven, and Wt was the final weight when the wet samples were dried in vacuum oven.

Scanning Electron Microscope (SEM)

The surface morphology of the hydrogel membranes was investigated by using SEM (JSM-64900). A thin palladium/platinum conductive layer was used to cover the samples before analysis. Sputter coater was used to create the layer. Sample surface was observed with a secondary electron detector using the accelerating voltage of 20 kV.

Fourier Transform Infrared Spectroscopy (FT-IR)

FT-IR (PerkinElmer, SpectrumTM100) was performed to evaluate the structural changes occurred in polymeric hydrogel membranes. The dried and impurity free samples were subjected to FT-IR. The spectra was recorded by FT-IR spectrometer equipped with an attenuated total reflection (ATR) unit in the range of 450–4000 cm−1. In case of hydrogel membranes the samples were put directly to FT-IR machine. However, in case of powdered samples, pellets were made together with the infrared grade KBr by pressing and then placed the pellet in the machine. All analysis was done at ambient temperature.

Results and Discussion

Anti-bacterial Activity of Hydrogel Membrane

Anti-bacterial activity is one of the most important properties of hydrogel membrane when it has to be used as a wound dressing. The anti-bacterial activity was investigated at different contents of turmeric i.e. 0, 0.2, 0.3, 0.4, 0.5, 1, 1.5, 2, 2.5-g. The anti-bacterial activity was carried out against both gram-negative and gram-positive bacteria i.e. the E. coli (DH5-alpha) and S. aureus (MRSA). Hydrogel membrane without turmeric had shown no anti-bacterial activity for both types of bacteria. Therefore all the anti-bacterial activity obtained was due to turmeric in both cases as shown in Fig. 1.

Figure 1 showed anti-bacterial activity of hydrogel membranes against both the bacteria’s. For DH5-alpha, the anti-bacterial activity started growing with increase in the content of turmeric and became constant after 0.5 g. The zone of inhibition at 0.5 g turmeric against gram-negative bacteria (DH5-alpha) was 9.9 mm. Further increase in content of turmeric did not significantly improve the anti-bacterial activity. This could be attributed to the anti-bacterial resistance development in bacteria. Therefore, the most effective content of turmeric was 0.5 g in case of DH5-alpha. Similarly, the anti-bacterial activity for gram-positive bacteria was also investigated. Here also the anti-bacterial activity was shown with increase in the content of turmeric and became constant after 0.5 g. No significant improvement in anti-bacterial activity was noticed due to further increase in turmeric. The zone of inhibition at 0.5 g turmeric against gram-positive bacteria (MRSA) was 11.3 mm. This confirmed that the gram-negative bacteria are more resistant to anti-biotic as compared to gram-positive bacteria [33]. The formation of zone of inhibition by hydrogel membrane using turmeric as antibody against both type of bacteria showed the effectiveness of hydrogel membrane. These values of the anti-bacterial activity of hydrogel membrane containing 0.5 g turmeric were in accordance with the values of the anti-bacterial activity of aqueous extract of turmeric given in literature [23]. This means that the turmeric in hydrogel is working properly and did not face any hindrance in leaching out of the hydrogel membrane.

Swelling Behavior of Hydrogel Membrane

The experiments were carried out with the neat hydrogel (without turmeric) and with hydrogel containing 0.5 g of turmeric. Figure 2 shows the % swelling of the hydrogel in different solutions i.e. water, blood, MgCl2 and NaCl that ranges between 105 and 170%. It was observed that for all four different solutions the swelling percentage was more than 100% [12]. That can be attributed to the hydrophilic nature of hydrogel membrane. The swelling percentage in water, MgCl2 and NaCl were comparable to each other. However, blood solution showed the maximum swelling percentage. This is due to clot formation, freeing the volume inside the hydrogel for more blood to come in.

The hydrogel membrane containing turmeric showed higher swelling behavior as compared to neat hydrogel. This increase in swelling behavior with the addition of turmeric could be due to the presence of additional hydroxyl group in turmeric. This is beneficial for wound healing. Moreover, the hydrogel membrane did not dissolve in to these solutions, showing the effectiveness of crosslinking agent.

The 0.9% MgCl2, 0.9% NaCl and water have pH 5.16, 5.84 and 7, respectively. The percentage swelling of the neat hydrogel membrane was in accordance with the values given in the literature against buffer solution of the same pH [12]. However, the values of hydrogel membrane with 0.5 g turmeric were higher, which helps the dressing to maintain the moist environment that could facilitate the healing of wound.

Tensile Strength of Hydrogel Membrane

The mechanical properties of hydrogel as wound dressing are important to determine their durability and strength to withstand external forces. To investigate mechanical properties, the tensile strength and percentage elongation of the dry hydrogel membrane was measured (Table 1). The hydrogel membrane formed was very thin, flexible and elastic. The hydrogel had to cover the wound, so it should be strong enough to withstand frictional stresses during activities and absorb them without breakage.

The value of tensile strength of neat hydrogel membrane was higher as compared to hydrogel membrane with 0.5 g turmeric. The lowering of mechanical strength could be attributed to the decrease in chain length and increase of chain mobility due to the presence of turmeric [34]. The fall in value was also due to decrease in polymer content. Moreover, as turmeric was not completely soluble in water [35], so it gives weak point for breakage. The tensile strength of human skin is 11.5 MPa [36]. The membrane with turmeric has higher strength than human skin and other hydrogels reported in literature [37], so it can be used effectively as wound dressing.

Water Vapor Transmission (WVT) Rate of Hydrogel Membrane

The hydrogel wound dressing should have ability to minimize the liquid fluid loss from the wound by maintaining the moist environment under the wound. Lower the value of WVT, good is the hydrogel for wound dressing. The loss of water from second and third degree wound burn skin wounds is 178.55 ± 4.5 and 143.2 ± 4.5 g/m2h, respectively [38]. Table 1 showed the values of WVT of the neat and 0.5 g hydrogel membrane. In this study, the vapor transport from both hydrogel dressings was less as compared to above-mentioned values, which was helpful to minimize the liquid loss from the wound and to maintain the moist environment. Hydrogel membrane with turmeric has even less WVT as compared to neat hydrogel. These values are also less as compared to literature, which is favorable for wound healing [25].

Moisture Retention Capability of Hydrogel Membrane

Greater is the loss of water, difficult for the wound to heal. The loss of water from the wound may cause the body temperature to come down that might cause the increase of metabolic rate. Table 1 revealed the moisture retention capability of neat and hydrogel membrane containing 0.5 g turmeric. Results showed higher retention capability for both hydrogel membrane i.e. neat and 0.5 g turmeric, which favors the wound healing. More over after 6 h no significant differences in moisture retention capability of hydrogel membranes was noticed i.e. 91.69–91.96%.

Gel Fraction of Hydrogel Membrane

Table 1 revealed the results of gel fraction for neat and 0.5 g turmeric hydrogel membrane. It was observed that the gel fraction results showed proper crosslinking. When the hydrogel was immersed for 4 days [32], the polymer content should dissolve in water, which was not cross-linked. The gel fraction value of neat hydrogel membrane was high as compared to the hydrogel membrane containing 0.5 g turmeric. Solubility of turmeric in water could be the reason for this. As discussed earlier, the turmeric particles were leached from the hydrogel membrane into the water and gives anti-bacterial activity.

SEM of Hydrogel Membrane

The hydrogel membranes prepared without turmeric were transparent and with turmeric were light yellow in color. The surface morphology of hydrogel membrane was investigated by SEM as shown in Fig. 3. It was observed that surface of hydrogel membrane was dense and even at very high magnification no pore was found. Dense surface will favorable for wound dressing; it did not allow the penetration of bacteria that can cause infection to the wound. Some of the starch particles, which remained insoluble, were visible in neat hydrogel membranes. Similarly, in hydrogel membranes with 0.5 g turmeric, the turmeric particles were also visible in the form of dots over the hydrogel membrane.

FT-IR of Hydrogel Membrane

FT-IR analysis was performed to identify the interactions between polymeric chains (see Fig. 4).

In the present research, the focus of FT-IR was on the presence of free hydroxyl groups, which were responsible for the water holding capacity of the hydrogel. The materials used in the preparation of hydrogel membrane showed the presence of free hydroxyl groups. The PVA, starch and turmeric showed peaks at 3420, 3390 and 3420 cm−1, respectively, representing the presence of free hydroxyl groups. Moreover, in case of hydrogel membrane without turmeric the peak at 3440 cm−1 showed the presence of free hydroxyl groups and peak at 2920 cm−1 indicated the Sp3 hybridized hydrocarbon chains. In case of hydrogel membrane containing 0.5 g turmeric, there was a strong peak observed at 3460 cm−1 showing the presence of hydroxyl group. Moreover, peak at 2155 cm−1 showed the Sp hybridized hydrocarbon chains. In both the hydrogel membranes the peaks between 1690 and 1740 cm−1 showed the C=O stretching vibrations of aldehyde group of glutaraldehyde. The glutaraldehyde is toxic to skin when used more than 0.5% aqueous solution [39].

Conclusion

Anti-bacterial wound dressing consisting of turmeric was successfully prepared by solution casting method. Higher the content of turmeric more yellow was the hydrogel membrane. However, the best content of turmeric was 0.5 g, which showed the highest anti-bacterial activity.

The physical properties of hydrogel membrane including swelling behavior, tensile testing, WVT, moisture retention capability and gel fraction were characterized. The swelling behavior of hydrogel membrane was increased and WVT of hydrogel membrane was decreased by the addition of turmeric, both properties were favorable to control the fluid loss from the body. The addition of turmeric resulted in the decrease of mechanical strength but had no effect on the moisture retention capability.

The hydrogel membrane showed anti-bacterial activity against both, gram-positive and gram-negative bacteria. The diameter of the zone of inhibition was less against gram-negative bacteria, which showed their higher resistance to anti-biotic. Therefore, the hydrogel membrane prepared containing turmeric has all the properties of the good wound dressing and it not only favors the wound healing but also prevents the wound from infection.

Abbreviations

- ATR:

-

Attenuated total reflection

- GA:

-

Glutaraldehyde

- HCl:

-

Hydrochloric acid

- FTIR:

-

Fourier transform infrared spectroscopy

- UTM:

-

Universal testing machine

- PVA:

-

Polyvinyl alcohol

- SEM:

-

Scanning electron microscopy

- WVT:

-

Water vapor transmission

References

Membrane technology in the chemical industry—membrane solutions. http://www.nylon66membrane.com/Membrane-Technology-In-The-Chemical-Industry.html. Accessed 22 Jul 2016

Michaels A (1990) Proceedings of the symposium on membrane technology membranes, membrane processes, and their applications: needs, unsolved problems, and challenges of the 1990’s. Desalination 77:5–34. doi:10.1016/0011-9164(90)85018-6

Martin C, Low WL, Amin MCIM, et al (2013) Current trends in the development of wound dressings, biomaterials and devices. Pharm Pat Anal 2:341–359. doi:10.4155/ppa.13.18

Kopeček J (2009) Hydrogels from soft contact lenses and implants to self-assembled nanomaterials. J Polym Sci Part A 47:5929–5946. doi:10.1002/pola.23607

Kamoun EA, Chen X, Mohy Eldin MS, Kenawy E-RS (2015) Crosslinked poly(vinyl alcohol) hydrogels for wound dressing applications: a review of remarkably blended polymers. Arab J Chem 8:1–14. doi:10.1016/j.arabjc.2014.07.005

Caló E, Khutoryanskiy VV (2015) Biomedical applications of hydrogels: a review of patents and commercial products. Eur Polym J 65:252–267. doi:10.1016/j.eurpolymj.2014.11.024

Hwang M-R, Kim JO, Lee JH et al (2010) Gentamicin-loaded wound dressing with polyvinyl alcohol/dextran hydrogel: gel characterization and in vivo healing evaluation. AAPS PharmSciTech 11:1092–1103. doi:10.1208/s12249-010-9474-0

Gould L, Abadir P, Brem H et al (2015) Chronic wound repair and healing in older adults: current status and future research. J Am Geriatr Soc 63:427–438. doi:10.1111/jgs.13332

Church D, Elsayed S, Reid O et al (2006) Burn wound infections. Clin Microbiol Rev 19:403–434. doi:10.1128/CMR.19.2.403-434.2006

Kunal P, Banthia AK, Majumdar DK (2006) Starch based hydrogel with potential biomedical application as artificial skin. Afr J Biomed Res 9:23–29

Edwards J (2010) Hydrogels and their potential uses in burn wound management. Br J Nurs 19:S12, S14–16. doi:10.12968/bjon.2010.19.Sup4.48419

Pal K, Banthia AK, Majumdar DK (2006) Preparation of transparent starch based hydrogel membrane with potential application as wound dressing. Trends Biomater Artif Organs 20:59–67

Mohamed NA, Fahmy MM (2012) Synthesis and antimicrobial activity of some novel cross-linked chitosan hydrogels. Int J Mol Sci 13:11194–11209. doi:10.3390/ijms130911194

Kamoun EA, Kenawy E-RS, Tamer TM et al (2015) Poly (vinyl alcohol)-alginate physically crosslinked hydrogel membranes for wound dressing applications: characterization and bio-evaluation. Arab J Chem 8:38–47. doi:10.1016/j.arabjc.2013.12.003

Yang JM, Su WY, Leu TL, Yang MC (2004) Evaluation of chitosan/PVA blended hydrogel membranes. J Membr Sci 236:39–51. doi:10.1016/j.memsci.2004.02.005

Pal K, Banthia AK, Majumdar DK (2008) Effect of heat treatment of starch on the properties of the starch hydrogels. Mater Lett 62:215–218. doi:10.1016/j.matlet.2007.04.113

Demir A, Cevher E (2011) Biopolymers as wound healing materials: challenges and new strategies. In: Pignatello R (ed) Biomaterials applications for nanomedicine. InTech, pp 383–414. doi:10.5772/25177

Niazi MBK, Zijlstra M, Broekhuis AA (2013) Spray drying thermoplastic starch formulations: need for processing aids and plasticizers? Eur Polym J 49:1861–1870. doi:10.1016/j.eurpolymj.2013.04.016

Kenawy E-R, Kamoun EA, Mohy Eldin MS, El-Meligy MA (2014) Physically crosslinked poly(vinyl alcohol)-hydroxyethyl starch blend hydrogel membranes: synthesis and characterization for biomedical applications. Arab J Chem 7:372–380. doi:10.1016/j.arabjc.2013.05.026

Hassan CM, Peppas NA (2000) Structure and applications of poly(vinyl alcohol) hydrogels produced by conventional crosslinking or by freezing/thawing methods. In: Biopolymers. PVA hydrogels, anionic polymerisation nanocomposites. Springer, Heidelberg, pp 37–65

Coviello T, Matricardi P, Marianecci C, Alhaique F (2007) Polysaccharide hydrogels for modified release formulations. J Controlled Release 119:5–24. doi:10.1016/j.jconrel.2007.01.004

Vieira MGA, da Silva MA, dos Santos LO, Beppu MM (2011) Natural-based plasticizers and biopolymer films: a review. Eur Polym J 47:254–263. doi:10.1016/j.eurpolymj.2010.12.011

Mukhtar S, Ghori I (2012) Antibacterial activity of aqueous and ethanolic extracts of garlic, cinnamon and turmeric against Escherichia coli ATCC 25922 and bacillus subtilis DSM 3256. http://www.ijabpt.com/Details.aspx?id=568

Tayyem RF, Heath DD, Al-Delaimy WK, Rock CL (2006) Curcumin content of turmeric and curry powders. Nutr Cancer 55:126–131. doi:10.1207/s15327914nc5502_2

Boonkaew B, Suwanpreuksa P, Cuttle L, et al (2014) Hydrogels containing silver nanoparticles for burn wounds show antimicrobial activity without cytotoxicity. J Appl Polym Sci 131:40215. doi:10.1002/app.40215

Cano A, Fortunati E, Cháfer M et al (2015) Effect of cellulose nanocrystals on the properties of pea starch–poly(vinyl alcohol) blend films. J Mater Sci 50:6979–6992. doi:10.1007/s10853-015-9249-9

Singh B, Sharma S, Dhiman A (2013) Design of antibiotic containing hydrogel wound dressings: biomedical properties and histological study of wound healing. Int J Pharm 457:82–91. doi:10.1016/j.ijpharm.2013.09.028

Bialik-Was k, Tyliszczak B, Wilk E, Pielichowski K (2013) Preparation of innovative hydrogel wound dressing based on poly (acrylic acid). CHEMIK 67(2):99–104

Pal K, Banthia AK, Majumdar DK (2007) Preparation and characterization of polyvinyl alcohol-gelatin hydrogel membranes for biomedical applications. AAPS PharmSciTech 8:E142–E146. doi:10.1208/pt080121

SOP—tensile testing of electrospun nanofiber membrane. http://electrospintech.com/SOP-ES2002.html#.V3WRGqJ5LFt. Accessed 30 Jun 2016

Roy N, Saha N, Kitano T, et al (2011) Effectiveness of polymer sheet layer to protect hydrogel dressings. In: Starov V, Procházka K (eds) Trends in colloid and interface science XXIV. Springer, Heidelberg, pp 127–130

Hago E-E, Li X (2013) Interpenetrating polymer network hydrogels based on gelatin and PVA by biocompatible approaches: synthesis and characterization. Adv Mater Sci Eng 2013:1–8. doi:10.1155/2013/328763

Silhavy TJ, Kahne D, Walker S (2010) The bacterial cell envelope. Cold Spring Harb Perspect Biol. doi:10.1101/cshperspect.a000414

Chemistry4life (2011) Chemistry4Life: factors affecting the polymer’s properties: Chemistry4Life

Parnell EA (1844) Applied chemistry: in manufactures, arts, and domestic economy. Taylor and Walton, London

Veronda DR, Westmann RA (1970) Mechanical characterization of skin-finite deformations. J Biomech 3:111–124

Fan L, Yang H, Yang J et al (2016) Preparation and characterization of chitosan/gelatin/PVA hydrogel for wound dressings. Carbohydr Polym 146:427–434. doi:10.1016/j.carbpol.2016.03.002

Nilsson G (1977) On the measurement of evaporative water loss: methods and clinical applications. Linköping Medical University, Linköping

Ballantyne B, Myers RC (2001) The acute toxicity and primary irritancy of glutaraldehyde solutions. Vet Hum Toxicol 43:193–202

Acknowledgements

This study was supported by National University of Sciences and Technology (NUST), Islamabad, Pakistan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest statement in the manuscript.

Rights and permissions

About this article

Cite this article

Hassan, A., Niazi, M.B.K., Hussain, A. et al. Development of Anti-bacterial PVA/Starch Based Hydrogel Membrane for Wound Dressing. J Polym Environ 26, 235–243 (2018). https://doi.org/10.1007/s10924-017-0944-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-0944-2