Abstract

A hydrophilic copolymer, ethylene–vinyl alcohol (EVOH), was incorporated into the poly(lactic acid) (PLA) matrix to improve the barrier property of PLA through twin-screw extrusion rather than the typical coextrusion process. A chain extender, poly[(ethylene)-co-(methyl acrylate)-co-(glycidyl methacrylate)] (PEMG), was used to reduce the probability of the thermal degradation of PLA during melt compounding. Biaxial stretching was used to enhance the microstructure and barrier property of PLA-PEMG/EVOH films. Experimentally, PEMG considerably reduced the probability of the thermal degradation of the PLA-PEMG sample. Biaxial stretching increased the tensile strength and decreased the value of elongation at break of the PLA-PEMG/EVOH80 (PLA/EVOH 100/80) film. Because of the efficient blending of PLA/EVOH in the twin-screw extruder, the dispersion of EVOH in the PLA matrix revealed homogeneous dispersion with a domain size of 1–5 μm. EVOH effectively improved the water vapour transmission rate (WVTR) of PLA through melt blending. Blending PLA-PEMG with EVOH substantially decreased the WVTR from 250 cc—20 μm/m2-day-atm for neat PLA to approximately 65 cc—20 μm/m2-day-atm for the PLA-PEMG/EVOH80 film, a decrease of approximately 74 % compared with neat PLA. Moreover, the WVTR decreased further from 65 cc—20 μm/m2-day-atm for the unstretched PLA-PEMG/EVOH80 film to 6.3 cc—20 μm/m2-day-atm for the film stretched at a stretch ratio of 3.5 × 3.5 and at 100 %/s, a decrease of approximately 90 % compared with neat PLA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Poly(lactic acid) (PLA) is an aliphatic and thermoplastic polyester that has attracted considerable attention because of its renewability, biodegradability, transparency, and mechanical properties [1–5]. However, the inherent brittleness of PLA at room temperature, low elongation at break (approximately 4.5 %), insufficient thermal stability, and costs restrict its range of applications. Several approaches, including copolymerization strategies [6–8], plasticization with a miscible component [2, 4, 9–12], blending with an immiscible homopolymer [13–16], and block copolymerization [17–19] have been investigated for producing PLA with a broad range of properties and improved processability. Similar to many other environment-friendly polymer materials, the costs of the PLA biopolymer and its processing are higher than those of other petroleum-based polymers. Except for the blending and copolymerization strategies, PLA composite techniques have been proposed to improve the desired properties and thermal hydrolysis and reduce the processing costs. Natural fibres, including rayon, jute bundle fibres [20], cellulose nanofibers (CNFs) [5], α-cellulose [21], and nanosilica particles [22] have also been proposed to toughen the PLA biopolymer.

Ethylene–vinyl alcohol (EVOH) copolymers possess outstanding barrier properties to gases and hydrocarbons and chemical resistance, and these copolymers exhibit highly hydrophilic characteristics and are biodegradable [23]. Nordqvist et al. used EVOH as a thermoplastic carrier to blend PLA with biodegradable amylopectin (AP) through melt blending. They demonstrated that the AP/EVOH blends were immiscible. However, by incorporating these blends into the PLA matrix under the addition of glycerol, satisfactory phase dispersion was finally observed [23]. Furthermore, the authors proposed that the barrier properties to oxygen at 0 % relative humidity and the biodegradability of the biopolyester PLA improved only for the PLA-EVOH blends [23]. Industrially, EVOH barrier films are fabricated through coextrusion or coextrusion lamination with other polymer films to improve the barrier properties of the resulting packaging materials, such as PP/EVOH/PE and polyethylene terephthalate (PET)/EVOH/LDPE films.

Chain extenders exert extremely positive effects on the thermal degradation and even on the molecular weight of PLA [24]. In our previous study, the chain extender Joncryl ADR 4368CS (BASF), a styrene-acrylic multifunctional-epoxide oligomeric agent, was used to improve the thermal hydrolysis of PLA, and we discovered that adding a chain extender during PLA melt compounding reduced the decrease of ultimate tensile strength (UTS) by approximately 43 % [25]. Thus, adding a chain extender considerably reduces the incidence of hydrolytic degradation.

As previously stated, EVOH can substantially improve the barrier properties of polymer films through lamination or coextrusion. For simplicity, in this study, we used twin-screw extrusion to obtain PLA/EVOH blends and improve the barrier properties of neat PLA. However, incorporating this highly hydrophilic polymer (EVOH) into PLA would potentially increase the probability of thermal hydrolysis. To decrease this probability, we used an alternative chain extender, poly[(ethylene)-co-(methyl acrylate)-co-(glycidyl methacrylate)] (PEMG), an ethylene–acrylic multifunctional-epoxide oligomeric agent, to reduce the occurrence of hydrolytic degradation of PLA during the melt compounding of PLA/EVOH. The melt index (MI) and apparent shear viscosity of the PLA/EVOH blends were determined to estimate the performance of the chain extender in these blends. The tensile and thermal properties (including dynamic mechanical and cold crystallisation properties) and barrier property to water before and after the biaxial stretch of the PLA/EVOH blends were also determined in order to investigate the effect of biaxial stretch on these properties of the PLA/EVOH blends.

Experimental

Materials

PLA (NatureWorks 4032D) was purchased from NatureWorks Company, and it contains 92 % l-lactide and 8 % meso-lactide. The molecular weight (M w ) and density of PLA are 1.8 × 105 – 2.0 × 105 g/mol and 1.25 g/cm3, respectively. Unmodified random copolymer of ethylene–vinyl alcohol (EVOH) under the trade name EVASIN EV-3201 V was purchased from Chang Chun Petrochemical Co., Ltd., Taiwan. Poly(ethylene-co-methyl acrylate-co-glycidyl methacrylate) (PEMG) pellets were purchased from Sigma-Aldrich (Product Number: 433640, epoxy content: 7–9 %). PEMG is an ethylene–acrylic multi-functional-epoxide oligomeric agent.

Preparation of the Biaxially Stretched PLA-PEMG/EVOH Films

The PLA-PEMG/EVOH films were extruded at temperatures ranging from 170 to 190 °C using a twin-screw (Werner and Pflederer, Model-ZSK 26 MEGA compounder). A screw speed of 500 rpm was applied to extrude the flat sheets 20 cm wide and 1 mm thick. From the sheets, 117 mm × 117 mm plates were cut. The plates were inserted into a biaxial film stretch machine (Bruckner, KARO IV) to prepare the biaxially stretched films. The biaxial stretch ratios were 1 × 1–3.5 × 3.5 at stretch rate of 100 %/s, and for a specific ratio 3.5 × 3.5, the stretch rates were changed from 10 to 100 %/s. Stretching process was performed at 105 °C. All the PLA-PEMG/EVOH blends before biaxial stretch investigated in the present study were tabulated in Tables 1 and 2.

Melt Index (MI) and Apparent Viscosity of PLA-PEMG/EVOH Blends

The MI was measured by a Dynisco apparatus (LMI D4000) with a load of 2.16 kg at 190 °C according to ASTM D1238. The rheological studies were determined using a capillary rheometer (Dynisco LCR7000) at a temperature of 190 °C with the shear rates of 205–1280 s−1. The capillary length (20 mm)-to-diameter (1 mm) ratio was 20 with a compound entrance angle of 120°. The pre-heat time for each sample was 5 min.

Room Tensile Properties of PLA-PEMG/EVOH Blends

All the samples in this testing are in the mechanical direction before and after biaxial stretches. Specimens used for tensile testing were cut from the stretched films according to ASTM D638 (5-mm width, and 50-mm length). Tensile tests were measured by a Universal Tensile Tester using a cross-head speed of 5 mm min−1 in compliance with the specifications of ASTM D638.

Dynamic Mechanical Properties Analysis PLA-PEMG/EVOH Blends

Glass transition temperature, storage modulus, and damping factor of the resulting PLA-PEMG/EVOH blends were measured using a dynamic mechanical analyzer (DMA, TA Q800). A tension mode testing was applied during the DMA scans, and the scanning range was from −100 to 150 °C at a heating rate of 3 °C/min and at a frequency of 1 Hz under nitrogen atmosphere.

X-ray Diffraction Measurement of PLA-PEMG/EVOH Blends

X-ray diffraction (XRD) measurement was conducted on a Rigaku D/Max RC X-ray diffractometer using CuK α radiation (λ = 1.5418 Å) at 40 kV and 100 mA with a scanning rate of 2° min−1.

Differential Scanning Calorimetry Analysis PLA-PEMG/EVOH Blends

A TA differential scanning calorimeter (TA Q2000) was applied to investigate the cold crystallization behavior of the neat PLA, PLA-PEMG, and PLA-PEMG/EVOH blends. The sample was heated up to 200 °C at a rate of 10 °C/min under nitrogen atmosphere. At 200 °C, this sample was held for 5 min to remove the previous thermal history, and then it was quenched to 30 °C. The thermal-history-erased sample was conducted the cold crystallization process from 30 to 200 °C at a heating rate of 5 °C/min, and it was held at 200 °C for 5 min to erased history of cold crystallization. Finally, the sample was cooled from 200 to 30 °C at a cooling rate of 5 °C/min to undergo cooling crystallization process.

Microstructure Observation

A Jeol 6700F field emission scanning electron microscope (SEM) was to estimate the dispersion of EVOH in the PLA matrix.

Water Vapor Transmission Measurement of PLA-PEMG/EVOH Films

The water vapor transmission rate (WVTR) was measured by Mocon OX-TRAN Model 2/61 universal apparatus. Water vapor transmission rate was conducted, according to ASTM F1249, at 40 and 100 % RH. The specimen test area and thickness were 5 cm2 and 0.6 mm, respectively, for all specimens.

Results and Discussion

Melt Index (MI) of PLA-PEMG/EVOH blends

EVOH copolymers are highly hydrophilic, whereas PLA is hydrophobic. Blending PLA with EVOH would bring more moisture into the PLA matrix and increase the possibility of hydrolytic degradation of PLA. Figure 1a presents the MI of the PLA-PEMG/EVOH blends. PEMG considerably improved the hydrolytic degradation of PLA because of the considerably lower MI for PLA/PEMG (6.23 g/10 min) than for neat PLA (10.25 g/10 min). Blending PLA with hydrophilic EVOH considerably increased the MI of the blends compared with that of neat PLA. The MI for neat EVOH was the same as that of the PLA-PEMG blend, and the more the amount of EVOH in the PLA matrix, the lower the MI for PLA-PEMG/EVOH blends. This phenomenon was slightly difficult to understand because the more the amount of EVOH in the PLA-PEMG/EVOH blends, the lower the MI for these blends. The presence of free volume in the PLA/EVOH blends might have contributed to the phenomenon. Figure 2 presents the schematic for the plausible structure of the PLA-PEMG/EVOH blends. PEMG, a multifunctional-epoxide oligomeric agent, can react with the hydroxyl or carboxyl end groups of PLA or EVOH [26] to form the anchorage structure in the blends and create more free volume for PLA/EVOH blends to flow. Therefore, a higher MI was observed when EVOH was incorporated into the PLA matrix. By contrast, the hydroxyl groups in the EVOH copolymers may have reacted with the PEMG oligomer and formed crosslinks between EVOH and PEMG to reduce the tendency of flow. Accordingly, a higher amount of EVOH in the PLA/EVOH blends lowered the MI for the blends.

In this study, we also determined the apparent viscosity of the PLA/EVOH blends, as shown in Fig. 1b. Incorporating PEMG increased the apparent viscosity of PLA, and blending PLA with hydrophilic EVOH reduced the viscosities of these blends. The apparent viscosity of the PLA-PEMG/EVOH blends decreased with increasing amount of EVOH in the PLA matrix. The results of the apparent viscosity of the PLA-PEMG/EVOH blends are consistent with the MI measurements of the blends.

Room Temperature Tensile Properties of PLA-PEMG/EVOH Blends

Figure 3 displays the tensile properties, including tensile strength at break and elongation at break, of the PLA-PEMG/EVOH blends. The values of tensile strength at break for neat PLA and EVOH were 59.6 and 76.4 MPa, respectively, and elongation at break were 5.4 and 180 %, respectively. Clearly, EVOH intrinsically has higher values of both tensile strength and elongation at break than neat PLA does. The value of elongation at break for PLA-PEMG was as high as 102 %, approximately 17.8 times higher than that of neat PLA. Oyama blended PLA with poly(ethylene-glycidyl methacrylate) (EGMA) through melt mixing in a twin-screw extruder and demonstrated that the PLA/EGMA blend containing 20 wt% of EGMA increased the elongation at break to more than 200 % under a high screw speed of 200 rpm. Even under a lower screw speed of 30 rpm, the elongation at break of this blend reached approximately 26 % [27]. Oyama proposed that the domain (approximately 100–300 nm) of EGMA at the interface of PLA/EGMA would be capable of dispersing energy and thus improve mechanical properties. Liu et al. [28] prepared a long-chain-branched (LCB) PLA by the successive reactions of the end hydroxyl groups of PLA with pyromellitic dianhydride (PMDA) and triglycidyl isocyanurate (TGIC). Najafi et al. prepared PLA/organoclay nanocomposites and controlled the thermal degradation of PLA during processing by using chain extenders. They incorporated three chain extenders, polycarbodiimide (PCDI), tris (nonyl phenyl) phosphite (TNPP) and Joncryl ADR 4368 into PLA and PLA-based nanocomposites and proposed that the mechanism of stabilisation was most likely responsible for the formation of the LCB structure formed by chain extension in the Joncryl-based nanocomposites [24]. As stated previously, PEMG, a multifunctional-epoxide oligomeric agent, can react with the hydroxyl or carboxyl groups end groups of PLA or EVOH [26] to form an anchorage structure. The elongation at break for PLA-PEMG reached as high as 102 % would follow the model happened in the PLA/EGMA blends [27]. For the PLA-PEMG/EVOH blends, the elongation at break increased with increasing amount of EVOH because of the high value of elongation at break for neat EVOH.

PEMG improved the elongation at break of PLA-PEMG and increased the tensile strength of PLA-PEMG through the LCB or anchorage structure (Fig. 3a). However, the value of tensile strength at break for PLA-PEMG/EVOH20 was reduced to 49.1 MPa, a decrease of 25 % compared with that for PLA-PEMG. Including hydrophilic EVOH into PLA substantially triggered the thermal degradation of PLA. Eventually, the tensile strength of PLA-PEMG/EVOH blends improved gradually as the amount of EVOH increased because of the high value of tensile strength for neat EVOH (approximately 76.4 MPa). The degree of thermal degradation of PLA was not as severe as the amount of hydrophilic EVOH increased. For PLA-PEMG/EVOH100, the tensile strength reached to 61.3 MPa, slightly higher than that for neat PLA.

Figure 3b shows the effects of the stretching ratio and rate on the tensile properties of the PLA-PEMG/EVOH80 film. Clearly, the increasing stretching ratio and rate increased the tensile strength and decreased the value of elongation at break of the film. Biaxial stretching enhanced the physical properties of the PLA-PEMG/EVOH80 film by increasing the crystallinity of the film and exerting a positive influence on the mechanical properties of the film.

Thermomechanical Properties of PLA-PEMG/EVOH Blends

As shown in Fig. 4a, the chain extender PEMG increased the storage modulus at 0 °C from 2200 MPa for neat PLA to 2700 MPa for PLA-PEMG, suggesting that PEMG could increase the stiffness of neat PLA through molecular entanglement resulting from the anchorage or LCB structure between PLA and PEMG. The storage modulus for neat EVOH at 0 °C was approximately 5113 MPa. Blending PLA with stiff EVOH increased the storage modulus of the PLA-PEMG/EVOH blends compared with those of neat PLA and PLA-PEMG, and the value of storage modulus increased with increasing EVOH content.

The glass transition temperatures (T g s) of both neat PLA and PLA-PEMG were approximately 75.7 °C according to their Tan δ peaks (Fig. 4b) and that of EVOH was 71.5 °C. The T g s of PLA-PEMG/EVOH blends were between 71.5 and 75.7 °C. All the Tan δ spectra of the PLA-PEMG/EVOH blends exhibited a single peak, suggesting that macrophase separation could not be detected during dynamic mechanical analysis (DMA) scans (Fig. 4b). The damping factor is defined as the peak value of the Tan δ spectrum. As shown in Fig. 4b, the damping factor values for PLA-PEMG and PLA-PEMG/EVOH blends were lesser than that for neat PLA, and these values decreased with increasing EVOH amount, indicating that introducing a chain extender or stiff EVOH substantially reduced the damping property of neat PLA. As stated previously, blending PLA with hydrophilic EVOH increased the value of the melt flow index and reduced the apparent shear viscosity of the PLA-PEMG/EVOH blends (Fig. 1). The events occurring in MI and viscosity tests contrasted the decrease in the damping factor of the PLA-PEMG/EVOH blends. As expected, the major plastic flow in neat PLA and PLA-PEMG and PLA-PEMG/EVOH blends occurred mainly in the plastic region but not in the elastic region. However, during DMA measurement, the magnitude of the applied sinusoidal deformation was linear and infinitesimal to cause apparent sliding in the PLA matrix, unlike the massive forces in the melt flow index and apparent shear viscosity tests. Therefore, the reduction in the damping factor of the PLA-PEMG and PLA-PEMG/EVOH blends might be associated with the increase in the storage modulus values of these blends.

Biaxial stretching can enhance the physical properties of a polymer film, which includes increasing the crystallinity of the polymer and exerting a positive influence on the mechanical properties and thermal stability of the polymer. In our previous study, we investigated the effects of biaxial stretching on the shrinkage and thermal and mechanical properties of PLA/SiO2 composite films, and we demonstrated that the storage modulus of the biaxially stretched PLA/SiO2 films increased substantially along with the stretching ratio and rate [29]. In the present study, we determined the effects of the stretch ratio and rate on the PLA-PEMG/EVOH80 film (Fig. 5). The storage modulus at 0 °C for the PLA-PEMG/EVOH80 film was approximately 3580 MPa, and it increased with increasing stretch ratio (Fig. 5a). For a stretch ratio of 3.5 × 3.5, the storage modulus was as high as 6640 MPa. We believed that a higher stretch ratio would bring the polymer molecules closer and uniformly orient the random molecules. This change during biaxial stretching made the polymer molecules of the stretched specimen stiffer than those of the unstretched specimen. Accordingly, PLA-PEMG/EVOH80 films with high stretch ratios were more rigid and exhibited a lower damping factor. In Fig. 5b, the damping factor for the unstretched PLA-PEMG/EVOH80 film was substantially higher than that for its stretched counterparts; this factor decreased with increasing stretch ratio. T g increased with the stretch ratio, suggesting less free volume in the biaxially stretched PLA-PEMG/EVOH80 films. Furthermore, a high stretch rate during biaxial stretching induced a stiff molecular configuration, because less time was available for the stressed polymer molecules to reorganise, and imparted a high storage modulus (Fig. 5c). The PLA-PEMG/EVOH80 films with high stretch rates were more rigid than the counterparts with slow stretch rates (Fig. 5d).

Compatibility of PLA-PEMG/EVOH Blends

Figure 6 shows the wide-angle X-ray diffraction (WAXD) patterns of neat PLA and PLA-PEMG and PLA-PEMG/EVOH blends crystallised through cold crystallisation. In Fig. 6a, two strong reflections (200)/(110) and (203) were observed for neat PLA [30, 31], PLA-PEMG, and PLA-PEMG/EVOH blends. The intensity of the (200)/(110) reflection gradually decreased with increasing amount of EVOH in the PLA matrix, indicating that EVOH inhibited the diffusion and deposition of PLA molecules. The arrow in Fig. 6a indicates the reflection peak associated with the reflection of the EVOH crystal. Consequently, two distinct crystalline structures resulted from PLA and EVOH in the patterns of PLA-PEMG/EVOH blends, implying the occurrence of microphase separation in the blends. Figure 6b shows the WAXD patterns of PLA-PEMG/EVOH80 films under various stretching ratios and rates. The intensity of reflections (200)/(110) and (203) for the PLA matrix became stronger with increasing stretch ratio and rate, suggesting that the crystal structure of PLA was more ordered at high stretch ratio and rate [29, 32]. In Fig. 6b, the reflection (203) of PLA became undetectable when the stretch rate was less than 80 %/s, suggesting that the PLA molecules restored to a less ordered configuration under a slow stretch rate.

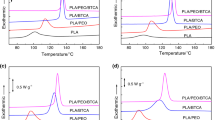

Figure 7 presents the differential scanning calorimetry (DSC) heating traces (cold crystallisation) and cooling traces from the melt. During cold crystallisation, neat EVOH exhibited a singlet endothermic peak at approximately 182.9 °C, which was associated with the melting temperature of neat EVOH (Fig. 7a). By contrast, neat PLA exhibited T g , cold crystallisation, and melting temperatures at 59.4, 96.7, and 170.6 °C, respectively. PLA-PEMG exhibited cold crystallisation and melting temperatures at 91.3 and 169.8 °C, respectively. As stated in “Melt index (MI) of PLA-PEMG/EVOH blends” section, incorporating the chain extender PEMG increased the molecular entanglement of PLA-PEMG, and this long chain entanglement increased the crystallisation rate of PLA-PEMG and reduced the cold crystallisation temperature of PLA-PEMG compared with those of neat PLA. Oyama proposed that blending PLA with EGMA can increase the crystallinity and reduce the cold crystallisation temperature of the blends [27]; the events in our study (PLA-PEMG) were consistent with those suggested by Oyama. Figure 7b shows the cooling DSC traces for the PLA-PEMG/EVOH blends. Neat EVOH exhibited a pronounced exothermic peak at 163.3 °C, and neat PLA and PLA-PEMG exhibited slightly broader exothermic peaks than neat EVOH did. The slow crystallisation rate for PLA during cooling crystallisation might be responsible for the broad exothermic peak. This exothermic peak for PLA-PEMG became undetectable when PLA-PEMG was blended with EVOH. This molecular entanglement also rendered the glass transition peak of PLA-PEMG to become negligible during DSC scans.

The DSC traces for the PLA-PEMG/EVOH blends revealed doublet melting peaks with T m1 (lower melting temperature) and T m2 (upper melting temperature) being approximately 169.8 and 182.9 °C, respectively. The PLA-PEMG/EVOH blends revealed phase separation because of the two melting temperatures in cold crystallisation DSC traces. All the Tan δ spectra of PLA/EVOH blends exhibited a singlet peak, and we proposed that no macrophase separation could be detected during DMA scans (Fig. 7b). However, based on the doublet melting peaks of the PLA-PEMG/EVOH blends, we believed that microphase separation occurred in these blends. The DSC traces of the PLA-PEMG/EVOH blends were consistent with the WAXD patterns of the blends. The scanning electron microscopy (SEM) images of neat PLA, PLA-PEMG, and PLA-PEMG/EVOH blends also showed the occurrence of microphase separation in the blends (Fig. 8). The image for the PLA-PEMG/EVOH blends shows the homogeneous dispersion of EVOH in the PLA matrix, and the domain size of EVOH was approximately 1–5 μm.

Barrier Property of PLA-PEMG/EVOH Films

EVOH is a common thermoplastic and environment-friendly polymer with excellent water and gas barrier properties. EVOH barrier films can be laminated with other polymer films, such polyolefins, polyamides (PAs), and PET, through the coextrusion or coextrusion lamination process to serve as packaging materials in food, medical, pharmaceutical, and cosmetic packaging applications. Unlike the typical coextrusion process, in the present study, EVOH was applied to improve the barrier properties of PLA by melt compounding by using the twin-screw extrusion technique, which demonstrates the benefits of simplicity and cost reduction in fabricating EVOH barrier films. Figure 9 shows the WVTRs of the PLA-PEMG/EVOH blends. In Fig. 9a, WVTR for neat PLA is approximatively 250 cc—20 μm/m2-day-atm. PEMG lowered the WVTR of PLA through molecular entanglement. Blending PLA-PEMG with EVOH substantially reduced the WVTR from 250 cc—20 μm/m2-day-atm for neat PLA to approximately 65 cc—20 μm/m2-day-atm for the PLA-PEMG/EVOH80 film, a decrease of approximately 74 % compared with neat PLA. Biaxial stretching considerably decreased the WVTR of the specimens (Fig. 9b). For the unstretched PLA-PEMG/EVOH80 film (sample 1), the WVTR was 65 cc—20 μm/m2-day-atm, and the WVTR decreased with an increasing stretch ratio. For the unstretched PLA-PEMG/EVOH80 film, the WVTR decreased from 65 cc—20 μm/m2-day-atm to 6.3 cc—20 μm/m2-day-atm for the stretch ratio of 3.5 × 3.5 at a rate of 100 %/s (sample 5), a decrease of 90.3 %. We proposed that increasing the stretch ratio and rate could render the crystal structure of PLA more ordered and result in a tighter molecular packaging [29, 32], consequently resulting in a lower WVTR. Compared with the stretch ratio of 3.5 × 3.5 at a stretch rate of 100 %/s, a stretch rate of less than 100 %/s (samples 6, 7, and 8) slightly reduced the WVTR (Fig. 9b).

Conclusions

In this study, a hydrophilic copolymer, EVOH, was incorporated into the PLA matrix to improve the WVTR of PLA by using the twin-screw extrusion technique, instead of the typical coextrusion process. Experimentally, PEMG substantially lowered the probability of the thermal degradation of PLA. However, blending PLA with the hydrophilic copolymer EVOH increased the MI of PLA-PEMG/EVOH than that of neat PLA. Chain extender reacted with PLA as well as with the hydrophilic EVOH to form an anchorage or LCB structure. Accordingly, the MI of PLA-PEMG/EVOH blends decreased with increasing amount of hydrophilic EVOH. Furthermore, biaxial stretching increased the tensile strength and reduced the value of elongation at break of the PLA-PEMG/EVOH80 film. Regarding compatibility, microphase separation with a domain size of 1–5 μm occurred in the PLA-PEMG/EVOH blends. Finally, EVOH successfully improved the WVTR of PLA though melt binding. Blending PLA-PEMG with EVOH considerably decreased the WVTR from 250 cc—20 μm/m2-day-atm for neat PLA to approximately 65 cc—20 μm/m2-day-atm for the PLA-PEMG/EVOH80 film, a decrease of approximately 74 % compared with neat PLA. Moreover, the WVTR decreased from 65 cc—20 μm/m2-day-atm for the unstretched PLA-PEMG/EVOH80 film to 6.3 cc—20 μm/m2-day-atm for the stretch ratio of 3.5 × 3.5 at a rate of 100 %/s, a decrease of 90.3 %.

References

Gross R, Kalra AB (2002) Science 297:803

Hu Y, Rogunova M, Topolkaraev V, Hiltner A, Baer E (2003) Polymer 44:5701

Bitinis N, Verdejo R, Cassagnau P, Lopez-Manchado MA (2011) Mater Chem Phys 129:823

Anderson KS, Hillmyer MA (2004) Polymer 45:8809

Jonoobi M, Harun J, Mathew AP, Oksman K (2010) Comp Sci Technol 70:1742

Grijpma DW, Penning AJ (1994) Macromol Chem Phys 195:1649

Hiljanen-Vainio M, Karjalainen T, Seppala J (1996) J Appl Polym Sci 59:1281

Ruckenstein E, Yuan Y (1998) J Appl Polym Sci 69:1429

Labrecque LV, Kumar RA, Dave V, Gross RA, McCarthy SP (1997) J Appl Polym Sci 66:1507–1513

Ljungberg N, Wesslen B (2003) Polymer 44:7679

Jacobsen S, Fritz HG (1996) Polym Eng Sci 36:2799

Jacobsen S, Fritz HG (1999) Polym Eng Sci 39:1303

Anderson KS, Lim SH, Hillmyer MA (2003) J Appl Polym Sci 89:3757

Wang Y, Hillmyer MA (2001) J Polym Sci Part A Polym Chem 39:2755

McCarthy SP, Ranganthan A, Ma W (1999) Macromol Symp 144:63

Tsuji H, Ikada Y (2003) J Appl Polym Sci 60:2367

Grijpma DWVan, Hofslot RDA, Super H, Nijenhuis AJ, Pennings AJ (1994) Polym Eng Sci 34:1674

Wang L, Ma W, Gross RA, McCarthy SP (1998) Polym Degrad Stab 59:161

Ruckenstein E, Yuan Y (1998) Polym Bull 40:485

Bledzki AK, Jaszkiewicz A (2010) Compos Sci Technol 70:1687

Wu JH, Kuo MC, Chen CW, Chen CW, Kuan PH, Wang YJ, Jhang SY (2013) J Appl Polym Sci 129:3007

Wu JH, Yen MS, Kuo MC, Chen BH (2013) Mater Chem Phys 142:726

Lagaron JM, Powell AK, Bonner G (2001) Polym Test 20:569

Najafi N, Heuzey M, Carreau C, Wood-Adams PJ, Paula M (2012) Polym Degrad Stab 97:554

Wu JH, Kuo MC, Chen CW (2015) J Appl Polym Sci 132:42378

Kim YF, Choi CN, Kim YD, Lee KY, Lee MS (2004) Fibers Polym 5:270

Oyama HidekoT (2009) Polymer 50:747

Liu J, Lou L, Yu W, Liao R, Li R, Zhou C (2010) Polymer 51:5186

Wu JH, Yen MS, Wu CP, Li CH, Kuo MC (2013) J Polym Environ 21:303

Zhang JM, Duan YX, Sato H, Tsuji H, Noda I, Yan S (2005) Macromolecules 38:8012

Kalish JP, Aou K, Yang X, Hsu SL (2011) Polymer 52:814

Huang S, Li H, Jiang S, Chen X, An L (2011) Polymer 52:3478

Acknowledgments

The authors gratefully acknowledge the sponsorship from Ministry of Science and Technology, Taiwan, ROC, under the Project No. MOST 103-2221-E-168-035.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wu, JH., Wu, CP., Kuo, M.C. et al. Characterization and Properties of Reactive Poly (Lactic Acid)/Ethylene–Vinyl Alcohol Copolymer Blends with Chain-Extender. J Polym Environ 24, 129–138 (2016). https://doi.org/10.1007/s10924-016-0755-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0755-x