Abstract

The vibration-based damage identification techniques use changes in modal properties of structures to detect damages. However, the results of these methods are not reliable under noise. Therefore, it is essential to clarify which method performs vigorous under noisy conditions. In this study, three damage detection methods, called modal strain energy-based damage index, modal flexibility, and modal curvature, are considered to detect damage with and without the presence of noise. The feasibility of these methods is demonstrated by applying a range of damage scenarios in the validated FE model of the I-40 Bridge. The info of the only first three bending mode shapes of the bridge is used to calculate damage indices. The outcome showed while all three methods were capable of detecting damage in the absence of noise, only the modal flexibility method could locate damages in the presence of noise. Thus, an approach is proposed to eliminate noise and quantify damage magnitude using an artificial neural network (ANN) and modal flexibility method. The modal flexibility damage index of different damage severities was contaminated with various noise levels used as input parameters to train the ANN. Results indicate the adequate performance of the trained ANN in noise-canceling and damage magnitude estimation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

One of the essential parts of transportation networks is bridges. However, these structures deteriorate by aging and take damages due to environmental effects, catastrophic events, and changes in load distribution [1,2,3,4,5,6,7]. The defects can spread through all the structural components and result in structural collapse if they are not detected at the first stage. Hence, it is crucial to detect damage at the early stages to prevent the structure's failure.

The vibration-based damage identification (VBDI) methods gained more importance in the past decades. The fundamental idea behind the vibration-based damage detection techniques is that damage alters the structure's dynamic properties, i.e., mode shapes, modal damping, and natural frequencies [8, 9]. These vibration parameter changes can be used as a damage indicator for damage identification. These methods are based on features extracted from dynamic parameters and categorized as follows: mode shape-based methods, natural frequency-based methods, strain/curvature mode shape-based methods, and other methods based on modal parameters [10, 11]. Civil engineers utilized vibration-based damage detection methods for damage identification on various structures such as beams [12,13,14,15,16], plate-like structures [17, 18], bridges [19,20,21,22,23,24,25], and trusses [26, 27] in the past decades.

Modal strain energy-based damage index (MSEDI) is one of the most common vibration-based damage detection methods. The MSEDI was initially developed by Kim and Stubbs [28, 29] to evaluate beam-like structures' integrity. Also, Kim and Stubbs [30] proposed an improved damage identification method based on modal information and evaluate its accuracy on a two-span continuous beam. Results indicate that the proposed method was capable of detecting damage. The MSEDI method was used by many researchers to detect and localize damage in various structures [15, 31,32,33,34,35,36]. The results of these studies showed the MSEDI method was a reliable damage locating method in different structures. However, it was incapable of estimating damage severity. In addition, the MSEDI method does not show a reliable performance under the noise effect.

One of the other most applied VBDI methods is the modal flexibility (MF) damage detection method. Pandey and Biswas [37] originally proposed the MF method that used modal flexibility changes as a damage indicator to detect damage in beams. The proposed method incorporates mass normalized mode shapes and the natural frequency of the structure. In the past decades, the MF damage identification method was utilized for damage detection in various structures due to its accuracy on damage locating and simplicity of calculation. The MF method was used to detect damage in bridges [38, 40, 42,43,44, 47], building [45], beams [16, 46], and truss [39]. From all these studies, it is evident that the MF damage identification method is a reliable method for damage identification of different structures. Although the MF method showed robustness in damage detection under noisy conditions, it could not estimate damage magnitude.

The modal curvature (MC) damage identification technique is another widely used VBDI method. Pandey et al. [48] originally developed modal curvature changes as a damage indicator for damage detection. The modal curvature damage index (MCDI) was evaluated in a cantilever and a simply supported beam. Results demonstrated the feasibility of the MCDI for damage identification. A couple of more research in damage detection via the modal curvature technique in beams, bridges, and buildings proves the modal curvature method's feasibility [49,50,51,52,53,54,55,56,57].

In addition, numerous research utilized the MF method, MSEDI method, and modal curvature method solely or simultaneously for damage identification in various structures such as beams, bridges, and buildings [5, 58,59,60,61,62,63,64,65,66,67]. However, these methods could not quantify the severity of damage properly. Also, the results of damage locating under the effect of noise for these methods were unreliable. Therefore, a couple of studies have been done to evaluate VBDI methods' performance under noisy conditions [54, 61, 64, 70, 71].

Modern tools such as artificial neural networks (ANNs) or machine learning gained more attention from researchers in recent years [77,78,79]. These methods are capable of learning through uncertainties and incomplete modal data to avoid the effect of noise or to estimate the severity of the damage. Tan et al. [36] proposed a two-stage using modal strain energy-based damage index and artificial neural network to locate damage and estimate damage magnitude in a steel beam. The results demonstrated that the proposed two-stage method could successfully. However, for calculating the damage index, they used only the first bending mode shape vibration data. This procedure cannot be reliable in complex structures. Kostic et al. [72] proposed a time-series-analysis-based integrated with ANN for damage detection in a finite element (FE) of a footbridge under varying temperatures. They utilized ANN to eliminate the effects of varying temperatures. Results demonstrated that the proposed method was capable of detecting and locating damage under the impact of temperatures. Paral et al. [73] proposed a mode shape derivative-based damage index using ANN for damage identification in shear frame buildings. They utilized the change in the first mode shape slope as input parameters to train the ANN. Results showed the efficiency of the proposed method for damage detection. Weinstein et al. [74] proposed an ANN approach to estimate a bridge behavior model. Results indicate that the damage localized successfully using the proposed method.

Jin et al. [75] presented a method based on ANN integrated with Kalman filter for damage detection under severe, varying temperatures in a composite steel girder bridge. Results indicated the feasibility of the proposed method in the reduction of uncertainty and damage detection. Tan et al. [76] proposed a damage detection method based on ANN and vibrational characteristics to detect damage in a composite slab-on-girder bridge. They utilized the MSEDI for damage locating and estimating the severity of the damage in steel girders. Also. They used the relative modal flexibility change to identify and quantify damage in the deck. Results showed the feasibility and efficiency of the proposed method to damage identification in composite bridges.

This paper investigated the vibration-based damage identification method to detect and locate damages in steel girder bridges. The modal flexibility damage index (MFDI) method, the modal strain energy-based damage index (MSEDI) method, and the modal curvature damage index method (MCDI) developed for damage detection. The presented VBDI methods performance was evaluated by applying a couple of damage cases in the I-40 bridge girders. The effects of noise were considered to assess each method's performance in damage detection under noisy conditions.

Also, a damage quantification method and a noise elimination technique were proposed using the modal flexibility method and ANN to estimate the severity of damage and eliminate the existing noise.

2 Method

2.1 Modal Flexibility Method

This method incorporates both the natural frequency and mode shape of a structure. The modal flexibility, F of a linear structure can be represented by Eq. (1)

From the above, i is the mode number and m is the total mode number considered, while \({\omega }_{i}\) is the natural frequency. \({\varnothing }_{i}\) and \({\varnothing }_{i}^{T}\) are the ith mode shape vector and its transpose, respectively.

The modal flexibility change can be expressed by Eq. (2), where d and h represent the structure's damaged and healthy state [37].

The normalized damage index based on modal flexibility change is defined by Eq. (3)

2.2 Modal Strain Energy-Based Damage Index Method

Kim and Stubbs [28, 29] originally developed this method. The MSEDI method calculates changes in the strain energy in deformed beams in particular mode shapes. These changes were utilized as a damage index. The modal strain energy for a beam will be calculated from Eq. (4).

where EI represents the flexural stiffness, \({d}^{2}\varnothing /{dx}^{2}\) is the modal curvature of the deformed beam. This damage indicator is based on the differences between the healthy and the damaged state of a structure in modal strain energy. The damage index for the ith mode of the jth element can be expressed by Eq. (5)

where \({{\varnothing }_{i}}^{"}\) is the mode shape curvature and star indicate the damaged state. Numerically the above formula can be rewritten by Eq. (6)

2.3 Modal Curvature Damage Index Method

The below equation can express the curvature function of the curve of bending

where M(x) and EI are bending moment and the flexural stiffness, respectively. The value of mode shape curvature can be approximately obtained by the central difference method based on mode shape displacements. The ith mode shape curvature value of the jth computational node is given by Eq. (8)

where h is the distance between two adjacent computational nodes. For damage indicator based on modal curvature, the mode shape curvature damage index is defined by the Eq. (9)

where d and h denote the damaged and healthy state of the structure, respectively.

2.4 Combination Method

To benefit all the I-40 Bridge vibration modes, it is proposed to combine damage indices (DIs) calculated from them by absolute values (AV) combination method. The normalized AV combination method can be expressed by Eq. (10).

where DI and N are the damage index and the number of damage indices calculated by each vibration-based damage index, respectively.

2.5 Artificial Neural Network

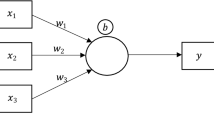

Artificial neural networks (ANNs) were originally developed from human biological brains. The main feature of ANNs is the ability to learn. This ability is to mapping a set of input variables to a set of output variables. The learning process is done by adjusting the weights and bias vectors. The ANNs commonly consist of three layers. An input layer, a hidden layer, and an output layer. Each layer consists of neurons, and the learning process is to find a relation between the neurons in the input layer with the ones in the output layer [36, 74, 76]. The Back-propagation neural network is one of the developed multi-layer networks, and it is one of the supervised learning ANN algorithms.

In this study, the back-propagation neural network and the MFDI method were utilized to eliminate noise and quantify the damage's severity. The noisy modal flexibilities were used as input parameters for training the ANN. Once the ANN is adequately trained, it can estimate the noise-free modal flexibilities. For the training function, the Levenberg–Marquardt back-propagation method was used. The technique existed in MATLAB software [77].

To evaluate the selected VBDI methods' performance, a couple of single and multiple damage cases were applied to a validated finite element (FE) model of the I-40 Bridge. The bridge's FE model is validated through a comparison between the resonant frequencies of the intact bridge and the ones extracted from the FE model (described later in Sect. 3.1). This study proposes using only the first three bending mode shapes of the intact and damaged bridge, which could be extracted from the FE model. The damage indices of three vibration-based damage detection methods were calculated using the extracted modal data from the FE model, separately. To incorporate all three bending modes, it is proposed to combine damage indices using combination methods to plot the combined damage index vs. distances along the bridge's girders for each damage index method. The peak value of the plot should examine the damage location. The numerical investigation is described later in Sects. 4.1 and 4.2. In addition, the performance of the proposed damage indices under noisy conditions evaluated. Further numerical investigations are described later in Sect. 4.3. To eliminate the noise and estimate the magnitude of damages by using the ANN, some numerical investigations were described later in Sect. 4.4.

For locating damage by introduced vibration-based damage detections, the following steps should be done.

-

Extract the modal data of the first three bending mode shapes of the intact and the damaged bridge.

-

Calculate the MFDI, MCDI, and MSEDI using the previous step's modal data for each bending mode shape along the girder.

-

Combine calculated DIs via the absolute values combination method.

-

Plot the calculated DIs along with the girders of the bridge

-

Locate the damage by specifying the peak value of the plot

To evaluate the performance of the mentioned VBDD methods under noise, the bridge's modal data contaminated with random noise. As will be discussed and investigated through numerical examples later, only the MFDI method can locate damage in the presence of noise. Thus, the MFDI method and ANN were utilized to eliminate noise and quantify the damage's severity. The following steps will do the process.

-

Locate the damaged location by specifying the peak value of the MFDI plot versus distance along girders in the presence of noise.

-

Simulate all available damage severities (10%, 15%, 20%, and 25% of stiffness reduction) in the detected damage location using the FE model.

-

Extract the first three noise-free bending mode shapes of all simulated damage severities from the FE model.

-

Calculated the noise-free MFDIs of each damage magnitude from the noise-free bending mode shapes.

-

Contaminate extracted mode shapes with eleven state of noises (1%, 3%, 5%, 7%, 10%, 13%, 15%, 17%, 20% 23% and 25% of noise) for each damage severity.

-

Calculate the noisy MFDIs from contaminated mode shapes of each damage severity.

-

Use calculated noisy MFDIs as input data and noise-free MFDIs as output data to train four different ANN for each damage magnitude.

-

Input the noisy MFDIs of the detected damage from the first step into each trained ANNs.

-

Each ANN will estimate the noise-eliminated MFDIs of each damage severity.

-

Plot the noisy MFDI of the detected damage and the noise-eliminated MFDI of four-damage magnitude.

-

The fitted noise-eliminated MFDI curve with the detected noisy MFDI shows the magnitude of the detected damage.

3 Application

3.1 Validation of the FE Model of the I-40

The proposed method's performance for damage identification was evaluated in a steel girder bridge. The I-40 Bridge was constructed over the Rio Grande in Albuquerque and razed in 1993. The bridge consisted of three spans. It was made up of a concrete slab, two main steel girders, three steel stringers, and steel floor beams. Loads were transferred to two steel-plate girders from stringers through floor beams, located at 6.1 m intervals. Further description of the I-40 Bridge is given by Farrar et al. [58, 59]. Figure 1a shows the bridge's cross-section geometry. Figure 1b shows the bridge's portion's elevation view, which was tested.

3.2 Sensors Deployment

The modal parameters (mode shapes and corresponding resonant frequencies) of the undamaged bridge were obtained using a force-vibration test. The excitation was generated by a hydraulic shaker mounted on the easternmost span between the abutment and the first pier. The set of twenty-six integrated-circuit, piezoelectric accelerometers were utilized for vibration test.

The number of thirteen accelerometers mounted in the vertical direction, on the inside web of each main girder at mid-height and the axial locations depicted in Fig. 2. Standard experimental modal analysis was done for the data obtained from the accelerometers during the force-vibration test. Therefore, the modal parameters of the intact bridge are identified. A further detailed description of the bridge and the force-vibration test is given by Farrar et al. [58,59,60,61,62,63,64,65,66,67,68,69].

3.3 Finite Element Modeling of Bridge

The full-scale model of the I-40 Bridge was created by the finite element software, namely ABAQUS [78]. A 3D-shell element was used to model the bridge's components, such as plate-girders, stringers, and floor beams. The S4R was used as the mesh element type. Figure 3 shows the 3D FE model of the I-40 Bridge. The material properties for the steel and the concrete for the bridge are given in Table 1.

For validation of the FE model, resonant frequencies obtained from the FE model via modal analysis compared to the ones from the intact bridge via force vibration was made. The comparison shows in Table 2. The percentage of the average difference between the FE model's resonant frequencies and the intact bridge is 5.8%, which displays a reliable correlation between the FE model and the real structure.

3.4 Damage Locations

To evaluate the proposed VBDI methods' performance, the validated FE model of the I-40 Bridge was used. As discussed in Sect. 3.1, the I-40 Bridge had three spans and two main girders, which the first and the third spans had equal lengths. Therefore, for the first and third spans equal to 39.96 m, nine 30 cm partitions were simulated in each girder's web of the bridge as damage locations. The mid-span, which had a 49.96-m length divided into eleven 30 cm partitions as damage locations. These partitions are simulated as damage locations, in which damage can occur. Figure 4 reveals the divided 30 cm partitions in the girder's web of the bridge's FE model.

3.5 Damage Scenarios

The proposed VBDI methods' performance is illustrated by applying several single and multiple damage scenarios to the validated FE model of the I-40 Bridge. Damage can be defined as stiffness reduction by reducing of young's modulus. Table 3 shows the details of the damage scenarios of single or multiple scenarios considered in the present study.

4 Results and Discussion

4.1 Single Damage Locating Without Noise

The feasibility and performance of the proposed vibration-based damage detection methods for damage locating demonstrated by applying various damage scenarios to the FE model of the I-40 Bridge. As it shows in Table 3., three damage cases (SD1, SD2, and SD3) were considered as single damage scenarios.

For the damage detection procedure, the damage indices of the proposed methods should be calculated. The MSEDI and MCDI are relative and sensitive to flexural stiffness. The first three bending mode shapes of the bridge obtained by frequency analysis of the FE model, which shows in Fig. 5.

In practice, it is challenging to obtain higher modes in experimental testing of models or full-scale testing of real bridges; therefore, it was proposed to calculate damage indices using only the bridge's first three bending mode shapes.

For the first damage case (SD1), the MSEDI, MFDI, and MCDI described in the "Method" section were calculated using only three bending mode shapes of the bridge. Also, the damage cannot locate accurately by using each bending mode shape at a time. Therefore, to overcome this problem and benefit all bending mode shapes, it is proposed to combine damage indices. The combination can be done by using the AV combination method. Figures 6, 7, 8 show the plot of combined DIs via the AV method along girders for SD1, SD2, and SD3.

The peak values (either negative or positive) of the calculated damage indices in these plots are expected to show the damage location for each damage scenario, indicated by red circles in plots.

It is evident from Figs. 6, 7, 8; all three proposed damage detection methods are capable of detecting damage locations correctly. Also, it can be seen that by using the proposed AV combination method, the accuracy of the damage locating increased.

4.2 Multiple Damages Locating Without Noise

Three damage cases were selected to evaluate the feasibility and capability of the proposed damage identification methods to locate multiple damages. The three multiple cases are shown in Table 3.

The MD1 damage case shows two damages that occurred in the girder one simultaneously. The MD2 shows two damages that happened in the third span of the girder one, and the other happened in the mid-span of the girder two, simultaneously. The MD3 damage case show three damages occurred in three different locations of two girders, simultaneously.

Figures 9, 10, 11 show the results of damage locating of proposed damage identification techniques.

Figures 9, 10, 11 show the capability of the proposed damage identification methods for multiple damage detection. It is clear that all three proposed damage identification methods could accurately locate the damage location for multiple damage cases.

4.3 Damage Identification Under Noisy Condition

The performance of the proposed damage detection methods in the presence of noise is essential since, in reality, the measured vibration data are contaminated by measurement noise and computational errors. The mode shapes used in this study are extracted from the FE model; therefore, they are noise-free. To evaluate the effect of noise in the proposed methods and simulate the environmental impact on mode shapes data, the mode shapes are polluted with random white Gaussian noise. The polluted mode shapes can be calculated by Eq. (11). [68]

where \(\stackrel{-}{{\varnothing }_{xi}}\) and \({\varnothing }_{xi}\) are the mode shape components of the jth mode at location x with and without noise, respectively. \({\gamma }_{x}^{\varnothing }\) and \({\rho }^{\varnothing }\) are the random number with a mean equal to zero and variance equal to one and random noise level, respectively. \(\left|{\varnothing }_{max,x}\right|\) is the largest component of the ith mode shape [47, 67].

The MD2 case from multiple damage scenarios and the SD3 case from single damage scenarios were considered to evaluate the vibration-based damage identification methods' performance in the presence of noise. Therefore, the first three bending mode shapes are polluted with 5% and 10% of white Gaussian noise in this study. The polluted mode shapes were used to calculate the MSEDI, MFDI, and MCDI. Figure 12, 13, 14 show the result of the MSEDI, MCDI, and MFDI damage locating for the SD3 damage case with and without 5% and 10% of noise.

The figure above shows that the MSEDI method cannot locate the damage location accurately. Despite the actual damage location, which occurred at the 93.6 m of the second girder and indicated through a red circle, the MSEDI detected some other false damage locations in the presence of noise. This result shows that the modal strain energy-based damage index method cannot detect the damage location in the presence of noise.

Figure 13 shows the result of damage locating via the MCDI with and without 5% and 10% noise.

Figure 13 shows that while the MCDI could locate the damage location without the presence of noise indicated by a red circle in the plot, it could not locate the damage location correctly with the presence of noise and had much more false damage location prediction. Therefore, it is not a reliable method to locate damage in the presence of noise.

Figure 14 shows the result of locating the damage using the MFDI method with and without 5% and 10% noise.

The figure above shows that the MFDI method accurately located the damage location, even with 5% or 10% noise. It is evident from the results that the modal flexibility damage index method is the only reliable damage locating technique in the presence of noise.

For the multiple damage case MD2, all three DIs are calculated and plotted along both the first and second girders in the presence of 5% and 10% of noise. Figures 15, 16, 17, 18, 19, 20 show the damage locating of the MD2 damage case using the proposed methods with and without 5% and 10% noise.

It is evident from Figs. 15, 16, 17, 18, 19, 20 that only the MFDI is a reliable method for locating multiple damages location even in the presence of 10% noise.

4.4 Noise Cancelation and Damage Severity Estimation Using the ANN

After the damage locating stage, from what has been debated above, only the modal flexibility damage detection method was robust enough to detect the damage location in the presence of noise. However, the bridge's bending mode shapes were still polluted by noise, and the damage severity is unidentified. Therefore, to cancel the effect of noise and estimate the magnitude of damage severity, the artificial neural network (ANN) was utilized. In the damage locating stage, the location of damage would be detected by the MFDI in the presence of noise.

To eliminate the noise and estimate the damage's severity, the neural network needs to train by all possible noisy conditions with different severity of damages. The FE model of the bridge was used to generate the learning data of the ANN. It is proposed to simulate all available damage severities in the located damage location through the FE model. The first three noise-free bending mode shapes are extracted from the FE model through the modal frequency analysis. Then the noise-free MFDIs are calculated separately by using the noise-free bending mode shapes for each damage severity. After that, different noise levels are added to the first three noise-free bending mode shapes. The noisy MFDIs are calculated by using the contaminated bending mode shapes for each damage severity. Since four different damage magnitude simulated in this study (10%, 15%, 20%, and 25% of stiffness reductions), four various neural networks were trained by inserting the noisy MFDIs as input parameters and the noise-free MFDIs as output parameters. Finally, by inserting the noisy MFDIs of the located damage into each trained ANN, the noise-eliminated MFDIs will be obtained.

4.4.1 Single Damage Scenarios

Figure 14 shows that the MFDI method located the location of the SD3 damage case in the presence of 5% and 10% noise. However, the severity of the damage is still unknown. It is proposed to simulate four available damage magnitude (10%, 15%, 20%, and 25% of stiffness reduction) in the SD3 damage location using the FE model. After that, the first three noise-free bending mode shapes were obtained from the FE model and used to calculate the noise-free MFDIs of each damage magnitude. Then, the first-three bending mode shapes of each simulated damage were then polluted by 11 different noises (1%, 3%, 5%, 7%, 10%, 13%, 15%, 17%, 20%, 23%, and 25% of noise) and used to calculate the noisy MFDIs. Therefore, 11 samples of noisy MFDIs for four different damage magnitude were calculated. The noisy MFDIs were used as input parameters to train four separate neural networks. 7 out of 11 samples were used for the training stage, while two samples were used for the validation stage, and 2 out of 11 samples were used for each ANN testing stage. The Levenberg–Marquardt back-propagation method was used as the training function in the ANN. Each ANN's input layer consisted of 100 neurons (noisy modal flexibility damage indices for 100 nodes along the girder). The hidden layer consisted of ten neurons selected by a trial and error process to reach a minimum mean square error (MSE). The output layer consisted of 100 neurons (noise-free modal flexibility damage indices for 100 nodes along the girders). During the ANN's training, the MSE of the ANN will be reduced by backward propagating errors through the network. The R-vector shows the correlation between the target and the output of the ANN. While the correlation is at the highest, the R-vector is 1. On the other hand, if there is no correlation at all, the R-vector is zero. Figure 21 shows the regression plots of each ANN's training. Each ANN has trained adequately with low MSE and near to one R-vector.

For testing the trained ANN, a new set of data is needed. The 18% noisy modal flexibilities of the SD3 damage case were inputted to each trained ANN to estimate the noise-eliminated modal flexibility damage indices of each simulated damage magnitude. The noise-eliminated MFDIs for each damage severity were plotted along the second girder. Figure 22 shows the damage detection of the SD3 damage case in 18% noise and the eliminated noisy MFDIs of each damage severity.

Figure 22 shows that the 18% noisy MFDI of the SD3 damage case is fitted to the noise-eliminated MFDI of 15% of damage severity. It can be concluded that the magnitude of the SD3 damage case is 15% of stiffness reduction, and the fitted curve is the noise-canceled MFDI of this damage case.

4.4.2 Multiple Damage Scenarios

To evaluate the proposed method's performance for eliminating the noise and quantifying damage severity in multiple damage scenarios, the MD2 damage case was selected. Figures 19 and 20 show that the MFDI could detect multiple damage locations in the presence of 5% and 10% of noise. However, the magnitude of located damages was still unidentified. To estimate the severity of the located damages and eliminate the existing noise, it is proposed to use the ANN. Since the MD2 damage case has two different damage locations in both girders of the bridge, it is suggested to simulate all four damage severities (10%, 15%, 20%, and 25%) in each location at a time. The first detected damage location is damage at 117.5 m of the first girder. Four different damage severities were simulated in this location using the FE model. The first three noise-free mode shapes of the bridge are obtained. These mode shapes are contaminated by eleven severities of noise similar to Sect. 4.4.1. The MFDIs of the noise-free and contaminated mode shapes are calculated for each damage severity and are used as input and output parameters to train four different ANN. Figure 23 shows the regression plots of each ANN's training.

To examine the trained ANN, a new set of data is used. The polluted MFDIs of the MD2 damage case with 22% noise were inputted into each trained ANN. Each trained ANN estimated the noise-eliminated MFDIs for each damage severity. By using these noise-eliminated modal flexibility damage indices, the MFDI vs. distance along the first girder plotted. Figure 24 shows the MFDI of the first damage of the MD2 damage case in the presence of a 22% noise with the eliminated noisy MFDIs of each damage severity in the first girder.

From the figure above, it can be seen that the polluted MD2 curve with 22% of noise was fitted to the curve of noise-eliminated with 20% of damage severity. Thus, the severity of the first detected damage in the MD2 damage case is 20% of stiffness reduction, and the fitted curve is the noise-free MFDI of this damage case, which is depicted in Fig. 25.

The second located damage location is damage at 77.2 m of the second girder. As the same as steps were done for the first girder's first damage location, all four damage severities (10%, 15%, 20%, and 25%) were simulated in this damage location. The noise-free MFDIs are calculated from the first three noise-free mode shapes of each damage magnitude as input. Then the mode shapes are contaminated by eleven states of noise. The noisy MFDIs are calculated from the polluted mode shapes of each damage severity as output. Thus four separate ANN is trained using generated input and output data. Figure 26 shows the regression plots of four ANN's training for the second located damage in the MD2 damage case.

Using the noise-canceled MFDIs of each damage severity obtained from each four trained ANN, the MFDI of the second detected damage of the MD2 damage case plotted. To test the trained neural networks, a new set of data is utilized. Therefore, contaminated MFDIs of the MD2 damage case with 22% noise were inputted into each trained network. Figure 27 shows the polluted MFDIs of the second damage in the second girder with 22% noise and the noise-eliminated MFDIs of each damage severity.

Figure 27 shows that the MFDI of the second damage of the MD2 damage case was fitted to the noise-eliminated curve with 25% of damage severity. It can be concluded that the magnitude of the second damage of MD2 is 25% of stiffness reduction, and the fitted curve is its noise-eliminated MFDIs, which reveals separately in Fig. 28.

5 Conclusion

This study utilized changes in vibration characteristics to develop and present a comparison between three damage identification techniques for damage locating in steel girder bridges: modal strain energy-based damage index, modal curvature, and modal flexibility methods. These methods' performance and feasibility in damage locating are evaluated through damage detection in a validated FE model of the I-40 Bridge. A couple of single and multiple damage scenarios were applied to the full-scale FE model of the bridge.

In this study, the damage identification indices were calculated and utilized using modal data of only the first three bending mode shapes. For more robust results, it was proposed to calculate damage indices from the modal data of each bending mode shapes at a time and then combined them via a combination method.

Results showed all three damage detection methods were capable and feasible to accurately identify damage locations in single or multiple damage scenarios in the absence of the noise. The MSEDI and MCDI were more sensitive to damages.

The performance of proposed damage detection methods is evaluated under noisy conditions by polluting modal data with random noise. Results demonstrated that the MSEDI and MCDI were not capable of damage locating in the presence of noise due to their high sensitivity to changes in modal data. Both techniques also utilized numerical methods to calculate modal curvature, which makes them more susceptible to errors.

However, results showed that the modal flexibility damage index method was the most robust damage identification method even in the presence of 5% and 10% random noise in modal data.

Since only the MFDI method could detect damage in noise, the MFDI method and the ANN were utilized to eliminate noise and estimate the magnitude of damage.

For a single damage scenario, 20% of stiffness reduction at the 93.6 m of the second girder in the presence of 18% of noise was selected. Using the proposed method, the magnitude of the damage was correctly estimated, and the noise was canceled successfully.

In multiple damage scenario, 20% of damage at 117.5 m of the first girder and 25% of damage at 77.2 m of the second girder were selected simultaneously in the presence of 22% noise. Using the proposed method, the severity of each damage was quantified adequately, and the noise was eliminated reliably.

Overall, this study's findings showed that the modal flexibility damage index method was more reliable for damage locating by using the modal data of only the first three bending mode shapes and with the presence of noise. The results also demonstrated the proposed method's accuracy and feasibility for canceling noise and estimating damage severity in steel girder bridges [41, 80, 81].

References

Beskhyroun, S., Oshima, T., Mikami, S.: Wavelet-based technique for structural damage detection. Struct. Control Health Monit. 17(5), 473–494 (2010)

Li, J., Dackermann, U., Xu, Y.L., Samali, B.: Damage identification in civil engineering structures utilizing PCA-compressed residual frequency response functions and neural network ensembles. Struct. Control Health Monit. 18(2), 207–226 (2011)

Beskhyroun, S., Wegner, L.D., Sparling, B.F.: New methodology for the application of vibration-based damage detection techniques. Struct. Control Health Monit. 19(8), 632–649 (2012)

Eftekhar Azam, S., Rageh, A., Linzell, D.: Damage detection in structural systems utilizing artificial neural networks and proper orthogonal decomposition. Struct. Control Health Monit. 26(2), e2288 (2019)

Wang, Y., Thambiratnam, D.P., Chan, T., Nguyen, A.: Damage detection in asymmetric buildings using vibration-based techniques. Struct. Control Health Monit. 25(5), e2148 (2018)

Rahai, A., Bakhtiari-Nejad, F., Esfandiari, A.: Damage assessment of structure using incomplete measured mode shapes. Struct. Control Health Monit. 14(5), 808–829 (2007)

OBrien, E.J., Malekjafarian, A.: A mode shape-based damage detection approach using laser measurement from a vehicle crossing a simply supported bridge. Struct. Control Health Monit. 23(10), 1273–1286 (2016)

Nguyen, K.-D., Chan, T.H., Thambiratnam, D.P.: Structural damage identification based on change in geometric modal strain energy–eigenvalue ratio. Smart Mater. Struct. 25(7), 075032 (2016)

Le, N.T., Thambiratnam, D., Nguyen, A., Chan, T.H.: A new method for locating and quantifying damage in beams from static deflection changes. Eng. Struct. 180, 779–792 (2019)

Fan, W., Qiao, P.: Vibration-based damage identification methods: a review and comparative study. Struct. Health Monit. 10(1), 83–111 (2011)

Rucevskis, S., Janeliukstis, R., Akishin, P., Chate, A.: Mode shape-based damage detection in plate structure without baseline data. Struct. Control Health Monit. 23(9), 1180–1193 (2016)

Kim, J.-T., Ryu, Y.-S., Cho, H.-M., Stubbs, N.: Damage identification in beam-type structures: frequency-based method vs mode-shape-based method. Eng. Struct. 25(1), 57–67 (2003)

Ooijevaar, T., Loendersloot, R., Warnet, L., de Boer, A., Akkerman, R.: Vibration based Structural Health Monitoring of a composite T-beam. Compos. Struct. 92(9), 2007–2015 (2010)

Pandey, A.K., Biswas, M.: Experimental verification of flexibility difference method for locating damage in structures. J. Sound Vib. 184(2), 311–328 (1995)

Raghuprasad, B., Lakshmanan, N., Gopalakrishnan, N., Sathishkumar, K., Sreekala, R.: Damage identification of beam-like structures with contiguous and distributed damage. Struct. Control Health Monit. 20(4), 496–519 (2013)

Sung, S.H., Koo, K.Y., Jung, H.J.: Modal flexibility-based damage detection of cantilever beam-type structures using baseline modification. J. Sound Vib. 333(18), 4123–4138 (2014)

Cornwell, P., Doebling, S.W., Farrar, C.R.: Application of the strain energy damage detection method to plate-like structures. J. Sound Vib. 224(2), 359–374 (1999)

Shih, H.W., Thambiratnam, D.P., Chan, T.H.: Vibration based structural damage detection in flexural members using multi-criteria approach. J. Sound Vib. 323(3–5), 645–661 (2009)

Magalhães, F., Cunha, A., Caetano, E.: Vibration based structural health monitoring of an arch bridge: from automated OMA to damage detection. Mech. Syst. Signal Process. 28, 212–228 (2012)

Kim, J.-T., Park, J.-H., Lee, B.-J.: Vibration-based damage monitoring in model plate-girder bridges under uncertain temperature conditions. Eng. Struct. 29(7), 1354–1365 (2007)

Teughels, A., De Roeck, G.: Structural damage identification of the highway bridge Z24 by FE model updating. J. Sound Vib. 278(3), 589–610 (2004)

Koto, Y., Konishi, T., Sekiya, H., Miki, C.: Monitoring local damage due to fatigue in plate girder bridge. J. Sound Vib. 438, 238–250 (2019)

Huth, O., Feltrin, G., Maeck, J., Kilic, N., Motavalli, M.: Damage identification using modal data: Experiences on a prestressed concrete bridge. J. Struct. Eng. 131(12), 1898–1910 (2005)

Caicedo, J.M., Dyke, S.J.: Experimental validation of structural health monitoring for flexible bridge structures. Struct. Control Health Monit. 12(3–4), 425–443 (2005)

Xiong, W., Kong, B., Tang, P., Ye, J.: Vibration-based identification for the presence of scouring of cable-stayed bridges. J. Aerospace Eng. 31(2), 04018007 (2018)

Kopsaftopoulos, F., Fassois, S.: Vibration based health monitoring for a lightweight truss structure: experimental assessment of several statistical time series methods. Mech. Syst. Signal Process. 24(7), 1977–1997 (2010)

Montazer, M., Seyedpoor, S.M.: A new flexibility based damage index for damage detection of truss structures. Shock Vib. 1, 12 (2014)

Stubbs, N., Kim, J.-T., & Farrar, C. (1995). Field verification of a nondestructive damage localization and severity estimation algorithm. Paper presented at the Proceedings-SPIE the international society for optical engineering.

Stubbs, N., Kim, J.-T.: Damage localization in structures without baseline modal parameters. AIAA J. 34(8), 1644–1649 (1996)

Kim, J.-T., Stubbs, N.: Improved damage identification method based on modal information. J. Sound Vib. 252(2), 223–238 (2002)

Park, S., Stubbs, N., Bolton, R., Choi, S., Sikorsky, C.: Field verification of the damage index method in a concrete box-girder bridge via visual inspection. Comput.-Aided Civil Infrastruct. Eng. 16(1), 58–70 (2001)

Samali, B., Li, J., Choi, F., Crews, K.: Application of the damage index method for plate-like structures to timber bridges. Struct. Control Health Monit. 17(8), 849–871 (2010)

Bagchi, A., Humar, J., Xu, H., Noman, A.S.: Model-based damage identification in a continuous bridge using vibration data. J. Perform. Construct. Facil. 24(2), 148–158 (2010)

Wahalathantri, B.L., Thambiratnam, D.P., Chan, T.H., Fawzia, S.: Vibration based baseline updating method to localize crack formation and propagation in reinforced concrete members. J. Sound Vib. 344, 258–276 (2015)

Eraky, A., Anwar, A.M., Saad, A., Abdo, A.: Damage detection of flexural structural systems using damage index method–experimental approach. Alex. Eng. J. 54(3), 497–507 (2015)

Tan, Z., Thambiratnam, D., Chan, T., Razak, H.A.: Detecting damage in steel beams using modal strain energy based damage index and Artificial Neural Network. Eng. Failure Anal. 79, 253–262 (2017)

Pandey, A.K., Biswas, M.: Damage detection in structures using changes in flexibility. J. Sound Vib. 169(1), 3–17 (1994)

Toksoy, T., Aktan, A.E.: Bridge-condition assessment by modal flexibility. Exp. Mech. 34(3), 271–278 (1994)

Gao, Y., Spencer, B.F.: Damage localization under ambient vibration using changes in flexibility. Earthq. Eng. Eng. Vib. 1(1), 136–144 (2002)

Patjawit, A., Kanok-Nukulchai, W.: Health monitoring of highway bridges based on a Global Flexibility Index. Eng. Struct. 27(9), 1385–1391 (2005)

Yan, A., Golinval, J.C.: Structural damage localization by combining flexibility and stiffness methods. Eng. Struct. 27(12), 1752–1761 (2005)

Catbas, F.N., Brown, D.L., Aktan, A.E.: Use of modal flexibility for damage detection and condition assessment: case studies and demonstrations on large structures. J. Struct. Eng. 132(11), 1699–1712 (2006)

Catbas, F.N., Gul, M., Burkett, J.L.: Damage assessment using flexibility and flexibility-based curvature for structural health monitoring. Smart Mater. Struct. 17(1), 015024 (2007)

Ni, Y.Q., Zhou, H.F., Chan, K.C., Ko, J.M.: Modal flexibility analysis of cable-stayed Ting Kau Bridge for damage identification. Comput.-Aided Civil Infrastruct. Eng. 23(3), 223–236 (2008)

Moragaspitiya, H.P., Thambiratnam, D.P., Perera, N.J., Chan, T.H.: Development of a vibration based method to update axial shortening of vertical load bearing elements in reinforced concrete buildings. Eng. Struct. 46, 49–61 (2013)

Yang, T., Li, J., Du, Y.: Delamination detection in composite structures based on modal flexibility curvature. J. Reinf. Plast. Compos. 35(10), 853–863 (2016)

Wickramasinghe, W.R., Thambiratnam, D.P., Chan, T.H., Nguyen, T.: Vibration characteristics and damage detection in a suspension bridge. J. Sound Vib. 375, 254–274 (2016)

Pandey, A.K., Biswas, M., Samman, M.M.: Damage detection from changes in curvature mode shapes. J. Sound Vib. 145(2), 321–332 (1991)

Wahab, M.A., De Roeck, G.: Damage detection in bridges using modal curvatures: application to a real damage scenario. J. Sound Vib. 226(2), 217–235 (1999)

Dutta, A., Talukdar, S.: Damage detection in bridges using accurate modal parameters. Finite Elements Anal. Des. 40(3), 287–304 (2004)

Zhang, J., Peng, H., You, C.H., Deng, Y.L., Zhang, H.Y.: Damage detection of plane member structures based on modal curvature difference method. Adv. Mater. Res. 163, 2848–2851 (2011)

Shiradhonkar, S.R., Shrikhande, M.: Seismic damage detection in a building frame via finite element model updating. Comput. Struct. 89(23–24), 2425–2438 (2011)

Dawari, V.B., Vesmawala, G.R.: Structural damage identification using modal curvature differences. IOSR J. Mech. Civil Eng. 4, 33–38 (2013)

Cao, M., Radzieński, M., Xu, W., Ostachowicz, W.: Identification of multiple damage in beams based on robust curvature mode shapes. Mech. Syst. Signal Process. 46(2), 468–480 (2014)

Dessi, D., Camerlengo, G.: Damage identification techniques via modal curvature analysis: overview and comparison. Mech. Syst. Signal Process. 52, 181–205 (2015)

Ciambella, J., Vestroni, F.: The use of modal curvatures for damage localization in beam-type structures. J. Sound Vib. 340, 126–137 (2015)

Ciambella, J., Pau, A., Vestroni, F.: Modal curvature-based damage localization in weakly damaged continuous beams. Mech. Syst. Signal Process. 121, 171–182 (2019)

Farrar, C.R., Jauregui, D.A.: Comparative study of damage identification algorithms applied to a bridge: I. Experiment. Smart Mater. Struct. 7(5), 704 (1998)

Farrar, C.R., Jauregui, D.A.: Comparative study of damage identification algorithms applied to a bridge: II. Numerical study. Smart Mater. Struct. 7(5), 720 (1998)

Doebling, S. W., Farrar, C. R., Prime, M. B., & Shevitz, D. W. (1996). Damage identification and health monitoring of structural and mechanical systems from changes in their vibration characteristics: a literature review (No. LA-13070-MS). Los Alamos National Lab., NM (United States).

Alvandi, A., Cremona, C.: Assessment of vibration-based damage identification techniques. J. Sound Vib. 292(1–2), 179–202 (2006)

Choi, F.C., Li, J., Samali, B., Crews, K.: Application of the modified damage index method to timber beams. Eng. Struct. 30(4), 1124–1145 (2008)

Zhou, Z., Wegner, L.D., Sparling, B.F.: Vibration-based detection of small-scale damage on a bridge deck. J. Struct. Eng. 133(9), 1257–1267 (2007)

Cruz, P.J., Salgado, R.: Performance of vibration-based damage detection methods in bridges. Comput.-Aided Civil Infrastruct. Eng. 24(1), 62–79 (2009)

Altunışık, A.C., Okur, F.Y., Karaca, S., Kahya, V.: Vibration-based damage detection in beam structures with multiple cracks: modal curvature vs. modal flexibility methods. Nondestruct. Test. Eval. 34(1), 33–53 (2019)

Shih, H., Thambiratnam, D., Chan, T.: Damage detection in slab-on-girder bridges using vibration characteristics. Struct. Control Health Monit. 20(10), 1271–1290 (2013)

Jayasundara, N., Thambiratnam, D., Chan, T., Nguyen, A.: Vibration-based dual-criteria approach for damage detection in arch bridges. Struct. Health Monit. 18(5–6), 2004–2019 (2019)

Shi, Z., Law, S.S., Zhang, L.: Structural damage detection from modal strain energy change. J. Eng. Mech. 126(12), 1216–1223 (2000)

Farrar, C. R., Baker, W. E., Bell, T. M., Cone, K. M., Darling, T. W., Duffey, T. A., ... & Migliori, A. (1994). Dynamic characterization and damage detection in the I-40 bridge over the Rio Grande (No. LA-12767-MS). Los Alamos National Lab., NM (United States).

Yin, T., Jiang, Q.H., Yuen, K.V.: Vibration-based damage detection for structural connections using incomplete modal data by Bayesian approach and model reduction technique. Eng. Struct. 132, 260–277 (2017)

Baneen, U., Kinkaid, N.M., Guivant, J.E., Herszberg, I.: Vibration based damage detection of a beam-type structure using noise suppression method. J. Sound Vib. 331(8), 1777–1788 (2012)

Kostić, B., Gül, M.: Vibration-based damage detection of bridges under varying temperature effects using time-series analysis and artificial neural networks. J. Bridge Eng. 22(10), 04017065 (2017)

Paral, A., Roy, D.K.S., Samanta, A.K.: Application of a mode shape derivative-based damage index in artificial neural network for structural damage identification in shear frame building. J. Civil Struct. Health Monit. 9(3), 411–423 (2019)

Weinstein, J.C., Sanayei, M., Brenner, B.R.: Bridge damage identification using artificial neural networks. J. Bridge Eng. 23(11), 04018084 (2018)

Jin, C., Jang, S., Sun, X., Li, J., Christenson, R.: Damage detection of a highway bridge under severe temperature changes using extended Kalman filter trained neural network. J. Civil Struct. Health Monit. 6(3), 545–560 (2016)

Tan, Z.X., Thambiratnam, D.P., Chan, T.H., Gordan, M., Abdul Razak, H.: Damage detection in steel-concrete composite bridge using vibration characteristics and artificial neural network. Struct. Infrastruct. Eng. 16, 1247–1261 (2019)

Rafiei, M.H., Adeli, H.: A novel machine learning-based algorithm to detect damage in high-rise building structures. Struct. Des. Tall Special Build. 26(18), e1400 (2017)

Kim, H.S., Chun, Y.S.: Structural damage assessment of building structures using dynamic experimental data. Struct. Design Tall Special Build. 13(1), 1–8 (2004)

Vahedi, M., Khoshnoudian, F., Hsu, T.Y., Partovi Mehr, N.: Transfer function-based Bayesian damage detection under seismic excitation. Struct. Des. Tall Special Build. 28(12), e1619 (2019)

MATLAB: 9.7.0.713579 (R2017b). The MathWorks Inc., Natick, Massachusetts (2017)

ABAQUS: User’s Manual, Version 6.14–1, 224 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nick, H., Aziminejad, A. Vibration-Based Damage Identification in Steel Girder Bridges Using Artificial Neural Network Under Noisy Conditions. J Nondestruct Eval 40, 15 (2021). https://doi.org/10.1007/s10921-020-00744-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-020-00744-8