Abstract

The 2020 decadal review recognized the measurement of the polarization of the cosmic microwave background (CMB) to be a top priority for the decade. CMB experiments including POLARBEAR2/Simons Array, Atacama Cosmology Telescope/Advanced-ACT, SPT-3G, the Simons Observatory, and CMB-S4 have or will use transition edge sensor (TES) bolometer fabricated with Aluminum doped with Manganese (AlMn). AlMn is a popular material choice as the superconducting transition temperature (\(T_c\)) and normal resistance (\(R_n\)) of the TES can be tuned with Mn concentration, geometric patterning, film thickness, and thermal annealing. In addition the conductivity is appropriate for both time division multiplexing and frequency division multiplexing that require 10 m\(\Omega\) and 1 \(\Omega\) sensors respectively. In this paper we present work on the ability to tune the \(T_c\) of a film based on its time and temperature thermal tuning profile combined with room temperature monitoring of film resistivity. Such control allows for the fabrication of a wide range of TES parameters from a single AlMn concentration. Scanning electron microscope (SEM) imaging shows that the AlMn film’s grain boundaries are changed by thermal annealing making the film more conductive and raising its superconducting transition temperatures, and that at high enough temperatures will eventually recover the \(T_c\) of bulk Al. We find that baking films at \(\sim\)200 \(^\circ\text{C}\) for tens of minutes yields a \(T_c\) that is suitable for 100 mK base temperature experiments and we present on the thermal tune profiles of several different thicknesses of AlMn.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Transition edge sensors (TESs) have been the preferred type of low temperature detector for cosmic microwave background (CMB) experiments for over a decade for three primary reasons [1,2,3,4,5]. First, the sensitivity of most CMB TESs is well below the background noise levels from the background of photons in the telescope. Secondly, they are lithographically fabricated on 150 mm silicon wafers, which provides excellent uniformity across a given detector array with \(\sim\) 1000 TESs. Finally, the normal resistance of the TES are compatible with multiple types of cyrogenic multiplexing making this technology scalable to experiments with many tens to hundreds of thousands of detectors [4, 5].

When constructing a TES bolometer the following design choices must be satisfied: (1) most of the TESs have the desired critical superconducting transition temperature (\(T_c\)) within a specified range, (2) the TES must have the appropriate normal resistance (\(R_n\)) both above \(T_c\) and in operation, (3) the properties of the TESs (\(T_c\) and \(R_n\)) are uniform across the wafer, and (4) the TESs properties do not vary from wafer to wafer across multiple fabrication runs. Aluminum doped with Manganese (AlMn) has emerged as top candidate for the production of TES bolometer arrays for CMB polarization experiments [2,3,4,5,6,7]. Deposition of AlMn is typically performed using state of the art sputter deposition equipment kept under consistently high vacuum providing natural solutions to criteria (3) and (4). [8, 9] The manganese concentration is typically just a few tenths of a percent (either by weight or atomic percentage) and these films have resistivities very close to that of aluminum. In our work, we present TESs films that have normal and operational resistances ranging from 6 m\(\Omega\) to 1.2 \(\Omega\), which are appropriate for time domain multiplexing, microwave squid multiplexing, and frequency domain multiplexing [3, 4, 6] which is a solution to criteria (2). Most importantly, we discuss the ability to tune the \(T_c\) of a AlMn film to the specification of a given experiment. The \(T_c\) of AlMn films depends on many things including but not limited to: manganese concentration, film thickness, thermal annealing temperature (\(T_{anneal}\)), thermal annealing time (\(t_{anneal}\)), and device geometry. We present our recent work on tuning AlMn films and the methods we use to modulate the \(T_c\) and \(R_n\) of a TES for all types of modern CMB polarization experiments.

2 Methodology

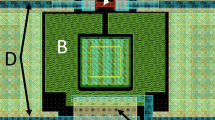

In this work, we fabricated and tested two types of devices: (1) singulated dice coated with unpatterned films of thin aluminum manganese and (2) patterned TES with niobium leads (see Fig. 1). The bare films are DC magnetron sputtered coated on to silicon substrates coated with an insulating layer of silicon nitride after an RF sputter-etch cleaning processes. These films are useful for both singulating into dice for cryogenic electrical characterization or kept as whole wafers as ‘witnesses’ to fully patterned TESs.

By contrast, the patterned TESs are constructed by sputter- depositing a layer of AlMn and then patterning the desired base geometry of the TES into the film. A passivating layer of silicon nitride is patterned to overlap the AlMn protecting most of the surface but leaving the AlMn edges exposed for contact with an overlapping layer of niobium leads. The interface of the AlMn, the silicon nitride passivation layer, and Niobium combined together define the geometry of the TES as shown in Fig. 1. Note that every time we process a device wafer with patterned TESs we have a corresponding bare film ‘witness’ wafer to accompany the patterned wafer in future thermal annealing steps. The resisitivity (\(R_s\)) of the wafer is measured as function of thermal annealing to compare against the \(T_c\) and \(R_n\) data coming from the patterned TESs.

A diagram of the TES construction stack used in this work. The three left panel have top and cross sectional views. The number of squares (\(\square\)) in the TES is defined by width (W) of the passivation layer, the height (H) of the AlMn panel as shown in the third panel. The thickness (t) of the TES plays a role in the final \(T_c\) and \(R_n\) of the device. A photograph of a completed TES is found in the right most panel

3 Phenomenology

In this work, we offer some insight into what is occurring in the bulk of the film, especially, at the grain boundaries that causes the changes to the normal resistance and superconducting transition temperature that we see which are shown in Table 1. We looked at physical effects of thermal tuning directly using a scanning electron microscope (SEM) as shown in Fig. 2. The most notable difference we find before and after thermal annealing is the softening of the grain boundaries in the film. These changes to the grain boundaries make the AlMn behave more and more like bulk Al as the effect of the Mn on the Al is reduces with further thermal annealing.

Left: A SEM image of the grain boundaries on un-annealed film. Right: A SEM image of the AlMn grain boundaries of a film on a sister die from the same wafer annealed to 250\(^\circ\) C for 30 min. We observe a softening of the grain boundaries in the annealed sample, which is consistent with other phenomenology and literature [8, 10]

4 Parameter Tuning

Ultimately one must be able to fabricate a TES according to the design specifications of a planned experiment. In this section we discuss both the tuning of the \(R_n\) and \(T_c\).

4.1 Normal Resistance

In this work, we focused on developing TESs with normal resistance of a \(\sim\)10 m\(\Omega\) for time division multiplexing (TDM) and microwave SQUID mutliplexing, and 1 \(\Omega\) for frequency division multiplexing (FDM). UCB has a strong heritage developing 1 \(\Omega\) sensors for FDM for POLARBEAR-1, the Simons Array and NIST has a strong heritage developing 10 m\(\Omega\) sensors for ACT, Advanced-ACT, SPIDER, and Simons Observatory [2, 6, 11, 12]. The \(R_n\) tuning is achieved by combining thickness (4000 Å vs 800 Å) and TES geometry (0.2 vs 1.8 \(\square\)) which is shown in Table 2 and Fig. 3.

Five different R vs Temperature curves for different dual TES designs. The transition depends quite strongly proximity effect which is controlled with the spacing of the Niobium leads. This effect makes fabricating TESs with a wide range of both \(T_c\) and \(R_n\) with a single AlMn thickness possible

4.2 Superconducting Transition Temperature

To understand this parameter space we took two primary approaches: (1) to explore the effect of annealing temperature and time vs \(T_c\) and (2) to explore the effect of using Nb to proximitize the TES with a higher transition temperature materials. For a constant anneal time (\(t_{anneal}\)), the \(T_c\) of a AlMn TES will increase with temperature. We generally find monotonic increase with bake temperature, while form a hockey stick shaped curve with a slow rising portion, a ‘knee’, and then a fast rising portion of the curve as shown in Fig. 4. Once a baking temperature is fixed and only the time is increased we find the \(T_c\) continues to monotonically increase but a diminishing rate. We have developed a strategy to walk up the temperature in 10 min increments until we can measure a \(T_c\) above the base temperature of our dilution refrigerator (\(\sim\)20 mK). At this point one can calculate the slope of that tuning rate and use the pseudo-linear annealing time vs \(T_c\) to dial in the desired \(T_c\) (see Fig. 4).

Top: \(T_c\) vs \(T_{anneal}\) (left) and \(T_c\) vs \(t_{anneal}\) (right) and for bare films of AlMn singulated into dice. Bottom Left: The same dual transition TES tested twice with a thermal anneal between cryogenic runs. The \(T_c\) increases and the \(R_n\) decreases in both transition as expected. Bottom Right: \(R_s\) of a witness wafer that was co-thermally annealed alongside the TESs measured in the dilution refrigerator at UC Berkeley

5 Conclusion

We presented the general framework to use sputter deposited AlMn to build TESs appropriate for modern CMB experiments. While, a large number of variable can affect the final operating resistance and transition temperature of the TES, we present a method to reduce the process to TES geometry and TES thermal tuning using both time and temperature as a control of \(T_c\). In addition, we showed that a dual transition can be constructed using a single layer of AlMn using the niobium leads and TES geometry to create two distinct transitions in the TES. This is particularly useful to use the same TES to characterize the overall pixel performance in the laboratory before deployment for observations.

References

J.A. Sobrin, A.J. Anderson, A.N. Bender, B.A. Benson, D. Dutcher, A. Foster, N. Goeckner-Wald, J. Montgomery, A. Nadolski, A. Rahlin, P.A.R. Ade, Z. Ahmed, E. Anderes, M. Archipley, J.E. Austermann, J.S. Avva, K. Aylor, L. Balkenhol, P.S. Barry, R.B. Thakur, K. Benabed, F. Bianchini, L.E. Bleem, F.R. Bouchet, L. Bryant, K. Byrum, J.E. Carlstrom, F.W. Carter, T.W. Cecil, C.L. Chang, P. Chaubal, G. Chen, H.-M. Cho, T.-L. Chou, J.-F. Cliche, T.M. Crawford, A. Cukierman, C. Daley, T. de Haan, E.V. Denison, K. Dibert, J. Ding, M.A. Dobbs, W. Everett, C. Feng, K.R. Ferguson, J. Fu, S. Galli, A.E. Gambrel, R.W. Gardner, R. Gualtieri, S. Guns, N. Gupta, R. Guyser, N.W. Halverson, A.H. Harke-Hosemann, N.L. Harrington, J.W. Henning, G.C. Hilton, E. Hivon, G.P. Holder, W.L. Holzapfel, J.C. Hood, D. Howe, N. Huang, K.D. Irwin, O.B. Jeong, M. Jonas, A. Jones, T.S. Khaire, L. Knox, A.M. Kofman, M. Korman, D.L. Kubik, S. Kuhlmann, C.-L. Kuo, A.T. Lee, E.M. Leitch, A.E. Lowitz, C. Lu, S.S. Meyer, D. Michalik, M. Millea, T. Natoli, H. Nguyen, G.I. Noble, V. Novosad, Y. Omori, S. Padin, Z. Pan, P. Paschos, J. Pearson, C.M. Posada, K. Prabhu, W. Quan, C.L. Reichardt, D. Riebel, B. Riedel, M. Rouble, J.E. Ruhl, B. Saliwanchik, J.T. Sayre, E. Schiappucci, E. Shirokoff, G. Smecher, A.A. Stark, J. Stephen, K.T. Story, A. Suzuki, C. Tandoi, K.L. Thompson, B. Thorne, C. Tucker, C. Umilta, L.R. Vale, K. Vanderlinde, J.D. Vieira, G. Wang, N. Whitehorn, W.L.K. Wu, V. Yefremenko, K.W. Yoon, M.R. Young, The Design and Integrated Performance of SPT-3G. Aapjs 258(2), 42 (2022). https://doi.org/10.3847/1538-4365/ac374f. arXiv:2106.11202 [astro-ph.IM]

BICEP2 Collaboration, Keck Array Collaboration, SPIDER Collaboration, Ade, P.A.R., Aikin, R.W., Amiri, M., Barkats, D., Benton, S.J., Bischoff, C.A., Bock, J.J., Bonetti, J.A., Brevik, J.A., Buder, I., Bullock, E., Chattopadhyay, G., Davis, G., Day, P.K., Dowell, C.D., Duband, L., Filippini, J.P., Fliescher, S., Golwala, S.R., Halpern, M., Hasselfield, M., Hildebrandt, S.R., Hilton, G.C., Hristov, V., Hui, H., Irwin, K.D., Jones, W.C., Karkare, K.S., Kaufman, J.P., Keating, B.G., Kefeli, S., Kernasovskiy, S.A., Kovac, J.M., Kuo, C.L., LeDuc, H.G., Leitch, E.M., Llombart, N., Lueker, M., Mason, P., Megerian, K., Moncelsi, L., Netterfield, C.B., Nguyen, H.T., O’Brient, R., Ogburn, I. R. W., Orlando, A., Pryke, C., Rahlin, A.S., Reintsema, C.D., Richter, S., Runyan, M.C., Schwarz, R., Sheehy, C.D., Staniszewski, Z.K., Sudiwala, R.V., Teply, G.P., Tolan, J.E., Trangsrud, A., Tucker, R.S., Turner, A.D., Vieregg, A.G., Weber, A., Wiebe, D.V., Wilson, P., Wong, C.L., Yoon, K.W., Zmuidzinas, J.: Antenna-coupled TES Bolometers Used in BICEP2, Keck Array, and Spider. Apj 812(2), 176 (2015) https://doi.org/10.1088/0004-637X/812/2/176arXiv:1502.00619 [astro-ph.IM]

...A. Suzuki, P. Ade, Y. Akiba, C. Aleman, K. Arnold, C. Baccigalupi, B. Barch, D. Barron, A. Bender, D. Boettger, J. Borrill, S. Chapman, Y. Chinone, A. Cukierman, M. Dobbs, A. Ducout, R. Dunner, T. Elleflot, J. Errard, G. Fabbian, S. Feeney, C. Feng, T. Fujino, G. Fuller, A. Gilbert, N. Goeckner-Wald, J. Groh, T.D. Haan, G. Hall, N. Halverson, T. Hamada, M. Hasegawa, K. Hattori, M. Hazumi, C. Hill, W. Holzapfel, Y. Hori, L. Howe, Y. Inoue, F. Irie, G. Jaehnig, A. Jaffe, O. Jeong, N. Katayama, J. Kaufman, K. Kazemzadeh, B. Keating, Z. Kermish, R. Keskitalo, T. Kisner, A. Kusaka, M.L. Jeune, A. Lee, D. Leon, E. Linder, L. Lowry, F. Matsuda, T. Matsumura, N. Miller, K. Mizukami, J. Montgomery, M. Navaroli, H. Nishino, J. Peloton, D. Poletti, G. Puglisi, G. Rebeiz, C. Raum, C. Reichardt, P. Richards, C. Ross, K. Rotermund, Y. Segawa, B. Sherwin, I. Shirley, P. Siritanasak, N. Stebor, R. Stompor, J. Suzuki, O. Tajima, S. Takada, S. Takakura, S. Takatori, A. Tikhomirov, T. Tomaru, B. Westbrook, N. Whitehorn, T. Yamashita, A. Zahn, O. Zahn, The polarbear-2 and the simons array experiments. J. Low Temp. Phys. 184(3–4), 805–810 (2016). https://doi.org/10.1007/s10909-015-1425-4

Galitzki, N., Baildon, T., Barron, D., Lashner, J., Lee, A.T., Li, Y., Limon, M., Lungu, M., Matsuda, F., Mauskopf, P.D., May, A.J., McCallum, N., McMahon, J., Nati, F., Niemack, M.D., Orlowski-Scherer, J.L., Parshley, S.C., Piccirillo, L., Rao, M.S., Salatino, M., Seibert, J.S., Sierra, C., Silva-Feaver, M., Simon, S.M., Staggs, S.T., Stevens, J.R., Suzuki, A., Teply, G., Thornton, R., Tsai, C., Ullom, J.N., Vavagiakis, E.M., Vissers, M.R., Westbrook, B., Wollack, E.J., Xu, Z., Zhu, N., Raum, C., Beckman, S., Jeong, O., Ali, A., Arnold, K.S., Ashton, P.C., Austermann, J.E., Baccigalupi, C., Beall, J.A., Bruno, S.M.M., Bryan, S., Calisse, P.G., Chesmore, G.E., Chinone, Y., Choi, S.K., Coppi, G., Crowley, K.D., Crowley, K.T., Cukierman, A., Devlin, M.J., Dicker, S., Dober, B., Duff, S.M., Dunkley, J., Fabbian, G., Gallardo, P.A., Gerbino, M., Goeckner-Wald, N., Golec, J.E., Gudmundsson, J., Healy, E.E., Henderson, S., Hill, C.A., Hilton, G.C., Ho, S.-P.P., Howe, L.A., Hubmayr, J., Keating, B., Koopman, B.J., Kuichi, K., Kusaka, A.: The simons observatory: instrument overview. In: Zmuidzinas, J., Gao, J.-R. (eds.) Millimeter, Submillimeter, and Far-Infrared Detectors and Instrumentation for Astronomy IX. SPIE, ??? (2018). https://doi.org/10.1117/12.2312985

Abazajian, K., Abdulghafour, A., Addison, G.E., Adshead, P., Ahmed, Z., Ajello, M., Akerib, D., Allen, S.W., Alonso, D., Alvarez, M., Amin, M.A., Amiri, M., Anderson, A., Ansarinejad, B., Archipley, M., Arnold, K.S., Ashby, M., Aung, H., Baccigalupi, C., Baker, C., Bakshi, A., Bard, D., Barkats, D., Barron, D., Barry, P.S., Bartlett, J.G., Barton, P., Basu Thakur, R., Battaglia, N., Beall, J., Bean, R., Beck, D., Belkner, S., Benabed, K., Bender, A.N., Benson, B.A., Besuner, B., Bethermin, M., Bhimani, S., Bianchini, F., Biquard, S., Birdwell, I., Bischoff, C.A., Bleem, L., Bocaz, P., Bock, J.J., Bocquet, S., Boddy, K.K., Bond, J.R., Borrill, J., Bouchet, F.R., Brinckmann, T., Brown, M.L., Bryan, S., Buza, V., Byrum, K., Calabrese, E., Calafut, V., Caldwell, R., Carlstrom, J.E., Carron, J., Cecil, T., Challinor, A., Chan, V., Chang, C.L., Chapman, S., Charles, E., Chauvin, E., Cheng, C., Chesmore, G., Cheung, K., Chinone, Y., Chluba, J., Cho, H.-M.S., Choi, S., Clancy, J., Clark, S., Cooray, A., Coppi, G., Corlett, J., Coulton, W., Crawford, T.M., Crites, A., Cukierman, A., Cyr-Racine, F.-Y., Dai, W.-M., Daley, C., Dart, E., Daues, G., de Haan, T., Deaconu, C., Delabrouille, J., Derylo, G., Devlin, M., Di Valentino, E., Dierickx, M., Dober, B., Doriese, R., Duff, S., Dutcher, D., Dvorkin, C., Dünner, R., Eftekhari, T., Eimer, J., El Bouhargani, H., Elleflot, T., Emerson, N., Errard, J., Essinger-Hileman, T., Fabbian, G., Fanfani, V., Fasano, A., Feng, C., Ferraro, S., Filippini, J.P., Flauger, R., Flaugher, B., Fraisse, A.A., Frisch, J., Frolov, A., Galitzki, N., Gallardo, P.A., Galli, S., Ganga, K., Gerbino, M., Giannakopoulos, C., Gilchriese, M., Gluscevic, V., Goeckner-Wald, N., Goldfinger, D., Green, D., Grimes, P., Grin, D., Grohs, E., Gualtieri, R., Guarino, V., Gudmundsson, J.E., Gullett, I., Guns, S., Habib, S., Haller, G., Halpern, M., Halverson, N.W., Hanany, S., Hand, E., Harrington, K., Hasegawa, M., Hasselfield, M., Hazumi, M., Heitmann, K., Henderson, S., Hensley, B., Herbst, R., Hervias-Caimapo, C., Hill, J.C., Hills, R., Hivon, E., Hlozek, R., Ho, A., Holder, G., Hollister, M., Holzapfel, W., Hood, J., Hotinli, S., Hryciuk, A., Hubmayr, J., Huffenberger, K.M., Hui, H., Ibá nez, R., Ibitoye, A., Ikape, M., Irwin, K., Jacobus, C., Jeong, O., Johnson, B.R., Johnstone, D., Jones, W.C., Joseph, J., Jost, B., Kang, J.H., Kaplan, A., Karkare, K.S., Katayama, N., Keskitalo, R., King, C., Kisner, T., Klein, M., Knox, L., Koopman, B.J., Kosowsky, A., Kovac, J., Kovetz, E.D., Krolewski, A., Kubik, D., Kuhlmann, S., Kuo, C.-L., Kusaka, A., Lähteenmäki, A., Lau, K., Lawrence, C.R., Lee, A.T., Legrand, L., Leitner, M., Leloup, C., Lewis, A., Li, D., Linder, E., Liodakis, I., Liu, J., Long, K., Louis, T., Loverde, M., Lowry, L., Lu, C., Lubin, P., Ma, Y.-Z., Maccarone, T., Madhavacheril, M.S., Maldonado, F., Mantz, A., Marques, G., Matsuda, F., Mauskopf, P., May, J., McCarrick, H., McCracken, K., McMahon, J., Meerburg, P.D., Melin, J.-B., Menanteau, F., Meyers, J., Millea, M., Miranda, V., Mitchell, D., Mohr, J., Moncelsi, L., Monzani, M.E., Moshed, M., Mroczkowski, T., Mukherjee, S., Münchmeyer, M., Nagai, D., Nagarajappa, C., Nagy, J., Namikawa, T., Nati, F., Natoli, T., Nerval, S., Newburgh, L., Nguyen, H., Nichols, E., Nicola, A., Niemack, M.D., Nord, B., Norton, T., Novosad, V., O’Brient, R., Omori, Y., Orlando, G., Osherson, B., Osten, R., Padin, S., Paine, S., Partridge, B., Patil, S., Petravick, D., Petroff, M., Pierpaoli, E., Pilleux, M., Pogosian, L., Prabhu, K., Pryke, C., Puglisi, G., Racine, B., Raghunathan, S., Rahlin, A., Raveri, M., Reese, B., Reichardt, C.L., Remazeilles, M., Rizzieri, A., Rocha, G., Roe, N.A., Rotermund, K., Roy, A., Ruhl, J.E., Saba, J., Sailer, N., Salatino, M., Saliwanchik, B., Sapozhnikov, L., Sathyanarayana Rao, M., Saunders, L., Schaan, E., Schillaci, A., Schmitt, B., Scott, D., Sehgal, N., Shandera, S., Sherwin, B.D., Shirokoff, E., Shiu, C., Simon, S.M., Singari, B., Slosar, A., Spergel, D., St. Germaine, T., Staggs, S.T., Stark, A.A., Starkman, G.D., Steinbach, B., Stompor, R., Stoughton, C., Suzuki, A., Tajima, O., Tandoi, C., Teply, G.P., Thayer, G., Thompson, K., Thorne, B., Timbie, P., Tomasi, M., Trendafilova, C., Tristram, M., Tucker, C., Tucker, G., Umiltà, C., van Engelen, A., van Marrewijk, J., Vavagiakis, E.M., Vergès, C., Vieira, J.D., Vieregg, A.G., Wagoner, K., Wallisch, B., Wang, G., Wang, G.-J., Watson, S., Watts, D., Weaver, C., Wenzl, L., Westbrook, B., White, M., Whitehorn, N., Wiedlea, A., Williams, P., Wilson, R., Winch, H., Wollack, E.J., Kimmy Wu, W.L., Xu, Z., Yefremenko, V.G., Yu, C., Zegeye, D., Zivick, J., Zonca, A.: Snowmass 2021 CMB-S4 White Paper. arXiv e-prints, 2203–08024 (2022) https://doi.org/10.48550/arXiv.2203.08024arXiv:2203.08024 [astro-ph.CO]

S.W. Henderson, R. Allison, J. Austermann, T. Baildon, N. Battaglia, J.A. Beall, D. Becker, F. De Bernardis, J.R. Bond, E. Calabrese, S.K. Choi, K.P. Coughlin, K.T. Crowley, R. Datta, M.J. Devlin, S.M. Duff, J. Dunkley, R. Dünner, A. van Engelen, P.A. Gallardo, E. Grace, M. Hasselfield, F. Hills, G.C. Hilton, A.D. Hincks, R. Hloẑek, S.P. Ho, J. Hubmayr, K. Huffenberger, J.P. Hughes, K.D. Irwin, B.J. Koopman, A.B. Kosowsky, D. Li, J. McMahon, C. Munson, F. Nati, L. Newburgh, M.D. Niemack, P. Niraula, L.A. Page, C.G. Pappas, M. Salatino, A. Schillaci, B.L. Schmitt, N. Sehgal, B.D. Sherwin, J.L. Sievers, S.M. Simon, D.N. Spergel, S.T. Staggs, J.R. Stevens, R. Thornton, J. Van Lanen, E.M. Vavagiakis, J.T. Ward, E.J. Wollack, Advanced ACTPol cryogenic detector arrays and readout. J. Low Temp. Phys. 184(3–4), 772–779 (2016). https://doi.org/10.1007/s10909-016-1575-z. arXiv:1510.02809 [astro-ph.IM]

Li, H., Li, S.-Y., Liu, Y., Li, Y.-P., Cai, Y., Li, M., Zhao, G.-B., Liu, C.-Z., Li, Z.-W., Xu, H., Wu, D., Zhang, Y.-J., Fan, Z.-H., Yao, Y.-Q., Kuo, C.-L., Lu, F.-J., Zhang, X.: Probing primordial gravitational waves: Ali CMB polarization telescope. arXiv e-prints, 1710–03047 (2017) https://doi.org/10.48550/arXiv.1710.03047arXiv:1710.03047 [astro-ph.CO]

D. Li, J.E. Austermann, J.A. Beall, D.T. Becker, S.M. Duff, P.A. Gallardo, S.W. Henderson, G.C. Hilton, S.-P. Ho, J. Hubmayr, B.J. Koopman, J.J. McMahon, F. Nati, M.D. Niemack, C.G. Pappas, M. Salatino, B.L. Schmitt, S.M. Simon, S.T. Staggs, J. Van Lanen, J.T. Ward, E.J. Wollack, AlMn transition edge sensors for advanced ACTPol. J. Low Temp. Phys. 184(1–2), 66–73 (2016). https://doi.org/10.1007/s10909-016-1526-8

A. Suzuki, E. Kane, A.T. Lee, T. Liu, C. Raum, M. Renzullo, P. Truitt, J. Vivalda, B. Westbrook, D. Yohannes, Recent developments of commercially fabricated horn antenna-coupled transition-edge sensor bolometer detectors for next-generation cosmic microwave background polarimetry experiments. J. Low Temp. Phys. 209(5–6), 1111–1118 (2022). https://doi.org/10.1007/s10909-022-02731-x

X. Qian, N. Parson, X.-G. Chen, Effects of mn content on recrystallization resistance of aa6082 aluminum alloys during post-deformation annealing. J. Mater. Sci. Technol. 52, 189–197 (2020). https://doi.org/10.1016/j.jmst.2020.04.015

Westbrook, B.e.a.: The POLARBEAR-2 and Simons Array Focal Plane Fabrication Status. J. Low Temp. Phys. 193(5-6), 758–770 (2018) https://doi.org/10.1007/s10909-018-2059-0arXiv:2210.04117 [astro-ph.IM]

Westbrook, B., Raum, C., Beckman, S., Lee, A.T., Farias, N., Sasse, T., Suzuki, A., Kane, E., Austermann, J.E., Beall, J.A., Duff, S.M., Hubmayr, J., Hilton, G.C., Lanen, J.V., Vissers, M.R., Link, M.R., Halverson, N., Jaehnig, G., Ghinga, T., Stever, S., Minami, Y., Thompson, K.L., Russell, M., Arnold, K., Seibert, J., Silva-Feaver, M.: Detector fabrication development for the LiteBIRD satellite mission. In: Lystrup, M., Perrin, M.D., Batalha, N., Siegler, N., Tong, E.C. (eds.) Space Telescopes and Instrumentation 2020: Optical, Infrared, and Millimeter Wave, vol. 11443, p. 114435. SPIE, ??? (2020). https://doi.org/10.1117/12.2562978 . International Society for Optics and Photonics

Acknowledgements

We acknowledge the support from the DOE and NSF for work done by UC Berkeley for the CMB-S4 Detector fabrication working group. This work was performed under intra-university transaction agreement No. 7591532. We also acknowledge support in part by the Simons Foundation Award #457687, B.K.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Westbrook, B., Prasad, B., Raum, C.R. et al. Thermal Annealing of AlMn Transition Edge Sensors for Optimization in Cosmic Microwave Background Experiments. J Low Temp Phys 216, 264–272 (2024). https://doi.org/10.1007/s10909-024-03130-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10909-024-03130-0