Abstract

We present a fabrication method for sub-micron lens-coupled lumped element kinetic inductance detectors (LEKIDs) for broadband sub-millimeter (sub-mm) and THz radiation detection. The LEKIDs are fabricated from very thin (12 nm) and narrow (200 nm) aluminum lines to match the impedance of the LEKID to the substrate impedance. The fabrication process is based on a combination of maskless laserwriter lithography and electron beam lithography, providing low (few microns) and high resolution (down to 200 nm) over large areas in a single process. Preliminary optical characterization shows that the fabricated LEKIDs are sensitive to 1.5 THz radiation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

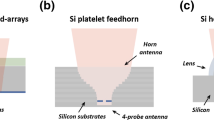

Lumped element kinetic inductance detectors are microwave resonators formed by an inductive meander in combination with an interdigitated capacitor fabricated on a suitable substrate such as high resistivity silicon. Whereas the capacitor is modified from pixel to pixel for frequency multiplexing, the meander is employed as the effective optical absorbing area. Therefore, matching the meander impedance to the impedance of an anti-reflection (AR)-coated substrate material is essential for effective broadband photon absorption [1]. The effective meander impedance is complex and depends on the normal-state sheet resistivity of the superconducting material used and the meander geometry. A high normal-state sheet resistance is convenient for matching the impedance at THz frequencies. Several high normal-state resistance superconducting materials have been proposed; among them, titanium nitride (TiN) has been recently called the attention due to its promising properties [2]. However, an anomalous optical response at 350 GHz in TiN-based micro-resonators resulting in a low absorbing efficiency at very low radiation powers is observed. This anomalous optical response is tentatively attributed to spatial variations of the superconducting energy gap [3]. From these results, an alternative to push LEKIDs detection to higher frequencies at very low powers is required. In this work, we propose the use of very thin (12 nm) and narrow (200 nm wide) Al for the LEKID, a very well-understood BCS superconductor that has already demonstrated very good optical performance [4, 5], coupled to a lens, to obtain broadband coupling from 1.4 to 2.8 THz.

2 Fabrication Process for a Sub-micron Broadband LEKID

In order to use Al to efficiently detect THz radiation, it is necessary to increase its sheet resistance from typical values of 0.45 \(\Omega \) for a 50-nm film [5]. Several Al films are sputtered deposited with thicknesses ranging from 5 to 40 nm, and their sheet resistance (R \(_\mathrm{s})\) and critical temperature (T \(_\mathrm{c})\) are measured (see Fig. 1 top-left). Both T \(_\mathrm{c}\) and R \(_\mathrm{s}\) increase as the thickness of the film decreases. Our design forms a LEKID with broadband absorption from 1.4 to 2.8 THz, using a 12-nm film with a normal-state sheet resistance of 2 Ohm/square [6] for the inductor/absorber and capacitor. The proposed THz radiation absorber of the LEKID consists of a very long (>10 mm) and narrow (200 nm) line of this 12-nm Al film, creating challenging fabrication conditions. The rest of the chip circuitry is made from NbTiN. The advantage of this is that it creates a robust circuit less prone to mechanical damage than the Al film. Additionally it allows the construction of lithographic bridges connecting the ground planes of the through line, which is needed to suppress odd modes that affect the resonator Q factor and enhance resonator cross-coupling. These use a photo-sensitive spin-on polyamide as dielectric support [7]. We start with a 320-nm-thick layer of NbTiN deposited on sapphire using DC magnetron sputtering (first step in Fig.1 bottom). This layer is patterned using photolithography and SF\(_{6}\)/O\(_{2}\) reactive ion etching (second step in Fig.1 bottom) to define the coplanar-waveguide feed line (CPW), ground planes, and alignment marks for electron beam lithography (EBL). A hydrofluoric acid (HF) cleaning is made prior Al deposition to remove possible oxide, which is present on the wafer in order to reduce the two-level system noise and to clean the NbTiN surface.

Top left: sheet resistance (R \(_\mathrm{s}\)—red circles) and critical temperature (T \(_\mathrm{c}\)—blue squares) as a function of the film thickness. Top-right and bottom figures show the designed LEKID and the fabrication flow, respectively. In both figures, green corresponds to the NbTiN that is used to define the CPW, ground planes, and alignment marks and violet represents the thin Al layer, which is used to define the LEKID capacitor by MLL (dark violet) and the absorbing meander by EBL (light violet). (Color figure online)

The thin 12-nm Al layer is then deposited by DC magnetron sputtering (third step in Fig.1 bottom). This layer is used to form the pixels, each of them consisting of a wide capacitor interdigitated fingers and the narrow inductor meander lines (fourth step in Fig.1 bottom). In this work, both the interdigitated capacitor and the meander are defined in a single resist-priming step using a negative resist compatible with a mix & match process that combines maskless laserwriter lithography (MLL) and electron beam lithography (EBL). The MLL is used to define the large interdigitated capacitors (dark violet in Fig.1 top-right), whereas EBL is used to define the narrow lines of the inductor meanders (light violet in Fig.1 top-right). This process overcomes the low throughput of the EBL and allows us to define low- and high-resolution motives over large areas, saving EBL time, i.e., EBL time for each pixel is reduced to 45 s. An overlay resolution below 100 nm is achieved between the EBL and the MLL steps by proper alignment and re-calibration using the previously defined NbTiN aligning marks. The design is transferred from the resist to the Al film by Argon ion milling, which ensures anisotropic etching with the very good directionality needed to define sub-micron lines. The accelerating voltage is set to 500 V to obtain good resist/Al selectivity. Oxygen plasma is used to remove the remaining resist.

A test array to test the material properties as well as the optical performance is fabricated. The main challenge is the fabrication of the 11 -mm-long and 200-nm-wide line meander over a 500 \(\times \) 500 \(\upmu \)m\(^{2}\) area without any critical breaks in the meander or misalignment to the capacitive structure. Fig. 2 shows atomic force microscopic (AFM) and scanning electron microscopic (SEM) images of one of the fabricated pixels.

3 Preliminary Cryogenic Characterization

A cryogen-free dilution refrigerator with a base temperature below 10 mK is used for a preliminary cryogenic characterization. Low-noise amplifiers at 4 and 300 K are used to amplify a low power microwave tone used to sweep each LEKID resonance. The LEKIDs are measured at a temperature (T) of 100 mK, well below T \(_\mathrm{c}\), and as designed resonate at around 0.7 GHz. The high geometric inductance allows for a relatively high readout power at the KID (P \(_\mathrm{int})\) of around \(-\)85 dBm. The internal quality factor (\(Q_\mathrm{i})\) and coupling quality factor (\(Q_\mathrm{c})\) are 6 \(\times \) 10\(^{3}\) and 2 \(\times \) 10\(^{4}\), respectively, and the estimated kinetic fraction is 0.91. The reason for the low internal quality factor is still unclear and tentatively attributed to the influence of the fabrication process to the Al properties. Dark measurement characterization including frequency shift and Q \(_\mathrm{i }\)as a function of the base temperature is shown in Fig. 3 left. For optical characterization, a blackbody radiator is installed on the 4 K shield filtered by a band-pass filter centered at 1.5 THz placed on the 850 mK shield A preliminary characterization of optical response at 1.5 THz is carried out at 100 mK and \(-\)85 dBm by sweeping the blackbody temperature from 9.5 to 28 K (see Fig.3 right). The LEKIDs clearly absorbs and responds to the 1.5THz radiation. The resonance frequency shifts and the amplitude of the dip become smaller as the blackbody source is swept. Further characterization and optimization, including the addition of an optical back short and Si lens fabricated with laser ablation, will be performed in an ultralow background cryogenic facility [8] for quantifying the overall sensitivity. A Fourier transform spectrometer (FTS) measurement will be carried out to verify the broadband coupling.

4 Conclusions

We present a fabrication process for sub-micron thin aluminum LEKIDs for broadband THz radiation detection at very low backgrounds. The fabrication process is based on a combination of maskless laserwriter lithography and electron beam lithography. This development provides with a fabrication process for combination of low- and high-resolution motives over large areas, which can be also used for other materials. A test array made of 200-nm -wide, 12-nm-thick Al meander has been fabricated. Preliminary optical characterization shows optical response at 1.5 THz radiation. Further optical characterization (sensitivity and FTS measurements) and improvement of the fabrication process (due the found low Q \(_\mathrm{i}\) in the resonators) are currently ongoing.

References

S. Doyle, P. Mauskopf, J. Naylon, A. Porch, C. Duncombe, J. Low Temp. Phys. 151, 530 (2008). doi:10.1007/s10909-007-9685-2

H.G. Leduc, B. Bumble, P.K. Day, B. Ho, Eom, J. Gao, S. Golwala, B. A. Mazin, S. McHugh, A. Merrill, D. C. Moore, O. Noroozian, A. D. Turner. J. Zmuidzinas Appl. Phys. Lett. 97, 102509 (2010). doi:10.1063/1.3480420

J. Bueno, P.C.J.J. Coumou, G. Zheng, P.J. de Visser, T.M. Klapwijk, E.F.C. Driessen, S. Doyle, J.J.A. Baselmans, Appl. Phys. Lett. 105, 192601 (2014). doi:10.1063/1.4901536

P.D. Mauskopf, S. Doyle, P. Barry, S. Rowe, A. Bidead, P.A.R. Ade, C. Tucker, E. Castillo, A. Monfardini, J. Goupy, M. Calvo, J. Low Temp. Phys. 153, 545 (2014). doi:10.1007/s10909-013-1069-1

P.J. de Visser, J.J.A. Baselmans, J. Bueno, N. Llombart, T.M. Klapwijk, Nat. Commun. 5, 3130 (2014). doi:10.1038/ncomms4130

B. Blazquez, N. Llombart, D. Cavallo, A. Freni, A. Neto, I.E.E.E. Trans, Antennas Propag. 62, 1624 (2008). doi:10.1109/TAP.2014.2341292

S.J.C. Yates, J.J.A. Baselmans, A.M. Baryshev, S. Doyle, A. Endo, L. Ferrari, S. Hochgürtel, B. Klein, Clean beam patterns with low crosstalk using 850 GHz microwave kinetic inductance detectors. J. Low Temp. Phys. 176, 761 (2014). doi:10.1007/s10909-013-1034-z

J. Baselmans, S. Yates, P. Diener, P. de Visser, J. Low Temp. Phys. 167, 360 (2012). doi:10.1007/s10909-012-0511-0

Acknowledgments

This work was supported as part of a collaborative project, SPACEKIDS, funded via Grant No. 313320 provided by the European Commission under Theme SPA.2012.2.2-01 of Framework Programme 7. D. G. acknowledges RYC-2012-09864 and MAD2D-CM Program (S2013/MIT-3007) for the financial support. A. G., P. P, and J.M-P acknowledge the support from projects AYA2010-21697-C05-01, FIS2012-39262-C06-01, and ESP2013-47809-C3-1-R.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gomez, A., Prieto, P., Bueno, J. et al. Development of Sub-micron Broadband Lens-Coupled LEKIDs for Sub-mm Astronomy. J Low Temp Phys 184, 148–153 (2016). https://doi.org/10.1007/s10909-016-1517-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10909-016-1517-9