Abstract

The article considers the influence of acid–base and structural-adsorption properties on the photocatalytic activity of TiO2 and TiO2–SnO2 nanocomposites obtained by hydrolytic (HL) and hydrothermal (HT) synthesis methods. Acid–base properties were evaluated by Hammett indicator method. Structural-adsorption properties were studied using Brunauer–Emmett–Teller surface analysis (BET). Photocatalytic activity of the nanocomposites was determined using photodegradation of methylene blue (MB) and Congo red (CR) organic dyes. Synthesized materials were also characterized by X-ray fluorescence (XRF), powder X-ray diffraction (PXRD), high-resolution transmission electron microscopy (HRTEM), scanning electron microscopy (SEM), Raman spectroscopy and X-ray photoelectron spectroscopy (XPS). All the synthesized photocatalysts are mesoporous materials with developed surface area. The results demonstrated that HT series samples with both acidic and basic sites of Brønsted type are universal sorbents and photocatalysts that effectively remove both cationic and anionic dyes. HL series composites with Brønsted basic sites are only selective towards cationic dyes. The improved photocatalytic performance of the HT series sample containing 1% of SnO2 may attribute to the increased surface area and high content of Brønsted sites of different types.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nowadays TiO2–SnO2 system is being extensively studied due to its special physical and chemical properties that make it suitable for effective applications in heterogeneous photocatalysis. Pure TiO2 is not photoactive enough to be used commercially [1, 2]. Its low effectiveness is attributed to poor quantum yield caused by the rapid electron-hole recombination. These charge carriers are generated as a result of the TiO2 irradiation with equal or higher energy than the band gap and further photon absorption. However, coupling such semiconductors as TiO2 and SnO2 to form heterojunctions is stated to be an effective and economic strategy to achieve high quantum efficiency. TiO2 and SnO2 are semiconductors that have different wide band gap energies, namely 3.2 eV for anatase form of TiO2, 3.0 eV for rutile form of TiO2 and 3.6 eV for SnO2 [3]. At the same time these materials have considerable similarities: they both have rutile-type tetragonal structure and almost similar ionic radii of the cations (0.605 Å for Ti4+ and 0.69 Å for Sn4+) [4]. Such similarities make it possible to provide intermixed electronic density states that allow better separation of the photogenerated charge carriers. Under the light irradiation photoelectrons are generated, which move from TiO2 to SnO2. As the conduction band of SnO2 is lower than that of TiO2, and the valence band of SnO2 is higher than that of TiO2, electrons transfer to the conduction band of SnO2, while holes accumulate in the valence band of TiO2 [5]. In this case SnO2 acts as a trap for photogenerated electrons that eventually prevents recombination of the charge carriers, enhances quantum efficiency and therefore contributes to the improved photocatalytic activity of the nanomaterial [4, 6,7,8,9,10].

Synthesis method significantly influences the properties and therefore performance of the material [11, 12]. Huge variety of TiO2–SnO2 system synthesis methods includes solid state method [5], electrospinning technology [13], spray pyrolysis [14, 15], laser pyrolysis [16], flame pyrolysis [17], liquid phase deposition method [2], electrophoretic deposition [18], polyol method [3], plasma electrolytic oxidation [8], templating synthesis [19], as well as green synthesis from plant extracts [20, 21]. However, the most widespread seem to be hydrolytic sol–gel method [1, 4, 6, 10, 22,23,24,25,26,27,28,29] and hydrothermal method [9, 30,31,32,33,34] as well as their combination [11, 35]. Sol–gel method is widely utilized to prepare TiO2–SnO2 photocatalysts due to its advantages, namely the cost-effective opportunity to synthesize materials with well-defined arrangement under low temperatures. As a lot of variables, for example precursor nature, solvent type, surfactant addition, etc., during the synthesis procedure influence directly the final properties of the obtained material, their variation can be used to obtain photocatalysts with predefined characteristics. However, this is at the same time the main drawback of the method. Lack of the strict control of the synthesis conditions can lead to the formation of inhomogeneous material with particle agglomeration. Another disadvantage is the necessity of calcination in order to obtain crystalline particles [1, 10, 22]. At the same time, hydrothermal synthesis is stated to be attractive as it is an environmentally friendly method that allows obtaining of homogeneous and highly crystalline nanoparticles using polar or non-polar solvents under relatively low temperatures [33, 34]. Therefore, hydrolytic and hydrothermal methods were chosen for the synthesis of photocatalysts in this study.

Despite numerous studies of TiO2–SnO2 system, it is still unclear which characteristics and properties of the system influence efficiency and properties of the photocatalytic process most of all. Undoubtedly, surface properties of the material, mainly acid–base and structural-adsorption properties, play a great, and sometimes even crucial, role in the process. However, acid–base properties of such systems are not often studied. Usually, the following methods are used for this purpose: titrimetric methods (potentiometric titration [36]) and instrumental methods (infrared spectroscopy of adsorbed pyridine Py-IR [36, 37], temperature programmed desorption of ammonia NH3-TPD [38, 39], hydrogen temperature programmed reduction H2-TPR [40]). Titrimetric methods are reliable and not expensive. The drawback is that they can be used only to assess total surface acidity, while instrumental methods allow distinguishing between Brønsted and Lewis acid sites and estimation of their amounts independently. Nevertheless, these methods are expensive and require special equipment. Unfortunately, among the studied literature, we have not found Hammett indicator method used for studying acid–base properties of TiO2-based composites. Standard Hammett method involves usage of dye solutions in non-aqueous solvents, and these solvents are usually quite expensive and difficult to find. An alternative Hammett method of determining acid–base properties involves usage of dye solutions in aqueous solutions, which is much easier to perform, since there is no need in special conditions. This method is also cheap, efficient and reliable.

The aim of the work is to evaluate acid–base properties of TiO2 and TiO2–SnO2 nanocomposites obtained by different synthesis methods using a simple and efficient Hammett indicator method, structural-adsorption properties, and assess their influence on the photocatalytic properties of the materials. Besides, additional study of the physical and chemical properties of the obtained nanocomposites is necessary in order to establish the influence of different parameters (synthesis conditions, chemical composition, morphology) on the peculiarities of acid–base and structural-adsorption properties formation on the photocatalysts surface.

2 Materials and Methods

2.1 Materials

Titanium(IV) chloride (TiCl4) and titanium(IV) isopropoxide, 98+% (Acros Organics, USA) were taken as the precursor of TiO2. Tin(IV) chloride (SnCl4) and tin(IV) isopropoxide, 99% (metal basis), 10% w/v in isopropanol (Alfa Aesar, USA) were taken as the precursor of SnO2. Isopropanol, 65% nitric acid and deionized water were used as reagents for the synthesis of photocatalysts.

Fuchsine, bromophenol blue, methyl red, bromothymol blue, phenol red, thymol blue, indigo carmine (Carlo Erba Reagents, France) and 2-nitroaniline (MainChem Co., Ltd., China) were used for acid–base properties evaluation of the obtained materials. Methylene blue and Congo red (Carlo Erba Reagents, France) were utilized in sorption and photocatalytic tests.

All chemicals used in the experiments were of analytical grade and were used as received without further purification. Commercially available TiO2 powders (P25 TiO2 AEROXIDE® and P90 TiO2 AEROXIDE®, Evonik, Germany) were used in sorption and photocatalytic degradation experiments as a reference of TiO2.

2.2 Synthesis Procedure of TiO2–SnO2 Nanocomposites

For hydrolytic (HL) synthesis titanium(IV) chloride and tin(IV) chloride were separately mixed with isopropanol in order to prepare TiO2 and SnO2 precursors with 19 wt% of TiCl4 and 44 wt% of SnCl4, respectively. Composite nanopowders were obtained using hydrolysis in aqueous and isopropanol solutions by mixing required amounts of titanium(IV) oxide precursor, tin(IV) oxide precursor and deionized water in order to have contents of 10, 25, 35 and 75 wt% of SnO2. For example, a sample with 10 wt% of SnO2 was synthesized by mixing 50 g of TiO2 precursor with 4 g of SnO2 precursor and 23 cm3 of deionized water. The mixture of reagents was heated up to 90 °C under vigorous stirring and then kept for 40 min for precipitation. The obtained white precipitates were then dried in an oven at 80 °C for 6 h and annealed at 500 °C for 2 h. Finally, the synthesized samples of nanocomposites were ground in mortar. The obtained samples (product yields in the range of 3.5–4.5 g) were denoted as HLXTiYSn, where X is the wt% of titanium(IV) oxide and Y is the wt% of tin(IV) oxide [41, 42].

For hydrothermal (HT) synthesis 25 cm3 of deionized water was added into 75 cm3 of isopropanol to give a solution under continuous magnetical stirring for 10 min at room temperature. Then 65% nitric acid was added dropwise to the above solution until pH 1.5 (solution A). A certain amount of tin(IV) isopropoxide (to have contents of 1, 3, 5, 7 and 10 wt% of tin(IV) oxide in the obtained samples) was dissolved in 5 cm3 of titanium(IV) isopropoxide (solution B). Afterward, solution B was added dropwise into 10 cm3 of solution A under vigorous stirring and was left to be stirred for further 5 min. The resulting colloidal solution (pH 2.5) was poured into a Teflon lined stainless steel autoclave which was sealed and heated at 180 °C for 24 h. After hydrothermal treatment, the vessels were cooled down at room temperature and then the obtained precipitates were collected by centrifugation and washed for five times with deionized water till being neutral. The washed powders were dried at 80 °C for 24 h in an oven and then ground in a mortar. The obtained samples (product yields in the range of 1.3–1.5 g) were labeled as HTXTiYSn, where X is the wt% of titanium(IV) oxide and Y is the wt% of tin(IV) oxide.

2.3 Chemical Composition of the Samples and Their Structural-Adsorption Properties

X-ray fluorescence (XRF) analysis of the obtained powders was performed on X-Supreme 8000 (Oxford Instruments, China) in order to determine quantitative chemical composition of the samples.

The powder X-ray diffraction (PXRD) patterns of the composites were recorded on Ultima IV X-ray diffractometer (Rigaku, Japan) with Cu Kα radiation (40 kV, 30 mA) for identification of the crystal phase composition and determination of the crystallite size in the composites. The average crystallite size (D) of the present phases was calculated automatically by software package PDXL from PXRD data according to the Scherrer Eq. 1 [43] using line broadening measurements

where K is the Scherrer constant (particle shape factor taken as 0.89), λ is the X-ray wavelength (nm), β is the full width at half maximum height (radians) and θ is the diffraction angle.

The specific surface area (Brunauer–Emmett–Teller (BET) method [44]), specific pore volume and pore size distribution (Barrett-Joyner-Halenda (BJH) method) of the obtained samples were determined by nitrogen adsorption–desorption isotherms collected at 77 K using Nova 4200e gas sorption analyzer (Quantachrome®, USA).

2.4 Acid–Base Properties Determination

Acid–base properties of nanocomposites surfaces, namely amount and nature of acidic-basic sites, were evaluated by Hammett indicator method as described in [45]. Hammett indicator method of assessing acidity is based on the selective adsorption of acid–base indicators with certain pKa of the acid–base transition and further spectrophotometric determination of the optical density change of solutions.

Indicators used were as follows: 2-Nitroaniline, hydrochloride (pKa = − 0.29); fuchsine, hydrochloride (pKa = 2.10); bromophenol blue (pKa = 3.90); methyl red (pKa = 5.25); bromothymol blue (pKa = 6.80); phenol red (pKa = 7.60); thymol blue (pKa = 8.80); and indigo carmine (pKa = 12.80).

For the acidity evaluation, 3 series of experiments were carried out.

Series 1. 0.02 g (m1) of the nanocomposite sample and 2 cm3 of standard indicator solution with certain pKa were placed into 5 cm3 test tube and then diluted with deionized water to 5 cm3, mixed thoroughly and kept for 2 h (until equilibrium was established) stirring periodically. After that optical density was measured at the wavelength corresponding to the maximum absorption of certain indicator that revealed residual concentration of the indicator (D1).

Series 2. At the same time a blank experiment was carried out. For this, 0.02 g (m2) of the nanocomposite sample and 3 cm3 of deionized water were placed into 5 cm3 test tube and kept for 2 h. Then the solution was decanted into another tube, and 2 cm3 of the indicator were added. After that the solution was diluted with deionized water to 5 cm3 and stirred. Finally, optical density of the solution D2 was measured.

Series 3. 2 cm3 of indicator were placed into 5 cm3 test tube and diluted with deionized water to 5 cm3, stirred, kept for 30 min and then optical density D0 was evaluated.

The amount of active sites with certain acid strength qpKa (mol‧g−1) was determined according to the Eq. 2:

where cInd is indicator solution concentration (mg-mol/cm3); VInd is indicator solution volume (cm3); m1 and m2 are amounts of the sample (g); D0, D1, D2 are optical densities of the indicator solution before adsorption, after adsorption and in the blank experiment, respectively.

Basing on the obtained data, distribution curves of acidic and basic sites on surfaces of the nanocomposites were built in coordinates qpKa = f(pKa).

2.5 Sorption and Photocatalytic Activity Evaluation

Sorption activity and photocatalytic activity of the as-prepared samples were evaluated from the change in the concentration of methylene blue (MB, C16H18ClN3S) and Congo red (CR, C32H22N6Na2O6S2) in the dark and under ultraviolet (UV) irradiation of a 10 W low-pressure mercury lamp, respectively. In a typical process, 50 mg of photocatalyst were suspended in 50 cm3 of a solution containing 10 mg/dm3 of methylene blue or 50 mg/dm3 of Congo red. The obtained mixture was dispersed by sonication for 5 min and then kept magnetically stirring in the dark for 30 min (5 min for Congo red) to allow adsorption equilibrium to be reached and thus estimate sorption activities of the samples. To determine photocatalytic activities, the stirred suspensions were further exposed to UV light irradiation to initiate photocatalytic reaction. After the 20 min photocatalytic degradation reaction (5 min for Congo red) suspensions were collected, centrifuged at 5000 r/min for 20 min and analyzed by UV–Vis spectrophotometry using UV-5800(PC) Spectrophotometer (Shanghai Metash Instruments, China). The decrease in dye concentration D (%) was calculated at 663 nm for methylene blue and at 490 nm for Congo red according to the Eq. 3

where C0 and C are the pre- and post-treatment dye concentrations.

2.6 Further Characterization

Morphologies of the prepared powders were observed using SEM-106I scanning electron microscope (SELMI, Ukraine) and high-resolution transmission electron microscopy (HRTEM) analysis performed on transmission electron microscope (JEM-2100F, JEOL, Japan). Samples for TEM analysis were prepared by drying sample materials-ethanol inks on amorphous carbon coated copper grids. SEM-106I microscope was also used to determine chemical composition of the samples.

Raman spectra were acquired in the range of 100–1200 cm−1 for further evaluation of phase components using Triple stage Raman Spectrometer (Horiba T64000, France) with Ar-Kr laser (Stabilite 2018-RM Spectra Physics, USA). Excitation laser operated at 488 nm with power of 1 mW.

X-ray photoelectron spectroscopy (XPS) spectra were obtained using Kratos AXIS 165 spectrometer with Al mono Kalfa X-ray.

3 Results

PXRD patterns of the obtained nanocomposite samples are presented in Fig. 1. Also, PXRD pattern of HL0Ti100Sn sample (pure SnO2 synthesized under the same conditions as HL series samples) is shown for comparison. All the PXRD patterns of HT series samples are similar, and therefore only HT100Ti0Sn pattern is demonstrated. Quantitative composition (obtained by XRF method) and crystallite sizes (obtained by PXRD method) of the TiO2–SnO2 nanocomposite samples are presented in Table 1.

Data from Fig. 1 and Table 1 show that hydrolytic synthesis allowed obtaining of nanostructured TiO2–SnO2 composites that consist of the following phases: anatase, rutile and cassiterite. HL100Ti0Sn sample (pure TiO2) includes only rutile phase, while samples with SnO2 contain mostly anatase phase, content of which gradually decreases (evidenced by a decrease in the intensity of anatase peaks) with the increase of SnO2 content. Moreover, HL65Ti35Sn and HL25Ti75Sn samples do not include rutile phase at all. Overlapping of the peaks makes it impossible to determine accurately the amount of anatase and rutile phases in the samples. It should be also noted that with the increase of SnO2 content in the samples, crystallite size also increases. Although PXRD method did not detect SnO2 in HL90Ti10Sn sample, results of the XRF analysis proved its presence in the amount of 10 wt%.

According to the presented data, all the HT series samples consist of anatase phase only. PXRD analysis did not reveal any presence of cassiterite phase that could be caused by Sn4+ incorporation into crystal lattice of titanium(IV) oxide or by overlapping of SnO2 and TiO2 diffraction peaks of rutile modification. However, XRF results indicate that composition of the HT series samples differs from the designated theoretically. For instance, HT90Ti10Sn sample consists of 99% TiO2 and 1% SnO2 instead of designated 90% and 10%, respectively.

Cell parameters of different modifications were compared with standard cell parameters according to the following cards: anatase—JCPDS 01-070-7348; rutile—JCPDS 01-070-7347; cassiterite—JCPDS 00-041-1445. Deviation of the parameters, to our opinion, indicates the presence of deformations and large amount of defects during crystallization process.

Figure 2 shows nitrogen adsorption–desorption isotherms and pore size distribution of the HL series nanocomposite samples.

Obtained isotherms of the samples HL100Ti0Sn, HL90Ti10Sn, HL75Ti25Sn, (isotherm of HL65Ti35Sn sample is similar to HL75Ti25Sn isotherm and therefore not shown), HL25Ti75Sn belong to the type IVa that is typical of mesoporous materials [46]. Hysteresis loop indicates capillary condensation in the pores. Since obtained isotherms demonstrate different shapes of hysteresis loops, HL series samples have different pore structure. All the samples contain pores of the same size, as adsorption branches of the isotherms lie in a common pressure range. Nevertheless, samples have different pore size distributions.

It can be seen that HL100Ti0Sn and HL75Ti25Sn samples give hysteresis loops of a quite similar shape that belong to type H2(b), which is attributed to the mesoporous materials composed of ink-bottle pores closed at one end [46]. The shape of adsorption branch depends on the radius of a wide pore body, while the shape of desorption branch is determined by the radius of a narrow pore neck. Asymmetrical shape of hysteresis loops is a sign of broad pore size distribution and might also indicate the presence of networks of interconnected pores [47, 48]. Gradual shape of isotherms is another evidence of heterogeneous pore size distribution—wide size distribution of both pore neck radii (desorption branch) and pore body radii (adsorption branch). Pore sizes of HL100Ti0Sn sample range from 1.6 to 41.6 nm with two clear peaks at 2.1 nm and 3.6 nm that is associated with a bimodal system, while pore sizes of HL75Ti25Sn sample vary from 1.8 to 45.0 nm with one peak at 2.5 nm. Comparing the shapes of the isotherms given in Fig. 2, it can be seen that wide hysteresis loop of HL100Ti0Sn sample is attributed to the big difference between the sizes of pore bodies and pore necks. The same appeals to the HL75Ti25Sn sample, but with higher degree of pore structure uniformity.

Hysteresis loop of HL25Ti75Sn sample also belongs to the type of H2(b). However, its shape resembles hysteresis loop of type H4. This indicates the presence of narrow, slit-like pores, also in micropore region [46]. In contrast to the other HL series samples, which are mesoporous, HL25Ti75Sn sample is a micro-mesoporous material. Pore size distribution is in the range of 1.8–55.3 nm; and there is a sharp peak at 1.8 nm with a very narrow base. This is the evidence of the predominance of almost the same pore size, i.e. the system is monodisperse.

Hysteresis loop of HL90Ti10Sn sample differs from the hysteresis loops of the other HL series samples. It is referred to the type H2(b), although it is quite similar to the type H1. This is related to the presence of open ink-bottle pores. Steeper shape of isotherms, as well as narrower and more symmetrical hysteresis loop compared to the other samples, gives a clear sign of more uniform pore structure and similarity between size distribution of pore bodies and pore necks [46]. Pore sizes of the sample range from 1.8 to 40.3 nm with a peak at 4.6 nm. Structural and adsorption properties of the HL series nanocomposites are presented in Table 2.

Figure 3 shows nitrogen adsorption–desorption isotherms and pore size distribution of the HT series nanocomposite samples.

Presented isotherms (HT99Ti1Sn, HT97Ti3Sn and HT95Ti5Sn isotherms are similar to the shown in Fig. 3) belong to type IVa and prove that HT series samples are mesoporous materials. Adsorption–desorption isotherms and hysteresis loops of the HT series samples, shown in Fig. 3, have the same appearance. Hysteresis loops of the isotherms belong to the type H2(b). Gradual shape of isotherms is related to the broad pore size distribution that lies in the range from 1.6 nm to 39.8 nm for HT100Ti0Sn sample and from 1.6 to 42.8 nm for HT90Ti10Sn sample with peaks at 3.7 nm and 3.6 nm, respectively. Quite uniform pore structure of the HT series samples is evidenced by comparatively narrow hysteresis loops. Table 2 gives structural and adsorption properties of the HT series nanocomposites.

Data presented in Table 2 show that structural and adsorption properties are significantly different for a pure TiO2 sample (HL100Ti0Sn) and other TiO2–SnO2 nanocomposite samples of the HL series. Specific surface area of the samples increases with the increase of SnO2 content in the nanocomposite, while pore size and porosity of the samples containing SnO2 decrease. It can be seen that composites with predominant content of TiO2 are mesoporous, while HL25Ti75Sn sample with predominant SnO2 content is mostly microporous.

Figure 4 shows the distribution curves of acidic and basic sites on the surfaces of nanocomposite samples.

Presented curves demonstrate that HL series samples contain basic sites of Brønsted type, and HL100Ti0Sn sample has the highest amount of these sites—12.4 µmol/g at pKa 7.6. It can be also seen that activity of the nanocomposites decreases with the increase of tin(IV) oxide content, and active sites move more and more to the basic area.

HT series samples contain Brønsted acid sites at pKa 6.8 as well as Brønsted basic sites at both pKa 7.6 and 12.8. Besides, the amount of active sites increases with the increase of SnO2 content in the samples (in the range of pKa 6.8–7.6), and the highest amount of active sites belongs to HT90Ti10Sn sample (1.5 µmol/g at pKa 6.8 and pKa 7.6; 0.6 µmol/g at pKa 3.9).

Commercial samples P25 and P90 have the maximal and almost the same amount of active sites: 16.8 µmol/g and 15.7 µmol/g at pKa − 0.29, respectively. In our opinion, that could be caused by their synthesis method, as the amount of active sites in the synthesized samples at pKa − 0.29 is insignificant in all cases. In addition, Brønsted basic sites prevail in P25 sample (8.2 µmol/g at pKa 8.8), while in P90 sample Brønsted acid sites predominate (4.8 µmol/g at pKa 5.25). It should be also noted that P25 sample has more active sites than P90 sample.

Figure 5 demonstrates the degradation degree of organic dyes (MB and CR) after sorption and photocatalysis with the use of synthesized nanocomposites and commercial samples as sorbents and photocatalysts.

Results of sorption and photocatalytic tests, shown in Fig. 5a, demonstrate that HL series samples have the highest photoactivity among the all synthesized samples regarding MB (performance close to commercial sample P90). It should be noted that in case of HT series, HT90Ti10Sn sample containing only 1% of SnO2 has photocatalytic activity 30% higher than the pure TiO2 sample—HT100Ti0Sn. Sorption and photocatalytic tests carried out on CR dye (Fig. 5b) show that HL series is not active in this case. In contrast, samples of HT series are very active and exhibit even higher sorption and photocatalytic activity than the commercial sample P25.

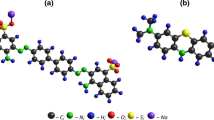

HRTEM and SEM-images of the synthesized TiO2–SnO2 nanocomposites are presented in Fig. 6.

Figure 6 demonstrates HRTEM images of some obtained samples. Fringe spacing of HL100Ti0Sn is 0.32 nm corresponding to the (110) plane of rutile TiO2. In HL90Ti10Sn, besides the identified (110) rutile TiO2 (d = 0.32 nm), (101) anatase TiO2 modification was also observed with a fringe spacing of 0.35 nm. In both HT100Ti0Sn and HT90Ti10Sn only fringe spacing of 0.35 nm was revealed belonging to the (101) plane of anatase TiO2. Lattice fringe spacing corresponding to SnO2 was not identified. Obtained HRTEM results are in a good agreement with the PXRD results.

In addition, Fig. 6 shows that SEM-image of HL100Ti0Sn sample is significantly different from the SEM-image of HL90Ti10Sn sample (SEM-images of the other HL series samples are identical to HL90Ti10Sn presented). According to the images, nanoparticles of the pure TiO2 sample have spherical shape and are rather uniform, while particles of TiO2–SnO2 nanocomposites form aggregates and agglomerates of different size and shape [41]. Also, Fig. 6 displays SEM-images of the HT series samples. Obtained images proved that all the samples have similar morphology and therefore SEM-images of the other samples are not shown. It can be also seen that nanocomposite particles exist as aggregates and agglomerates of almost similar size and shape.

Further identification and corroboration of the nanocomposites composition was carried out using Raman spectroscopy. Raman spectra of the selected samples are shown in Fig. 7 (PXRD patterns of the same samples are presented for comparison).

According to the obtained spectra, HL series samples present well-defined vibration bands at 144 cm−1 (Eg), 198 cm−1 (Eg), 400 cm−1 (B1g), 517 cm−1 (A1g) and 640 cm−1 (Eg) attributed to the anatase phase structure. Anatase phase main peaks of HT series are detected at 144 cm−1 (Eg), 195 cm−1 (Eg), 394 cm−1 (B1g), 517 cm−1 (A1g) and 637 cm−1 (Eg) [9, 10]. Raman spectroscopic analysis also revealed rutile peaks for HL series at 234 cm−1, 445 cm−1 and 609 cm−1 [9, 10]. Vibration bands characteristic for the structure of cassiterite (490 cm−1, 547 cm−1, 636 cm−1, 776 cm−1 [9, 10]) were not detected. That can be caused by the overlap between TiO2 and SnO2 vibrational bands and low content of SnO2 in the samples as well as by possible incorporation of Sn4+ into the TiO2 crystal lattice. Results of the Raman spectroscopy are in a good agreement with PXRD results (Raman spectroscopy being a more sensitive technic than X-ray spectroscopy also revealed the presence of < 2% anatase phase in HL100Ti0Sn sample that was not detected by PXRD analysis).

To further study chemical composition and surface chemical states of the synthesized TiO2–SnO2 nanocomposites, XPS method was applied. Figure 8 demonstrates XPS spectra of the selected TiO2–SnO2 samples.

Figure 8a shows the survey spectra of the following samples: HL100Ti0Sn, HL90Ti10Sn, HT100Ti0Sn and HT90Ti10Sn, indicating the presence of Ti, Sn, O and C (hydrocarbons from the XPS device). The XPS spectra of Ti 2p, shown in Fig. 8b, consist of two peaks, observed at approximately 464.3 eV and 458.8 eV, which correspond to the binding energies of Ti 2p1/2 and Ti 2p3/2, respectively. XPS data report revealed tetravalent state of titanium (Ti4+). The XPS spectra of Sn 3d are shown in Fig. 8c. Binding energies of Sn 3d3/2 and Sn 3d5/2 were observed at approximately 494.9 eV and 486.4 eV, respectively, indicating Sn4+ oxidation state of tin. Figure 8d shows the XPS spectra of O 1 s, containing two different peaks at 531.1 eV and 529.9 eV. The peak at the lower binding energy is attributed to surface bridging oxygen (TiO2), while the peak at the higher binding energy indicates surface hydroxyl oxygen (Ti–OH) [7, 49]. XPS results further corroborate previously obtained results.

4 Discussion

Both hydrolytic and hydrothermal synthesis methods allowed obtaining of nanostructured TiO2 and TiO2–SnO2 composites with crystallite size in the range of 3–24 nm according to the data presented in Fig. 1 and Table 1. Hydrolytic synthesis utilizing TiCl4 precursor resulted in pure rutile modification of titanium (IV) oxide, while hydrothermal synthesis with TTIP precursor led to the obtaining of pure anatase phase of TiO2. According to the SEM-images shown in Fig. 6, morphology of HL100Ti0Sn sample, obtained by hydrolytic method, differs greatly from the morphology of HT100Ti0Sn sample, synthesized under hydrothermal conditions. Also, HT series samples have higher degree of crystallinity than HL series nanocomposites, proved by HRTEM-images presented in Fig. 6. All these results indicate the significant effect of the synthesis method and its conditions.

Addition of SnO2 to the composites of HL series stabilized anatase phase, but did not influence phase composition of the HT series composites. It was found out, that the chosen hydrothermal synthesis conditions were irrelevant and did not allow complete crystallization of SnO2 or/and complete incorporation of Sn4+ into crystal lattice, and therefore SnO2 content in the HT series nanocomposites did not exceed 1%. Subsequently, all the HT series samples contain almost similar amount of SnO2 that explains the similarity of the obtained PXRD patterns (Fig. 1), nitrogen adsorption–desorption isotherms (Fig. 3), SEM-images (Fig. 6) and Raman spectra (Fig. 7).

The results obtained by nitrogen adsorption–desorption method and presented in Figs. 2, 3 and Table 2 are in a good agreement with the results of PXRD analysis. According to the data, specific surface area of the samples increases, and the pore size and porosity decrease with the increase of SnO2 content in the nanocomposite that leads to the decrease in the size of TiO2 crystallites in accordance with the PXRD results. Data from Table 2 also demonstrate that structural and adsorption properties of HT series TiO2–SnO2 nanocomposites are almost identical: all synthesized samples have the same average pore size and approximately the same pore volume that was caused, from our point of view, by almost the same amount of tin(IV) oxide in each sample. The only exception is the specific surface area that is larger in case of samples containing SnO2. It should be noted that nanocomposites are different in terms of pore size distribution (Fig. 3). For example, as shown in Fig. 3 and in Table 2, HT100Ti0Sn and HT90Ti10Sn samples have the same pore volume, but different specific surface areas. This can be explained by the difference in pore size distribution: HT90Ti10Sn sample has a larger number of pores in a narrower range than HT100Ti0Sn, and therefore has larger specific surface area.

Although low content of SnO2 in the HT series samples did not affect phase composition and structural-adsorption properties of the nanocomposites, acid–base properties changed (Fig. 4). That resulted into absolutely different photocatalytic performance of the synthesized samples, presented in Fig. 5. It is widely known that photocatalytic properties of the material depend directly on the sorption properties. The latter, in turn, can be explained by acid–base properties of the investigated material surface. The predominant content of Brønsted basic centers in HL series samples contributes to the high sorption activity of the samples regarding cationic methylene blue dye and low efficiency in case of anionic Congo red dye sorption. In contrast, HT series samples and commercial samples also contain a large amount of Brønsted acid sites that results in the high activity of the samples relative to the anionic dye. Thus, commercial samples and HT series samples, which have both acidic and basic sites of Brønsted type, are simultaneously active regarding both cationic and anionic dyes making them universal materials. HL series samples in this case are selective sorbents, revealing activity regarding cationic dyes only. It should also be noted that results of sorption and photocatalytic experiments performed with commercial TiO2 samples are in a good agreement with their acid–base properties. Sample P25, containing a larger amount of basic Brønsted sites than P90 sample, is more active regarding MB. Sample P90, in turn, has a larger number of acidic Brønsted sites and is therefore more active regarding CR compared to P25 sample.

5 Conclusions

Acid–base properties of the synthesized TiO2 and TiO2–SnO2 nanocomposites were effectively evaluated using simple Hammett indicator method. It was found out that nanocomposite samples containing both acidic and basic sites of Brønsted type (samples obtained by hydrothermal method) were universal sorbents and photocatalysts that effectively removed both cationic (methylene blue) and anionic (Congo red) dyes. In contrast, composites containing Brønsted basic sites only (samples obtained by hydrolytic method) are active only towards cationic dyes, and therefore can be used as selective sorbents and photocatalysts.

Structural-adsorption study revealed obtaining of mesoporous materials with highly developed surface. Addition and increase of SnO2 content in the composites led to the significant increase in surface area and porosity of the photocatalysts. TiO2–SnO2 samples obtained by hydrothermal method demonstrated better properties, than materials obtained via hydrolytic synthesis (SBET HT100Ti0Sn—136 m2/g; SBET HT90Ti10Sn—152 m2/g in comparison with SBET HL100Ti0Sn—19 m2/g; SBET HL90Ti10Sn—48 m2/g) that also influenced photocatalytic activity of the nanocomposites. The improved photocatalytic performance of the HT series sample containing 1 wt% of SnO2 may attribute to the increased surface area and high content of Brønsted sites of different types.

Physical and chemical characteristics, which were obtained using such methods as HRTEM, Raman spectroscopy and XPS, are in a good agreement with each other and correlate well with photocatalytic properties of the nanocomposites. In particular, HRTEM and Raman spectroscopy corroborated presence of rutile in HL series samples and anatase in HT series samples. HRTEM also revealed higher crystallinity of HT series nanocomposites that contributed to the better photocatalytic performance of these materials.

References

V.R. De Mendonça, O.F. Lopes, R.P. Fregonesi, T.R. Giraldi, C. Ribeiro, Appl. Surf. Sci. 298, 182 (2014)

J. Yuan, X. Zhang, H. Li, K. Wang, S. Gao, Z. Yin, H. Yu, X. Zhu, Z. Xiong, Y. Xie, Catal. Commun. 60, 129 (2015)

R. Bargougui, A. Pichavant, J.F. Hochepied, M.H. Berger, A. Gadri, S. Ammar, Opt. Mater. (Amst). 58, 253 (2016)

S.M. Patil, A.G. Dhodamani, S.A. Vanalakar, S.P. Deshmukh, S.D. Delekar, J. Phys. Chem. Solids 115, 127 (2018)

G. Yang, Z. Yan, T. Xiao, Appl. Surf. Sci. 258, 8704 (2012)

S.M. Hassan, A.I. Ahmed, M.A. Mannaa, Ceram. Int. 44, 6201 (2018)

C. Jia, H.S. Chen, P. Yang, J. Ind. Eng. Chem. 58, 278 (2018)

S. Stojadinović, N. Tadić, N. Radić, B. Grbić, R. Vasilić, Mater. Lett. 196, 292 (2017)

M. Huang, J. Yu, B. Li, C. Deng, L. Wang, W. Wu, L. Dong, F. Zhang, M. Fan, J. Alloys Compd. 629, 55 (2014)

I. Rangel-Vázquez, G. Del Angel, V. Bertin, F. González, A. Vázquez-Zavala, A. Arrieta, J.M. Padilla, A. Barrera, E. Ramos-Ramirez, J. Alloys Compd. 643, S144 (2015)

M. Huang, S. Yu, B. Li, L. Dong, F. Zhang, M. Fan, L. Wang, J. Yu, C. Deng, Ceram. Int. 40, 13305 (2014)

S. Das, V. Jayaraman, Prog. Mater. Sci. 66, 112 (2014)

L. Zhang, W. Yu, C. Han, J. Guo, Q. Zhang, H. Xie, J. Electrochem. Soc. 164, 651 (2017)

M. Shipochka, A. Eliyas, I. Stambolova, V. Blaskov, S. Vassilev, S. Simeonova, K. Balashev, Mater. Chem. Phys. 220, 249 (2018)

A. Enesca, L. Isac, L. Andronic, D. Perniu, A. Duta, Appl. Catal. B 147, 175 (2013)

M. Scarisoreanu, C. Fleaca, I. Morjan, A.M. Niculescu, C. Luculescu, E. Dutu, A. Ilie, I. Morjan, L.G. Florescu, E. Vasile, C.I. Fort, Appl. Surf. Sci. 418, 491 (2017)

K.K. Akurati, A. Vital, R. Hany, B. Bommer, T. Graule, M. Winterer, Int. J. Photoenergy 07, 153 (2005)

G.O. Testoni, R.A.C. Amoresi, G.M.M.M. Lustosa, J.P.C. Costa, M.V. Nogueira, M. Ruiz, M.A. Zaghete, L.A. Perazolli, Solid State Sci. 76, 65 (2018)

A.K. Patra, S.K. Das, A. Bhaumik, J. Mater. Chem. 21, 3925 (2011)

G. Nabi, Qurat-ul-Aain, N. R. Khalid, M. B. Tahir, M. Rafique, M. Rizwan, S. Hussain, T. Iqbal, A. Majid, J. Inorg. Organomet. Polym. Mater. 28, 1552 (2018).

M. Rafique, J. Jahangir, B. A. Z. Amin, M. Bilal Tahir, G. Nabi, M. Isa Khan, N. R. Khalid, S. S. A. Gillani, I. Sadaf, J. Inorg. Organomet. Polym. Mater. 29, 2133 (2019).

M.F. Abdel-Messih, M.A. Ahmed, A.S. El-Sayed, J. Photochem. Photobiol. A 260, 1 (2013)

D. Chandra, N. Mukherjee, A. Mondal, A. Bhaumik, J. Phys. Chem. C 112, 8668 (2008)

A. Farhadi, M.R. Mohammadi, M. Ghorbani, J. Photochem. Photobiol. A 338, 171 (2017)

N.P. Tangale, P.S. Niphadkar, V. Samuel, S.S. Deshpande, P.N. Joshi, S.V. Awate, Mater. Lett. 171, 50 (2016)

A. Marzec, M. Radecka, W. Maziarz, A. Kusior, Z. Pedzich, J. Eur. Ceram. Soc. 36, 2981 (2016)

A. Kusior, J. Klich-Kafel, A. Trenczek-Zajac, K. Swierczek, M. Radecka, K. Zakrzewska, J. Eur. Ceram. Soc. 33, 2285 (2013)

B.K. Kaleji, R. Sarraf-Mamoory, Mater. Res. Bull. 47, 362 (2012)

W. Zhang, X. Chen, Y. Han, S. Yao, Rare Met. 30, 229 (2011)

V.R. de Mendonça, W. Avansi, R. Arenal, C. Ribeiro, J. Colloid Interface Sci. 505, 454 (2017)

F. Du, X. Zuo, Q. Yang, B. Yang, G. Li, Z. Ding, M. Wu, Y. Ma, S. Jin, K. Zhu, Ceram. Int. 42, 12778 (2016)

H.A.J.L. Mourão, W.A. Junior, C. Ribeiro, Mater. Chem. Phys. 135, 524 (2012)

M. Hirano, H. Dozono, T. Kono, Mater. Res. Bull. 46, 1384 (2011)

E. Arpaç, F. Sayilkan, M. Asiltürk, P. Tatar, N. Kiraz, H. Sayilkan, J. Hazard. Mater. 140, 69 (2007)

A. Marzec, P. Zbigniew, W. Maziarz, Process. Appl. Ceram. 10, 249 (2016)

S.M. Hassan, A.I. Ahmed, M.A. Mannaa, Colloids Surf. A Physicochem. Eng. Asp. 577, 147 (2019)

H. Li, M. Vrinat, G. Berhault, D. Li, H. Nie, P. Afanasiev, Mater. Res. Bull. 48, 3374 (2013)

R.M. De Almeida, F.T.C. Souza, M.A.C. Júnior, N.J.A. Albuquerque, S.M.P. Meneghetti, M.R. Meneghetti, Catal. Commun. 46, 179 (2014)

Y. Jiao, H. Zhang, S. Li, C. Guo, P. Yao, J. Wang, Fuel 233, 724 (2018)

M. Aguilar-Romero, R. Camposeco, S. Castillo, J. Marín, V. Rodríguez-González, L.A. García-Serrano, I. Mejía-Centeno, Fuel 198, 123 (2017)

A.S. Kutuzova, T.A. Dontsova, Appl. Nanosci. 9, 873 (2019)

A. Kutuzova, T. Dontsova, in Proc. 2017 IEEE 7th Int. Conf. Nanomater. Appl. Prop. N. 2017 (Zatoka, 2017), pp. 286–290.

P. Scherrer, Göttinger Nachrichten Gesell. 2, 98 (1918)

S. Brunauer, P.H. Emmett, E. Teller, J. Am. Chem. Soc. 60, 309 (1938)

T.A. Dontsova, E.I. Yanushevskaya, S.V. Nahirniak, O.V. Makarchuk, A.I. Ivanets, M.Y. Roshchina, A.S. Kutuzova, L.M. Kulikov, J. Nanomater. 2018, 1 (2018)

M. Thommes, K. Kaneko, A.V. Neimark, J.P. Olivier, F. Rodriguez-Reinoso, J. Rouquerol, K.S.W. Sing, Pure Appl. Chem. 87, 1051 (2015)

A. Grosman, C. Ortega, Langmuir Am. Chem. Soc. 24, 3977 (2008)

T. Horikawa, D.D. Do, D. Nicholson, Adv. Colloid Interface Sci. 169, 40 (2011)

D. Toloman, O. Pana, M. Stefan, A. Popa, C. Leostean, S. Macavei, D. Silipas, I. Perhaita, M.D. Lazar, L. Barbu-Tudoran, J. Colloid Interface Sci. 542, 296 (2019)

Acknowledgements

The authors would like to acknowledge V.E. Lashkaryov Institute of Semiconductor Physics NAS of Ukraine and especially Dr. Viktor Strelchuk and PhD Iurii M. Nasieka for providing Raman spectroscopy.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by AK, TD and WK. The first draft of the manuscript was written by AK and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kutuzova, A., Dontsova, T. & Kwapinski, W. TiO2–SnO2 Nanocomposites: Effect of Acid–Base and Structural-Adsorption Properties on Photocatalytic Performance. J Inorg Organomet Polym 30, 3060–3072 (2020). https://doi.org/10.1007/s10904-020-01467-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-020-01467-z